Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Won't turn yellow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature-resistant ink, preparation method thereof and OGS touch panel

ActiveCN104151925AImprove high temperature resistanceSimple processInksTemperature resistanceSolvent

The invention provides high-temperature-resistant ink. The high-temperature-resistant ink comprises the following components: 100 parts of organosilicone-modified resin, 60-240 parts of titanium dioxide powder, 0.5-10 parts of fumed silica, 1-30 parts of crosslinking agent, 0.01-1 part of silanol condensation catalyst, 0.1-4 parts of polysiloxane defoaming agent, 0.1-4 parts of alkyl and / or aralkyl-modified polyorganosiloxane leveling agent and 50-150 parts of solvent. According to the high-temperature-resistant ink disclosed by the invention, since organosilicone-modified resin is adopted as a main component and functional additives such as the specific crosslinking agent, the silanol condensation catalyst, the defoaming agent and the leveling agent, are mixed to jointly improve the performances, such as high temperature resistance, resistance to yellowing, stability and the like of an ink product and thus a white glass ink product with excellent high temperature resistance and chemical resistance is obtained.

Owner:SHENZHEN SUCCESS ELECTRONICS LTD

Waterborne polyurethane finishing agent for PVC (Polyvinyl Chloride) protective gloves and preparation method thereof

InactiveCN101845269AGood storage stabilityExtended service lifePolyurea/polyurethane coatingsPolyether polyurethaneEmulsion

The invention relates to a waterborne polyurethane finishing agent for PVC (Polyvinyl Chloride) protective gloves and a preparation method thereof, in particular to a waterborne polyurethane finishing agent for protective gloves and a preparation method thereof, belonging to polyurethane coating combinations. The waterborne polyurethane finishing agent is characterized in that firstly, mixed polyether glycol and aliphatic diisocyanate are used as raw materials to synthesize isocyanate-terminated perpolymer, wherein the mole ratio of a isocyanato group and a hydroxyl group is NCO:OH=2.0-3.2; secondly, dimethylopropionic acid DMPA is used as a hydrophilic chain extender, and the dosage of the DMPA is 3-6 percent of the weight of the perpolymer; thirdly, triethylamine is used as a branched chain extender, and the dosage of the triethylamine is 1-4 percent of the weight of the perpolymer; fourthly, a coupling agent is added in emulsion with the addition quantity of 2-5 percent of the weight of the perpolymer; and fifthly, the solid content of the emulsion is 25-30 percent. The invention provides the waterborne polyurethane finishing agent for the PVCprotective gloves, which has the advantages of favorable storage stability, strong adhesive force, strong elasticity, strong drawing force, long service life, comfortable wearing and free removal. and the preparation method thereof.

Owner:淄博永麒化工技术开发有限公司

Single-component crystal flowing-type dealcoholized room temperature vulcanized silicone rubber and preparation method thereof

The invention relates to single-component crystal flowing-type dealcoholized room temperature vulcanized silicone rubber and a preparation method of the dealcoholizing room temperature vulcanized silicone rubber. The dealcoholized room temperature vulcanized silicone rubber is characterized in that the crystal silicone rubber comprises the components in parts by weight as follows: 100 parts of base rubber are taken as a unit, and the other needed components are 0-100 parts of a plasticizer, 2-20 parts of a cross-linking agent, 0.1-10 parts of a coupling agent, 0.01-10 parts of a solidifying accelerator and 0.01-5 parts of a catalyst; and the silicone rubber product is produced by a certain process method. The single-component crystal flowing-type dealcoholized room temperature vulcanized silicone rubber provided by the invention is good in adhesion, has no corrosion to the metal such as copper materials and the like, is capable of rapid solidification and keeping high-transparency and high-light transmission before and after solidification, can be yellowing resistant for a long period before and after solidification, and boiling resistant after solidification, and is long in storage period.

Owner:FOSHAN PULIDA TECH

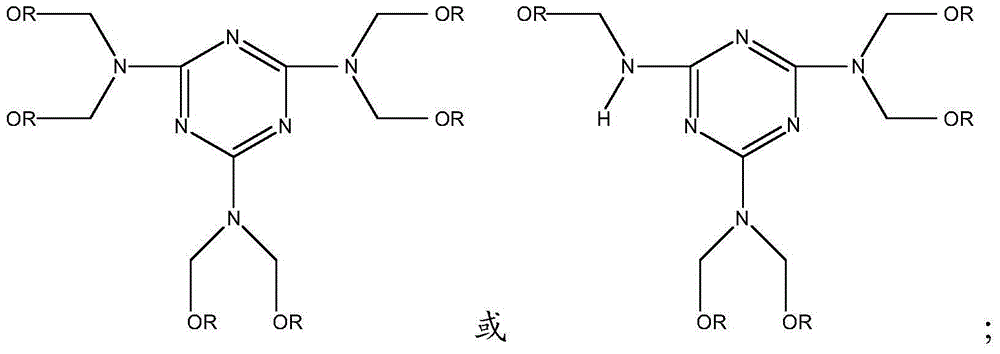

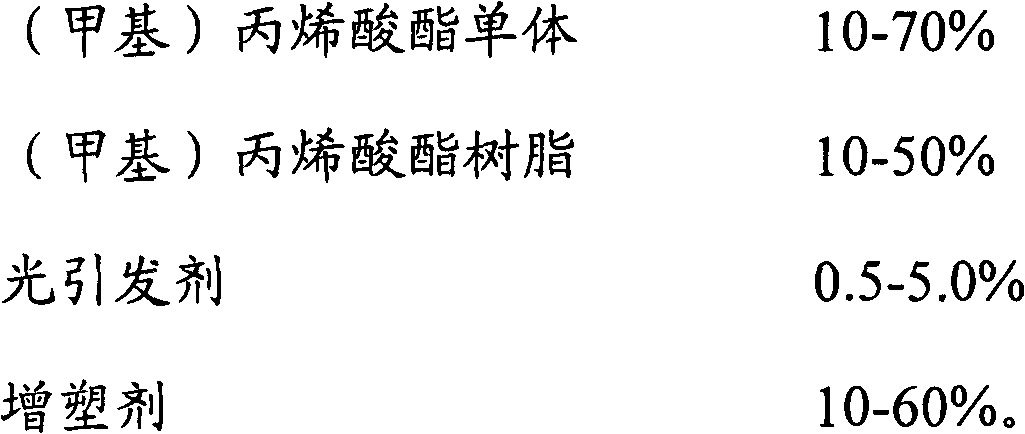

Bonding method of touch screen substrates, and binder for same

ActiveCN102426494AWon't turn yellowShort curing timeSemiconductor/solid-state device manufacturingInput/output processes for data processingCooking & bakingRoom temperature

The invention discloses a bonding method of touch screen substrates, comprising the following steps of: (1) preparing a substrate to be bonded, wherein the substrate has a shadow region and a transparent region; (2) uniformly coating a prime coat binder on the shadow region at one surface of the substrate; (3) uniformly coating a main binder on the transparent region at the same surface of the substrate; (4) bonding the other substrate with the substrate coated with the prime coat binder and the main binder; (5) procuring the two substrates via a UV lamp; (6) curing the procured substrates through ultraviolet radiation by the UV lamp; (7) baking the two substrates in a baking oven. The invention further discloses a binder for bonding of the touch screen substrates, wherein the binder comprises the prime coat binder and the main binder, and can cure and curdle under a lower temperature, the curing time is short, the main binder is free of hyperoxide and can be stored at room temperature, so that the binder cannot turn yellow in the storage process, and a view area of the touch screen cannot turn yellow.

Owner:塔威新材料科技(上海)有限公司

High-efficiency decontamination laundry detergent

InactiveCN104479893ANot dimWon't turn yellowInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsPreservativeWhitening Agents

The invention relates to a laundry detergent, and particularly relates to a high-efficiency decontamination laundry detergent. The high-efficiency decontamination laundry detergent comprises the following components in percentage by weight: 15%-20% of surface active agents, 2%-5% of acidic auxiliary agents, 0.2%-0.6% of flake caustic soda, 0.3%-0.5% of sterilizing agents, 0.3%-0.5% of chelating agents, 0.4%-0.6% of fluorescent whitening agents, 0.2%-0.4% of preservative agents, 1%-2% of thickening agents, 1%-2% of anti-redeposition agents, 0.2%-0.4% of rosemary essential oil, 0.5%-1% of perfume fixatives, 2%-4% of tea saponins and the balance of deionized water. The laundry detergent disclosed by the invention is mild in smell, capable of removing multiple stubborn stains and high in decontamination capacity; in addition, a fabric can not be darkened and yellowed after being washed by using the laundry detergent.

Owner:QINGDAO HOUKE INFORMATION ENG

UV-LED glass ink and preparation method and use method thereof

The invention discloses a UV-LED glass ink and a preparation method thereof. The glass ink is prepared by the steps: taking polyester acrylate, difunctional polyurethane acrylate and hexafunctional polyurethane acrylate as main raw materials, adding an active monomer, a filling agent, a photoinitiator, an auxiliary agent and silicon dioxide, and evenly mixing the raw materials and grinding to prepare the glass ink. The glass ink has the characteristics of fast curing speed and high curing efficiency. By adjustment of the composition of the filling agent, the glass ink with different appearanceeffects can be prepared. The invention also provides a use method for the UV-LED glass ink; 250-300 mesh screen printing is adopted, the thickness of an ink layer is controlled to 10-30 [mu]m, and photo-curing is carried out for 40-60 s after printing is completed. The glass ink has short curing time and good curing effect, cannot make glass products yellowed, and does not cause damage to operator bodies due to too strong light illumination in the curing process.

Owner:FOSHAN CITY GREEND CHEM

Water-soluble acrylic resin and preparation method thereof

InactiveCN102153696AWon't turn yellowGood outdoor weather resistanceCoatingsDispersityFunctional monomer

The invention discloses a water-soluble acrylic resin which comprises functional monomers, (methyl)acrylic acid, (methyl)hydroxyalkyl acrylate, acrylamide, an initiator, a reducer and water. The waterborne resin can not become yellow, has the advantages of high outdoor weather resistance, favorable dispersity for pigment, low cost, favorable water solution resistance, favorable punching oil resistance, favorable solvent resistance, high formability, favorable heat resistance, favorable bending resistance, no odor and simple production technique, and is in the leading position in China. The water-soluble acrylic resin can be widely used for surface coating of aluminum and aluminum alloy products, and especially for coating surfaces of heat exchanger fins of air conditioners.

