Preparation method for branched silane and polyether alkyl co-modified silicone oil

A technology of polyether alkyl and branched chain, which is applied in the preparation of polyether alkyl co-modified silicone oil and the field of branched chain silane, which can solve problems such as skin hazards, pungent odor, and difficulty in achieving long-term stability, and achieve Good compatibility, increase washability, solve oil phase compatibility and stability problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) prepare platinum catalyst: get 1g dry chloroplatinic acid (H 2 PtCl 6 ) was dissolved in 200 g of distilled isopropanol and sonicated, so that chloroplatinic acid was completely dissolved in isopropanol, and allowed to stand overnight to obtain a transparent orange-yellow liquid, which was kept in a brown bottle away from light for use. The effective platinum content of the prepared catalyst is: Pt 0.1875%.

[0032] (2) Add 15g of hydrogen-containing silicone oil (50cst, hydrogen content 1.8mmol / g) and 10ml of isopropanol into a three-necked flask, heat and reflux to 50°C in a constant temperature magnetic stirring water bath, then add 0.315ml of platinum catalyst .

[0033] (3) Slowly add 3.92 g of allyl polyether dropwise with a constant pressure funnel, heat to 85° C., and finish adding dropwise within 20 minutes.

[0034] (4) After reacting for 2 hours, start to drop a mixture of 1.66g dodecene and 3.12g vinyl tris(trimethylsiloxane) silane (allyl polyether, ...

example 1

[0042] Chemical titration method is measured Si-H bond content in the example 1, and conversion ratio calculation formula:

[0043]

[0044] Using the chemical titration method to measure the hydrogen content before and after the reaction, it is calculated that the conversion rate of the modified silicone oil product is as high as 94.32%, and the purity reaches 96.42%. The invention limits the operation process in the preparation process and improves the conversion rate of the co-modified silicone oil. During the preparation process, selecting sodium hydroxide solution and washing with water can remove unreacted silicon-hydrogen bonds and residual platinum catalyst, selecting hydrochloric acid solution and washing with water can remove odor impurities such as by-product aldehydes, so that the obtained product has a high purity.

