Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Strong chemical inertness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weather-proof reflecting coating material used for road labels, and preparation method thereof

InactiveCN107189661AGood film formingImprove mechanical propertiesFireproof paintsLuminescent paintsFiberMoisture resistance

The invention discloses a weather-proof reflecting coating material used for road labels. The weather-proof reflecting coating material used for road labels comprises, by weight, 7 to 9 parts of an energy-storage self luminescent material, 4 to 6 parts of a nanometer grade reflecting powder, 5 to 7 parts of a reflecting material, 20 to 30 parts of a highlight transparent polyurethane emulsion, 10 to 14 parts of water-borne alkyd resin, 2 to 4 parts of an aluminate coupling agent, 8 to 10 parts of a processing auxiliary agent, 4 to 6 parts of an ore additive powder material, 5 to 7 parts of anti-cracking fiber, and 3 to 7 parts of polyethylene wax. The weather-proof reflecting coating material possesses excellent energy storage self luminescent and reflective functions, so that road labels are provided with excellent reflective identification properties at dark and light conditions, light intensity is high, and fluorescent lifetime; the adhesive force is relatively high; high temperature resistance is excellent; corrosion and moisture resistance is achieved; the material cost of the preparation method is relatively low; the raw materials are easily available; the preparation method is simple; and high practical value and promising application prospect are achieved.

Owner:HEFEI SHANGHAN DECORATION ENG CO LTD

Microporous high-penetration-resistance high-aluminum casting material, and preparation method and application method thereof

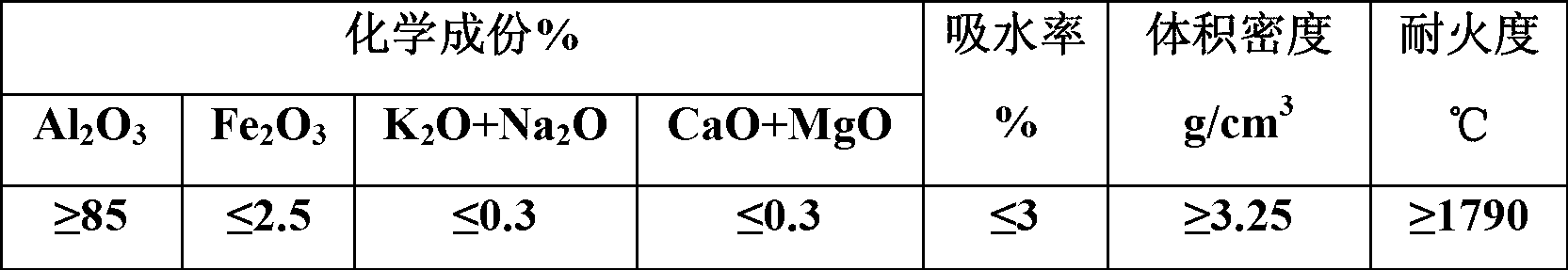

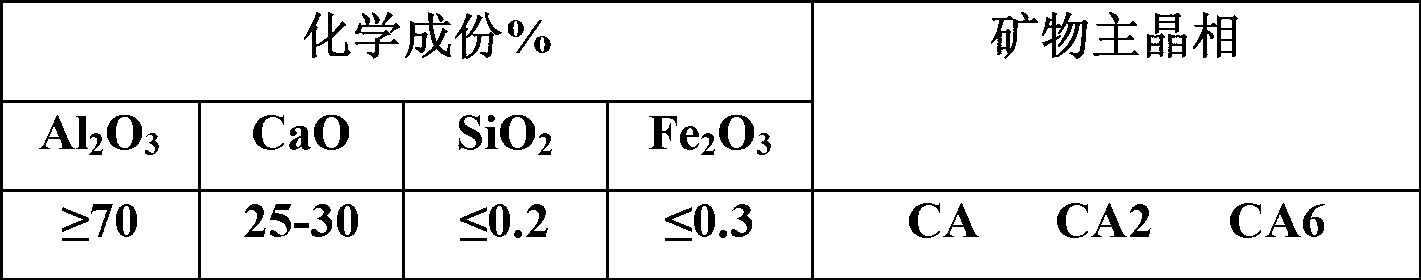

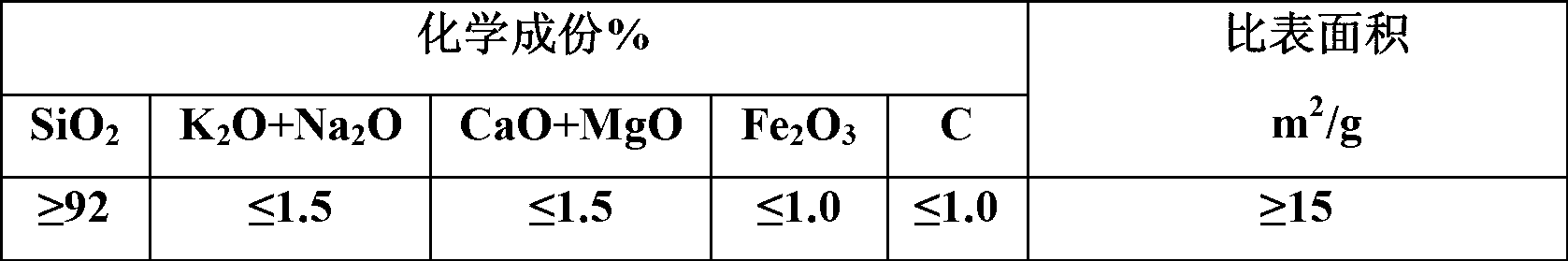

The invention discloses a microporous high-penetration-resistance high-aluminum casting material, and a preparation method and an application method thereof. The casting material is prepared from the following components in parts by weight: 51-95 parts of aggregate, 23.5-41.5 parts of powder, 3-6 parts of composite dewetting agent and 0.02-0.4 part of composite water reducing agent, wherein the aggregate is superfine bauxite chamotte; and the powder contains 180-mesh superfine bauxite fine powder, 800-mesh superfine bauxite fine powder, CA-70 cement, alpha-Al2O3 micro powder and SiO2 micro powder. A lining cast by the microporous high-penetration-resistance high-aluminum casting material provided by the invention is low in porosity, small in pore size of air pores and high in resistance to aluminum alloy liquid-state or vapor-state element penetration and corrosion; the aluminum alloy melt penetration resistance is improved; the mechanical strength is high, the high-temperature volume is stable, and the thermal shock resistance is favorable; and nodulation and bulge phenomena at the three-phase juncture can be effectively avoided.

Owner:贵阳联合高温材料有限公司

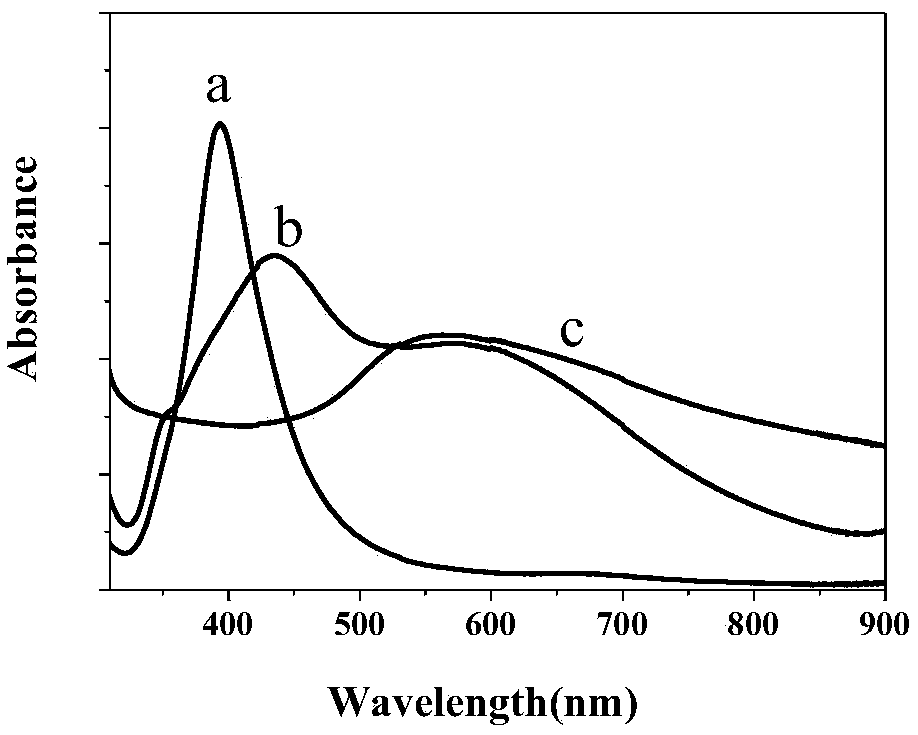

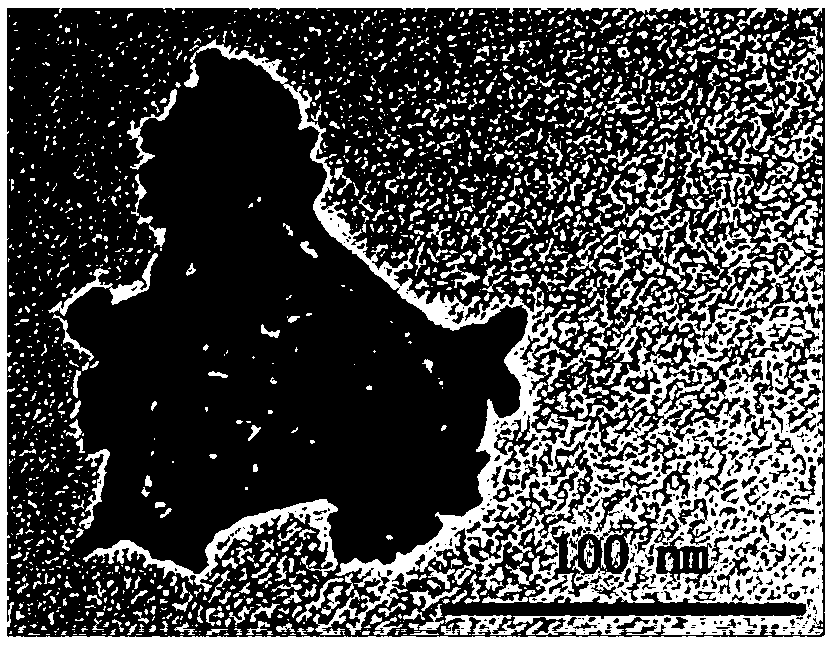

Electrochemical sensor constructed based on nitrogen-sulfur co-doped graphene-loaded triangular core-shell nanocomposite, and application thereof for detecting quercetin

ActiveCN109187691AChange transportImprove bindingMaterial electrochemical variablesDoped grapheneCore shell nanocomposites

The invention provides an electrochemical sensor constructed based on a nitrogen-sulfur co-doped graphene-loaded silver-gold triangular core-shell nanocomposite. The electrochemical sensor is preparedfrom the following steps: loading a prepared silver-gold triangular core-shell nano material on a nitrogen-sulfur co-doped graphene surface, modifying a glassy carbon electrode with the composite toobtain the electrochemical sensor for detecting quercetin in a product. The beneficial effect is that the electrochemical sensor is used for detecting the quercetin, the detection current of the quercetin can be greatly improved, the sensitivity is high, the response speed is high, the reproducibility is good, and the anti-interference performance on an ascorbic acid in a sample to be tested is good.