Owner:SNTO TECH GRP

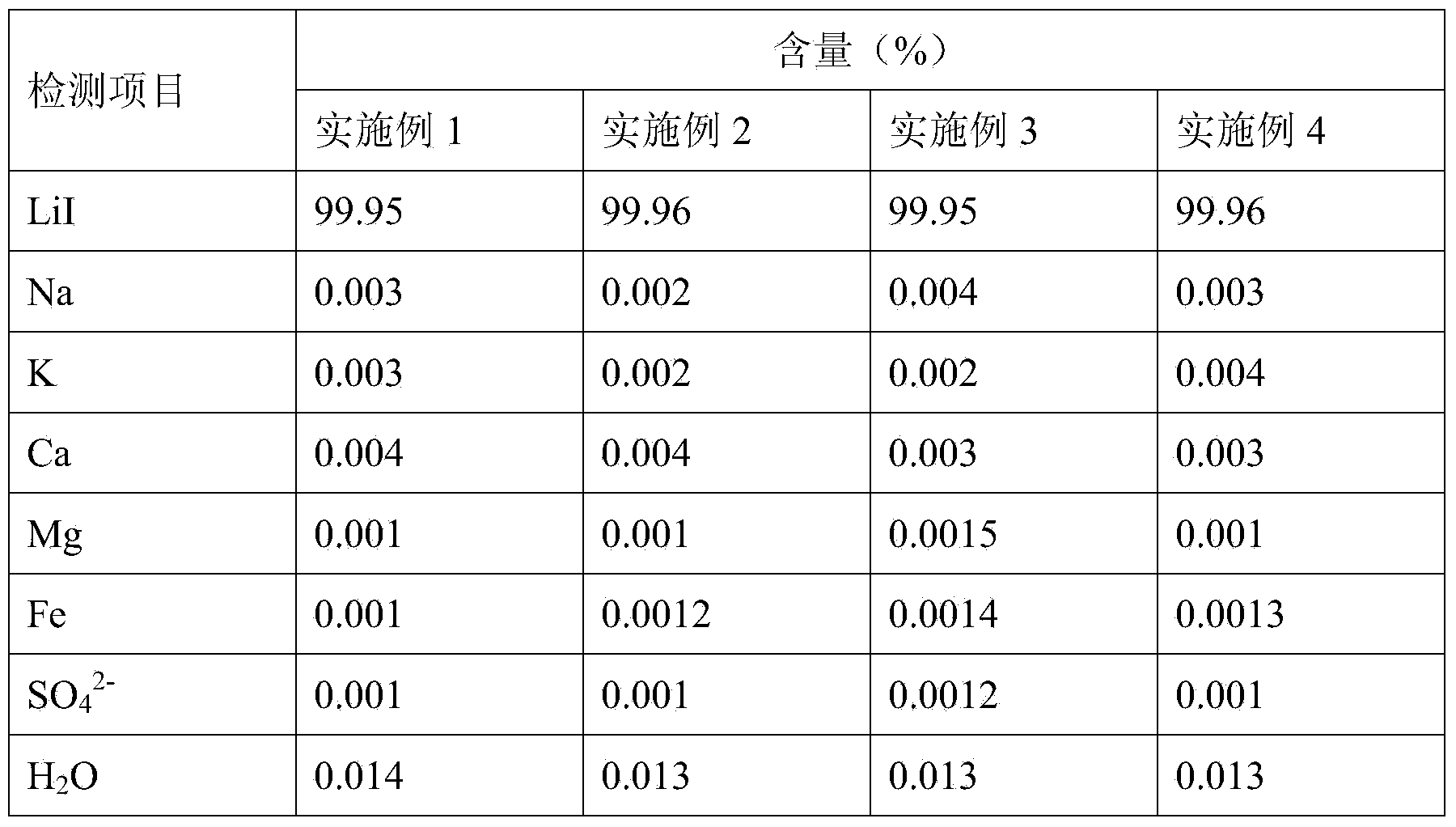

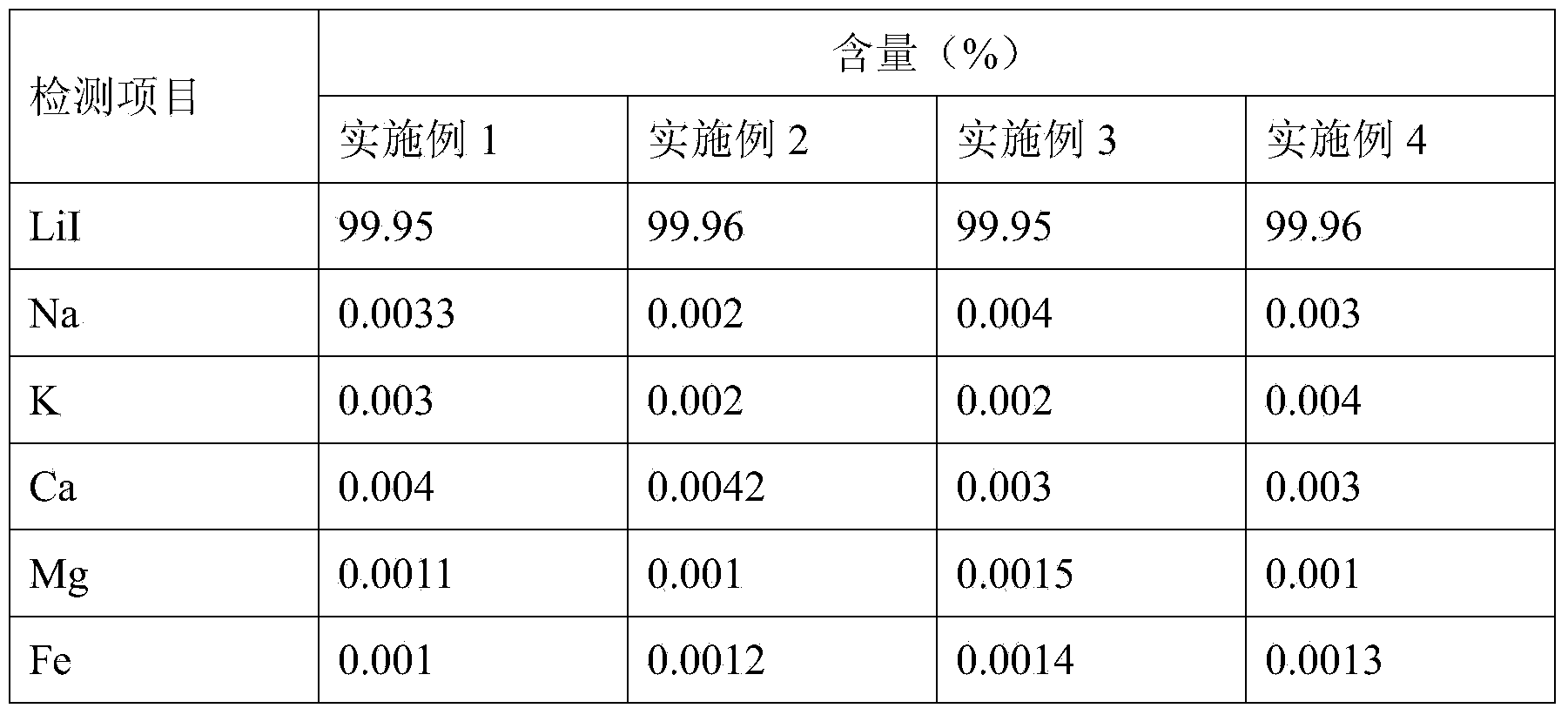

Preparation method of anhydrous lithium iodide

The invention belongs to the technical field of electrolyte preparation of lithium battery electrolytic liquids, and particularly relates to a preparation method of anhydrous lithium iodide. The preparation method of anhydrous lithium iodide comprises the following steps of reacting iodine, hydrazine hydrate and lithium hydroxide by using an aqueous liquid method, sequentially carrying out evaporation and concentration, filtration, and heated concentration on the obtained product, feeding inert gas into the obtained product to dehydrate, and packaging the obtained product under the protection of the inert gas. No organic solvent is added in the whole process; and the method is simple in technological process and short in time consumption, and solves the problems that traditional production methods are long in time consumption, iodide lithium packages are deliquescent, and the like.

Owner:HUBEI BAIJIERUI ADVANCED MATERIALS

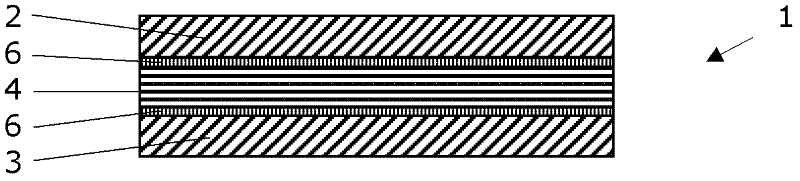

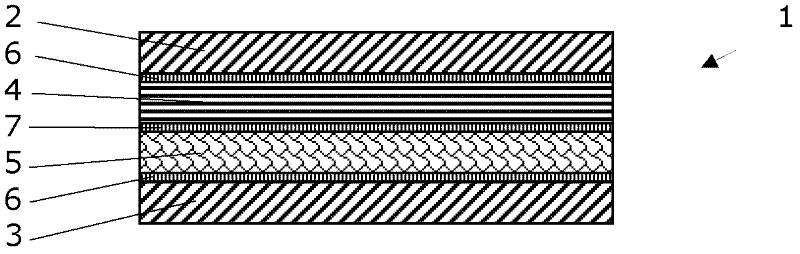

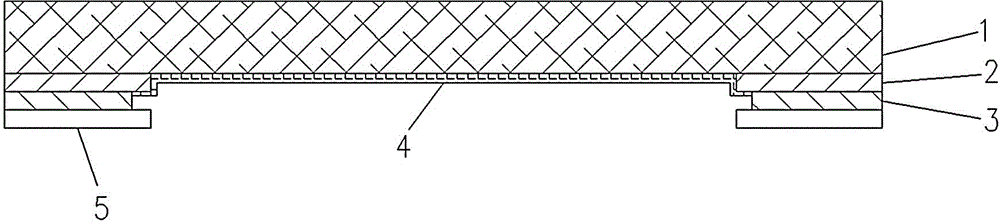

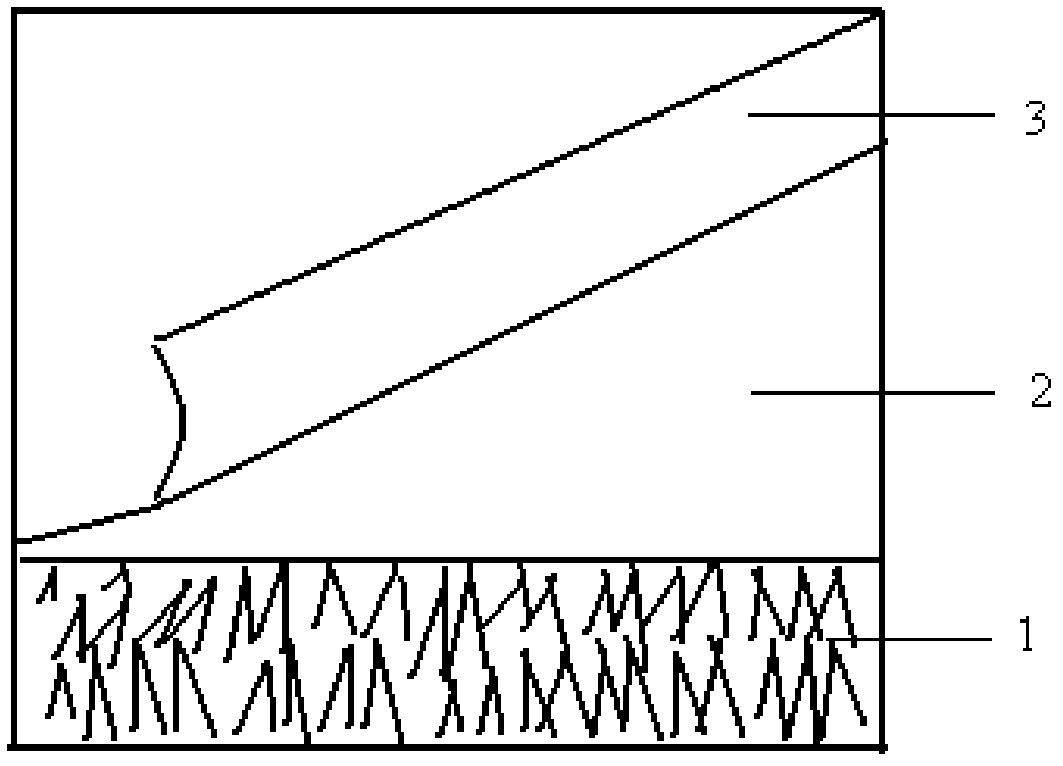

Multilayer backsheet for photovoltaic modules, and its production and use in the production of photovoltaic modules

InactiveCN102343699AWon't turn yellowNot subject to entrySynthetic resin layered productsElectrical equipmentPolyesterWater vapor

A multilayer backsheet (1) for a photovoltaic module according to the invention comprises a first outside layer (2), a second outside layer (3) and at least one inside layer (4, 5) which is arranged between these outside layers (2, 3). This at least one inside layer (4, 5) forms a water-vapor barrier and / or oxygen barrier. All these layers (2, 3, 4, 5) are composed of polymers. The multilayer backsheet (1) for a photovoltaic module according to the invention is characterized in that at least one of the two outside layers (2, 3) comprises a polyamide, and that the at least one inside layer (4, 5) consists of polymers which are no fluoropolymers and do not comprise any polyethylene. Inside layers (4, 5) made of partly aromatic polyesters are used only in combination with at least one outside adhesion promoter layer (6) made of block copolyesteramide.

