Bonding method of touch screen substrates, and binder for same

A technology of adhesives and screen substrates, applied in the direction of adhesive types, grafted polymer adhesives, adhesives, etc., can solve the problems of yellowing of the visible area of the touch screen and unavoidable yellowing of adhesives, and achieve The effect of short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

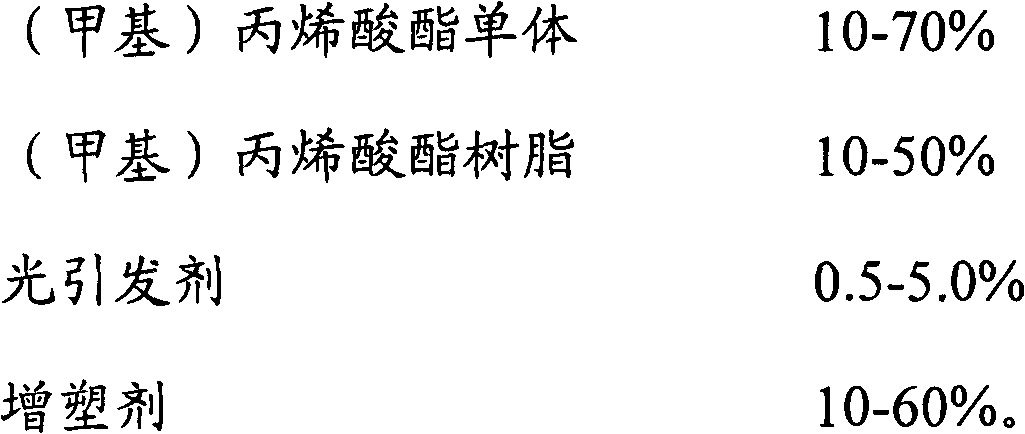

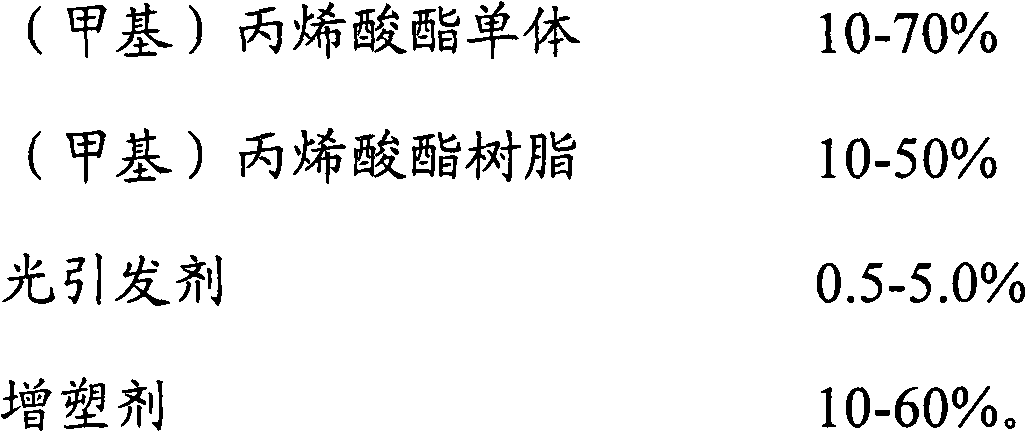

Embodiment 1

[0033] First prepare the substrate with shaded area and transparent area; then take 45.0g of isopropanol and 50.0g of ethyl acetate and mix them evenly in a blender, then add 5.0g of 2,2-azobisisobutyronitrile and stir until no visible particles , during the stirring process, the temperature is controlled not to be higher than 20 °C to prepare the primer adhesive, take a certain amount of the prepared primer adhesive and evenly apply it to the shadow area on one side of the substrate, and let it stand to be in the primer adhesive The organic solvent is completely volatilized; then take 10.0g (meth)hydroxypropyl acrylate, 50.0g polyether (meth)acrylate and 37.5g polyester polyol and add them to the stirrer and stir for 30 minutes, then add 2.5g N-formazol N-methyldiethanolamine benzophenone is stirred for 60-90 minutes to completely dissolve the N-methyldiethanolamine benzophenone to prepare the main body adhesive. Take a certain amount of main body adhesive and apply it evenly ...

Embodiment 2

[0036]First prepare the substrate with shaded area and transparent area; then take 29.0g of toluene, 25.0g of n-hexane and 45.0g of chloroform into the mixer and mix evenly, then add 1.0g of dilauroyl peroxide and stir until there are no visible particles. Control the temperature not higher than 20°C to prepare the primer adhesive. Take a certain amount of the prepared primer adhesive and apply it evenly on the shadow area on one side of the substrate, and let it stand until the organic solvent in the primer adhesive is completely Volatilize; take 70.0g (meth)isobornyl acrylate, 10.0g polyester (meth)acrylate and 19.5g polyether polyols and add them to the stirrer and stir for 30 minutes, then add 0.5g 2-hydroxyl-2-methyl Base-1-phenylpropan-1-one was stirred for 60-90 minutes to completely dissolve 2-hydroxy-2-methyl-1-phenylpropan-1-one to prepare the main body adhesive, take a certain amount of main body adhesive The binder is evenly coated on the transparent area on the sa...

Embodiment 3

[0039] First prepare the substrate with shaded area and transparent area; then take 30.0g of toluene, 30.0g of acetone and 30.0g of dichloromethane into the mixer and mix evenly, then add 10.0g of dibenzoyl peroxide and stir until no visible particles, During the stirring process, the temperature is controlled not to be higher than 20°C to prepare the primer binder, take a certain amount of the prepared primer binder and evenly coat the shadow area on one side of the substrate, and let it stand until the organic primer in the primer binder The solvent is completely evaporated; then take 15.0g ethoxy (meth)acrylate, 20.0g urethane (meth)acrylate and 60.0g liquid polybutadiene and add it to the stirrer and stir for 30 minutes, then add 5.0g 1-hydroxyl Cyclohexyl phenyl ketone was stirred for 60-90 minutes to completely dissolve 1-hydroxycyclohexyl phenyl ketone to obtain the main body adhesive. Take a certain amount of main body adhesive and evenly coat the transparent area on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com