Graphene-based low-altitude airborne infrared remote sensor

A graphene-based, graphene-based technology, applied in sustainable manufacturing/processing, climate sustainability, semiconductor devices, etc., can solve the problems of low absorbance, inability to generate photocurrent, high carrier mobility, etc., and achieve chemical inertness Strong, improve imaging clarity, high sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: Preparation of graphene film enhanced by weak coupling

[0051] Graphene oxide is prepared by centrifugal spraying method to prepare nano-thick films. After detaching the nano-film from the substrate, the temperature is raised to 2000 degrees at a rate of 10 degrees Celsius per minute, maintained for 2 hours, and then heated to 2300 degrees Celsius for 4 hours.

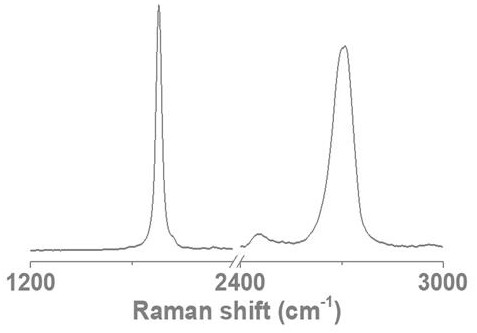

[0052] Such as figure 1 , the measured ID / IG of the graphene film is 0, the AB structure content is 50%, and the graphene structure contains 63 graphene units, and the average number of layers of the graphene units is 2 layers, including several Graphene units composed of graphene sheets and several graphene units composed of more than two layers of graphene sheets in an AB stacking manner, for example, 5 graphene units composed of single-layer graphene sheets and 1 graphene unit composed of 7 layers of graphene A graphene unit composed of sheets in an AB stacking manner.

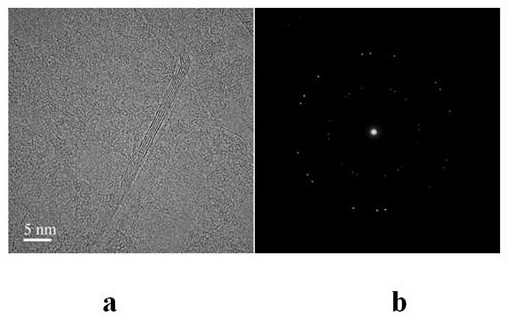

[0053] figure 2 It ...

Embodiment 2

[0059] The graphene film that embodiment 1 prepares is made optoelectronic device according to the following steps:

[0060] 1) First reserve a working window on the Si substrate, plate an insulating layer outside the working window, and then sputter the Pt electrode layer in the insulating layer;

[0061] 2) Spread the graphene film on the working window first, and contact with the electrode layer, drop ethylene glycol on the edge of the graphene film, ethylene glycol penetrates from the edge of the graphene film to the inside, volatilize the solvent, and use the surface of the solvent Tension realizes the tight combination of film and semiconductor;

[0062] (3) Repeat steps 1-2 to prepare an array of windows by photolithography, transfer the film to the windows, and continue to remove the excess parts outside the windows by photolithography. The size of a single window is controlled within 5um, the window spacing is 5um, and the size of the array is 3cm×3cm.

[0063] (4) ...

Embodiment 3

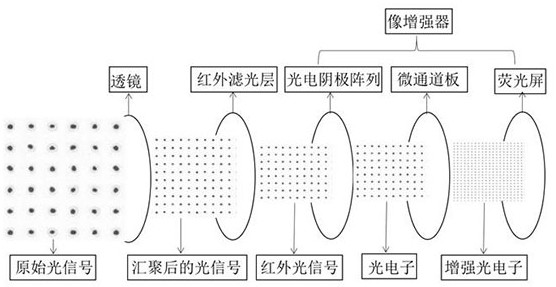

[0084]A layer of Thorlabs infrared filter layer is installed on the back of the lens. This filter layer can filter out light waves with wavelengths other than 750nm-1mm, and the transmittance of light in the range of 750nm-1mm is greater than 90%, so as to eliminate other The impact of light in the wavelength band; it is loaded on the front end of the image intensifier, where the image intensifier contains a photocathode array for photoelectric conversion, a microchannel plate for electron multiplication and a phosphor screen for electron imaging (such as image 3 shown).

[0085] The photocathode units in the photocathode arrays of the remote sensing devices 1 and 2 are 3000×3000 photocathode arrays composed of photocathode units prepared in Example 2 and Comparative Example remote sensing device 1, respectively.

[0086] Such as Figure 4 As shown, when the aircraft flies to 2 kilometers, 4 kilometers, and 6 kilometers away from the ground fire source, three fire sources A,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com