Heat-resisting, damp-proof and environment-friendly paint suitable for furniture plates

An environmentally friendly paint and sheet technology, applied in anti-corrosion coatings, fire-resistant coatings, coatings, etc., can solve the problems of environmental protection performance discount, damage to physical health and other problems, and achieve the effect of not easy to fall off, reducing the amount of use, and maintaining color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

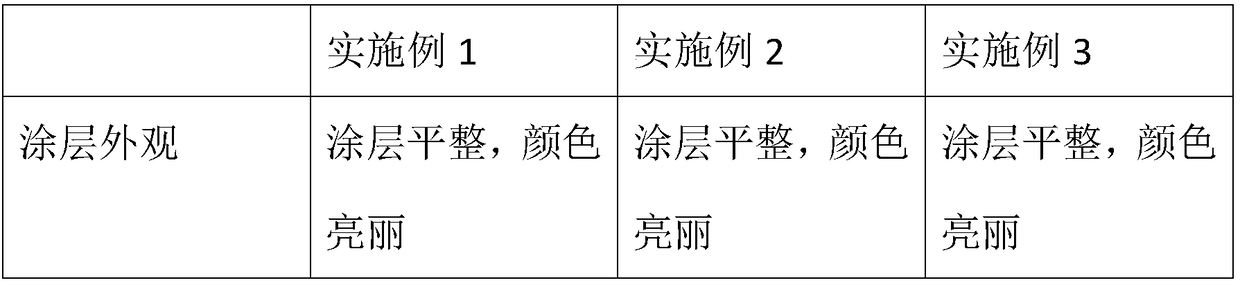

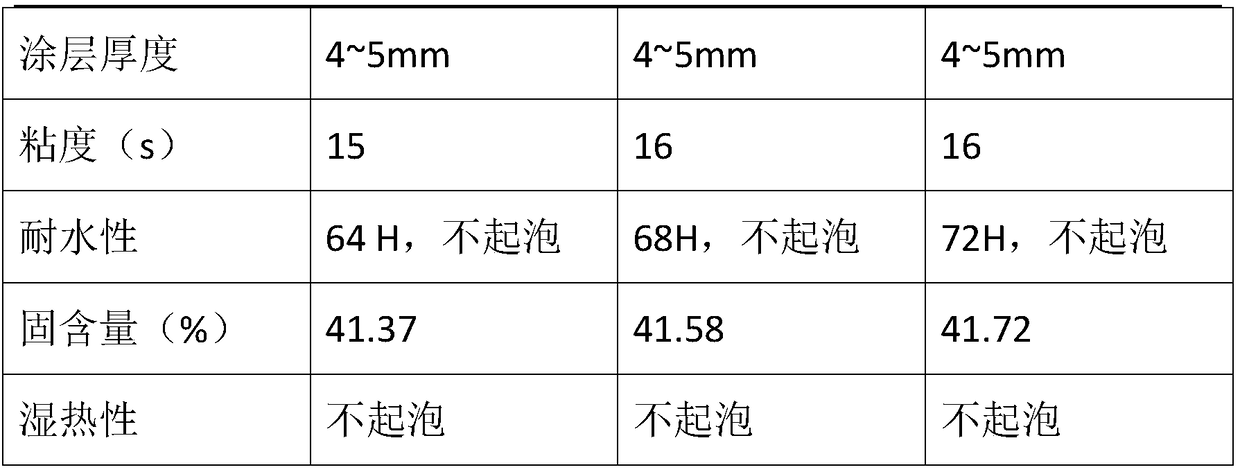

Embodiment 1

[0013] 1) Preparation of modified phenolic resin: it will be mainly made of the following components: bisphenol, benzaldehyde and maleimide, the molar ratio of bisphenol and benzaldehyde is 1.2:1.0, and the maleimide The mass of amine is 0.6 times of the total mass of bisphenol and benzaldehyde;

[0014] Weigh bisphenol and benzaldehyde, put them into the reaction kettle, stir for 0.5h, mix evenly, heat to 70°C, add catalyst, stir, keep warm for 2 hours, add polyimide, stir and mix well, adjust the temperature to 80°C , keep warm for 2 hours, heat to 130°C for dehydration for 0.5 hour, cool down to 40°C to obtain modified phenolic resin.

[0015] 2) Preparation of modified epoxy resin: by weight, 100 parts of epoxy resin, 10 parts of rosin, heated at 130°C to melt, add 10 parts of bisphenol A, heat up at 160°C, stir for 1H, cool down to 80°C, add formaldehyde 12 Parts, 1 part of accelerator hexamethylenetetramine, stir at constant temperature 90°C for 2 hours, add 10 parts of...

Embodiment 2

[0019] 1) Preparation of modified phenolic resin: it will be mainly made of the following components: bisphenol, benzaldehyde and maleimide, the molar ratio of bisphenol and benzaldehyde is 1.5:1.0, and the maleimide The mass of amine is 0.7 times of the total mass of bisphenol and benzaldehyde;

[0020] Weigh bisphenol and benzaldehyde, put them into the reaction kettle, stir for 0.5h, mix well, heat to 85°C, add catalyst, stir, keep warm for 3 hours, add polyimide, stir and mix well, adjust the temperature to 90°C , keep warm for 2.5 hours, heat to 135°C for dehydration for 0.5 hour, cool down to 45°C to obtain modified phenolic resin.

[0021] 2) Preparation of modified epoxy resin: by weight, 100 parts of epoxy resin, 10 parts of rosin, heated at 130°C to melt, add 15 parts of bisphenol A, heat up at 180°C, stir for 1.5H, cool down to 90°C, add formaldehyde 21 parts, 2 parts of accelerator hexamethylenetetramine, stir at constant temperature 95°C for 2.5 hours, add 12 par...

Embodiment 3

[0025] 1) Preparation of modified phenolic resin: it will be mainly made of the following components: bisphenol, benzaldehyde and maleimide, the molar ratio of bisphenol and benzaldehyde is 1.8:1.0, and the maleimide The mass of amine is 0.8 times of the total mass of bisphenol and benzaldehyde;

[0026] Weigh bisphenol and benzaldehyde, put them into the reaction kettle, stir for 1 hour, mix well, heat to 100°C, add catalyst, stir, keep warm for 4 hours, add polyimide, stir and mix well, adjust the temperature to 100°C, Heat preservation reaction for 3 hours, heat to 140°C for dehydration for 1 hour, cool down to 50°C to obtain modified phenolic resin.

[0027] 2) Preparation of modified epoxy resin: by weight, 100 parts of epoxy resin, 10 parts of rosin, heated at 150 ° C to melt, add 20 parts of bisphenol A, heat up to 200 ° C, stir for 2 hours, cool down to 100 ° C, add formaldehyde 30 Parts, 3 parts of accelerator hexamethylenetetramine, stir at constant temperature 100°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com