Environment-friendly colored TPU film for furniture and preparation method thereof

An environmentally friendly and colorful technology, applied in the field of polymer materials, can solve the problems of easy fading and color difference, easy yellowing of materials, and affect the appearance, so as to improve waterproof performance and barrier performance, ensure color brilliance, and increase color fastness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

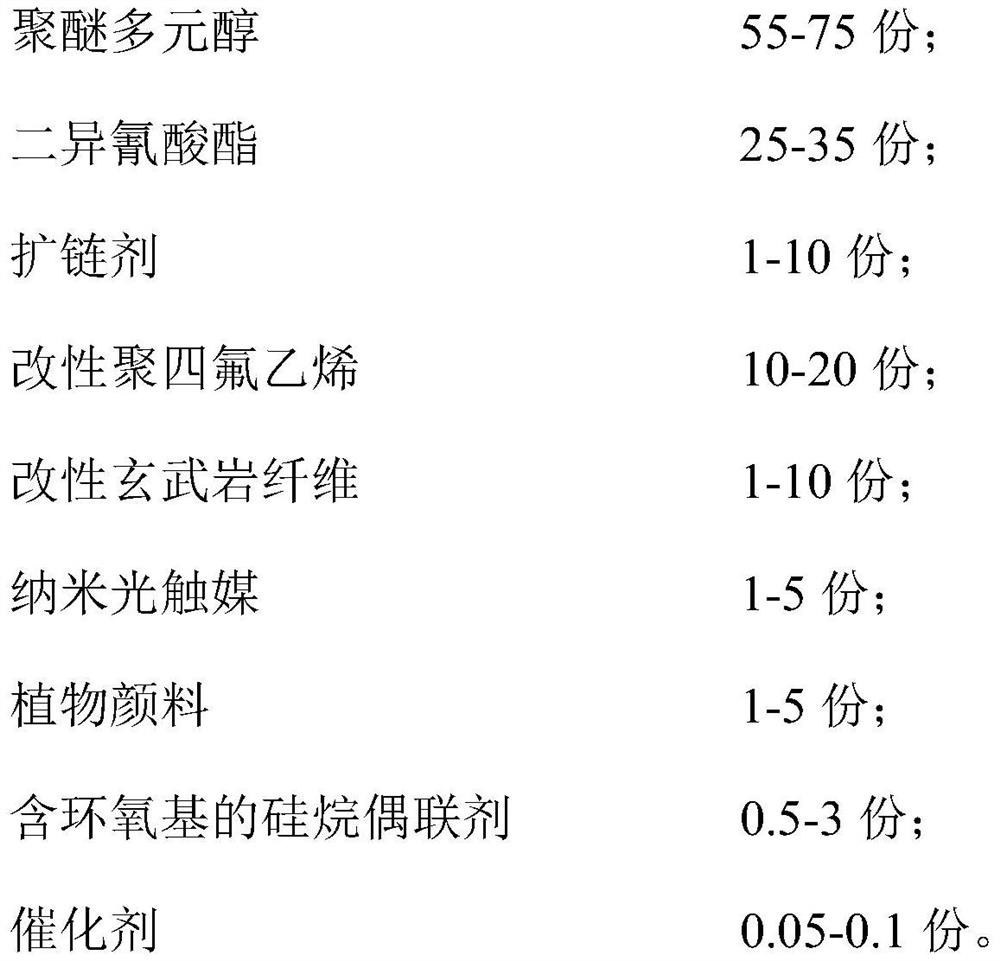

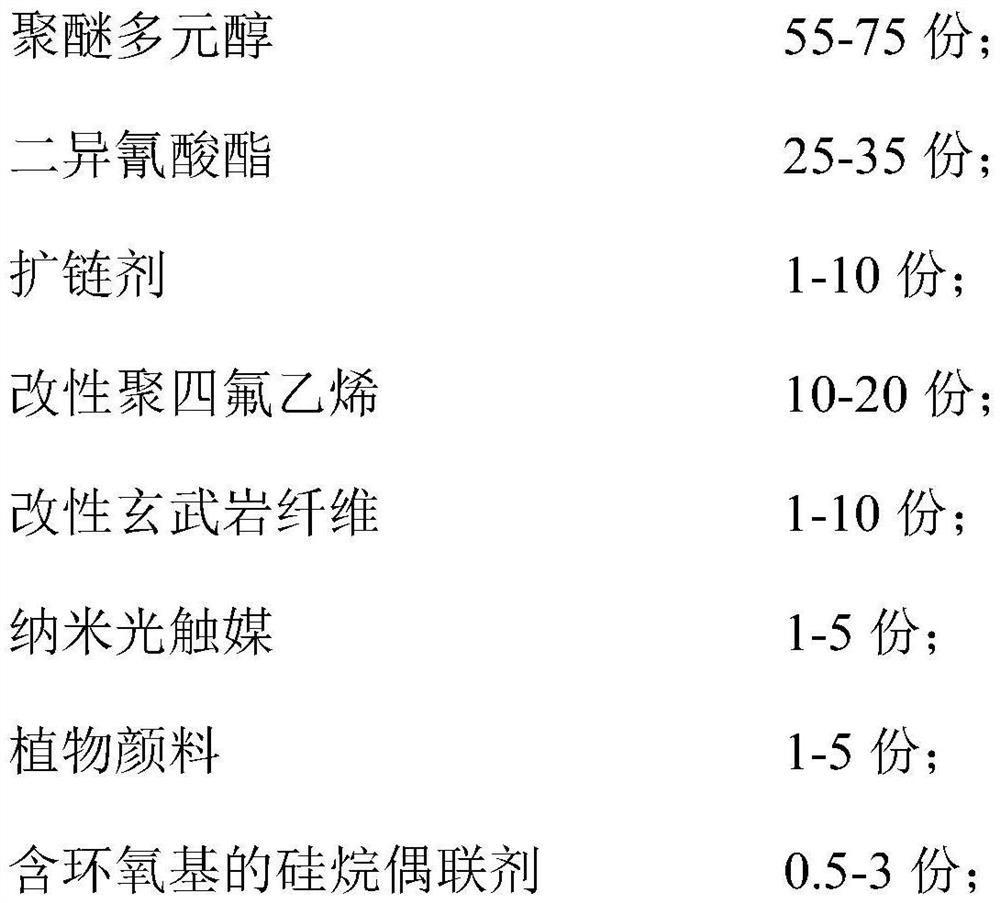

Method used

Image

Examples

preparation example 1

[0066] This preparation example provides a kind of modified polytetrafluoroethylene I, and described modified polytetrafluoroethylene I is prepared by following preparation method: 100g sodium naphthalene solution (taking the quality of described sodium naphthalene solution as 100%, sodium 3%, naphthalene 12%, the balance is tetrahydrofuran) and 40g polytetrafluoroethylene (the number average molecular weight is 400,000) after mixing and stirring at 15°C for 6min, filtering, and drying at 30°C for 2h to obtain modified polytetrafluoroethylene Vinyl I.

preparation example 2

[0068] This preparation example provides a kind of modified polytetrafluoroethylene II, and described modified polytetrafluoroethylene II is prepared by following preparation method: 100g sodium naphthalene solution (taking the quality of described sodium naphthalene solution as 100%, sodium 4%, naphthalene 15%, the balance is tetrahydrofuran) and 50g polytetrafluoroethylene (the number average molecular weight is 500,000) mixed and stirred at 20°C for 10min, filtered, and dried at 35°C for 1.5h to obtain modified polytetrafluoroethylene Vinyl Fluoride II.

preparation example 3

[0070] This preparation example provides a kind of modified polytetrafluoroethylene III, and described modified polytetrafluoroethylene III is prepared by the following preparation method: 100g sodium naphthalene solution (taking the quality of described sodium naphthalene solution as 100%, sodium 3%, naphthalene 10%, the balance is tetrahydrofuran) and 30g polytetrafluoroethylene (the number-average molecular weight is 300,000) at 10°C and mixed and stirred for 10min, filtered, and dried at 20°C for 2h to obtain modified polytetrafluoroethylene Vinyl III.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com