Owner:EMS PATENT AG

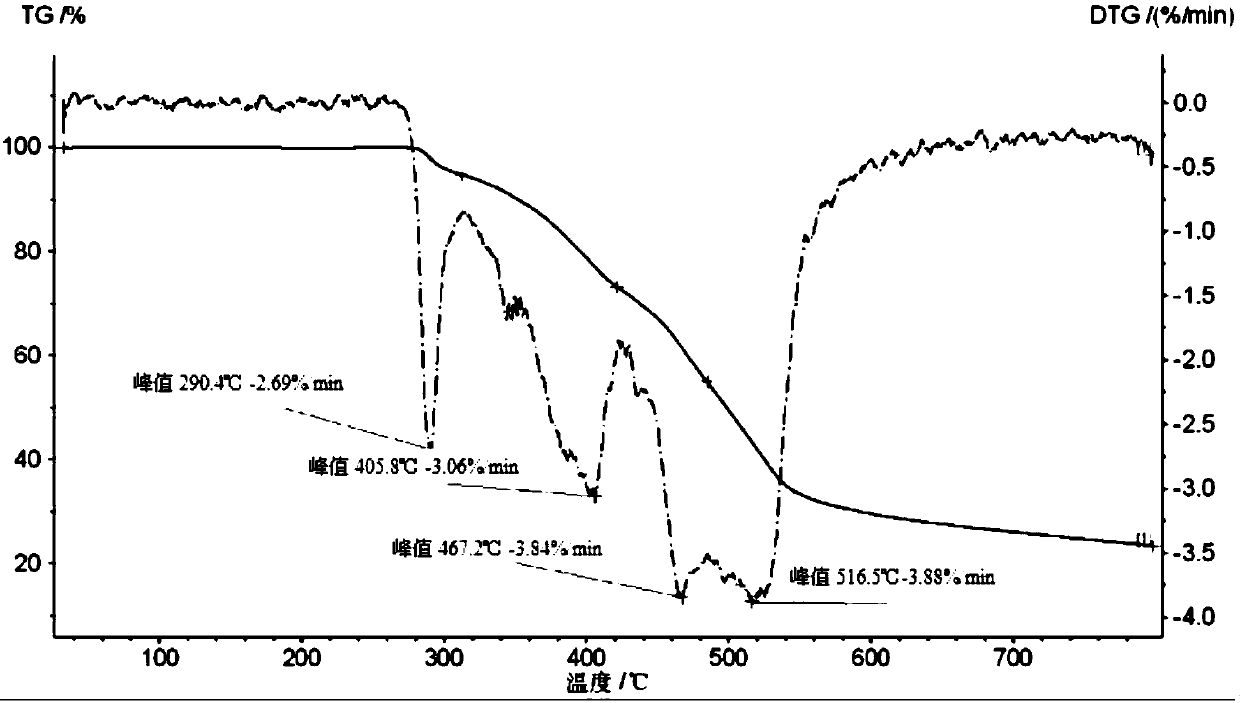

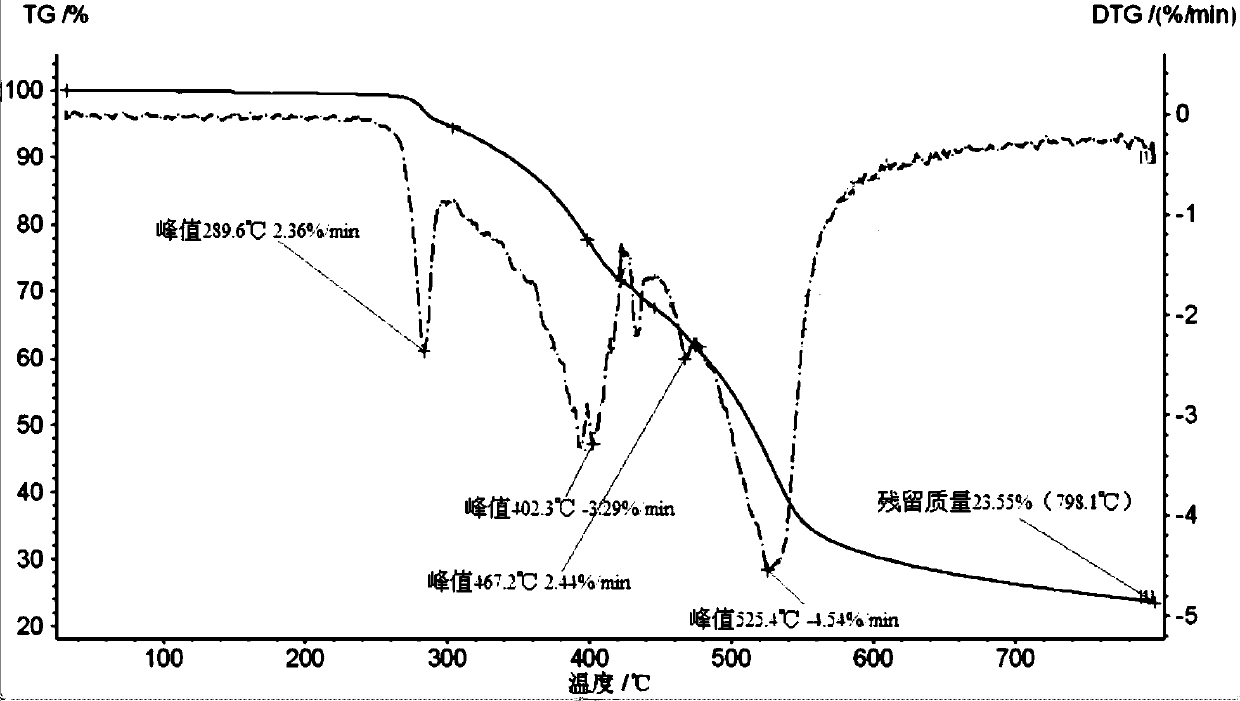

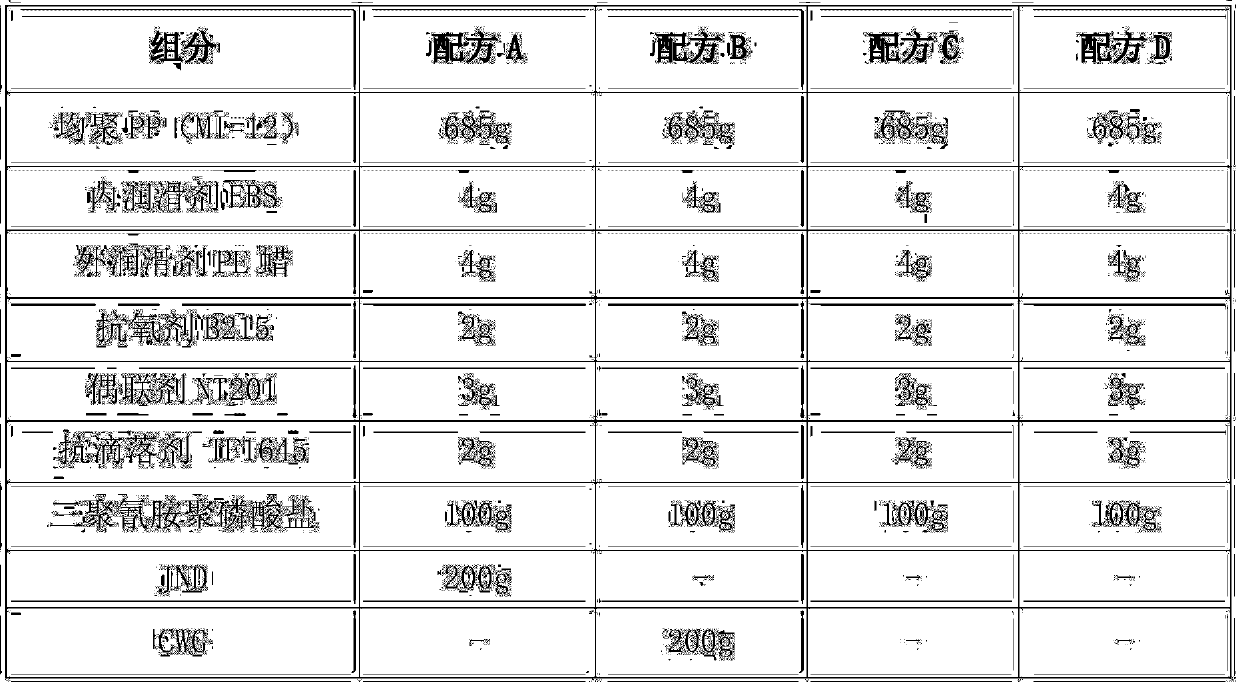

Method for preparing high-purity and high-yield pyrophosphoric acid piperazine and application thereof

The invention discloses a method for preparing high-purity and high-yield pyrophosphoric acid piperazine. Phosphorus pentoxide is added into a reaction still which is provided with a stirring and recycling device, stirring is conducted while 85% phosphoric acid is added in a dropwise mode, and after dropping is finished, the temperature of the reaction still is adjusted to 150-250 DEG C and kept for 0.5-5 h through the temperature rising control of the reaction still; the temperature of the reaction still is reduced to 50-100 DEG C through the temperature decreasing control of the reaction still, and glacial acetic acid is added into the reaction still and stirred for 0.1-2 h; piperazine is added in batches, and the temperature of the reaction still is kept between 80 DEG C and 150 DEG C for 1-5 h; the temperature is decreased to the indoor temperature, filter pressing is conducted, filter cakes are dried through a rake type drier, a clamping sleeve of the rake type drier is heated by heat transfer oil, the temperature of the heat transfer oil of the clamping sleeve of the rake type drier is controlled between 100 DEG C and 250 DEG C, the vacuum degree is 0.01-0.1 Mpa, a vacuum desolventizzazione is kept for 1-6 h, and then high-purity pyrophosphoric acid piperazine crystals are prepared. The purity of the product prepared through the method is 99% or above, the yield of the product prepared through the method is 95% or above, the whiteness of the product prepared through the method is 93% or above, the heat stability of the prepared pyrophosphoric acid piperazine is good, no byproduct is produced, and cost is low.

Owner:ZHONGSHAN COMPLORD NEW MATERIALS CO LTD

Method for fabricating white OGS touch screen

InactiveCN104866160AReduce exposure to high temperaturesImprove production yieldInput/output processes for data processingCoatingYield rate

The invention discloses a method for fabricating a white OGS (One Glass Solution) touch screen, and the fabricating method comprises the following steps of a) performing coating and shadow elimination to a glass substrate; b) silk-screen printing a first white ink layer in the frame region of the lower surface of the glass substrate; a steel wire gauze adopted during silk-screen printing is no less than 420 meshes and the printed white ink adopts screen printing ink which bears the temperature more than 230 degrees centigrade; c) silk-screen printing a second white ink layer on the lower surface of the first white oil ink layer; the steel wire gauze adopted during silk-screen printing is no less than 420 meshes and the printed white ink adopts screen printing ink which bears the temperature more than 230 degrees centigrade; d) fabricating an ITO layer in a transparent region at the bottom of the glass substrate through a yellow light process; the ITO layer is in a single-layer multiple-point caterpillar structure; e) silk-screen printing a gray oil ink layer on the lower surface of the second white oil ink layer; printing the white oil ink layer through the steel wire gauze with the high mesh number, thereby improving uniformity of the white oil ink layer and reducing thickness of the white oil ink layer; the white oil ink layer cannot become yellow by adopting heat-resistant screen printing ink after high-temperature processing, and thus the yield rate of the white OGS touch screen is increased.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

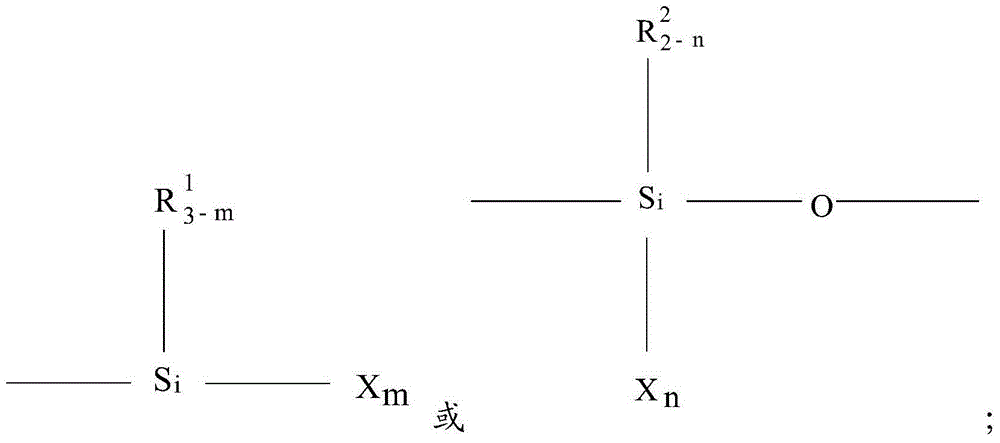

Crosslinkable materials based on organosilicon compounds

InactiveCN101712802AEasy to manufactureWon't colorGroup 4/14 element organic compoundsAdhesivesSilane compoundsPolymer science

Moisture-curable crosslinkable composition (I) comprises: at least one silane compound (A1); one or more organosilicon compounds (B1) containing basic nitrogen; and one or more oxaldianilides. Moisture-curable crosslinkable composition (I) comprises: at least one silane compound of formula (A-[(C(R 1>) 2) b-SiR a(O(R) 2) 3 - a] x) (A1); and one or more organosilicon compounds (B1) containing basic nitrogen and one or more oxaldianilides of formula (R 3>-NH-C(=O)-C(=O)-NH-R 3>) (C1). A : x-valent polymer radical bonded via nitrogen, phosphorus, oxygen, sulfur, carbon or a carbonyl group; R : monovalent, optionally substituted hydrocarbon radicals; R 1>H or a monovalent, optionally substituted hydrocarbon radical optionally linked to the carbon atom via nitrogen, phosphorus, oxygen, sulfur or a carbonyl group; R 2>H or a monovalent, optionally substituted hydrocarbon radical; R 3>monovalent, optionally substituted phenyl radicals; x : 1-10; a : 0-2; and b : 1-10. An independent claim isincluded for a molding produced by (I).

