High-temperature-resistant ink, preparation method thereof and OGS touch panel

A high-temperature-resistant ink and silicone technology, applied in ink, household utensils, applications, etc., can solve problems such as easy yellowing, OGS touch panel display effect, etc., to achieve stable properties, good display effect, and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

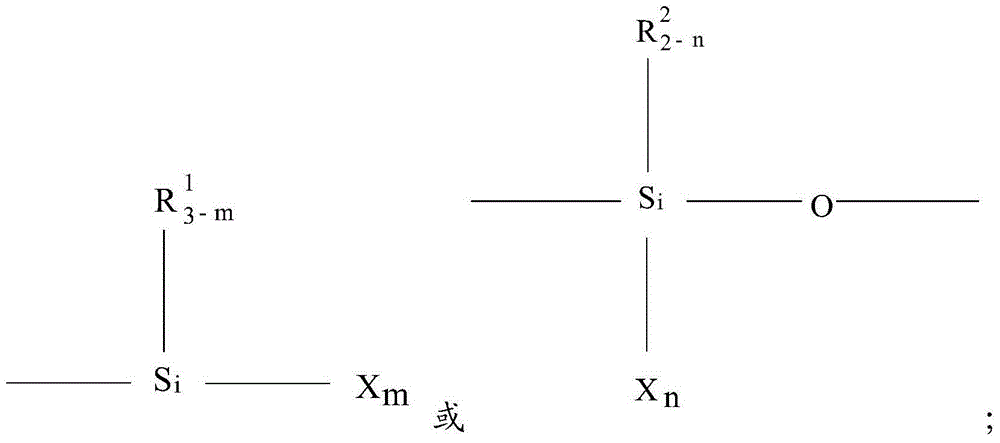

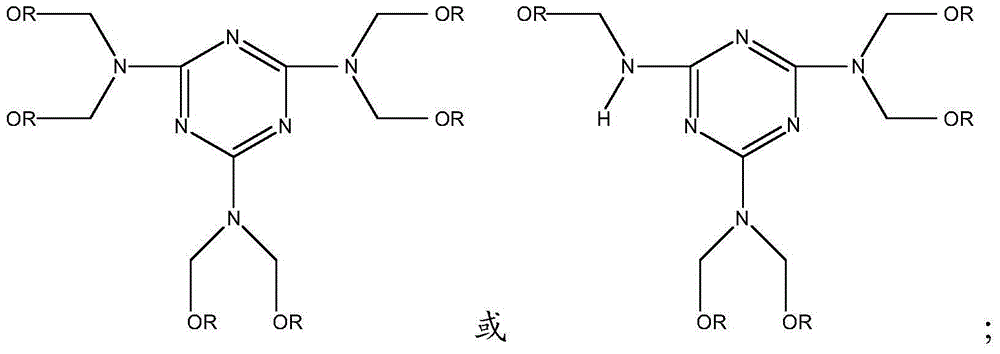

Method used

Image

Examples

Embodiment 1

[0060] S10, with 36g of silicone modified polyester resin CSH3000 (solid content is 60%, provided by Shenzhen Chuangshiheng Trading Co., Ltd.), 0.5g of fumed silica (Evonik Degussa company) and 50g of rutile titanium dioxide (DuPont company) mix, disperse 30 minutes with the rotating speed of 4000rpm / min with high-speed disperser (band diameter 3cm dispersing disk), form uniformly dispersed slurry;

[0061] S20, then the dispersion slurry is ground with a three-roller until the fineness reaches below 10 μm, and then supplemented with 14g of CSH3000 resin, 0.5g of defoamer BYK-077 (BYK company), 0.5g of leveling agent BYK-322 ( BYK company) and the DBE solvent of 3g, stir, make the main agent of the high temperature resistant white glass ink composition of the present invention;

[0062] S30, the methyltrimethoxysilane of 3g, the dibutyltin dilaurate Dabco T-12 (AIR PRODUCTS company) of 0.03g and the toluene of 2.2g are mixed homogeneously, make the high temperature resistan...

Embodiment 2

[0065] Replace the silicone modified polyester resin CSH3000 in Example 1 with silicone modified polyester resin SRE-906 (solid content is 60%, provided by Guangzhou Dongfugui Chemical Raw Materials Co., Ltd.), in order to compare with the example 1 In the same manner, the high-temperature-resistant white glass ink composition of the present invention was prepared and tested for performance.

Embodiment 3

[0067] S10, with 36g of silicone modified polyester resin CSH3000 (solid content is 60%, provided by Shenzhen Chuangshiheng Trading Co., Ltd.), 0.8g of fumed silica (Evonik Degussa company) and 50g of rutile titanium dioxide (HUNTSMAN company) mix, disperse 30 minutes with the rotating speed of 4000rpm / min with high-speed disperser (band diameter 3cm dispersing disk), form dispersion slurry;

[0068] S20, then grind the dispersed slurry with a three-roller until the fineness reaches below 10 μm, and then add 14g of CSH3000 resin, 0.5g of defoamer BYK-077, 0.5g of leveling agent BYK-322 and 3g of DBE solvent , and stir evenly to obtain the main agent of the high temperature resistant white glass ink composition of the present invention;

[0069] S30, uniformly mix 3g of methyltriacetoxysilane, 0.03g of tris(acetylacetonate)aluminum and 2.21g of toluene to prepare the curing agent for the high temperature resistant white glass ink composition of the present invention.

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com