Owner:HONGHE COLLEGE

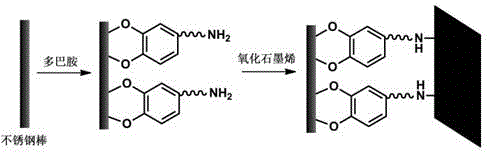

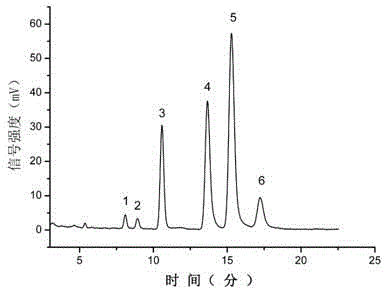

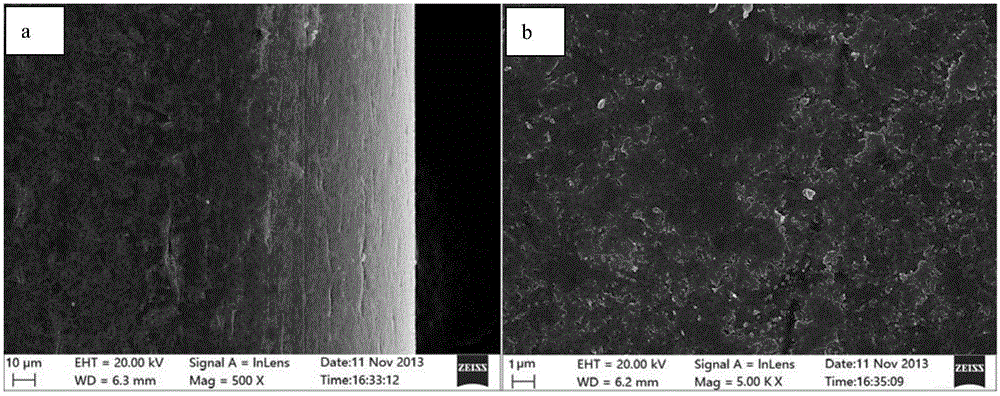

Stainless steel extraction stirring rod and preparation method thereof

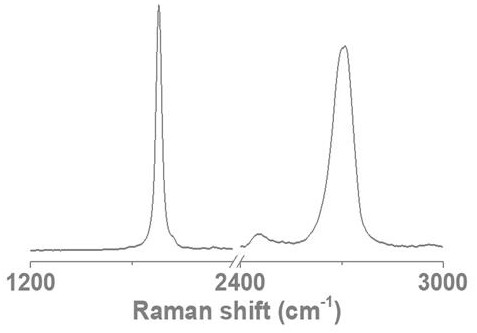

ActiveCN103949229AImprove reliabilityImprove stabilityIon-exchange process apparatusOther chemical processesPolycyclic aromatic hydrocarbonDopamine

The invention discloses a stainless steel extraction stirring rod and a preparation method thereof, and belongs to the field of analytical chemistry. The preparation method is as follows: dipping a stainless steel rod into an oxidized dopamine alkaline solution, washing, drying to prepare a poly dopamine modified stainless steel rod; dipping the poly dopamine modified stainless steel rod into a graphene oxide solution, sealing, heating for reacting, drying to obtain the stainless steel extraction stirring rod. The stainless steel extraction stirring rod is successively repeatedly dipped into the oxidized dopamine alkaline solution and the graphene oxide solution, and then a multilayer graphene modified stainless steel extraction stirring rod can be prepped. The preparation method is simple without adding of pollutional reducing agents, the coating stability is strong, and the thickness can be controllable. The stainless steel extraction stirring rod prepared by the method has very good enrichment effect on polycyclic aromatic hydrocarbons and other compounds, can be combinedly used with liquid chromatography, and is suitable for enrichment and analysis of the polycyclic aromatic hydrocarbons in the environment, food and other fields.

Owner:WUHAN UNIV

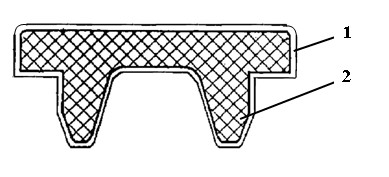

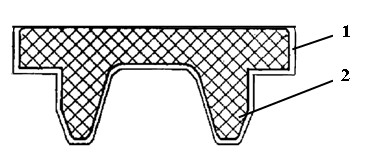

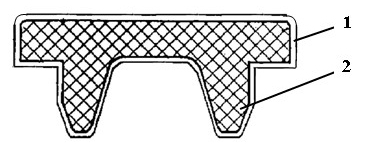

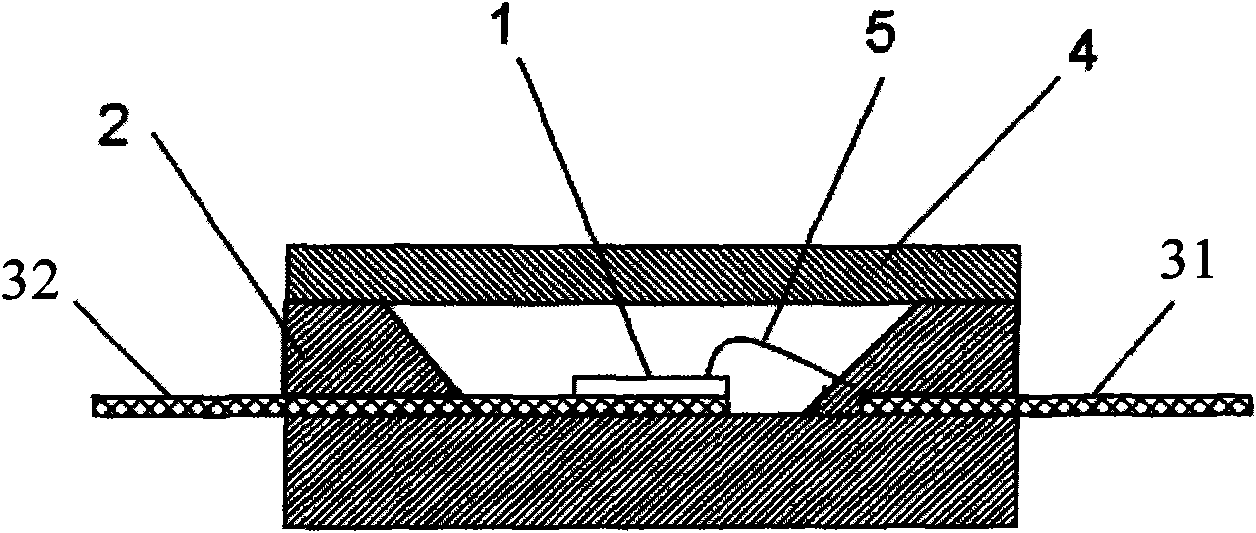

Fluorocarbon film rubber plug and preparation method thereof

ActiveCN101953751ALow deposition temperatureHigh speedPharmaceutical containersMedical packagingPolymer scienceAdhesive

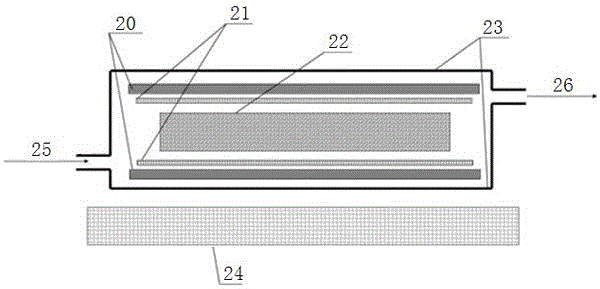

The invention relates to a fluorocarbon film rubber plug and a preparation method thereof. The fluorocarbon film rubber plug comprises a rubber plug body, part or all of the surface of the rubber plug body is covered with a fluorocarbon polymer film, and the rubber plug body and the fluorocarbon polymer film are physically and / or chemically bonded and integrated into a whole without any adhesive between of both. The fluorocarbon polymer film is obtained by being deposited on the surface of an ordinary rubber plug by adopting a method of plasma chemical vapor deposition of reaction gas glow discharge. By strongly combining the ordinary rubber plug with the fluorocarbon polymer film with the advantages of high hydrophobicity, strong chemical inertness, uniform and compact structure and precise and controllable film thickness, the invention not only can obviously improve compatibility with contacted medicines, but also can effectively avoid the adhesion phenomenon of the rubber plug and easily remove surface contamination and preserve the original elasticity and tightness of the rubber plug in order to significantly improve product quality of the ordinary rubber plug and further expand application scope of the ordinary rubber plug.