Owner:WACKER CHEM GMBH

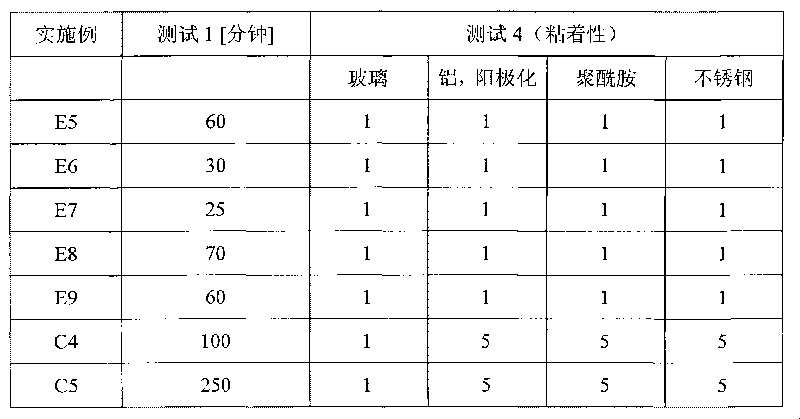

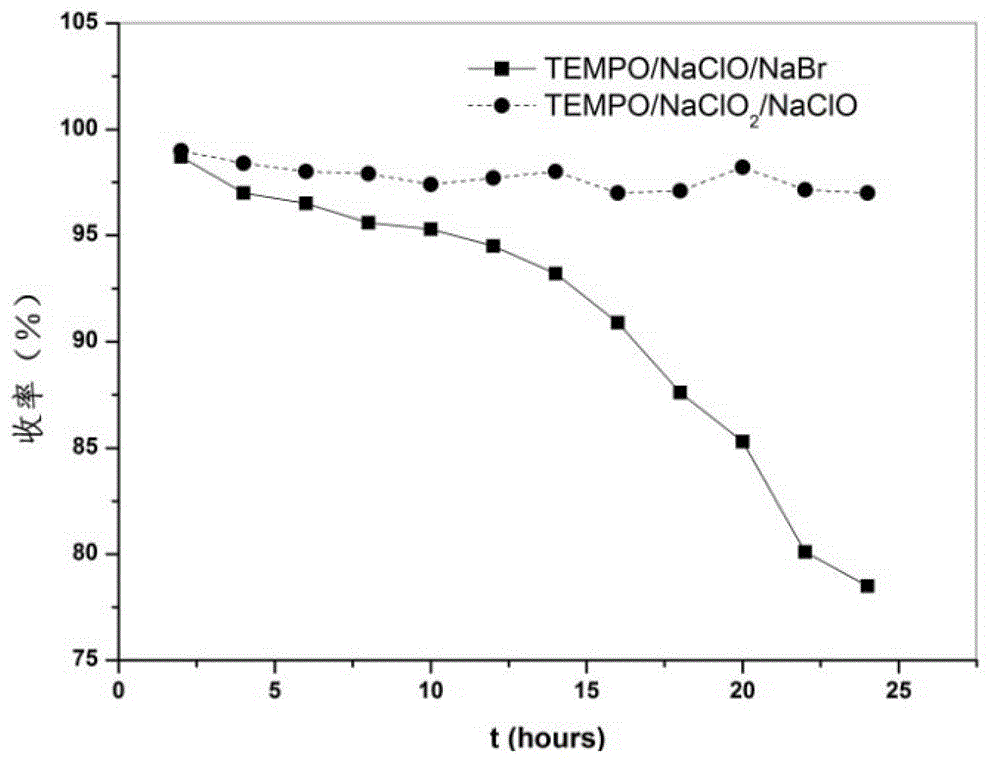

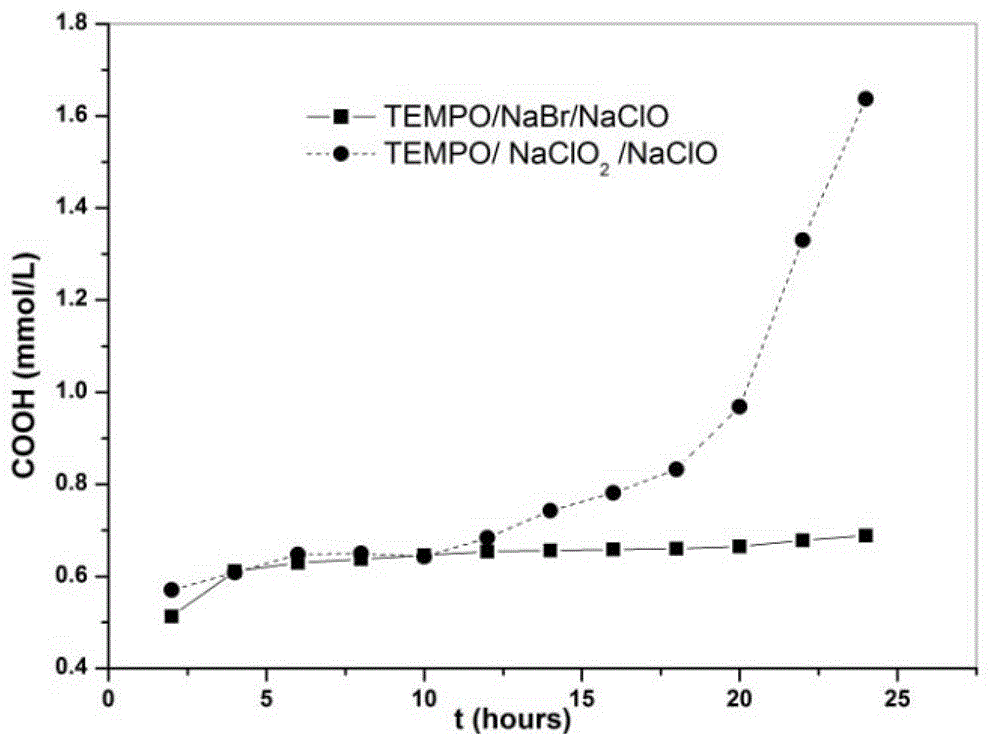

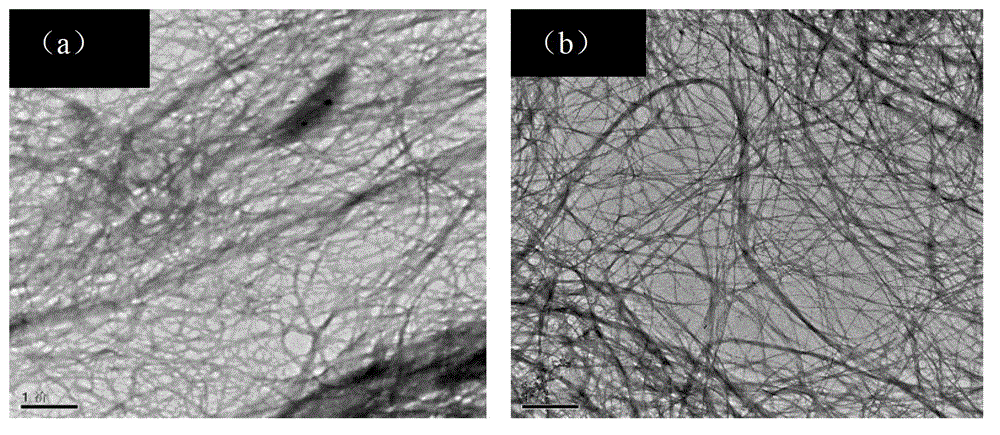

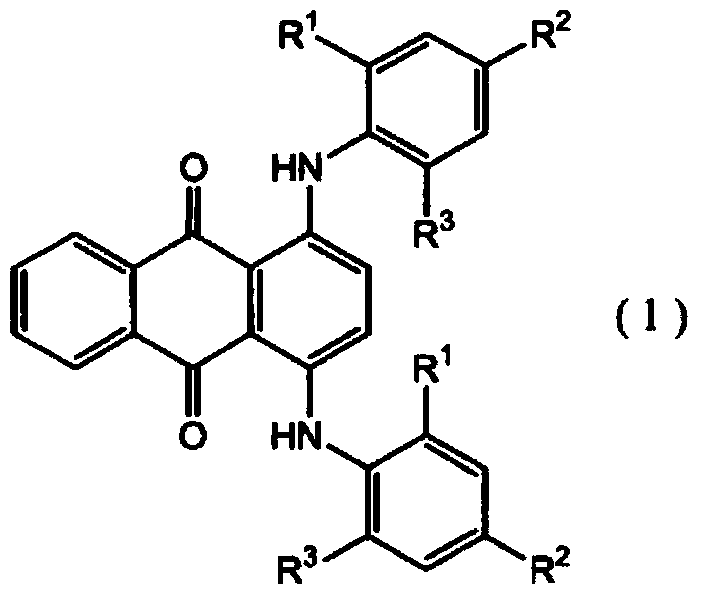

Catalyst and method for performing carboxyl reaction on C6 of bacterial cellulose

ActiveCN103157515B-High COOH contentWon't turn yellowOrganic-compounds/hydrides/coordination-complexes catalystsHypochloriteCrystallinity

The invention discloses a TEMPO / soluble chlorite / soluble pypocholoride catalytic system for performing a carboxyl reaction on C6 of a bacterial cellulose, and the soluble chlorite is a main catalyst. The invention further discloses a method for performing the carboxyl reaction on the C6 of the bacterial cellulose. The TEMPO / soluble chlorite / soluble pypocholoride catalytic system serves as the catalyst of the carboxyl reaction of the C6 of the bacterial cellulose, a product of COOH after the reaction is high in content, and yield is greatly increased. Crystallinity degree and a micro state of BC after the reaction are not changed, oxidation only occurs to the C6 position of the BC, and Cs at the other positions are not influenced. The soluble chlorite in the system is the main catalyst and is sold and bought in a solid form, is easy to store, use amount is easy to control. A product after the reaction cannot become yellow, and controllability and repeatability of the reaction are both high.

Owner:北京诺博特生物科技有限公司

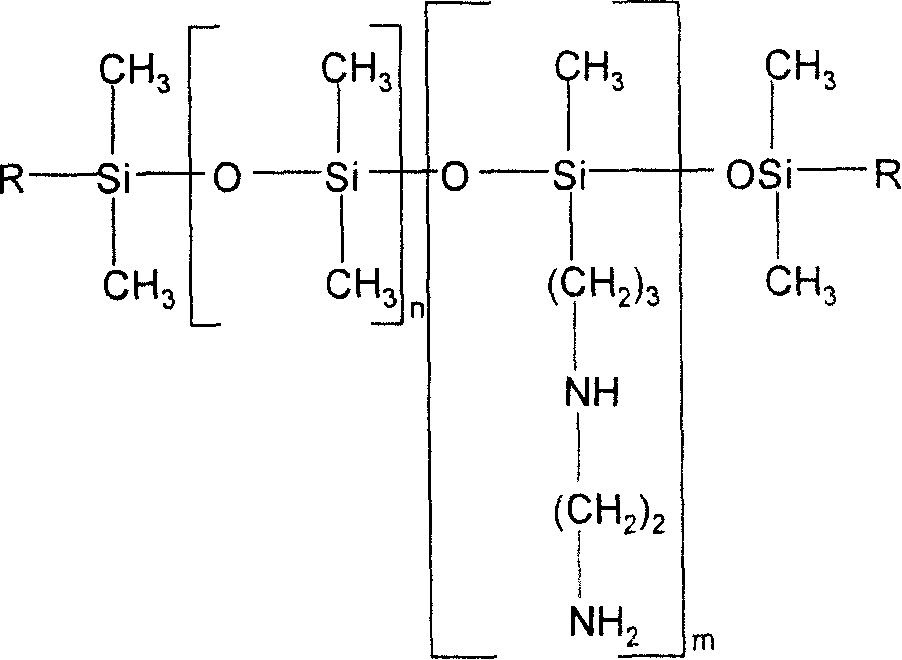

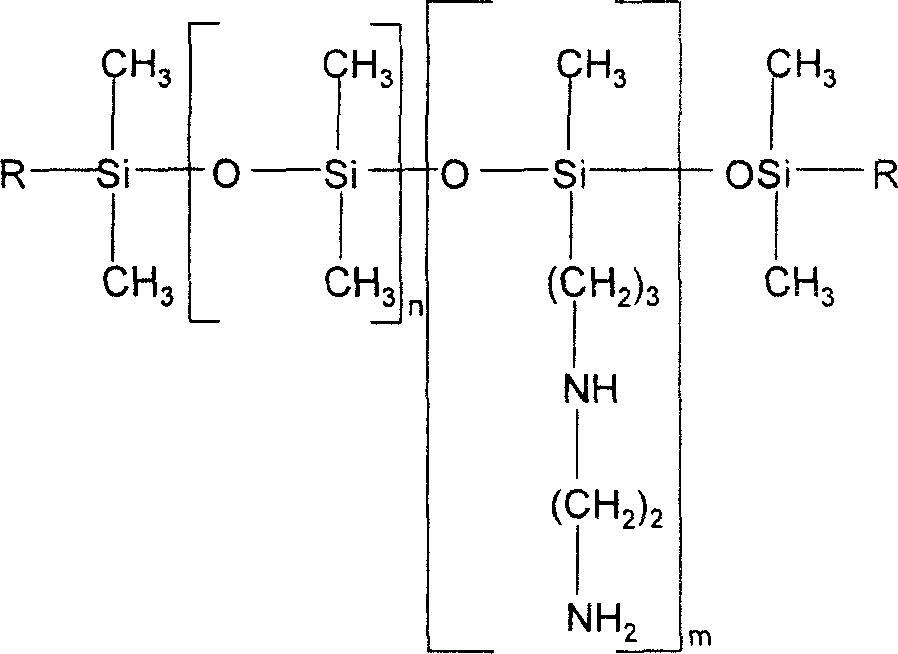

Liquid laundry detergent compositions with silicone fabric care agents

InactiveCN1942572AExcellent Care BenefitsAvoid wastingOrganic detergent compounding agentsDetergent dyesNitrogenLiquid laundry detergent

The invention is directed to aqueous liquid laundry detergent compositions for cleaning and imparting fabric care benefits to fabrics laundered therewith. Such compositions comprise (A) at least one detersive surfactant; (B) droplets of a silicone blend comprising a nitrogen-containing amino or ammonium functionalized polysiloxane and a nitrogen-free non-functionalized polysiloxane; and (C) at least one additional non-silicone laundry adjunct selected from detersive enzymes, dye transfer inhibiting agents, optical brighteners, suds suppressors and combinations thereof. The functionalized polysiloxane component of the silicone blend has a relatively low, i.e., less than 30 mol%, content of reactive / curable groups, a nitrogen content which ranges from 0.05% to 0.50% by weight and a viscosity which ranges from 0.00002 m<2> / s to 0.2 m<2> / s. The nitrogen-free, non-functionalized polysiloxane material ranges in viscosity from 0.01 m<2> / sec to 2.0 m<2> / sec. Such compositions may not additionally contain coacervate phase-forming polymers and / or cationic deposition aids.

Owner:THE PROCTER & GAMBLE COMPANY

Synthesis method of polyester glycol

The invention discloses a synthesis method of polyester glycol. The synthesis method comprises the following steps: 1) carrying out normal-pressure reaction: uniformly mixing dihydric alcohol , binary acid or binary acid anhydride in a normal-pressure and nitrogen atmosphere; adding an organic titanate catalyst and carrying out the normal-pressure reaction; 2) carrying out vacuum reaction: reducing temperature to enable a mixture to be subjected to esterification reaction; vacuumizing to remove water generated by the reaction; cooling and dropwise adding an alkaline solution to reduce the acid value of the product polyester glycol; finally, raising the temperature until less unreacted dihydric alcohol is distilled out; cooling to obtain the polyester glycol which has the acid value less than 0.4mgKOH / g, the molecular weight of 800 to 3500 and the hydroxyl value of 30mgKOH / g to 100mgKOH / g and is suitable for preparing polyurethane prepolymer. According to the method disclosed by the invention, a synthesis process is subjected to quantitative treatment so that the synthesis stability is greatly improved and the acid value of the synthetic product polyester glycol is reduced.

