Electrolyte, electrolyte preparation method and aluminum electrolytic capacitor

A technology of electrolyte and flash voltage, which is applied in the preparation of electrolyte and in the field of electrolyte, can solve the problems that cannot fully meet the development needs, achieve excellent working performance, improve temperature resistance and stability, and achieve low leakage current effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

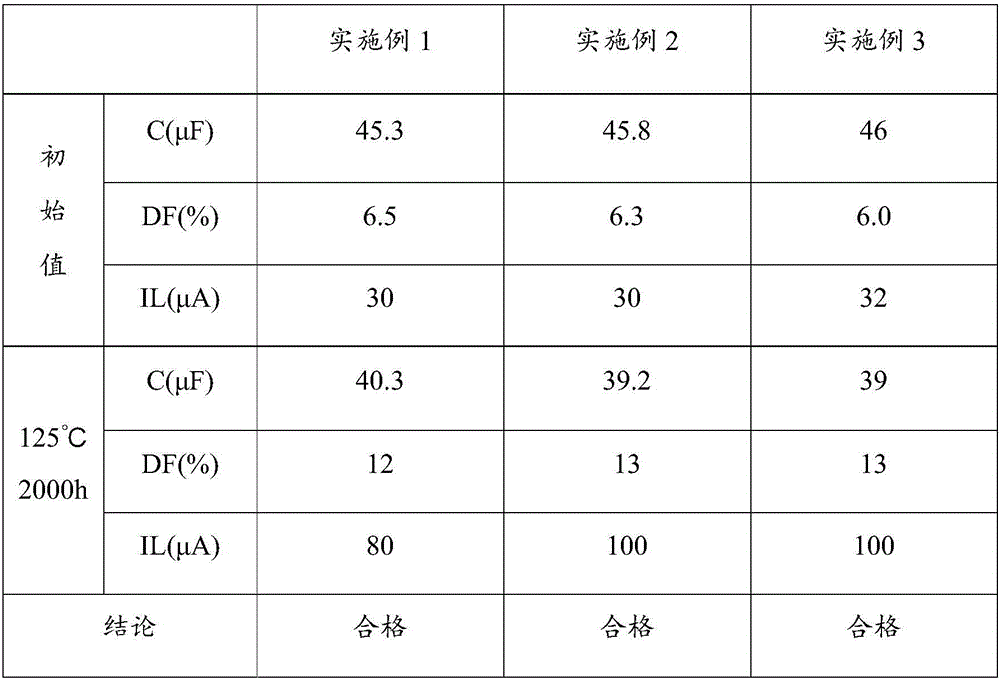

Examples

preparation example Construction

[0074] The present invention also proposes a preparation method of an electrolyte, the preparation method comprising the following steps:

[0075] heating the first solvent to 140°C to 145°C;

[0076] Add flash fire voltage booster and keep warm for 30min~60min;

[0077] Add the second solvent and heat to 150°C-155°C.

[0078] Add part of the first solute and keep warm for 30min to 60min.

[0079] Lower the temperature to 130°C-135°C, add the remaining part of the first solute, the second solute, stabilizer, and function enhancer, and keep warm for 30min-60min.

[0080] Add the third solute and lower the temperature to 95°C to 100°C.

[0081] Add hydrogen absorbing agent and waterproof mixture.

[0082] Wherein, the first solute includes one selected from boric acid and ammonium benzoate, one selected from ammonium dodecanoate and 2,7-dibutyl ammonium suberate, and one selected from ammonium sebacate and One of the alkyl ammonium sebacate.

[0083] The second solute incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com