Owner:郑州翱翔医药科技股份有限公司

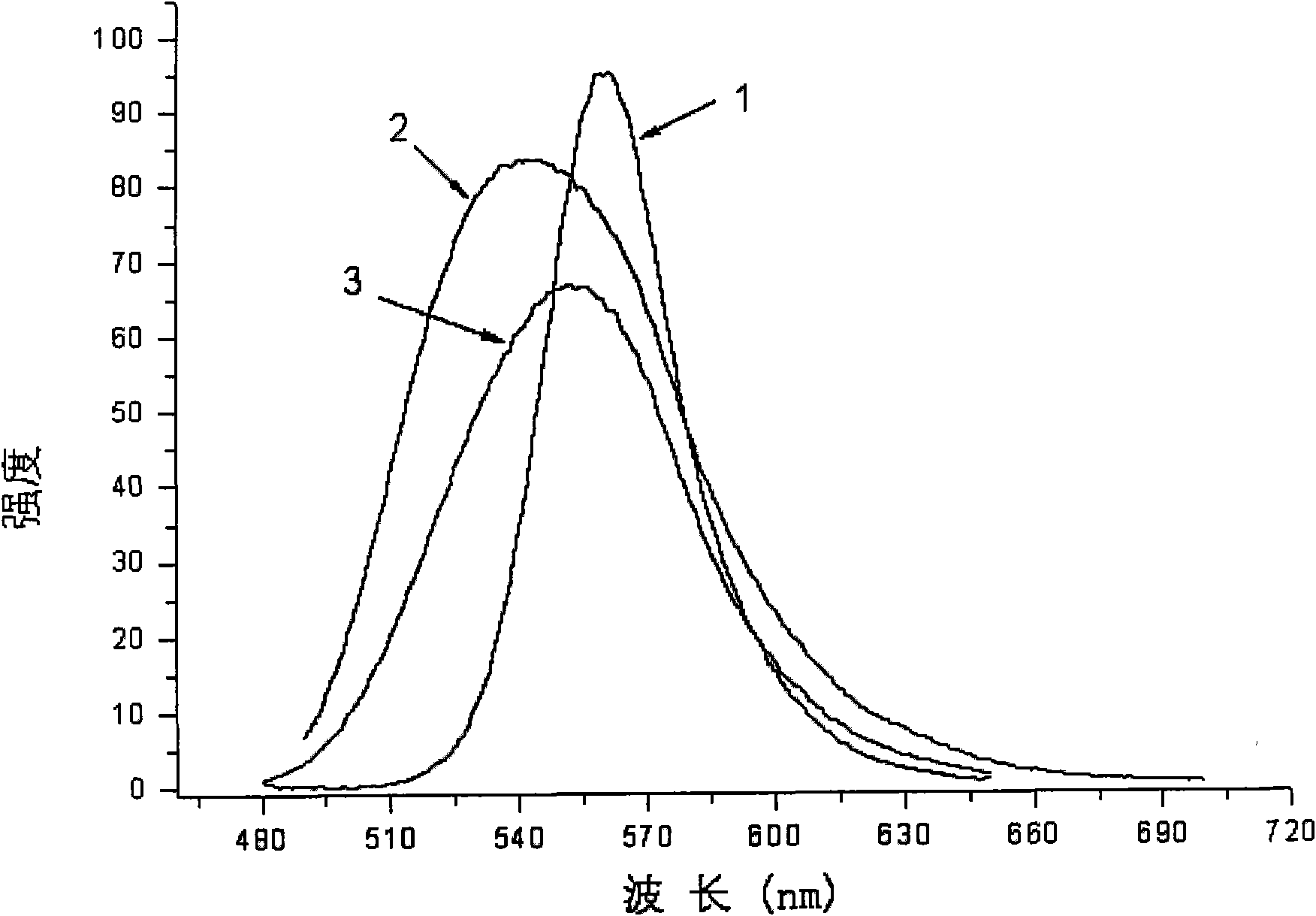

Luminescent glass, making method and application thereof

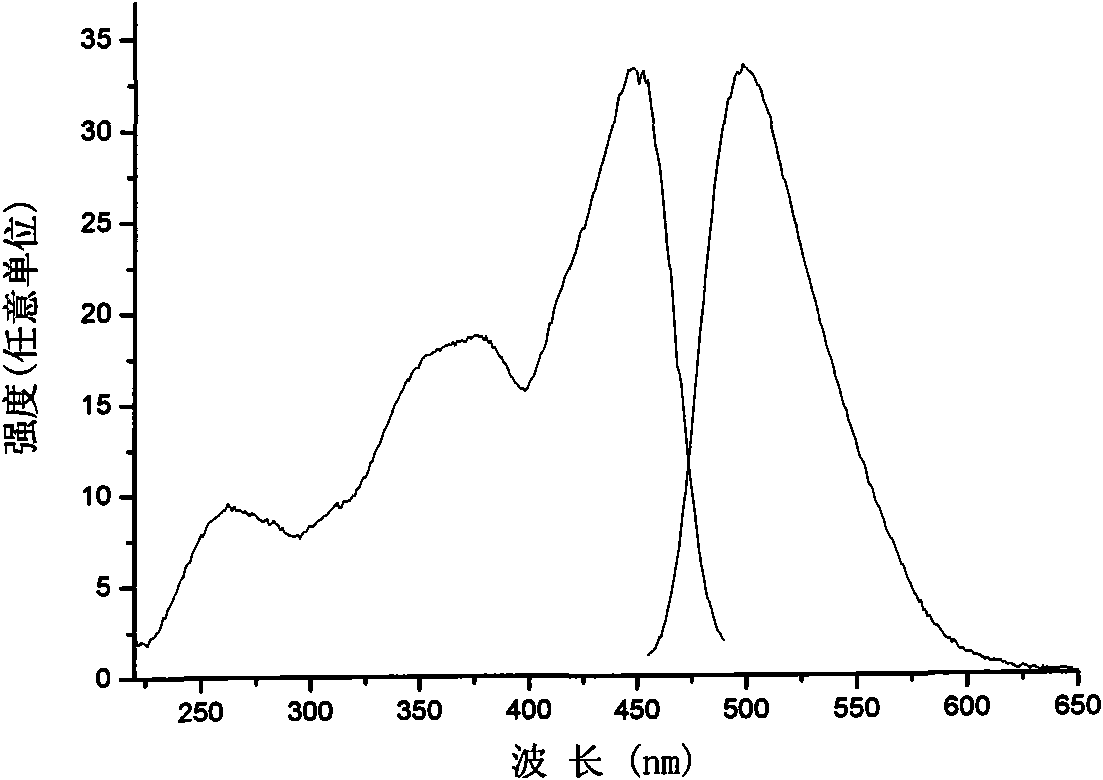

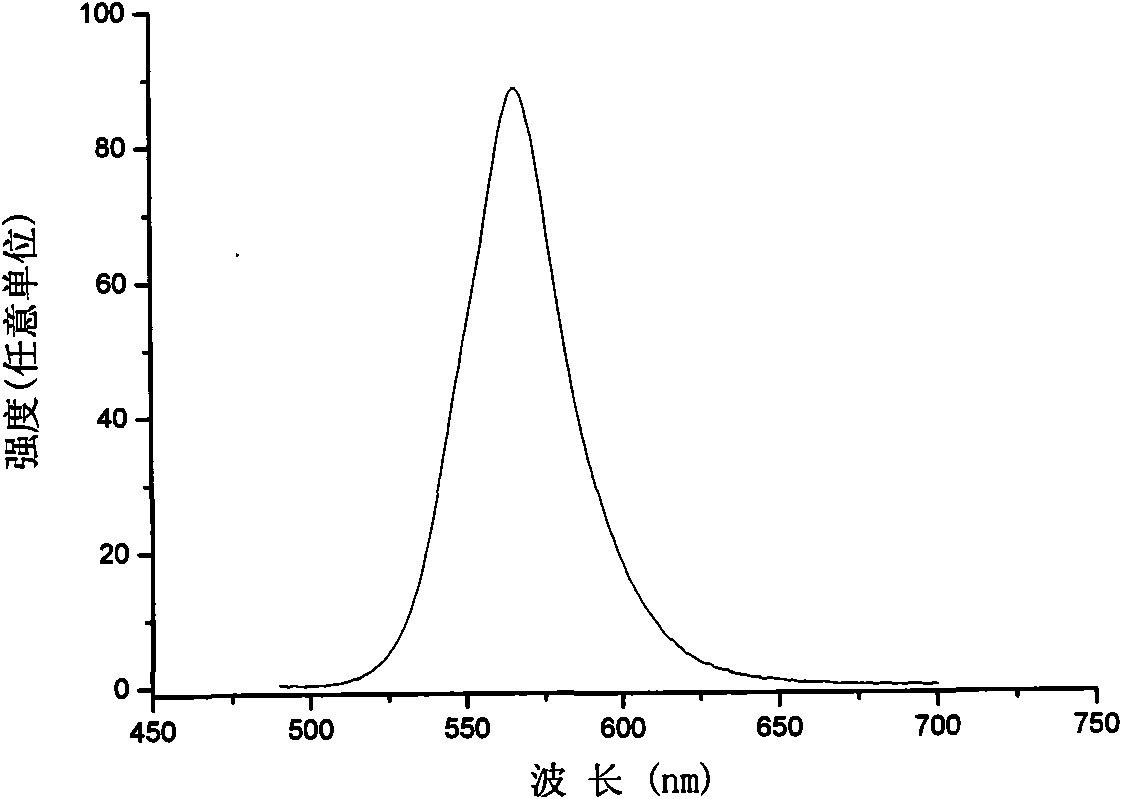

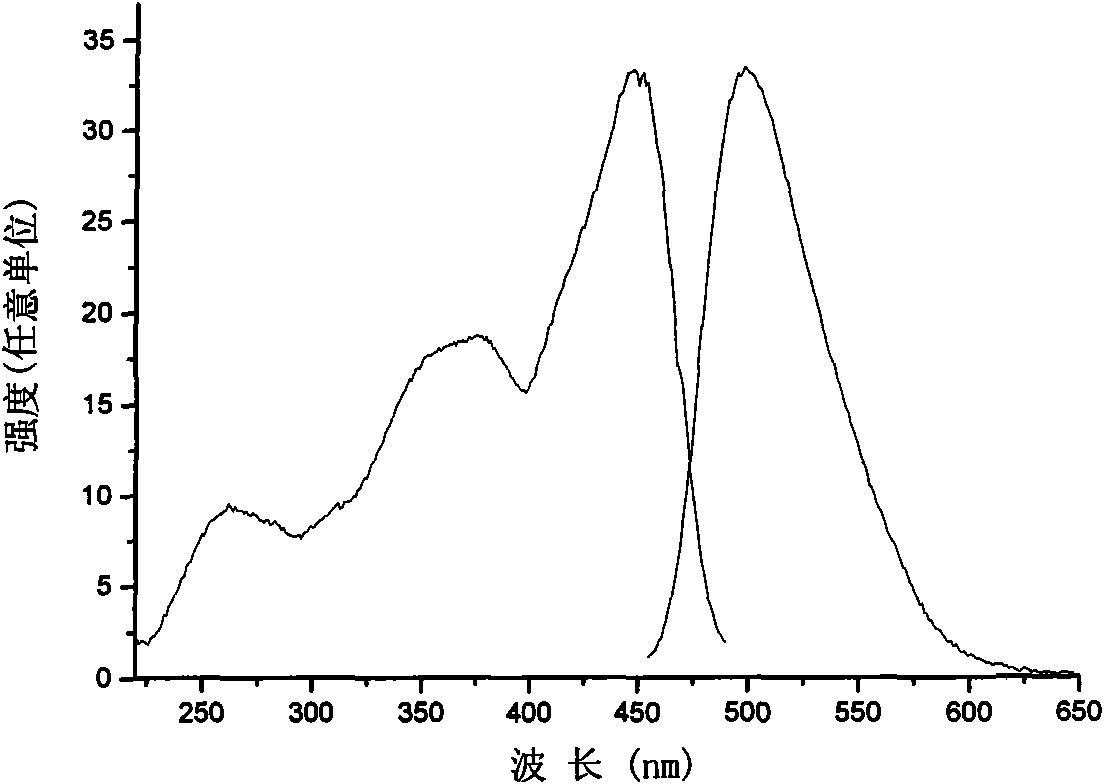

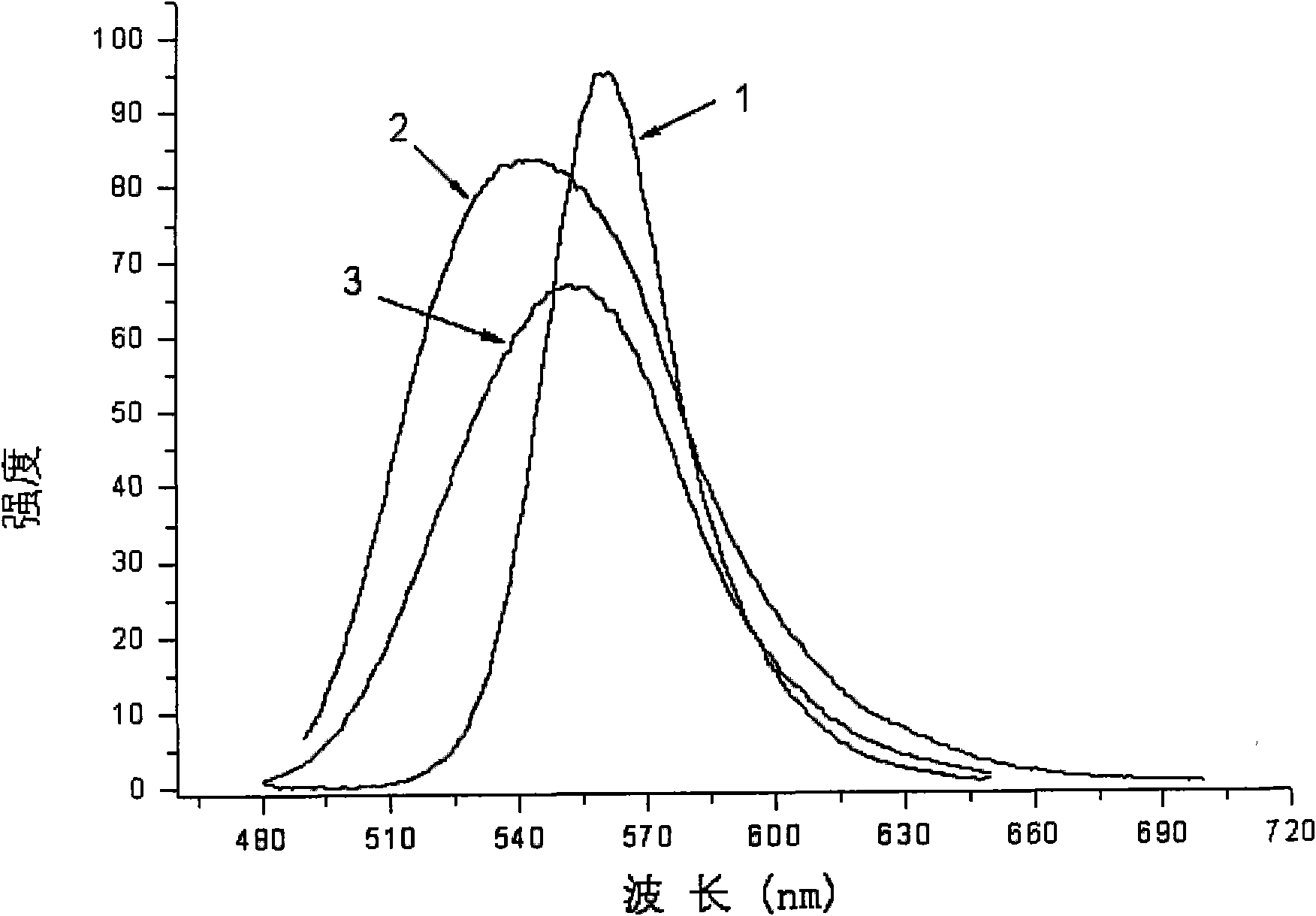

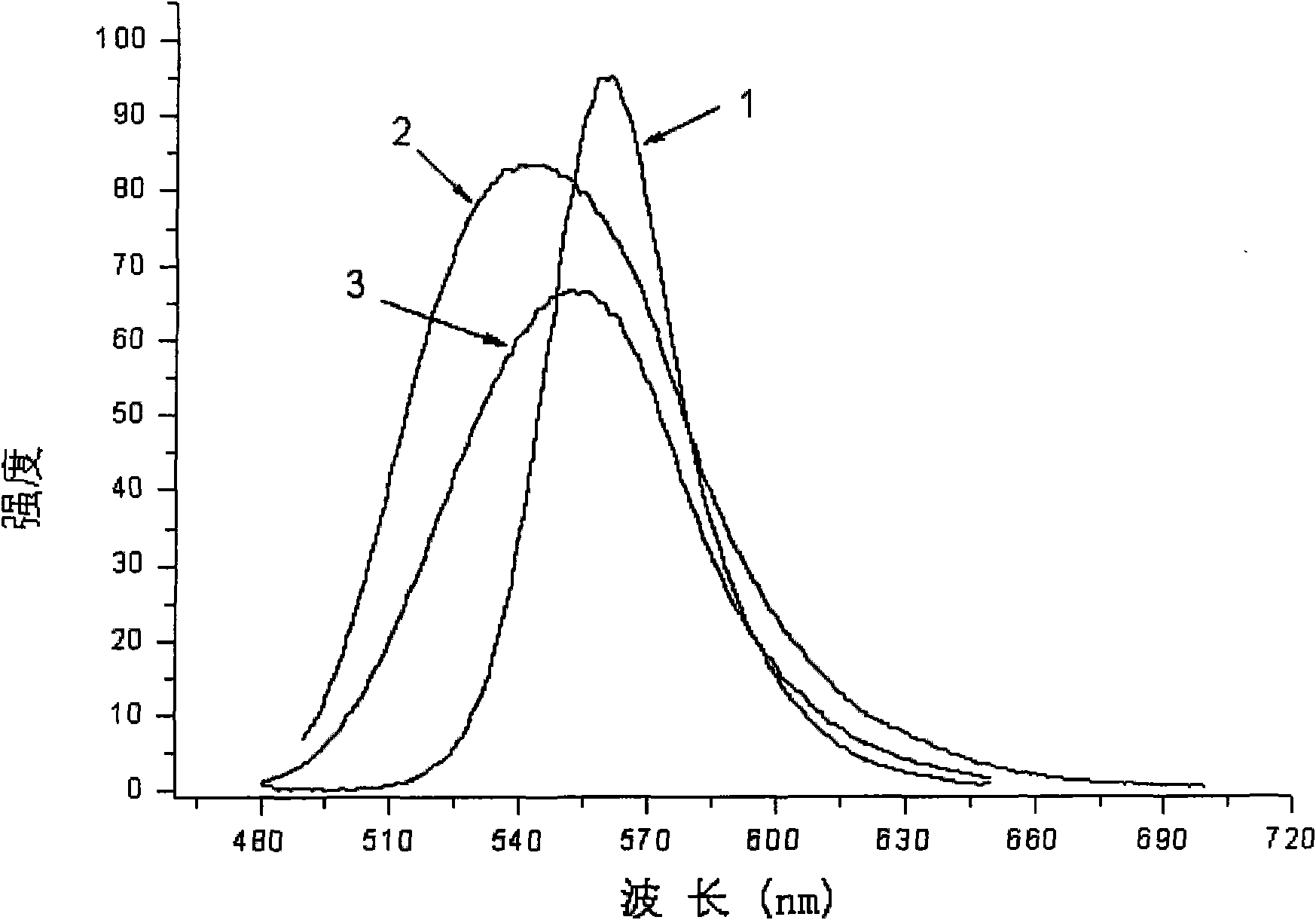

ActiveCN101928111AImprove quantum efficiencyImprove stabilityLuminescent compositionsSemiconductor devicesFluorescenceSolvent

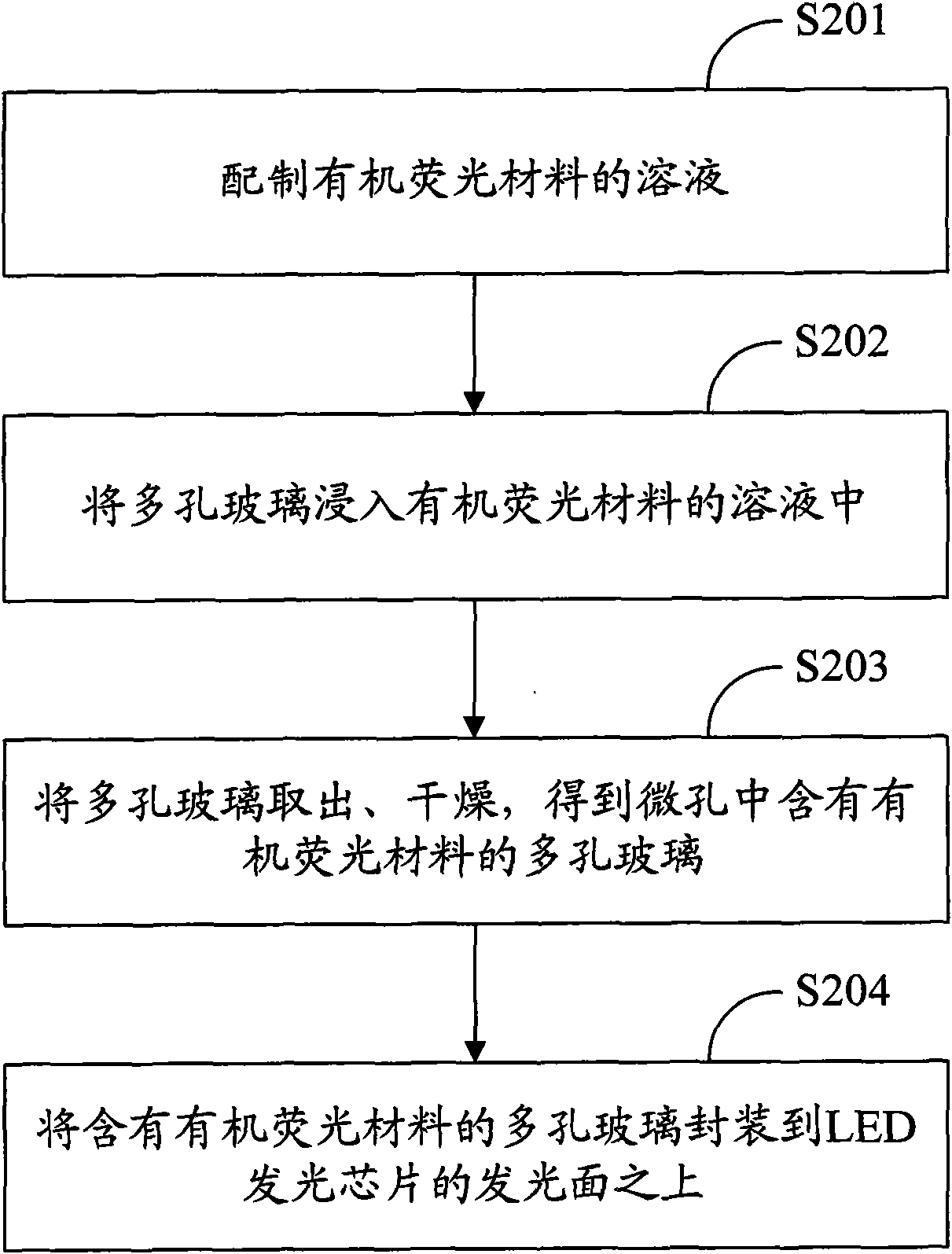

The invention provides luminescent glass, a making method and application thereof. The making method comprises the following steps of, firstly, dissolving organic fluorescence materials in a solvent to form an organic fluorescence material solution; secondly, immersing porous glass into the organic fluorescence material solution, and absorbing the organic fluorescence material solution; and thirdly, taking out the porous glass immersed with the organic fluorescence material solution, and drying to prepare the luminescent glass. The luminescent glass is prepared by the method and can be matched with a semiconductor light emitting diode within a range of 200-550 nm to make a light emitting device. The making method of the luminescent glass has simple making technology, and the luminescent glass prepared by the method can be directly applied to the light emitting device of the semiconductor light emitting diode as fluorescence conversion substances and packaging materials, thereby solving the problem of photochemical reaction between the organic fluorescence materials and the organic packaging materials.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

Composite material for repairing non-excavated pipeline and preparation method thereof

The invention discloses a composite material for repairing a non-excavated pipeline and a preparation method thereof and relates to preparation of the composite material. The composite material is characterized by including the following steps that a polyester needle-punched non-woven fabric and TPU are used as raw materials, hot-pressing molding processing is firstly performed, and then resin injection is performed by