Owner:ZHANGJIAGANG NANGUANG CHEM

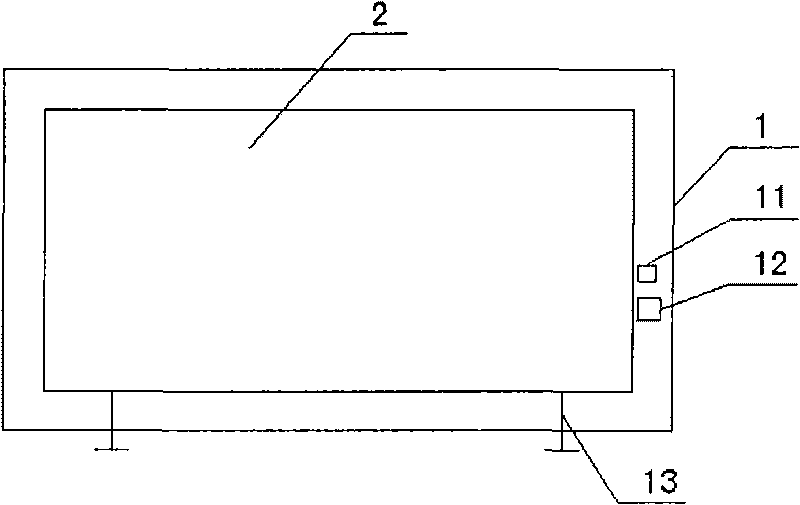

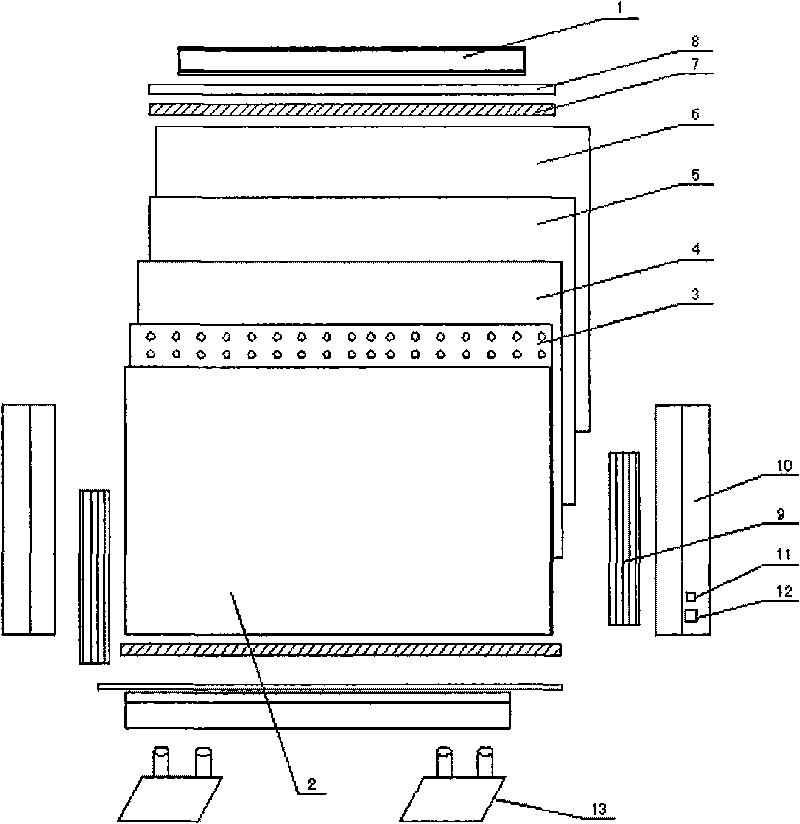

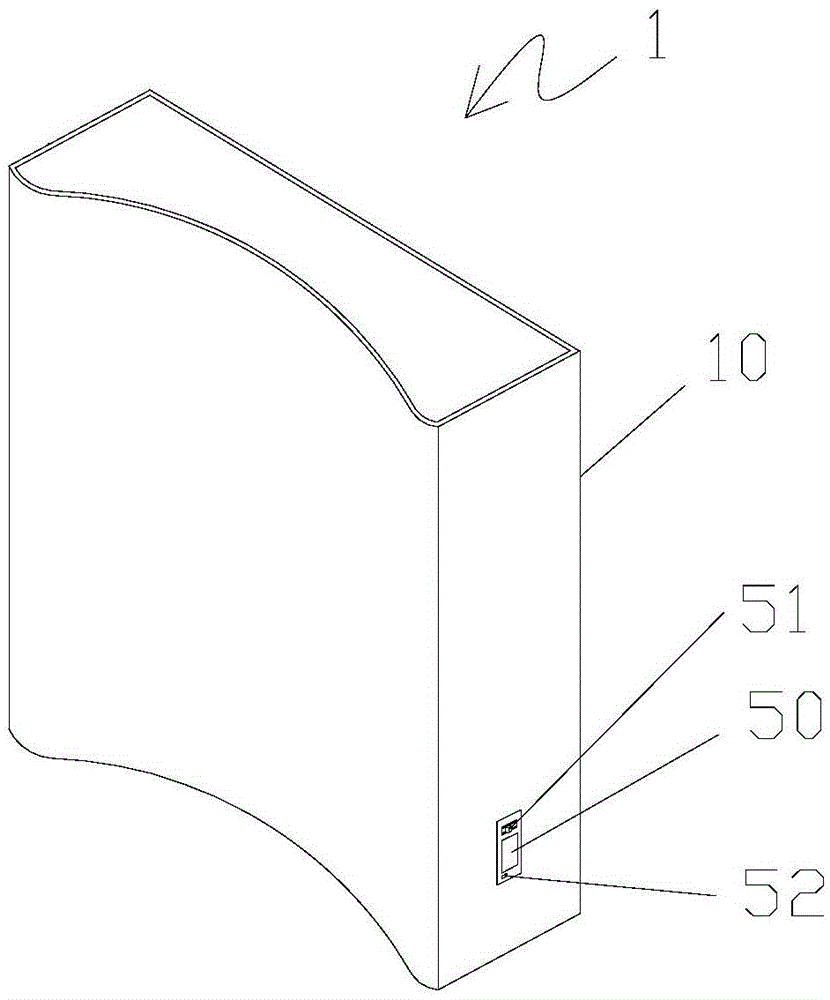

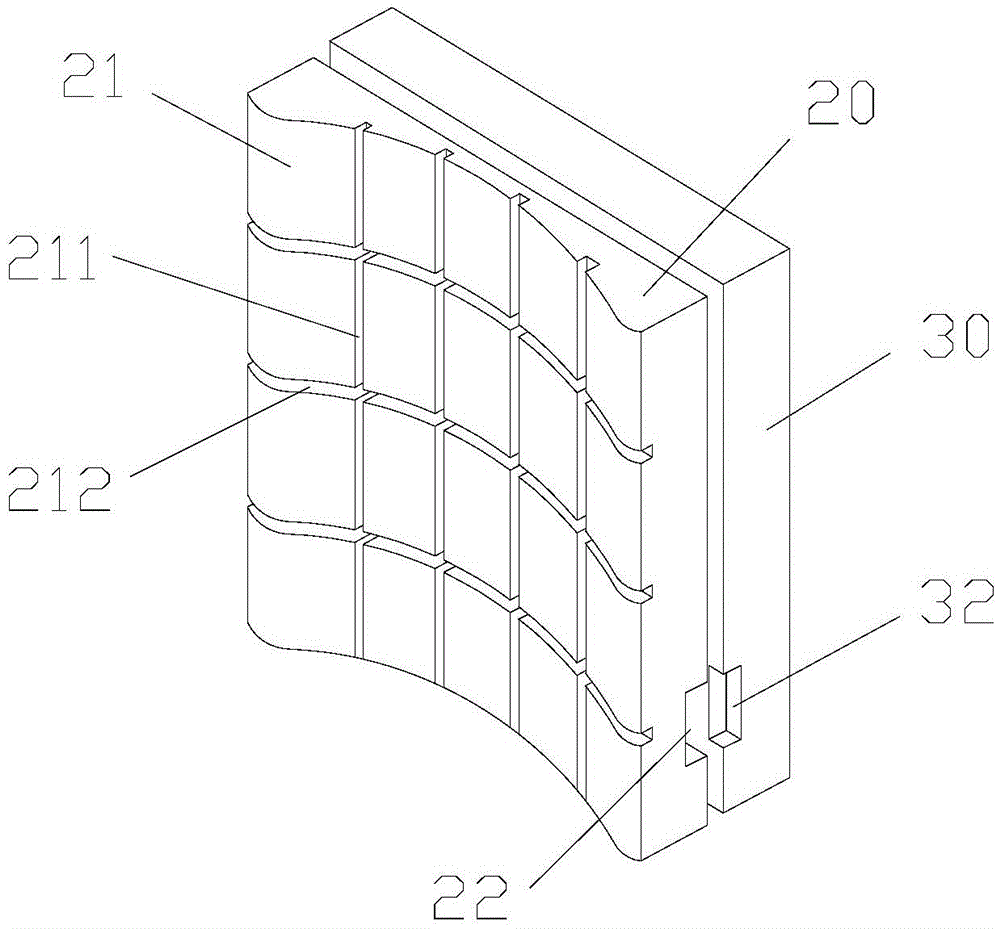

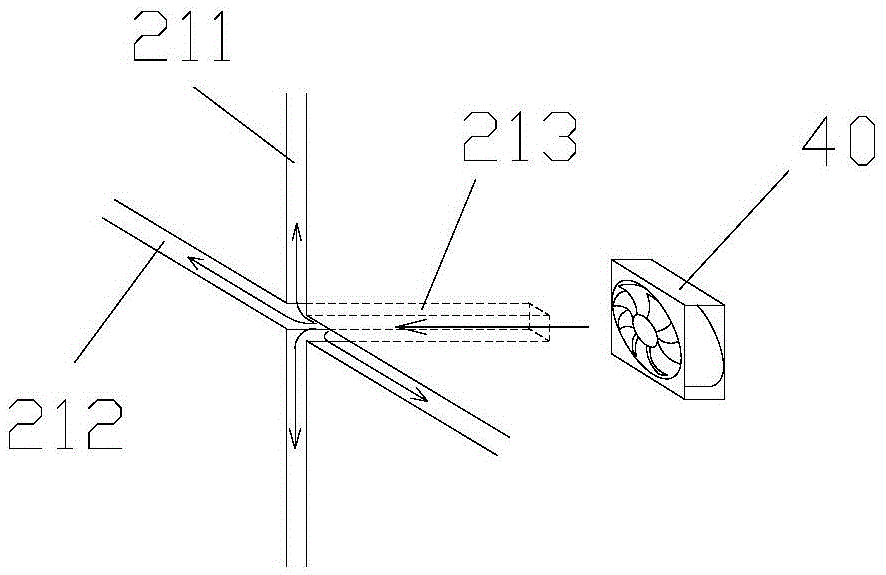

Ultra-thin film viewing illuminator

InactiveCN101725925AModern appearanceSmall appearanceMechanical apparatusLight guides for lighting systemsProtecting eyeLight guide

The invention discloses an ultra-thin film viewing illuminator, which comprises a frame body, a transparent device, a backboard, a light source and a drive. The ultra-thin film viewing illuminator is characterized in that the frame body is sequentially and fixedly provided with a light guide plate and the rear panel from the front side to the back side; an edge of the light guide plate is provided with a reflecting shade, and the light source is arranged inside the reflecting shade. The reflecting shade comprises a reflecting shade body with an arch structure and a planar lateral wing, and the lateral wing is connected with the front side of the light guide plate. The invention has the advantages of even illumination, safe energy conservation, correct film-reading, eyes protection, ultra-thin shape and low production cost.

Owner:SHANGHAI EDGE LIGHT IND

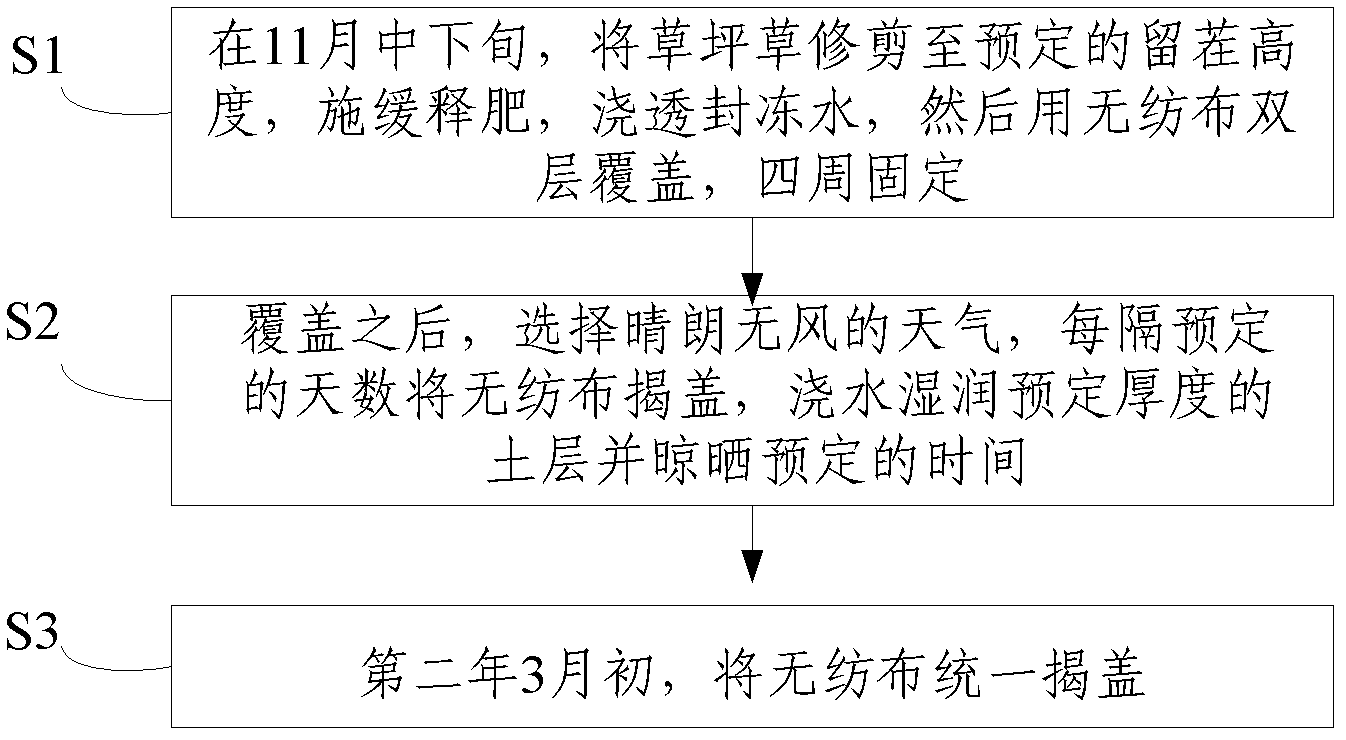

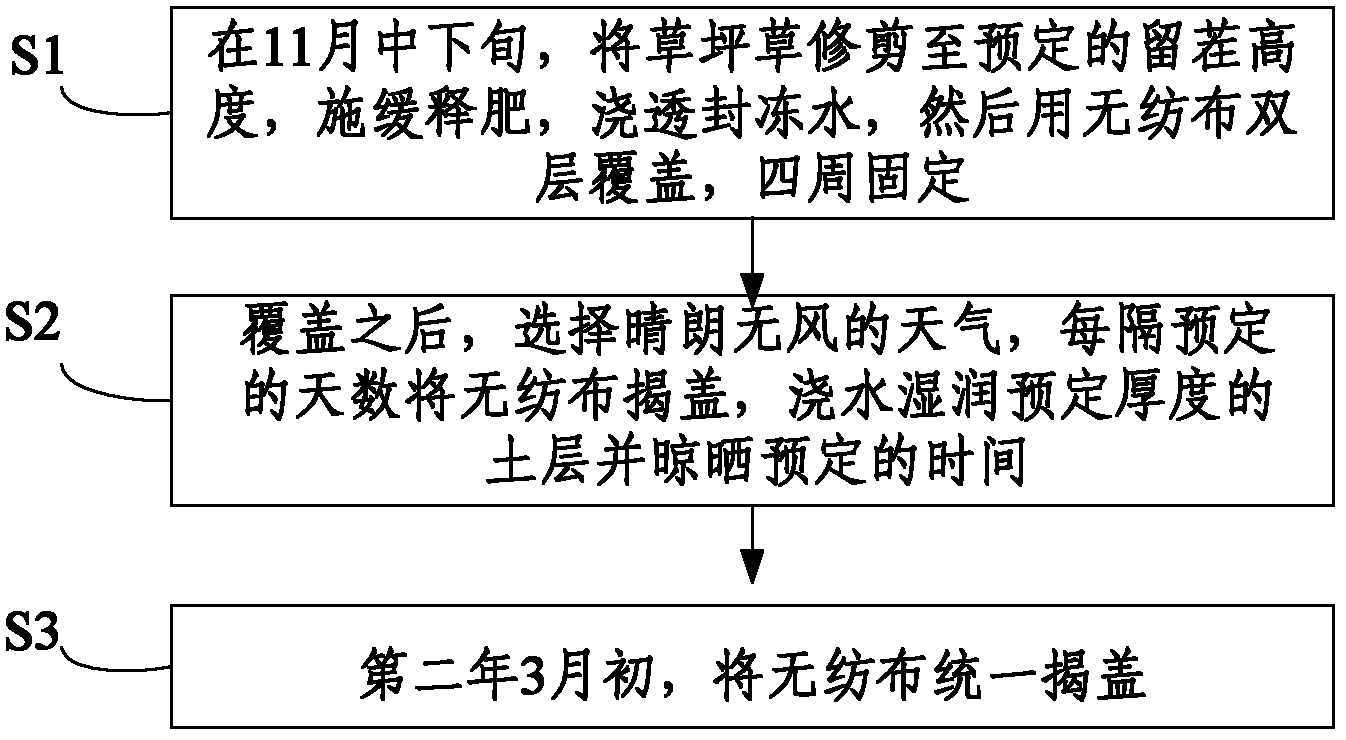

Method for prolonging green period of lawn

InactiveCN102524000AIncrease moisture contentAvoid yellowing and even deathPlant protective coveringsFiberFreeze injury

The invention discloses a method for prolonging a green period of a lawn. In winter, a covering object is used for protecting the lawn in a covering way, the covering object adopts non-woven fabrics which can increase the temperature of soil, and maintain the stable changing temperature difference between day and night, thus having important significance on promoting root system growth and preventing influence of freeze injury. The non-woven fabrics can increase the soil moisture content, so that the cases that grass in the lawn becomes withered and yellow and even dies due to droughty and water shortage in dry and blowy winter can be avoided. The non-woven fabrics have large fiber gaps and good air permeability, can avoid the freeze injury to the lawn caused by droplets generated by the changing temperature difference between day and night. Besides the non-woven fabrics have poor light transmission, which can reduce the light intensity and avoid the strong light exposure of the lawn in winter. Compared with the lawn without using any covering object, the lawn covered by non-woven fabrics in winter cannot be yellow in winter, when the covering object is uncovered in March next year, the lawn viewing quality can be achieved the using standards after about one week.