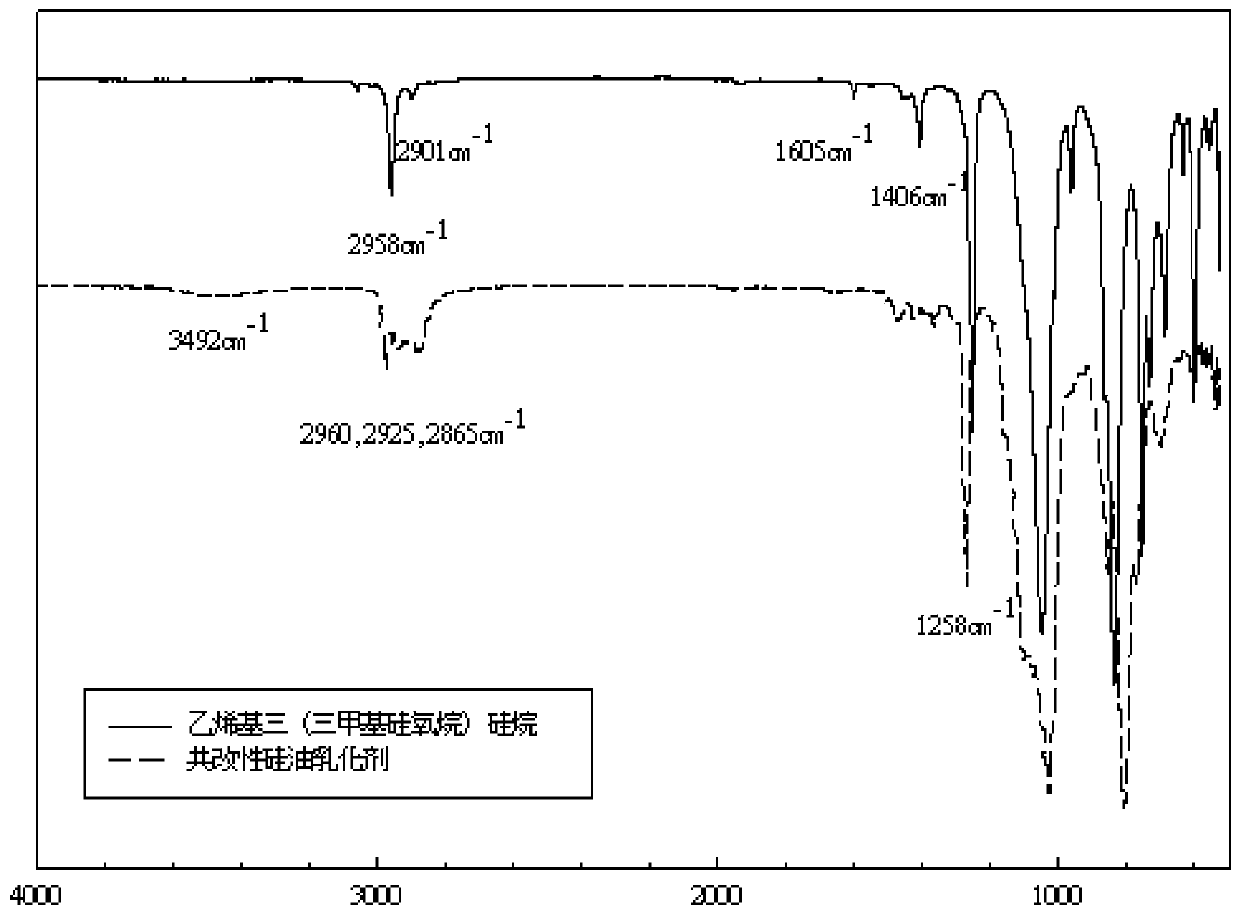

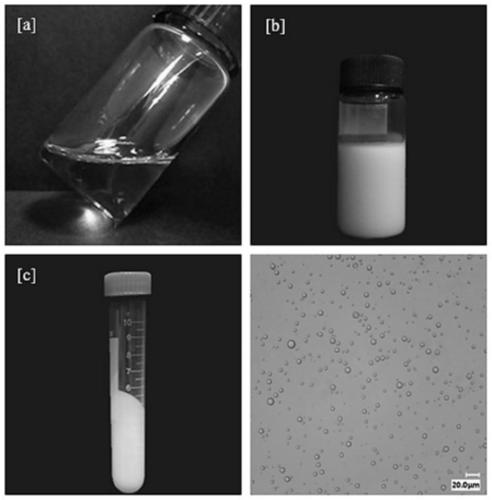

[0045] figure 1 It is the total reflection Fourier transform infrared spectrogram of the obtained branched-chain silane and polyether alkyl co-m...

Embodiment 2

[0051] (1) prepare platinum catalyst: get 1g dry chloroplatinic acid (H 2 PtCl 6 ) was dissolved in 200 g of distilled isopropanol and sonicated, so that chloroplatinic acid was completely dissolved in isopropanol, and allowed to stand overnight to obtain a transparent orange-yellow liquid, which was kept in a brown bottle away from light for use. The effective platinum content of the catalyst is: Pt 0.1875%

[0052] (2) Add 15g of hydrogen-containing silicone oil (50cst, hydrogen content 3.8mmol / g) and 10ml of isopropanol into a three-necked flask, heat it in a constant temperature magnetic stirring water bath to reflux to 50°C, and then add 0.219ml of platinum catalyst .

[0053] (3) Slowly add 8.4 g of allyl polyether dropwise with a constant pressure funnel, heat to 85° C., and finish adding dropwise within 20 minutes.

[0054] (4) After reacting for 2 hours, start to drop a mixture of 3.53g dodecene and 6.73g vinyl tri(trimethylsiloxane) silane (allyl polyether, dodece...

PUM

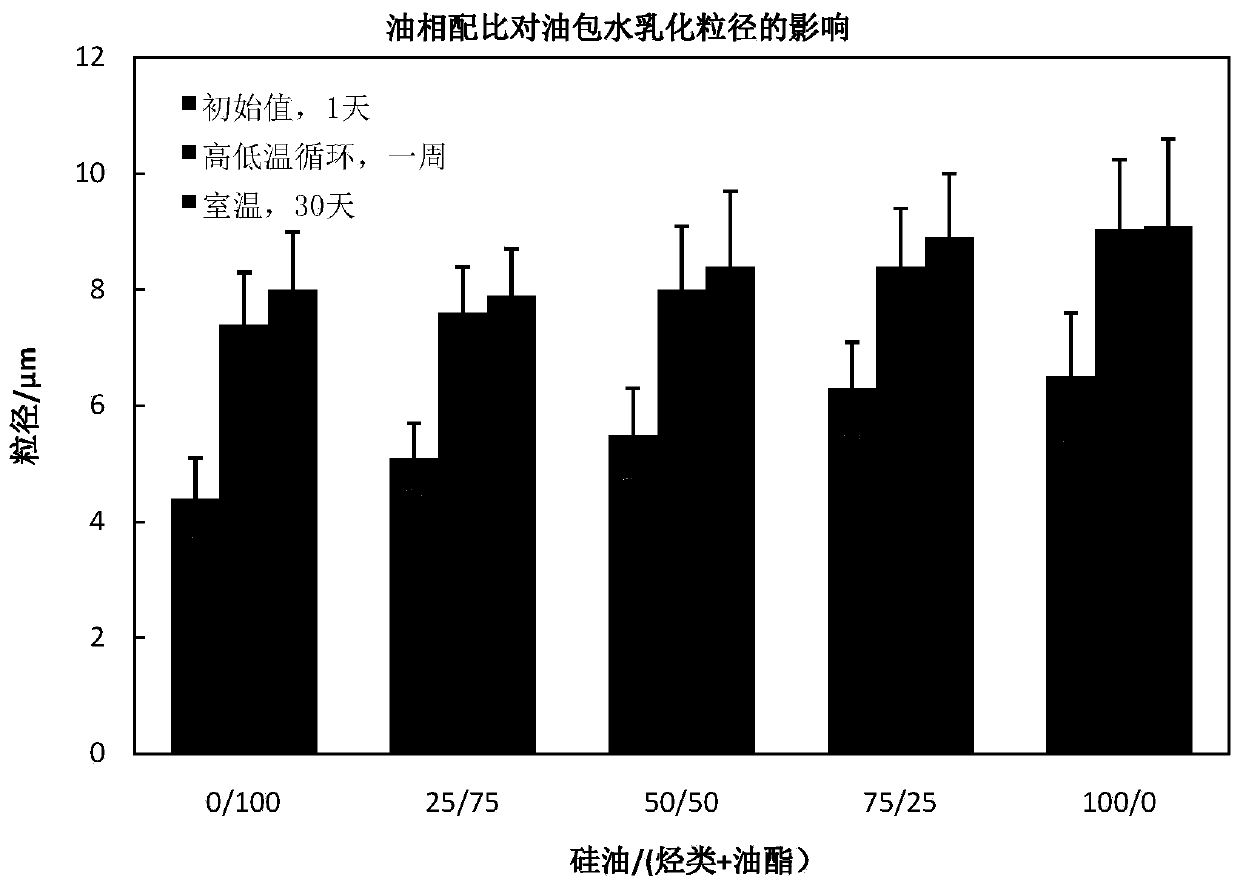

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com