adopting a VARI molding process to prepare the composite material for repairing the non-excavated pipeline. The hot-pressing molding and the VARI molding process are combined to develop the composite material for repairing the non-excavated pipeline. The preparation method is short in technological process and lower in cost, the mechanical properties of the developed composite material exceed that of similar composite materials, the composite material can be applied to different diameters of drainage pipelines, water supply pipelines, industrial pipelines and oil, gas and water delivery pipelines and can also be used for repair of different specifications of pipelines and main pipeline joints, repair and renovation of artificial wells and other fields.

Owner:北京北燃环能工程科技有限公司

Indoor antibacterial and environment-friendly powder paint for removing formaldehyde

InactiveCN106833041AHigh tinting strengthStrong covering powerAntifouling/underwater paintsPaints with biocidesBarium sulfatePollution

The invention discloses indoor antibacterial and environment-friendly powder paint for removing formaldehyde, and the indoor antibacterial and environment-friendly powder paint comprises the following components by weight: 0.03-0.05% of nano silver, 0.3-1% of chitosan, 5-10% of pure diatom, 5-10% of anatase titanium dioxide, 30-45% of heavy calcium carbonate, 25-35% of light calcium carbonate, 15-25% of barium sulfate and balance of an assistant. The raw materials adopted by the indoor antibacterial and environment-friendly powder paint are environmentally-friendly non-toxic and pollution-free, the indoor antibacterial and environment-friendly powder paint is effectively antibacterial and durable in antibacterial effect, can automatically absorb the formaldehyde and other toxic and harmful gases in indoor air, has long lasting purification effect, may not cause secondary pollution, has the advantages of simple preparation and convenient packaging and storage, and is suitable for indoor decoration of all kinds of buildings.

Owner:程艳青

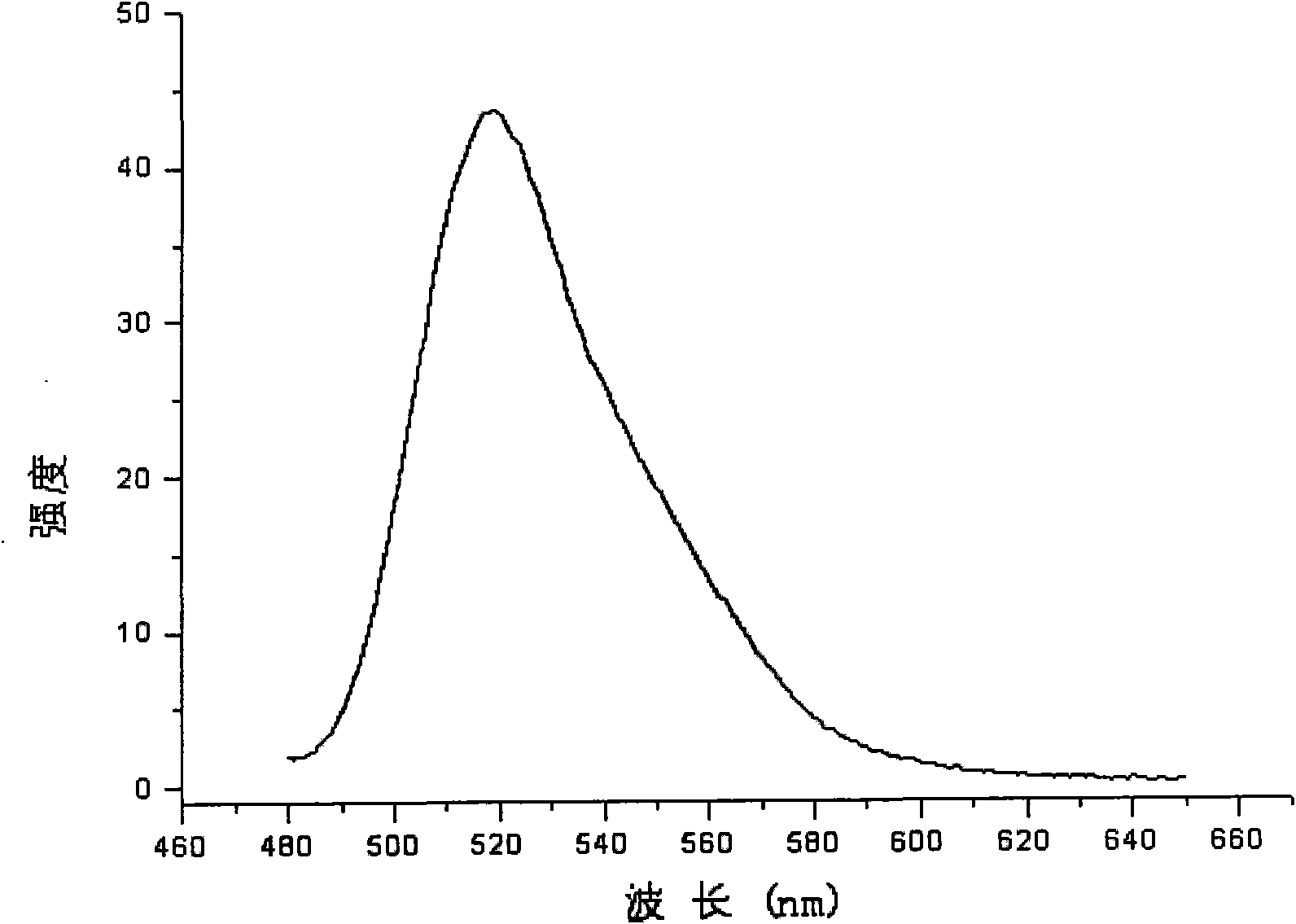

Organic-inorganic compound fluorescent powder, manufacturing method and application