Owner:BEIJING FORESTRY UNIVERSITY

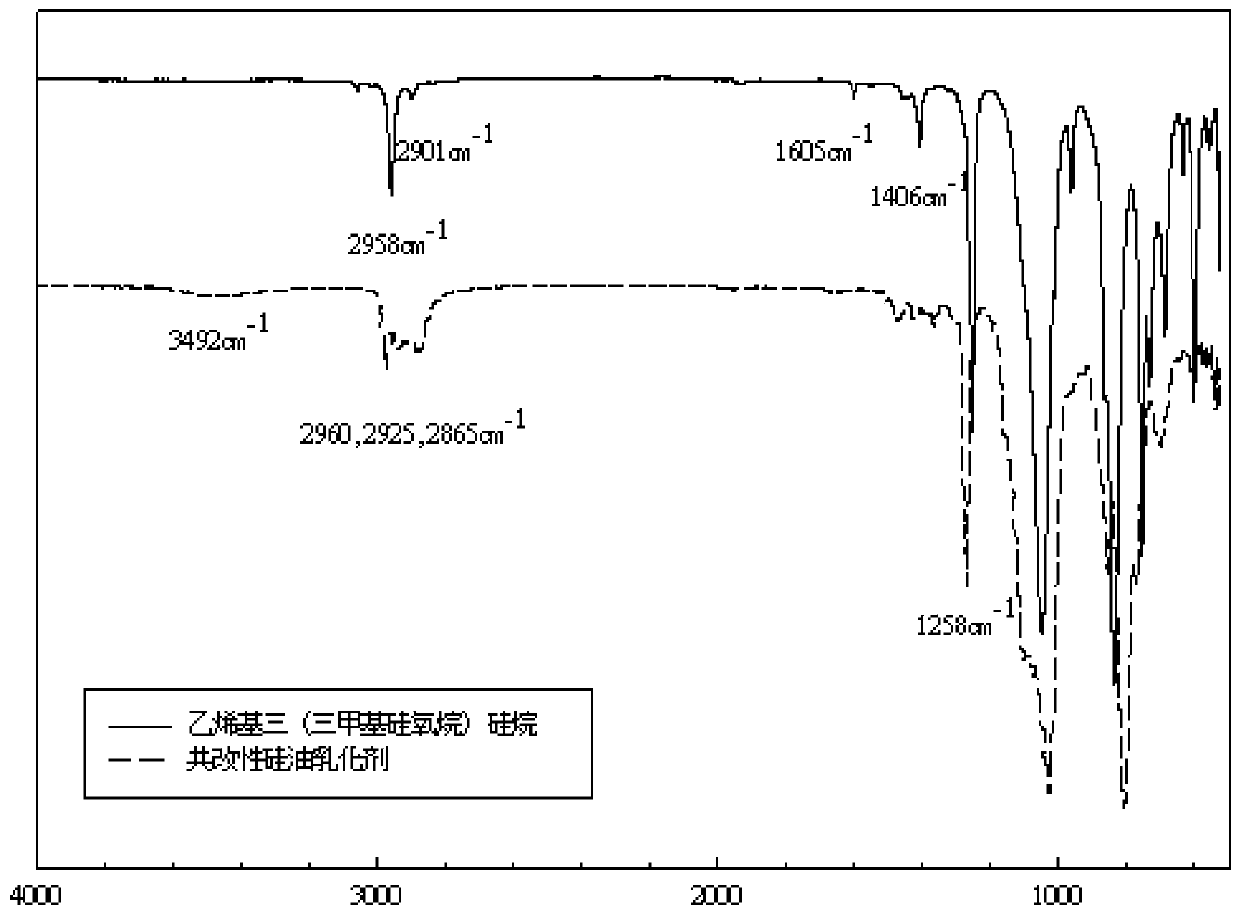

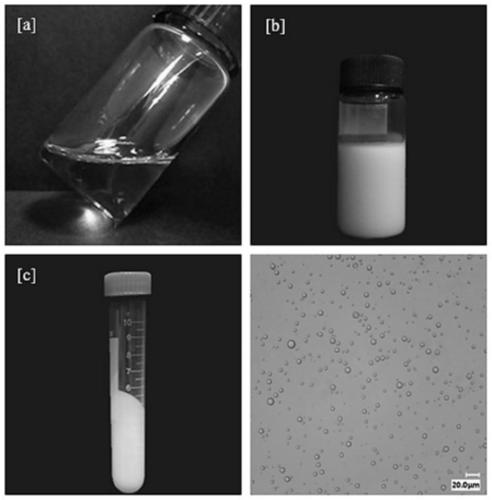

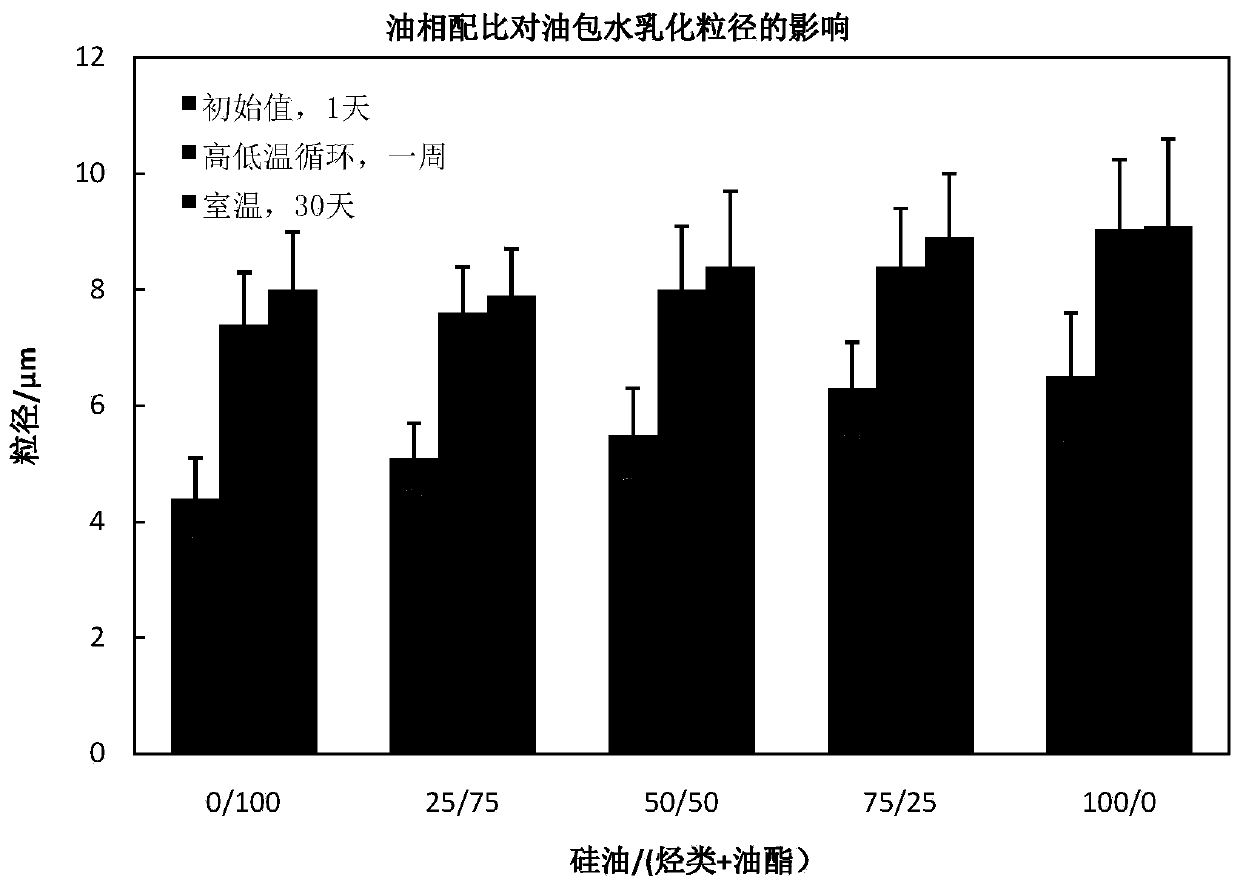

Preparation method for branched silane and polyether alkyl co-modified silicone oil

The invention discloses a preparation method for branched silane and polyether alkyl co-modified silicone oil. According to the preparation method, a silicone oil emulsifier is prepared through three-radical co-modification, and the product obtained by using the method has no pungent smell and has no visible gel impurities, the emulsion prepared by using the method cannot become yellow after long-time storage, and the silicone oil is high in stability, high in compatibility with various types of oil and suitable for W / Si, W / O and W / Si+O emulsifying systems. The product prepared by using the method has a highly-branched silicon chain structure, can be used in make-up products and sunscreen and has the functions of improving washability and durability.

Owner:JIANGNAN UNIV

Historic garden colored drawing repair paint

InactiveCN106497178AImprove durabilityWill not embrittleAntifouling/underwater paintsPaints with biocidesMethacrylateMixing ratio

The invention relates to historic garden colored drawing repair paint. The historic garden colored drawing repair paint comprises the following components in percentage by mass: at least 70% of basic addition materials, 3% to 5% of color particles, 5% to 7% of ferric oxide based additives and the balance of auxiliary addition materials, wherein the ferric oxide based additives consist of a mixture of red iron oxide and magnesium oxide and the mixing ratio of the red iron oxide to the magnesium oxide is 1:2 to 1:1; the basic addition materials comprise the following components in percentage by mass: 20% to 30% of acrylic ester, 10% to 15% of metacrylic acid ester, 10% to 15% of acrylic acid, 10% to 15% of methacrylic acid and the balance of a thickening agent and a filling agent. The historic garden colored drawing repair paint provided by the invention can be matched with the ageing degree of historic garden colored drawing to realize perfect repair of the historic garden colored drawing.

Owner:SUZHOU IND PARK LANDSCAPING ENG CO LTD

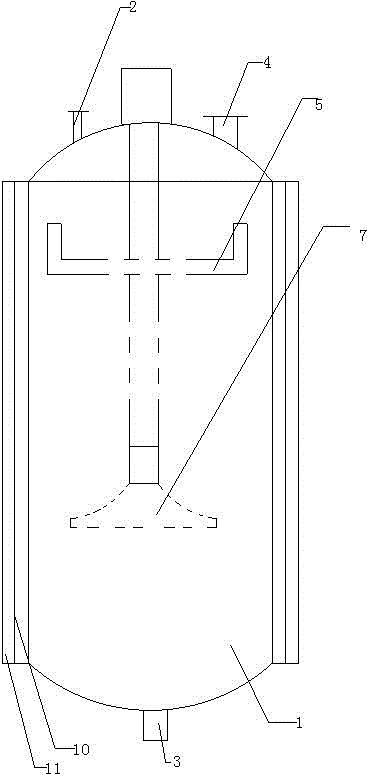

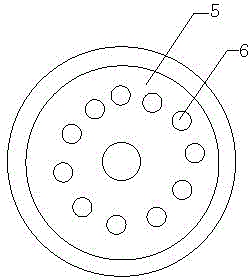

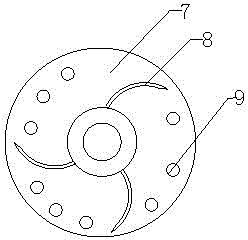

Dehydrating device of epoxidized soybean oil

ActiveCN104548640AShorten spin timeShorten distillation timeOrganic chemistryDistillation separationDistillationPulp and paper industry

The invention relates to a dehydrating device of epoxidized soybean oil. The device comprises a dehydrating tank body, wherein a feed inlet is formed in the top of the dehydrating tank body, a discharge opening is formed in the bottom of the dehydrating tank body, a vacuum interface for extracting moisture is further formed in the top of the dehydrating tank body, a rotary groove which is driven by a motor to rotate is inserted into the dehydrating tank, a plurality of leak holes are respectively formed in the left and right side faces and the bottom face of the rotary groove, a rotary disc is arranged below the rotary groove, a plurality of arc-shaped catches are arranged on the upper surface of the rotary disc, and an electric tracing ribbon is arranged outside the dehydrating tank body. The dehydrating device provided by the invention is simple structure and skillful in design, and the distillation time of the epoxidized soybean oil is obviously shortened, thus the distilling temperature can be properly lowered, and the defects that the prepared finished product is poor in thermal stability and the product is yellow are avoided.

