Method for fabricating white OGS touch screen

A production method and touch screen technology, which are applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problems of yellowing ink color, difficulty in mass production, and low production yield of white OGS touch screen. , to reduce the number of times of exposure to high temperature and improve the production yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

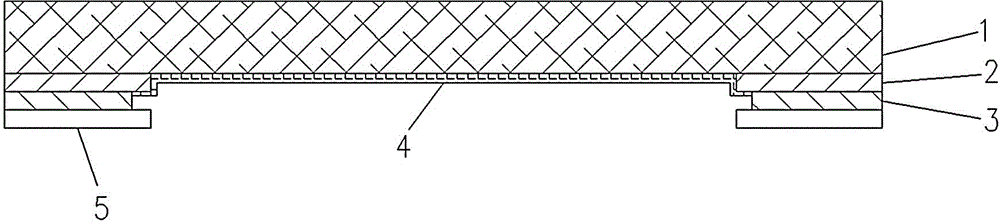

[0018] Such as figure 1 As shown, the present invention provides a kind of manufacture method of white OGS touch screen, comprises the following steps:

[0019] a) The glass substrate 1 is subjected to coating and shadow removal treatment to enhance the light transmittance of the glass substrate. The glass substrate 1 can be made of 0.7mm Asahi Glass II glass;

[0020] b) screen printing the first white ink layer 2 on the frame area of the lower surface of the glass substrate 1, the steel screen used in the screen printing in this step is ≥ 420 mesh, and the white ink is screen printing ink that can withstand a temperature above 230°C;

[0021] c) screen printing the second white ink layer 3 on the lower surface of the first white ink layer 2, the steel screen used for screen printing in this step is ≥420 mesh, and the white ink is screen printing ink that can withstand temperatures above 230°C; the second The inner edge of the white ink layer 3 is expanded by 0.5 mm relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com