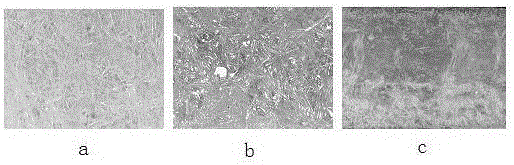

InactiveCN101962533AStrong chemical inertnessWide range of choicesSolid-state devicesSemiconductor/solid-state device manufacturingLight emitting deviceLight-emitting diode

The invention provides organic-inorganic compound fluorescent powder, a manufacturing method and application thereof. The method comprises the following steps of: immerging porous glass into the solution of an organic fluorescent material; taking the porous glass out after the porous glass absorbs the solution of the organic fluorescent material; and smashing the porous glass which absorbs the solution of the organic fluorescent material. The organic-inorganic compound fluorescent powder is prepared by the manufacturing method. The organic-inorganic compound fluorescent powder can be made into a light-emitting device by matching a semiconductor light-emitting diode in the range of between 200 and 550nm. The organic-inorganic compound fluorescent powder of the invention has a simple manufacturing process, can be doped into an encapsulating material of the semiconductor light-emitting diode, and solves the problem of a photochemical reaction between an organic light-emitting material and an organic encapsulating material.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

Weather-resistant anti-corrosion polyester powder coating containing glass fiber and clay minerals

InactiveCN109971319APermeation barrierStrong chemical inertnessAntifouling/underwater paintsPaints with biocidesGlass fiberPolyester

The invention relates to a preparation method of a weather-resistant anti-corrosion polyester powder coating containing glass fiber and clay minerals. Carboxyl-terminated polyester, GMA acrylic resin,unsaturated polyester resin and triglycidyl isocyanurate (TGIC) are simultaneously introduced into a powder coating cross-linking structure, and a micron-sized powder product is obtained after mixingand extruding by a screw and crushing by an air flow mill. The weather resistance, the corrosion resistance and the impact performance can be effectively improved under the condition that excellent other performances such as surface glossiness are ensured, and compared with polyester / TGIC type powder without glass fiber and clay of a common formula, the weather-resistant anti-corrosion polyesterpowder has better performance, low in cost and easy to operate and control.

Owner:NANJING UNIV

Preparation method of wear-resistant corrosion-resistant coating

InactiveCN112143343ALess pollutionNo "three wastes" pollutionAnti-corrosive paintsPowdery paintsCarbon fibersNanoceramic

The invention relates to a preparation method of a wear-resistant corrosion-resistant coating, which comprises the following steps: (1) preparing the following raw materials in percentage by weight: 50-60% of resin, 23-40% of filler, 1-3% of leveling agent, 4-6% of curing agent, 2-3% of coupling agent and 3-5% of modifier; and (2) putting all the raw materials in the step (1) into an ultrafine powder ball mill, mixing and grinding until the particle size is 1200 meshes or above, thereby obtaining the wear-resistant and corrosion-resistant coating. According to the technical scheme, the carbonnano tubes selectively used in the coating have the characteristics of wear resistance, corrosion resistance, good stability and the like, the nano microlite has the characteristics of permeation resistance, good wear resistance and the like, and the nano sepiolite powder has the advantages of high adsorbability, high flame retardance, high temperature resistance, good wear resistance and the like; the carbon nanofibers have the advantages of wear resistance, corrosion resistance, high surface gloss and the like, and the nano ceramic powder has the advantages of wear resistance, high temperature resistance, corrosion resistance and the like.

Owner:广东科盛防腐科技有限公司 +1

Synthetic rubber seal ring material and preparation method thereof

The invention relates to a synthetic rubber seal ring material and a preparation method thereof. The synthetic rubber seal ring material is mainly prepared from components in parts by weight as follows: 10-100 parts of fluorelastomer, 10-100 parts of 3F fluorelastomer, 0.1-100 parts of bisphenol AF, 0.1-5 parts of a vulcanizing agent, 0.1-5 parts of an accelerant BPP, 3-130 parts of inorganic filler, 1-100 parts of calcined diatomite, 1-30 parts of tetrafluoro micropowder, 0.1-5 parts of a polymer processing aid, 0.1-5 parts of American palm wax, 1.1-50 parts of a rubber pigment coloring agentand 0.1-10 parts of fluororubber polymers. The preparation method comprises steps as follows: components are weighted in proportion; fluorelastomer, 3F fluorelastomer and fluororubber polymers are premixed; the mixture and the remaining components are added to an internal mixer for mixing, the mixture is left to stand for hours, the internal mixer is opened to discharge sheets; heating and vulcanization molding are performed, still standing is performed for hours after molding, and a product is obtained. The synthetic rubber seal ring material has high chemical inertness, good stability, superhigh wear resistance, acid-base resistance and corrosion resistance, tear resistance and the like; the synthetic rubber seal ring material can resist the temperature of 220 DEG C, which is far higherthan that of ordinary rubber seal rings; the average service life is 4 times or longer that of the ordinary rubber seal rings.

Owner:上海正兴阀门制造有限公司

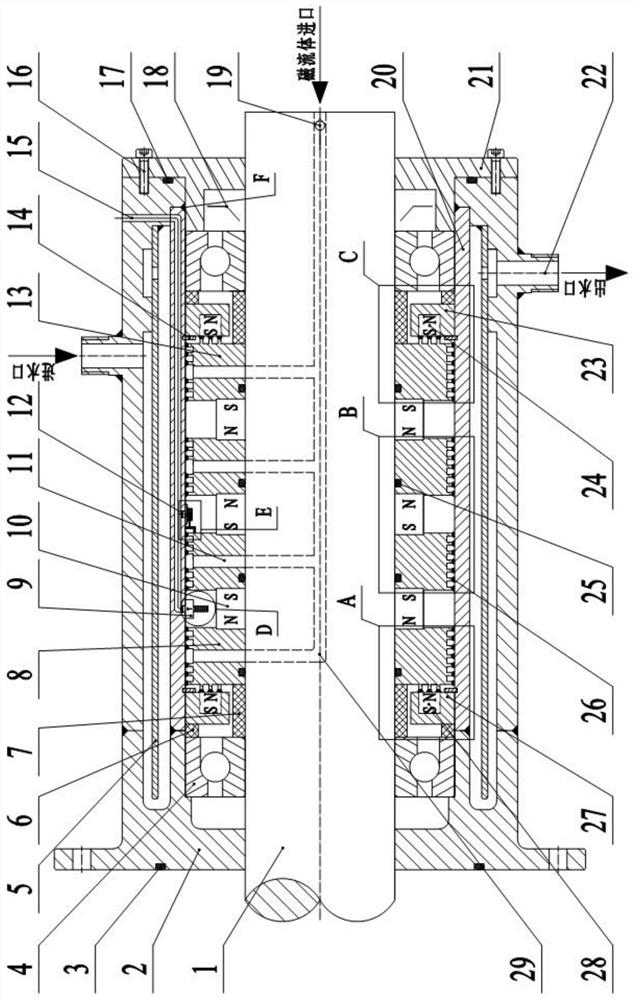

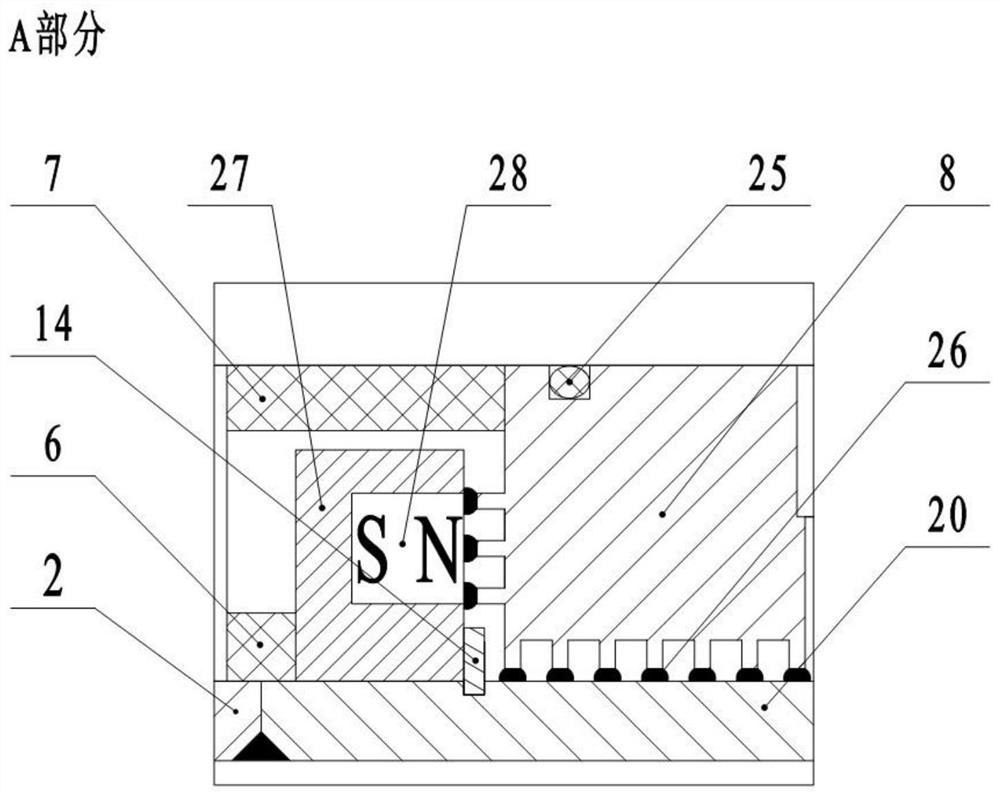

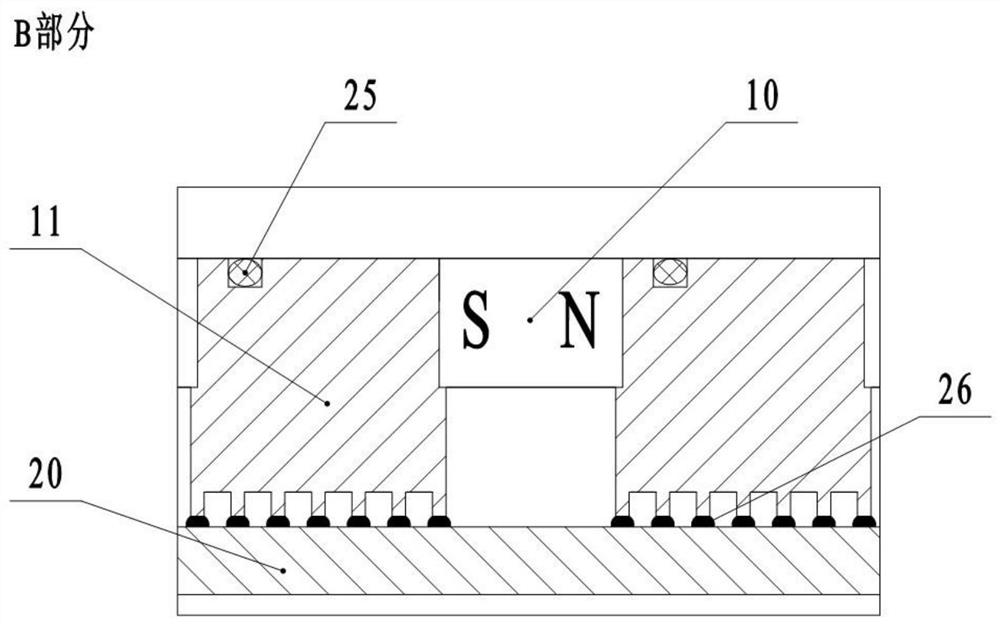

High-speed magnetic fluid sealing device for high-temperature working condition

The invention relates to the technical field of magnetic fluid sealing, in particular to a high-speed magnetic fluid sealing device for a high-temperature working condition. The high-speed magnetic fluid sealing device comprises a sealing shell, a rotating shaft rotatably connected to the interior of the sealing shell, a fixed magnetic assembly fixedly connected to the inner wall of the sealing shell, and a rotating magnetic assembly fixedly connected to the outer wall of the middle of the rotating shaft in a sleeved mode; a magnetic fluid channel communicated with the rotating magnetic assembly is arranged in the rotating shaft, and a one-way check valve is arranged at an inlet end of the magnetic fluid channel; the fixed magnetic assembly comprises a magnetic conductive plate fixedly connected to the inner wall of the sealing shell; the joint face of the rotating magnetic assembly and the fixed magnetic assembly is magnetically connected with magnetic fluid; a temperature sensor and a springback displacement sensor assembly are arranged on the inner wall of the magnetic conductive plate; and a cooling part is arranged in the sealing shell. The purpose that the magnetic fluid sealing device can still work normally under the high-temperature working condition can be achieved.