Owner:DANYANG CITY AUX CHEM PLANT

Oil detergent

InactiveCN104893853AEfficient removalGood degreasing effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsBiotechnologyPhosphoric Acid Esters

The invention relates to the technical field of articles of daily use, in particular to an oil detergent. The oil detergent comprises the following raw materials in parts by weight: 8 to 12 parts of acrylic acid, 6 to 10 parts of alkyl phosphate, 6 to 10 parts of sodium alkylarysulfonate, 4 to 8 parts of trishydroxyethyl methyl quaternary ammonium sulfate, 4 to 8 parts of lauryl sodium sulfate, 2 to 6 parts of sesame oil, 1 to 5 parts of tea tree oil and 80 to 120 parts of deionized water. The oil detergent disclosed by the invention has the advantages of reasonable formula, capability of effectively removing edible oil, engine oil or other oils on clothes, good oil removing effect, high oil removing ability, less foam, no damage to the clothes, low production cost, no irritation, no toxicity, and no harm to the skin, human body and the environment; the oil detergent meets the requirement of environmental protection and can be widely suitable for cleaning velveteen clothes, fiber clothes, silk clothes and the like.

Owner:陈 明志

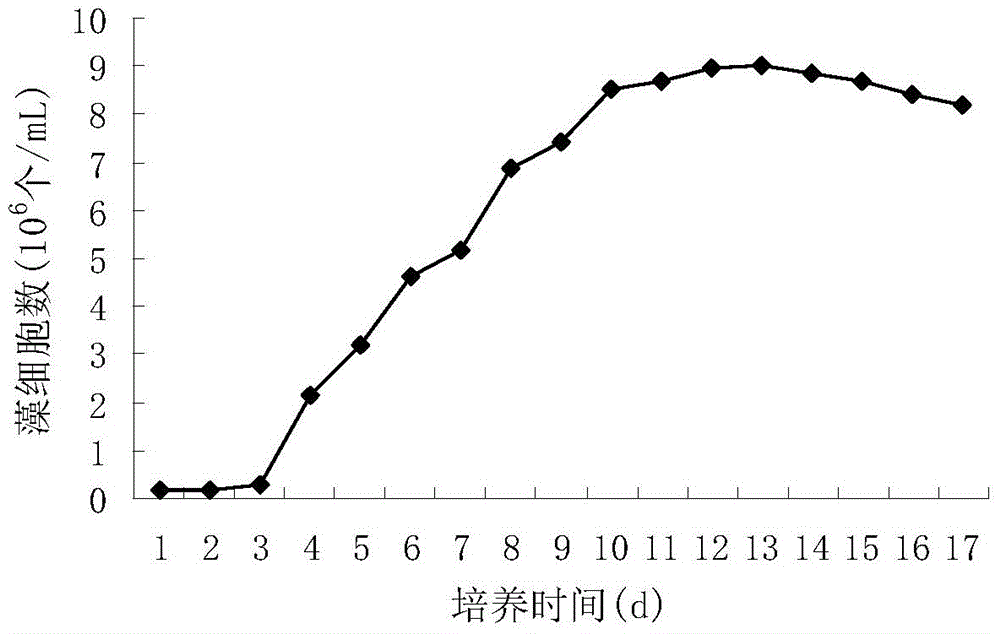

Culture medium for microcystis aeruginosa and application of culture medium

ActiveCN103555635AWon't turn yellowReduce incubation timeBacteriaMicroorganism based processesBiotechnologyMicrobiology

The invention relates to a culture medium for microcystis aeruginosa and an application of the culture medium. The technical scheme is as follows: the culture medium consists of NaCl, K2HPO4, MgSO4.7H2O, Ca(NO3)2, citric acid, FeCl3, triammonium citrate, EDTANa2, Na2CO3, a A5 storage liquid and water. By adopting the culture medium and a culture method, not only can the culture time be shortened, but also the microalgae liquid is free from turning yellow in the culture process, and the frustule number of the cultured microcystis aeruginosa when reaching a growth stable stage can reach 9*10<6> / mL.

Owner:LIAONING UNIVERSITY

Synthesis method of low-viscosity hydroxyl silicone oil

The invention relates to a synthesis method of low-viscosity hydroxyl silicone oil, which comprises the following steps: by using hexamethylcyclotrisiloxane and a solvent as raw materials and one or more of sodium hydroxide, potassium hydroxide and tetramethylammonium hydroxide as a catalyst, carrying out ring-opening equilibrium, neutralization and desolvation to obtain the transparent low-viscosity hydroxyl silicone oil. The viscosity of the synthesized hydroxyl silicone oil is 20-35 mm <2> / s, and the hydroxyl content is 6-12%.

Owner:HUBEI XINGRUI SILICON MATERIAL CO LTD

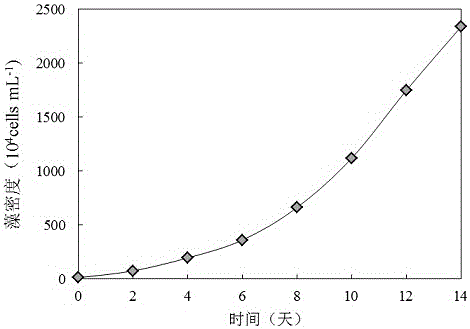

Microcystis aeruginosa culture method

InactiveCN106434485AImprove survival rateWon't turn yellowBacteriaMicroorganism based processesBacteroidesGemella

The invention relates to a microcystis aeruginosa culture method. The microcystis aeruginosa culture method includes the steps of a, previous preparation, b, microcystis aeruginosa preculture, and c, inoculation and culture of microcystis aeruginosa. The microcystis aeruginosa culture method has the advantages that the microcystis aeruginosa culture method is high in microcystis aeruginosa survival rate and microcystis aeruginosa growing rate, and a microcystis aeruginosa solution cannot yellow during culture and is less prone to being contaminated by other bacteria.

Owner:NANJING UNIV ECOLOGICAL RES INST OF CHANGSHU

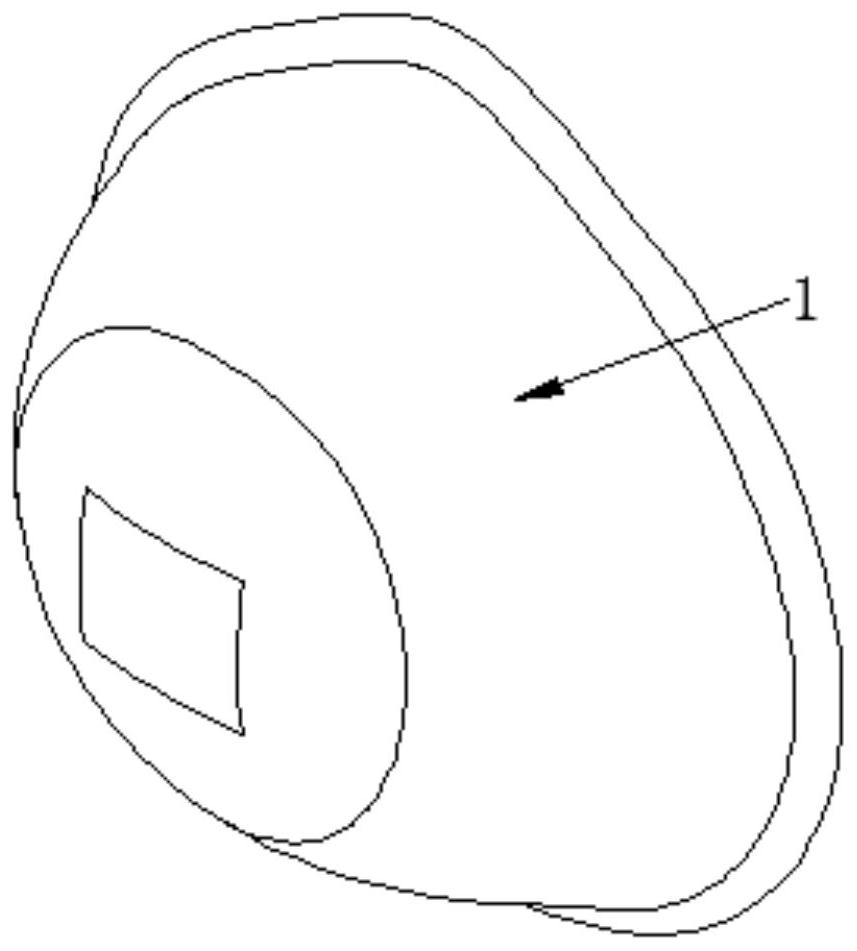

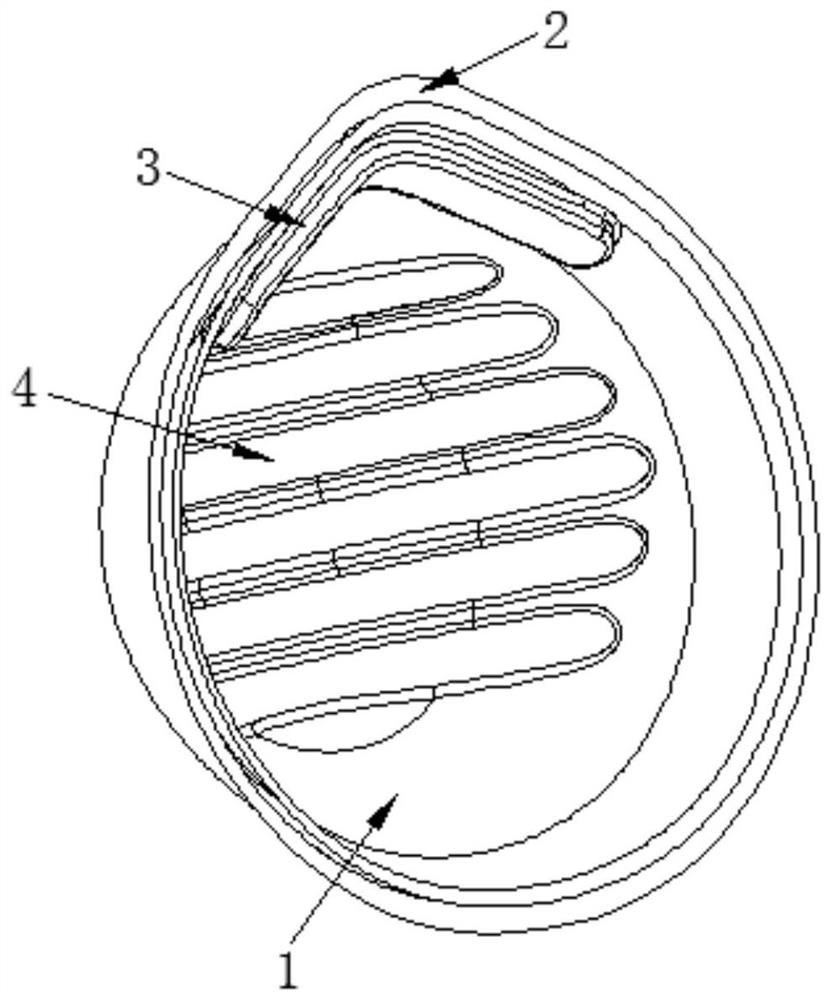

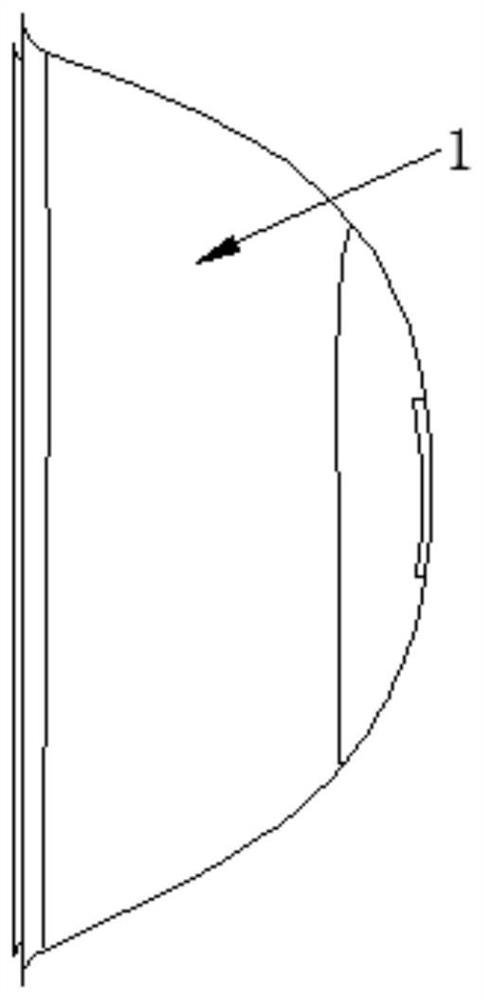

Environment-friendly traceless mask capable of being recycled

PendingCN111642835ASolve the problem of unclear visionNice appearanceSynthetic resin layered productsSevering textilesAirway structureEngineering

The present invention discloses an environment-friendly traceless mask capable of being recycled. The mask comprises a mask body, and the mask body is formed by bonding two or more of outer-layer waterproof cloth, aliphatic polyurethane sponge, a nano PTFE film and inner-layer antibacterial cloth; a protruding part is arranged at the top of the side, attached to the face, of the mask body, a pressing sealing strip is arranged on the inner wall of the protruding part, and an air channel structure is arranged on the inner wall of the mask body. The invention relates to the technical field of masks. According to the environment-friendly traceless mask capable of being recycled, the aliphatic polyurethane sponge is used for replacing common sponge, the mask does not turn yellow after being washed with water, the mask can be repeatedly used and is more environmentally friendly, a hot-press forming production method is adopted for the mask, one-time compression molding can be carried out, the process is simple, the production efficiency is high, masks of different sizes can be machined, people can select proper masks according to the face shapes of themselves, the use comfort degree is improved, and indentation is not likely to occur after the mask is worn for a long time.

