Ultralow-temperature aluminum electrolytic capacitor and manufacturing method thereof

A technology for aluminum electrolytic capacitors and manufacturing methods, applied in electrolytic capacitors, liquid electrolytic capacitors, capacitors, etc., can solve the problems of weakened electrical performance, easy solidification of electrolyte, weakened activity, etc., achieve good temperature performance and stability, improve Chemical stability, the effect of improving high and low temperature characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

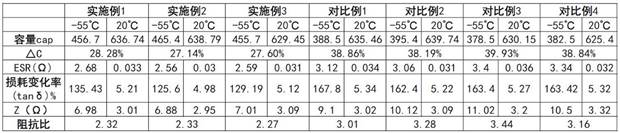

Examples

Embodiment 1

[0030] This embodiment provides a method for manufacturing an ultra-low temperature aluminum electrolytic capacitor. Specifically, the method includes the following steps:

[0031] (1) Core pack winding: Electrolytic paper is inserted between the anode foil and cathode foil, and wound into a core pack, wherein the width of the anode foil and the cathode foil are equal, so that the upper end of the anode foil in the obtained core pack exceeds the electrolytic paper and the cathode foil are exposed, the lower end of the cathode foil is exposed beyond the electrolytic paper and the anode foil, and the wound core package is wrapped and fixed with adhesive tape.

[0032] Wherein, the electrolytic paper is a double-layer fiber composite paper, its water-soluble chloride content is less than 2mg / kg, and iron particles are more than 0.1mm 2 , Suction height value: 21mm / 10min.

[0033] (2) Impregnation step: immerse the wound core package in the electrolyte solution for impregnation t...

Embodiment 2

[0040] This embodiment provides a method for manufacturing an ultra-low temperature aluminum electrolytic capacitor. Specifically, the method includes the following steps:

[0041] (1) Core pack winding: Electrolytic paper is inserted between the anode foil and cathode foil, and wound into a core pack, wherein the width of the anode foil and the cathode foil are equal, so that the upper end of the anode foil in the obtained core pack exceeds the electrolytic paper and the cathode foil are exposed, the lower end of the cathode foil is exposed beyond the electrolytic paper and the anode foil, and the wound core package is wrapped and fixed with adhesive tape.

[0042] Wherein, the electrolytic paper is a double-layer fiber composite paper, its water-soluble chloride content is less than 2mg / kg, and iron particles are more than 0.1mm 2 , Suction height value: 21mm / 10min.

[0043] (2) Impregnation step: immerse the wound core package in the electrolyte solution for impregnation t...

Embodiment 3

[0050] This embodiment provides a method for manufacturing an ultra-low temperature aluminum electrolytic capacitor. Specifically, the method includes the following steps:

[0051] (1) Core pack winding: Electrolytic paper is inserted between the anode foil and cathode foil, and wound into a core pack, wherein the width of the anode foil and the cathode foil are equal, so that the upper end of the anode foil in the obtained core pack exceeds the electrolytic paper and the cathode foil are exposed, the lower end of the cathode foil is exposed beyond the electrolytic paper and the anode foil, and the wound core package is wrapped and fixed with adhesive tape.

[0052] Wherein, the electrolytic paper is a double-layer fiber composite paper, its water-soluble chloride content is less than 2mg / kg, and iron particles are more than 0.1mm 2 , Suction height value: 21mm / 10min.

[0053] (2) Impregnation step: immerse the wound core package in the electrolyte solution for impregnation t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com