Owner:长春鑫利密封制品有限公司

Preparation method of aluminum phosphate clad carbonyl iron anti-oxidation wave-absorbing material

ActiveCN107253738AImprove thermal stabilityAdjust electromagnetic wave parametersOther chemical processesIron carbonylsPhosphateMetal particle

The invention relates to a preparation method of an aluminum phosphate clad carbonyl iron anti-oxidation wave-absorbing material, which solves the problems that the activity among carbonyl iron metal particles is high, and carbonyl iron metal particles and oxygen in the air easily have oxidation reaction. The preparation method comprises the following steps: (1) preparing a precursor carbonyl iron suspension; (2) preparing a phosphate suspension; (3) pouring the phosphate suspension into the precursor carbonyl iron suspension, mixing and reacting and cleaning and separating; and (4) performing high-temperature calcination on a sample under the inert atmosphere condition to obtain an aluminum phosphate clad carbonyl iron (Fe@AlPO4) composite material. The obtained composite material can well keep the basic skeleton and crystal form of the precursor carbonyl iron, the oxidization reaction of internal material iron with oxygen in the air can be delayed under the condition of certain temperature air, and the thermal stability of the carbonyl iron composite material can be enhanced. The electromagnetic parameters of the composite material can be regulated by modification of phosphate, the impedance of the composite material is beneficially better matched, and the wave absorbing performance of the composite material can be improved; in addition, the composite material can still keep better wave absorbing performance after being subjected to thermal treatment in the air for 24h and 48h.

Owner:HARBIN INST OF TECH

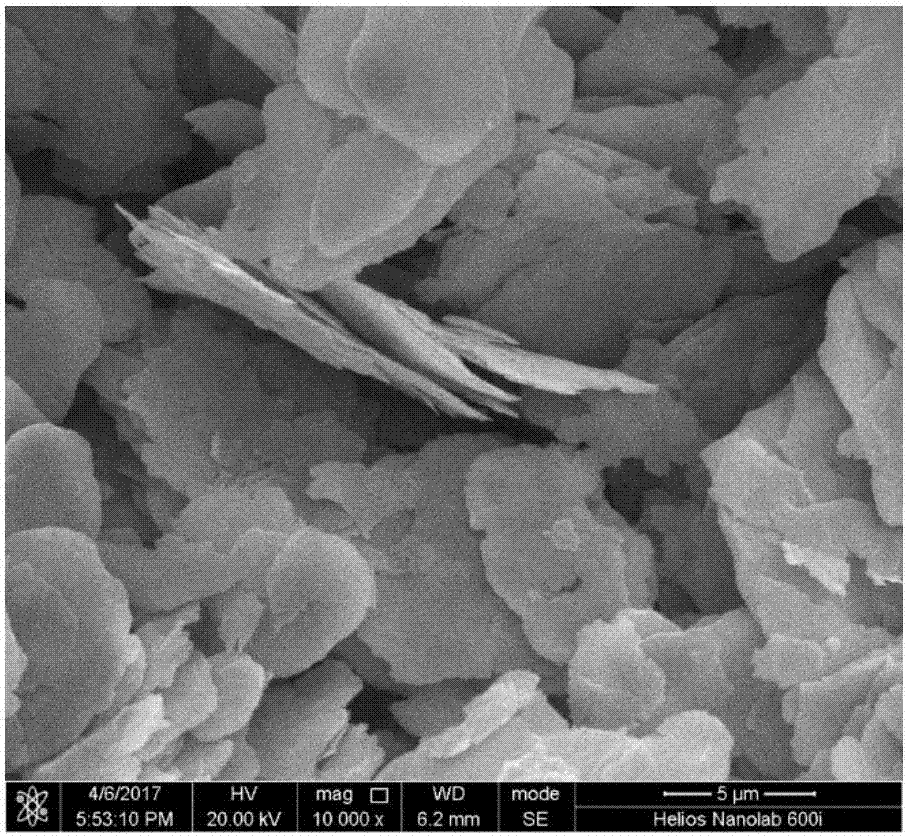

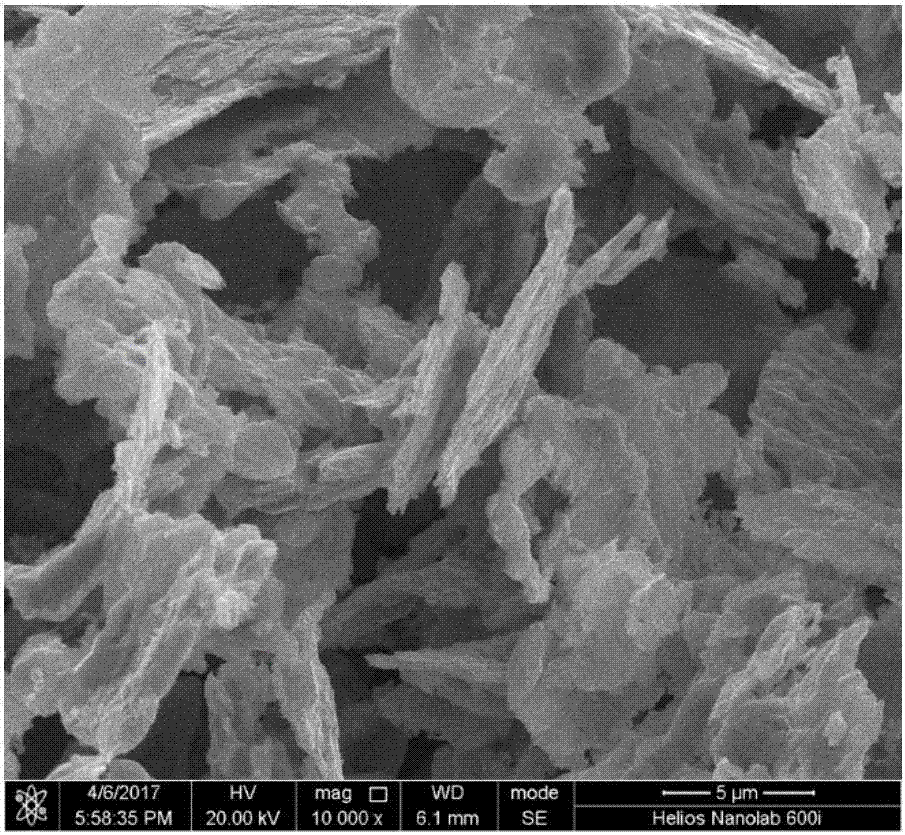

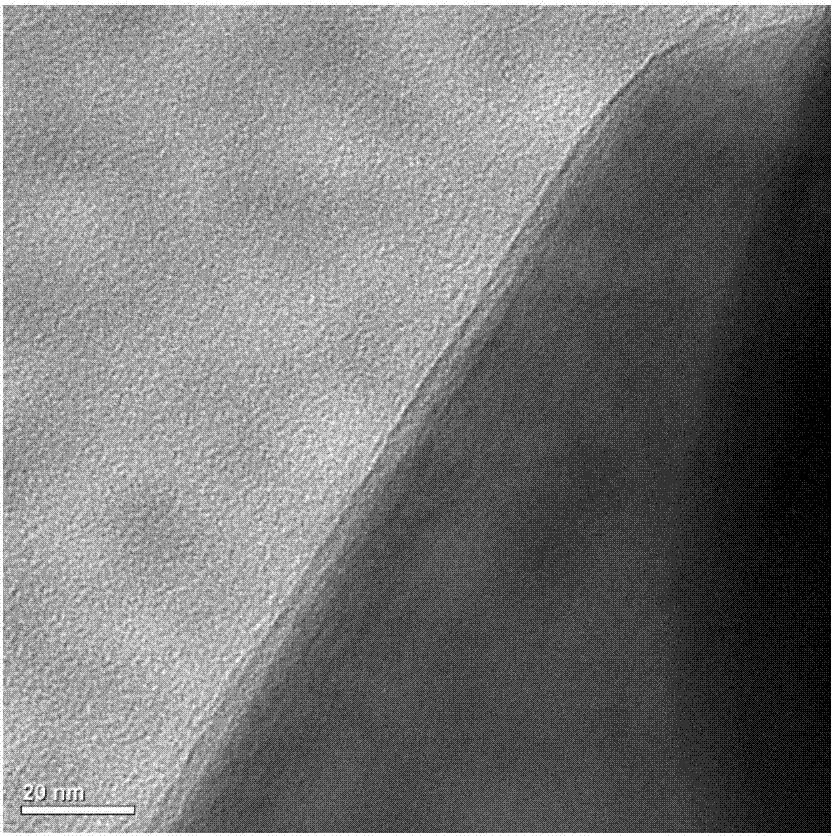

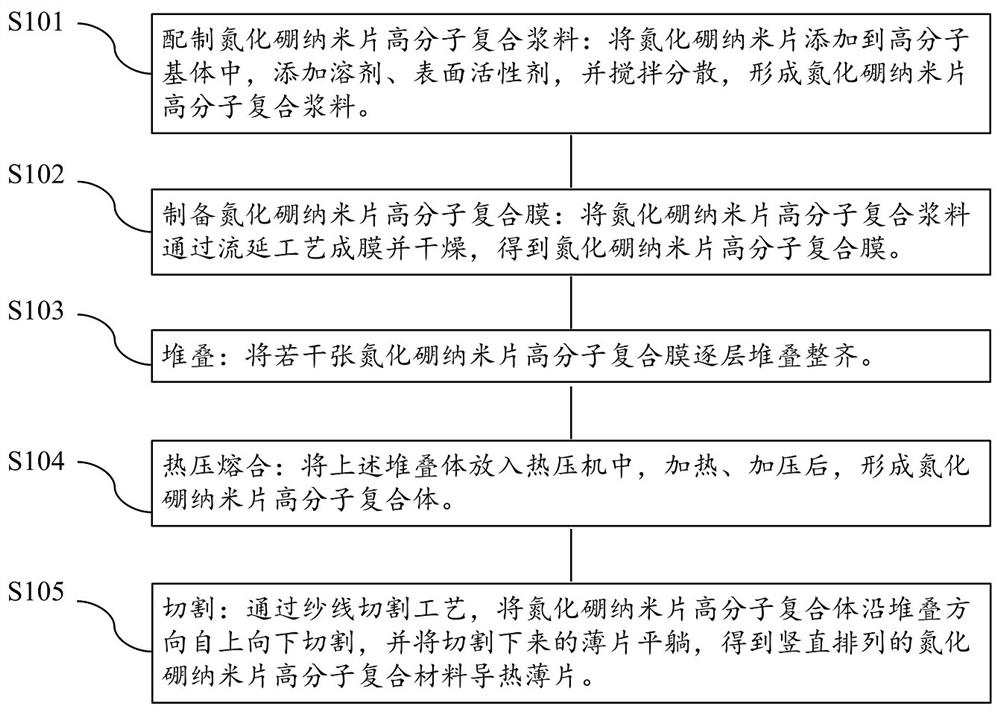

Vertically-arranged boron nitride nanosheet polymer composite material heat-conducting sheet and preparation method thereof

InactiveCN113524741AOvercoming the Problem of Polymer CompoundingEasy to prepareFlat articlesYarnBoron nitride

The invention provides a vertically arranged boron nitride nanosheet polymer composite material heat-conducting sheet and a preparation method thereof. A composite material takes a boron nitride nanosheet with a sheet structure as a filler, the filler is added into a polymer matrix, and a horizontally arranged boron nitride nanosheet polymer composite film is formed through stirring and casting processes, and stacking, hot-pressing fusion and yarn cutting processes are performed on the boron nitride nanosheet polymer composite film to prepare the vertically arranged boron nitride nanosheet polymer composite material heat-conducting sheet. Boron nitride nanosheets are vertically arranged in the polymer matrix, so that the interface thermal resistance is reduced, the heat conductivity coefficient of the material is improved, the composite material heat-conducting sheet with the thickness of 0.05-0.40 mm can be obtained through the yarn cutting process, the thermal resistance is smaller, and heat transfer is facilitated. The method is simple, reliable and high in operability, and can be applied to preparation of polymer composite materials of boron nitride nanosheets and various systems. The boron nitride nanosheet composite material heat-conducting sheet prepared by the method provided by the invention can be widely applied to heat management of electronic products.