Owner:YINGMING DRESS PART ZHONGSHAN

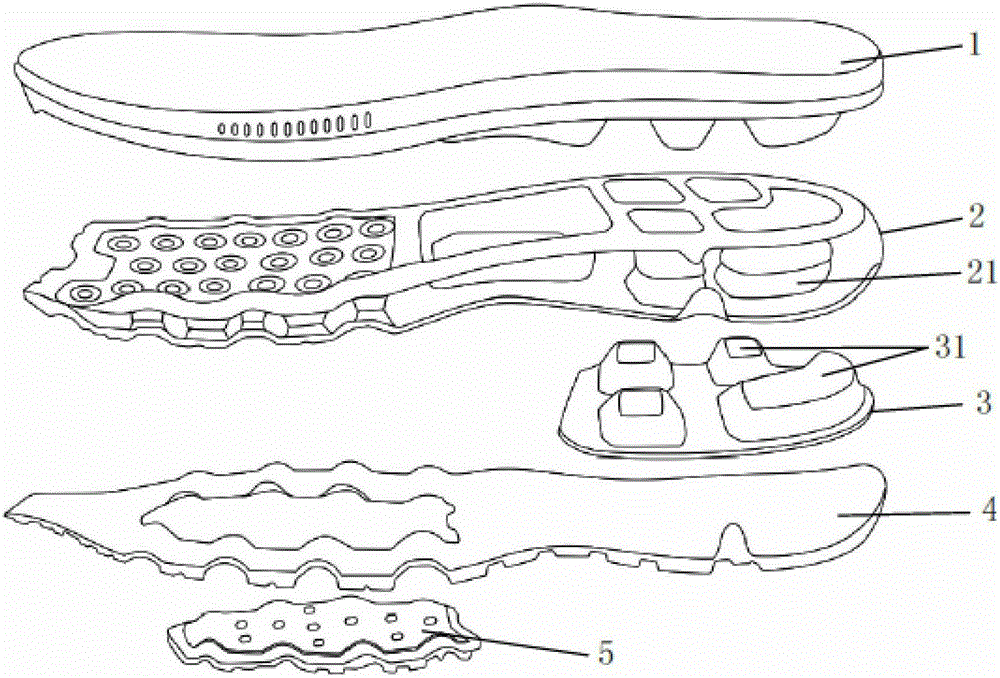

Air-cushioned sole of highly elastic sports shoes and production method thereof

The invention provides a high-elasticity sneaker air cushion sole and a production method thereof and researches a sneaker sole with high elasticity, high wear resistance and low hardness. The high-elasticity sneaker air cushion sole comprises a phylon (MD) midsole, an air cushion and a large sole which are sequentially and fixedly connected with one another from top to bottom, wherein an ethylene-vinyl acetate copolymer (EVA) cushion piece is assembled on a heel part of the air cushion; and the material formula of the MD midsole comprises the following components in parts by weight: 40-60 parts of EVA, 0-20 parts of ethylene propylene ternary gel, 0-30 parts of polyolefin elastomer (POE), 0-10 parts of talcum powder, 2.0-4.0 parts of a foaming agent, 0.6-1.0 part of a bridging agent, 1.0-2.0 part of a zinc oxide desulfurizing agent, 0.6-1.2 parts of stearic acid, 0.5-1.0 part of zinc stearate, 0.8-1.5 parts of a flow promotor and 0.3-0.8 part of a bridging addition agent.

Owner:新侨伟(福建)鞋服有限公司

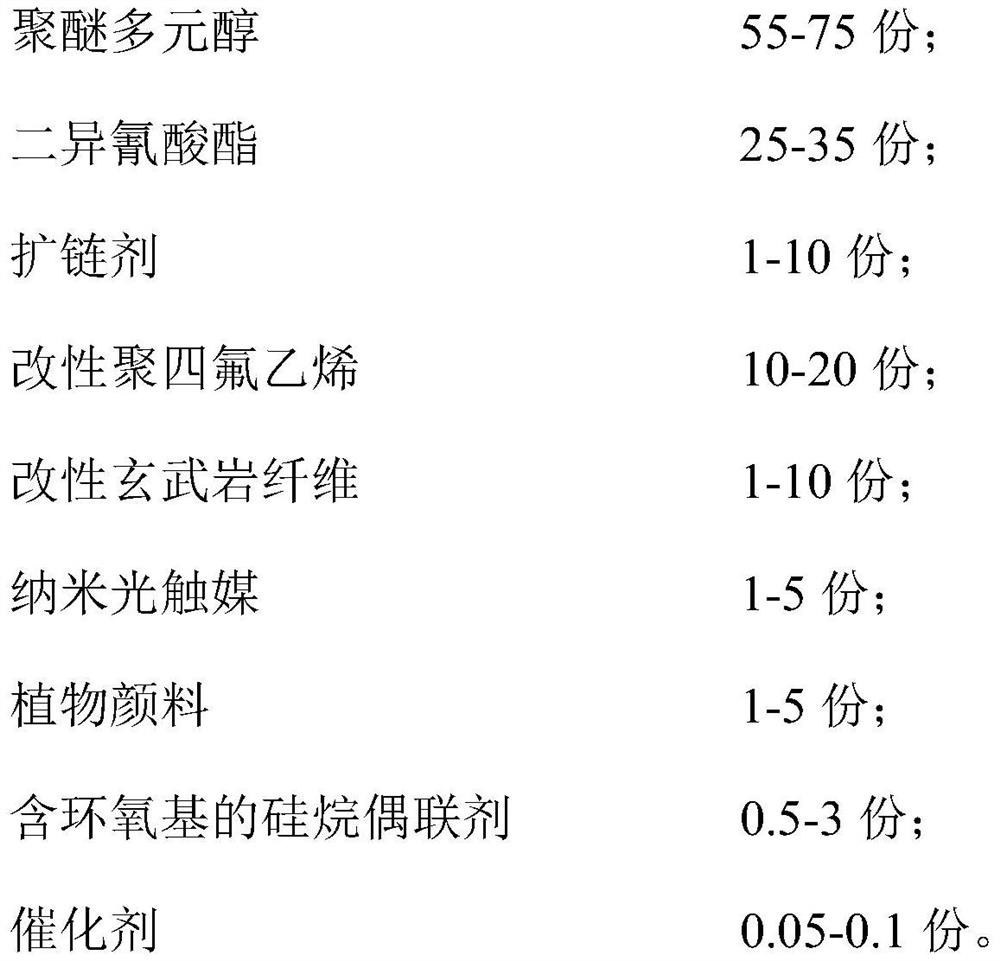

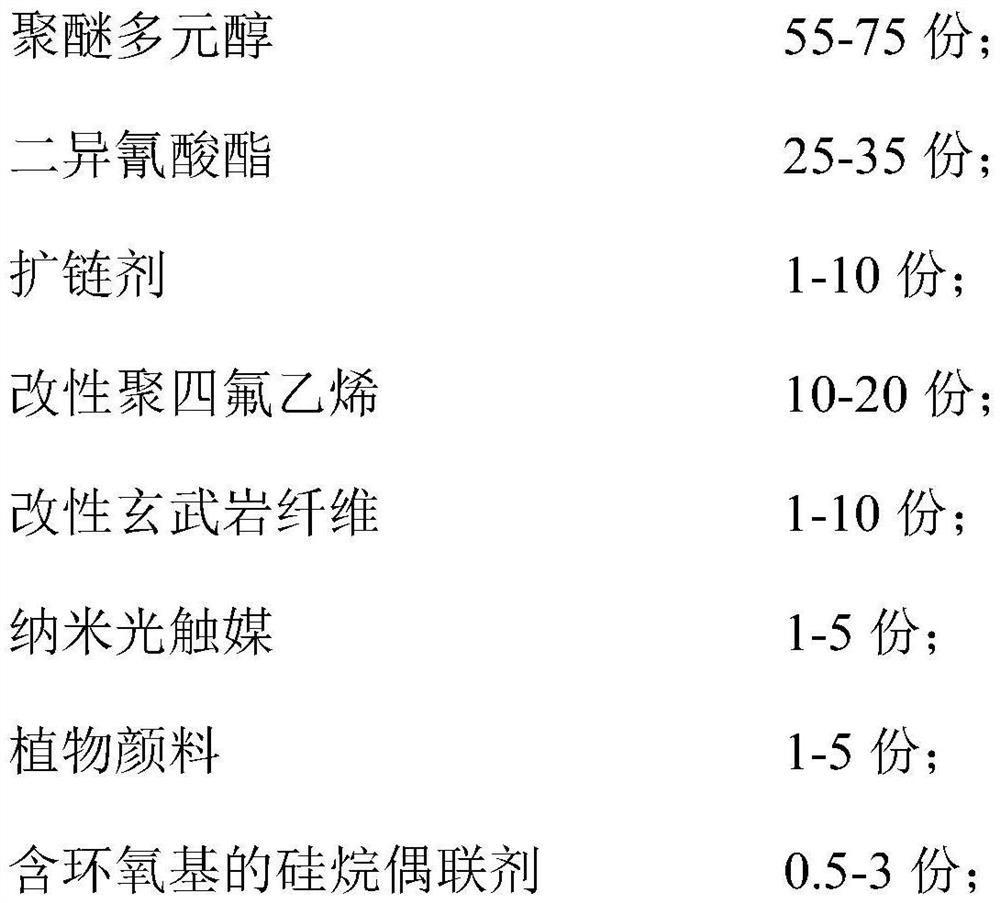

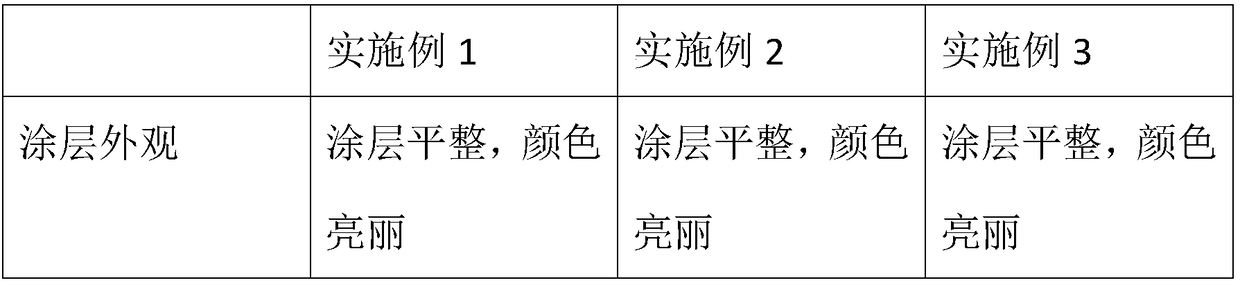

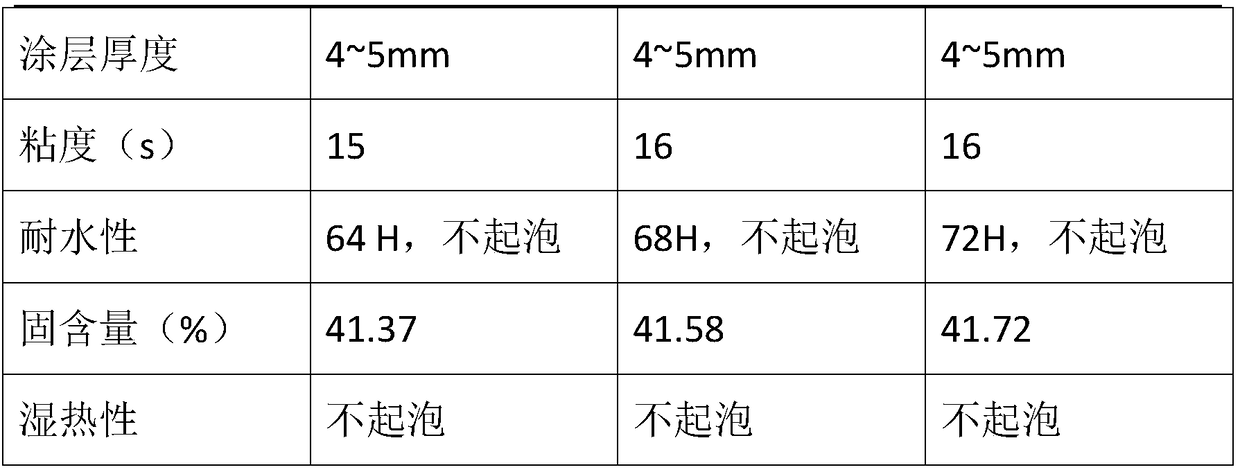

Environment-friendly colored TPU film for furniture and preparation method thereof

The invention provides an environment-friendly colored TPU film for furniture and a preparation method of the environment-friendly colored TPU film. The environment-friendly colored TPU film for furniture is prepared from the following raw materials in parts by weight: 55-75 parts of polyether polyol, 25-35 parts of diisocyanate, 1-10 parts of a chain extender, 10-20 parts of modified polytetrafluoroethylene, 1-10 parts of modified basalt fibers, 1-5 parts of a nano photocatalyst, 1-5 parts of a plant pigment, 0.5-3 part of an epoxy group-containing silane coupling agent and 0.05-0.1 part of acatalyst. The environment-friendly colored TPU film for furniture is uniform in component color dispersion, free of color stripes and free of local color difference, has excellent waterproof performance and various mechanical properties, is green and environment-friendly in component raw materials, and is suitable for the field of furniture protection.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

Heat-resisting, damp-proof and environment-friendly paint suitable for furniture plates

InactiveCN108707351AReduce usageHas anti-corrosion propertiesFireproof paintsAnti-corrosive paintsPentaerythritolAcrylic resin

The invention discloses heat-resisting, damp-proof and environment-friendly paint suitable for furniture plates. The heat-resisting, damp-proof and environment-friendly paint is prepared from, by weight, 10-20 parts of modified phenolic resin, 10-15 parts of thermoplastic acrylic resin, 20-40 parts of alkyd resin, 20-30 parts of modified epoxide resin, 5-10 parts of nanometer calcium carbonate powder, 5-15 parts of nanometer titanium dioxide, 10-15 parts of nanometer zinc oxide, 5-10 parts of pentaerythritol, 30-40 parts of limonene, 1-2 parts of vermiculite powder, 20-40 parts of ethylene glycol and 0.5-2 parts of coupling agent. The heat-resisting, damp-proof and environment-friendly paint suitable for furniture plates is good in damp-proof and heat-resisting effect, safe, environmentally friendly, low in production cost and bright in paint color.

Owner:ANHUI XUEYU SANITARYWARE

Multifunctional vertical cotton waist pad

ActiveCN105476317AImprove breathabilityWon't turn yellowSeat heating/ventillating devicesBack restsEngineeringCOTTON WOOL

The invention discloses a multifunctional vertical cotton waist pad, comprising a front part and a back part each made by cutting a whole piece of vertical cotton. The front part has an arc-shaped concave front end surface that is provided with a plurality of crisscross guide grooves, and both the longitudinally extended guide grooves and the transversely extended guide grooves have front-back through hollowed-out holes in intersections; the back part is provided with a fan corresponding to at least one hollowed-out hole. Compared with the prior art, the multifunctional vertical cotton waist pad rarely yellows or blackens, is longer in life and better in supporting performance, is more comfortable to use, has greatly improved heat-radiating effect and is very suitable for use in summer.

Owner:SUZHOU MEISHANZI GARMENTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com