Owner:HARBIN INST OF TECH AT WEIHAI

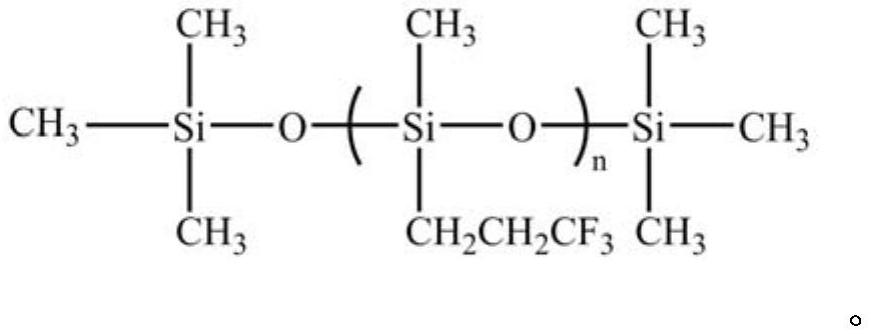

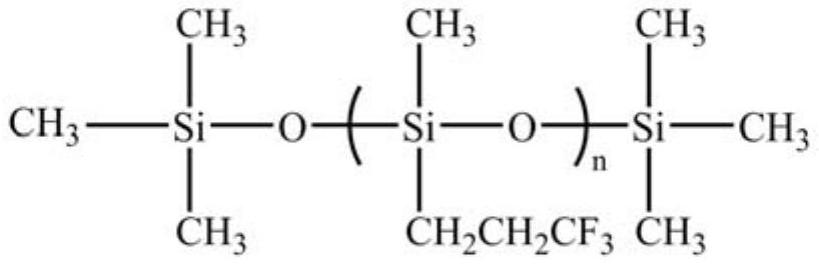

Chemical-medium-resistant fluorosilicone lubricating grease and preparation method thereof

ActiveCN111876220AHigh bond energyImprove high temperature resistanceLubricant compositionFriction reductionPolymer science

The invention provides chemical-medium-resistant fluorosilicone lubricating grease and a preparation method thereof. The fluorine-silicon lubricating grease comprises the following components in percentage by weight: 60-80wt% of composite fluorine-containing base oil; 10-35 wt% of a thickening agent; and 1-15 wt% of a high temperature performance improver; wherein the composite base oil comprisesfluorosilicone oil and linear perfluoropolyether oil. The fluorosilicone lubricating grease provided by the invention has excellent chemical medium resistance and high temperature resistance, can be used under extremely harsh working conditions such as 220 DEG C or above and strong chemical active media, and can effectively reduce friction and protect normal operation of equipment, so that the service life of the equipment is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP

Soft floating roof method for reducing evaporation of liquid fuel storage tank through hollow plastic product

The invention discloses a soft floating roof method for reducing evaporation of a liquid fuel storage tank through a hollow plastic product. The hollow plastic product is prepared from nylon 6, nylon 66 and PEEK (polyether-ether-ketone) or PI (polyimide) as substrate materials (master batch) as well as a flame retardant and a static electricity conductive agent with an injection welding process or a hollow blow molding process. The hollow plastic product adopts hollow spheres with the diameter ranging from phi 10 mm to phi 200 mm and the wall thickness ranging from 0.5 mm to 5 mm, and the surfaces are not coated. The soft floating roof method is applicable to storage tanks in various shapes, can realize mechanical filling and solves the problems of high fabrication cost, high maintenance cost, limited lifting and dropping speeds, high probability of subsiding accidents of a chuck and a floating tray, limited lowest dropping height and the like of traditional floating roofs; and the hollow plastic product floating on the liquid level in the storage tank is flame-retardant, high-temperature resistant, high in chemical inertness and long in service life, can be mechanically recovered, has no adverse effect on the structure of the storage tank and does not affect normal maintenance of the storage tank.

Owner:北京众信远新能源技术有限公司

Nylon composite material excellent in waterproofing and wear-resisting properties and preparation method of composite material

The invention discloses a nylon composite material excellent in waterproofing and wear-resisting properties. The composite material is characterized by being prepared from the following raw materials in parts by weight: 0.1-0.3 part of diphenylamine, 5-7 parts of precipitated barium sulfate, 8-12 parts of graphite fiber, 0.5-1 part of polyethylene wax, 2-4 parts of nano aluminum nitride, 1-2 parts of sodium lignin sulfonate, 90-100 parts of nylon 6, 2.5-3.2 parts of lithium chloride, 3-9 parts of epoxy resin E51, 10-15 parts of an EVA emulsion, 60-80 parts of ethyl acetate, 1-3 parts of castor oil, 4-7 parts of ethylene / vinyl alcohol copolymer powder and 15-30 parts of distilled water. By adding the graphite fiber, the wear resistance, the toughness, the rigidity and other properties of the material are enhanced; the added precipitated barium sulfate has the advantages of strong chemical inertness, good stability, acid and base resistance, and moderate hardness, and is able to absorb harmful rays an the like; by adding the nano aluminum nitride, the mechanical performance and heat-conducting effect of a finished product are significantly improved; and the material disclosed by the invention is excellent in waterproofing and heat-conducting effects, simple in processing and worthy of popularizing.

Owner:HEFEI KANGLING HEALTH TECH

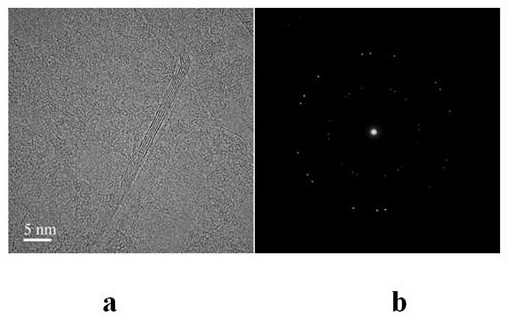

Graphene-based transparent conductive film electrode as well as preparation method and application thereof

ActiveCN111999359AImprove stabilityImprove photoelectric performanceMaterial electrochemical variablesThin film electrodeThin membrane

The invention belongs to the technical field of electrodes, and particularly relates to a graphene-based transparent conductive film electrode as well as a preparation method and application thereof.The graphene-based transparent conductive film electrode provided by the invention comprises a transparent substrate, a silver nanowire grid loaded on the surface of the transparent substrate, a two-dimensional layered structure compound layer on the surface of the silver nanowire grid and a graphene film outer layer. According to the graphene-based transparent conductive film electrode as well asthe preparation method and the application thereof, the two-dimensional layered structure compound, the silver nanowires and the graphene film cooperate with one another, so that the defect that a single material is poor in mechanical stability or poor in photoelectric property is overcome, and the obtained graphene-based transparent conductive film electrode has relatively low resistance, relatively high transmittance and good mechanical flexibility and stability. Experimental results show that the square resistance of the graphene-based transparent conductive film electrode provided by theinvention is less than 50 ohm / sq, and the transmittance is 88.5-90.5%.

Owner:SHANGHAI UNIV

Plastic for environment-friendly packaging box

InactiveCN108912633AStrong heat resistanceImprove antibacterial propertiesSodium bicarbonatePolyvinyl chloride

The invention discloses a plastic for an environment-friendly packaging box. The plastic is characterized by comprising the following materials in parts by weight: 35-40 parts of polylactic acid, 15-17 parts of hydrolyzed starch, 16-18 parts of polyvinyl chloride, 8-10 parts of diatomite, 5-7 parts of nanometer calcium carbonate, 1-2 parts of sodium bicarbonate, 3-4 parts of talcum powder, 1.5-1.7parts of calcium stearate, 1-1.2 parts of borax, 2-3 parts of pentaerythritol, 2-4 parts of a coupling agent, 8-10 parts of epoxy soybean oil, 2.1-2.3 parts of nanometer silver ion, 2-5 parts of an anti-ageing agent and 1-3 parts of agar. The plastic has the advantages that the prepared plastic packaging boxes are safe and non-toxic, conform to green environment-friendly concept, have high heat resistance and good antimicrobial property, and are very suitable for food packaging. Moreover, the plastic packaging boxes have strong physical and chemical inertness, can be repeatedly used, and areharmless to human body and convenient to degrade.

Owner:苏州瑞沁精密机械有限公司

Preparation method for plastic packing box

InactiveCN109135223AStrong heat resistanceImprove antibacterial propertiesSodium bicarbonatePolyvinyl chloride

The invention discloses a preparation method for a plastic packing box. The preparation method comprises the following steps that 1) polylactic acid, hydrolyzed starch, polyvinyl chloride, kieselguhr,nanometer calcium carbonate, a coupling agent, sodium bicarbonate, borax, calcium stearate and clear water are stirred and mixed for 20-30 minutes, and then the mixture is added into a reaction stilland stirred for 30-35 minutes at the temperature of 50-55 DEG C; 2) after stirring, the mixture is subjected to standing for 10 minutes, then pentaerythritol, epoxidized soybean oil, talcum powder, agar, an anti-aging agent and an auxiliary agent are added and continuously stirred for 30-40 minutes; 3) after stirring, the mixture is subjected to standing for 10 minutes, then the auxiliary agent is heated to 60-65 DEG C, and the mixture is stirred and mixed for 2-2.5 hours; 4) the stirred mixed mixture is taken out and placed in a water groove for cooling shaping, then demolding is conducted,and the environmentally friendly plastic packing box is obtained. The preparation method has the advantages that the packing box is safe and non-toxic, meets the green and environmentally friendly concept and is quite suitable for food packaging, and the method is simple and practical, improves the production rate and reduces cost.

Owner:苏州瑞沁精密机械有限公司

Ceramic waste rustproofing pigment

InactiveCN102585576BStrong chemical inertnessReduce erosionAnti-corrosive paintsFilling materialsPrice ratio

The invention discloses a ceramic waste rustproofing pigment. Ceramic waste is adopted as a raw material, a ceramic waste powder material is obtained by water washing, drying, smashing, fine grinding and grading, other filling materials and auxiliaries are further added, and a powder surface treatment agent is used for surface treatment so as to get a product. According to the ceramic waste rustproofing pigment disclosed by the invention, solid waste resources are comprehensively utilized and transformed into the rustproofing pigment with high value and high performances, which is suitable for coatings, and harmless and resource treatment of the ceramic waste is thus realized. Furthermore, the rustproofing pigment shows the excellent characteristics, such as excellent rustproofing performance, high performance-price ratio, environment-friendly and non-toxic properties and the like, in the rustproofing coatings.

Owner:HUNAN RUISHI SCI & TECH DEV

Plastic packing box and preparation method thereof

A plastic packing box relates to the field of packing box processing and manufacturing technologies and is characterized by being prepared from the following materials (by weight): 16-21 parts of polyvinyl chloride, 2-5 parts of modified kaolin powder, 2-4 parts of myrcene, 2-5 parts of a coupling agent, 3-5 parts of alkyl sodium sulfonate, 1-4 parts of white carbon black, 1-2 parts of aluminium powder, 4-8 parts of talcum powder, 2-3 parts of distearoyl isopropoxy aluminate, 3-6 parts of an anti-ageing agent, 6-10 parts of an auxiliary agent and 14-18 parts of clear water. The method of the invention is reasonable and is convenient to operate; and the product is nontoxic and harmless.

Owner:合肥盛鼎包装材料有限公司

Preparation method of aluminum phosphate-coated carbonyl iron anti-oxidation wave-absorbing material

ActiveCN107253738BAdjust electromagnetic wave parametersImprove absorbing performanceOther chemical processesIron carbonylsPhosphateALUMINUM PHOSPHATE

Owner:HARBIN INST OF TECH

Plastic packaging film and preparation method thereof

The invention discloses a plastic packaging film, and relates to the technical field of plastic packaging product processing and production. The plastic packaging film is characterized in that the plastic packaging film is prepared from the following materials in parts by weight: 16 to 21 parts of polyvinyl chloride, 3 to 6 parts of modified kaoline powder, 7 to 11 parts of resin, 2 to 4 parts of methyltrimethoxysilane, 2 to 5 parts of a coupling agent, 3 to 5 parts of alkyl sodium sulfonate, 1 to 4 parts of waterborne polyurethane, 4 to 8 parts of talcum powder, 2 to 5 parts of tri-n-butyl citrate, 3 to 6 parts of an anti-aging agent, 5 to 8 parts of an accessory ingredient and 14 to 18 parts of clean water. The method is reasonable, and the plastic packaging film is non-poisonous, harmless and high in tenacity.

Owner:合肥盛鼎包装材料有限公司

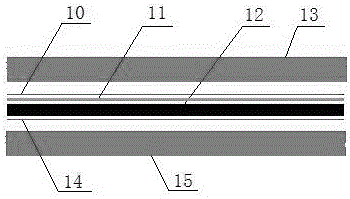

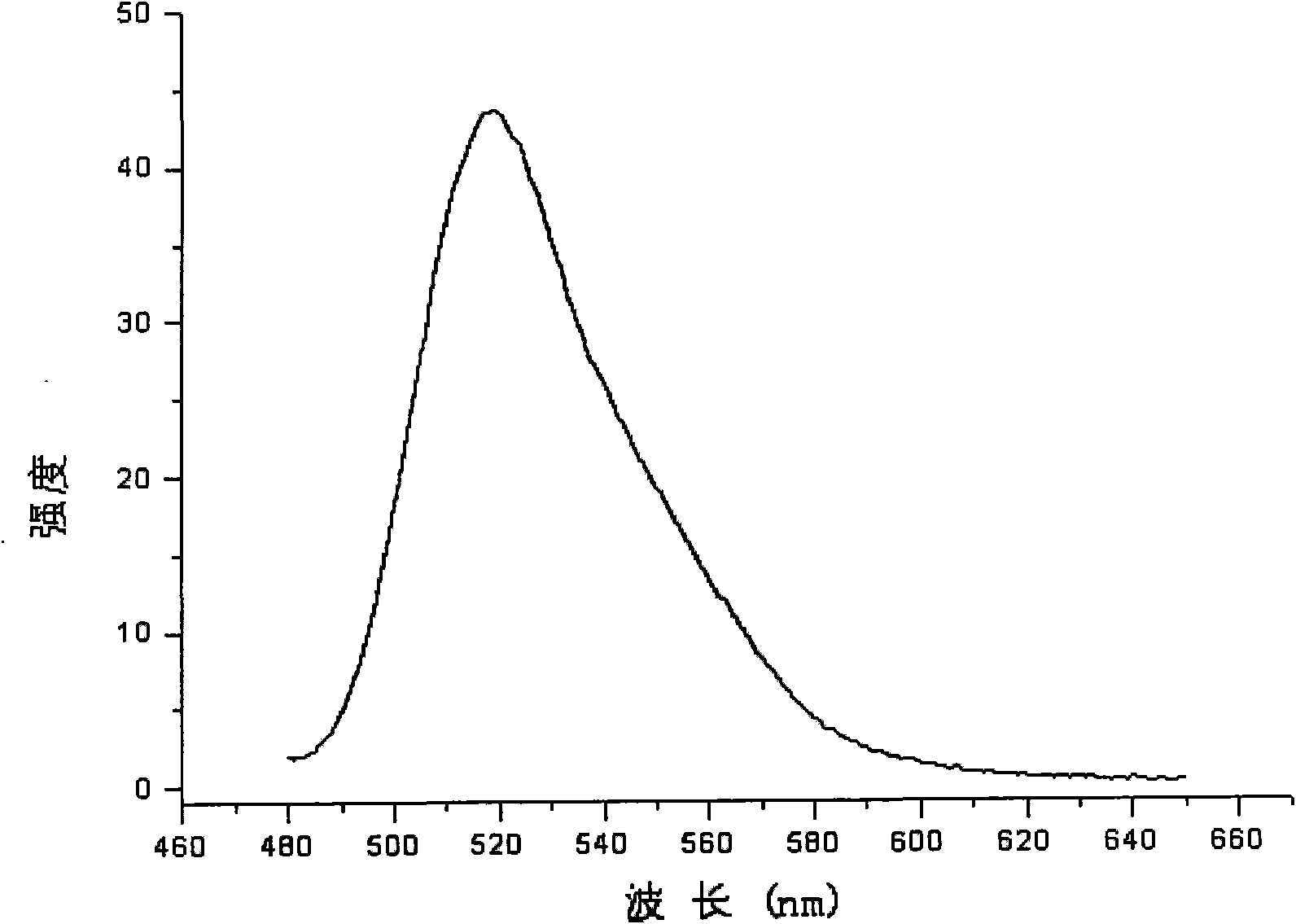

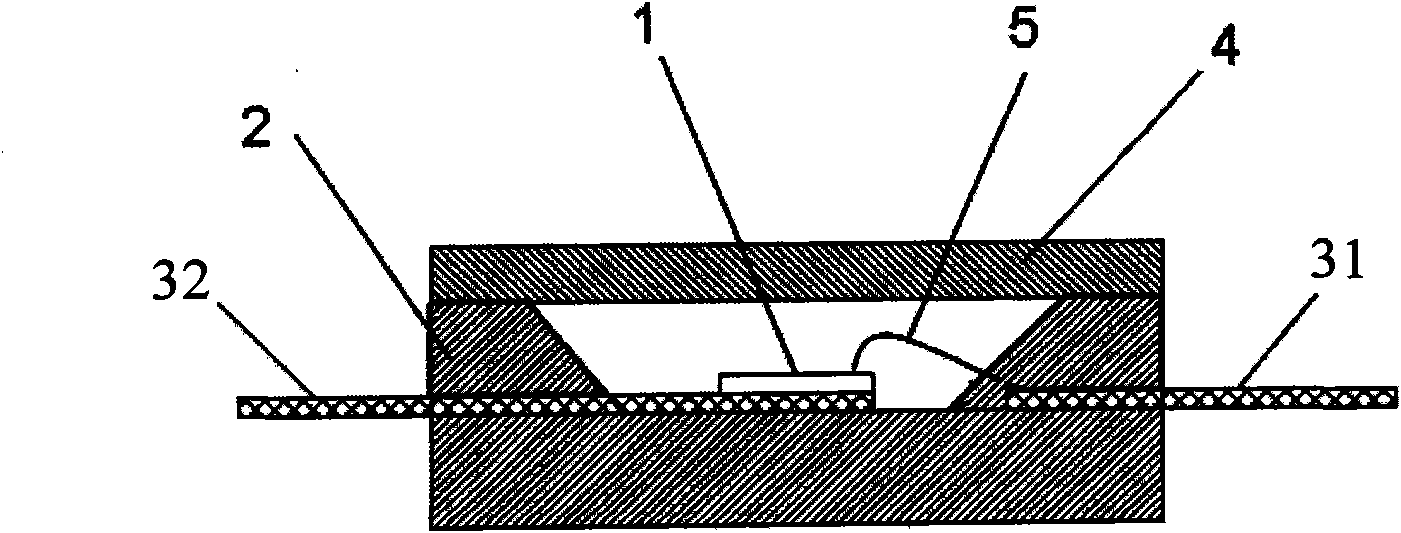

White light diode and manufacturing method thereof

ActiveCN101931033AExtended service lifeImprove luminous efficiencySemiconductor devicesEnergy transferCompound (substance)

The invention belongs to the technical field of photoelectricity, and provides a white light diode and a manufacturing method thereof. The white light diode comprises a light-emitting chip and porous glass which is encapsulated on the light-emitting surface of the light-emitting chip and contains an organic fluorescent material. As for the white light-emitting dioxide in the invention, the porous glass is used as a carrier for the organic fluorescent material to encapsulate so as to manufacture the white light-emitting diode, and as the porous glass has strong chemical inertness, the photochemical reaction between the organic fluorescent material and the porous glass as well as nonradiative energy transfer due to the photochemical reaction are prevented, thus maintaining higher luminous efficiency for the organic fluorescent material, improving the whole stability and prolonging the service life of the white light-emitting diode.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

Agricultural machine environment-friendly anti-rust coating and preparation method of same

InactiveCN107163730AGood anti-rust functionImprove bindingAnti-corrosive paintsBurned skinAcrylic resin

The invention discloses an agricultural machine environment-friendly anti-rust coating which includes, by weight, 40-50 parts of acrylic resin, 3-5 parts of antimonous oxide, 8-10 parts of polyethylene glycol, 7-9 parts of a composite filler, 6-10 parts of a processing aid, 0.4-0.8 parts of polydimethylsiloxane, 0.6-0.8 parts of SiO2, 5-9 parts of a sodium salt additive, 6-10 parts of a composite synergist, 4-6 parts of EDTA, 3-7 parts of glycerol and 15-25 parts of deionized water. The anti-rust coating has strong adhesive force on metal products and has excellent anti-rust protective effect on the metal products, can be used repeatedly, is free of discharge of waste liquid and acid fog which causes environment pollution, is free of burning skin during use, is irritation-free and damage-free on human body and is easy to use. The raw materials are low in cost and easy to obtain. The preparation method has simple processes, high practical value and excellent application prospect.

Owner:HEFEI HUIZHI NEW MACHINERY TECH CO LTD

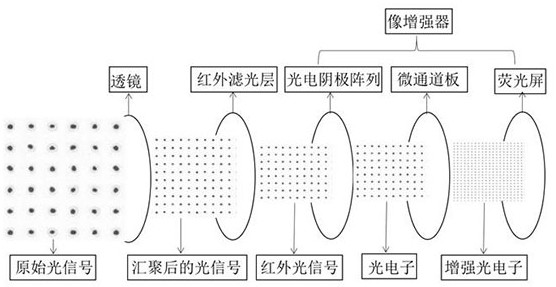

Graphene-based low-altitude airborne infrared remote sensor

ActiveCN113140651AIncreased sensitivityStrong chemical inertnessClimate change adaptationSemiconductor devicesInfrared remote sensingPhotocathode

The invention discloses a graphene-based low-altitude airborne infrared remote sensor. The graphene-based low-altitude airborne infrared remote sensor comprises a lens, an infrared filter layer and an image intensifier, the image intensifier comprises a photoelectric cathode array used for realizing photoelectric conversion, a micro-channel plate used for realizing electron multiplication and a fluorescent screen used for electronic imaging, a photoelectric cathode unit in the photoelectric cathode array adopts a photoelectric device composed of a semiconductor and a graphene film, and the graphene film is laid on the semiconductor. The lens gathers external light, the infrared filter layer is used for filtering the gathered light and filtering out light beyond an infrared band, the photoelectric cathode unit performs photoelectric conversion on the filtered light, and imaging is realized on the fluorescent screen after the light is subjected to an electron multiplication effect of the micro-channel plate. According to the infrared remote sensor, the detection height of the remote sensor is greatly improved, and meanwhile, the infrared response sensitivity and the temperature adaptability are also improved.

Owner:ZHEJIANG UNIV

Method for grinding superhard material

The invention provides a method for grinding a superhard material. The rotating speed of a grinding apparatus is controlled, the back cutting depth of the grinding apparatus is adjusted, the speed and axial feeding speed of a workpiece are controlled, and the grinding speed ranges from 15m / s to 25 m / s; the back cutting depth ranges from 0.005 mm to 0.01 mm; the speed of the workpiece ranges from 15 m / min to 25 m / min; and the axial feeding speed ranges from 0.5 m / min to 1 m / min. The good surface roughness can be obtained through the grinding speed ranging from 15 m / s to 25 m / s, and meanwhile, the temperature of the workpiece and the temperature of a grinding wheel are low, so that the abrasion of the grinding wheel can be controlled within the small range; the back cutting depth ranging from 0.005 mm to 0.01 mm balances the grinding quality of the workpiece and protection of the grinding wheel; when the workpiece is ground at the speed ranging from 15 m / min to 25 m / min, a steady grinding process is achieved, and the noise is low; and the axial feeding speed ranging from 0.5 m / min to 1 m / min enables the surface roughness of the workpiece to be good, and the abrasion of the grinding wheel is good.

Owner:刘永红

Organic-inorganic compound fluorescent powder, manufacturing method and application

InactiveCN101962533BStrong chemical inertnessWide range of choicesSolid-state devicesSemiconductor/solid-state device manufacturingPhysical chemistryLight emitting device

The invention provides organic-inorganic compound fluorescent powder, a manufacturing method and application thereof. The method comprises the following steps of: immerging porous glass into the solution of an organic fluorescent material; taking the porous glass out after the porous glass absorbs the solution of the organic fluorescent material; and smashing the porous glass which absorbs the solution of the organic fluorescent material. The organic-inorganic compound fluorescent powder is prepared by the manufacturing method. The organic-inorganic compound fluorescent powder can be made into a light-emitting device by matching a semiconductor light-emitting diode in the range of between 200 and 550nm. The organic-inorganic compound fluorescent powder of the invention has a simple manufacturing process, can be doped into an encapsulating material of the semiconductor light-emitting diode, and solves the problem of a photochemical reaction between an organic light-emitting material and an organic encapsulating material.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com