Graphene-based transparent conductive film electrode as well as preparation method and application thereof

A transparent conductive film, graphene-based technology, applied in the field of electrodes, can solve the problems of introducing defects, wrinkles, reducing photoelectric performance, low light transmittance, etc., achieving good mechanical flexibility and stability, overcoming poor mechanical stability, guaranteeing The effect of optoelectronic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

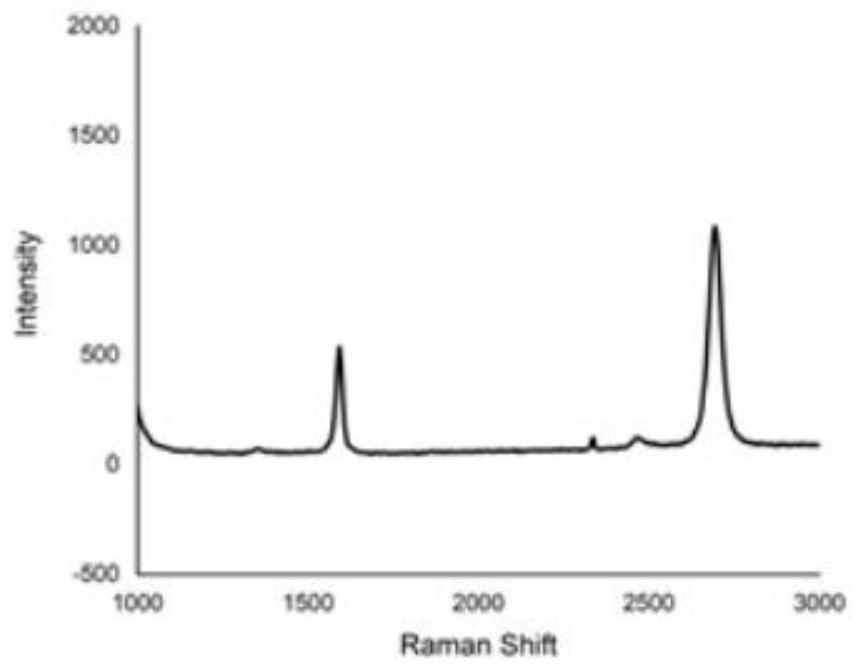

Image

Examples

preparation example Construction

[0036] The present invention also provides a method for preparing a graphene-based transparent conductive film electrode described in the above technical solution, comprising the following steps:

[0037] Under the condition of protective gas-reducing gas mixture, the carbon source precursor gas is used to conduct chemical vapor deposition on one side of the copper plate to obtain a graphene-copper plate;

[0038] The copper plate surface of the graphene-copper plate is subjected to argon plasma treatment, and the graphene surface is coated with polymethyl methacrylate to obtain a graphene composite layer;

[0039] Remove the copper plate in the graphene composite layer to obtain a polymethyl methacrylate-graphene layer;

[0040] Coating the silver nanowire dispersion liquid and the two-dimensional layered structure compound dispersion liquid sequentially on one side of the transparent substrate to obtain the primary electrode;

[0041] The two-dimensional layered structure c...

Embodiment 1

[0079] The copper plate was cleaned successively in acetone, ethanol and deionized water under the condition of ultrasonic power of 30W for 3min to remove surface impurities and organic matter. Subsequently immerse it in hydrochloric acid with a mass concentration of 10% for 2 min, then carry out electrochemical polishing for 70 s under a voltage of 7 V and a current of 1 A (the polishing solution includes deionized water, absolute ethanol, orthophosphoric acid, isopropanol and Urea, wherein the volume ratio of deionized water, absolute ethanol, orthophosphoric acid, and isopropanol is 10:5:5:1, and the ratio of the volume of isopropanol to the mass of urea is preferably 1mL:1.8g), and then Sonicate in acetone and ethanol for 2 minutes respectively, and finally immerse in deionized water several times for rinsing, and blow dry with nitrogen;

[0080] Put the pretreated copper plate on the quartz boat, put it into the high-temperature reaction furnace, turn on the mechanical pu...

Embodiment 2

[0092] The copper plate was cleaned successively in acetone, ethanol and deionized water under the condition of ultrasonic power of 30W for 3min to remove surface impurities and organic matter. Subsequently immerse it in hydrochloric acid with a mass concentration of 10% for 2 min, then carry out electrochemical polishing for 70 s under a voltage of 7 V and a current of 1 A (the polishing solution includes deionized water, absolute ethanol, orthophosphoric acid, isopropanol and Urea, wherein the volume ratio of deionized water, absolute ethanol, orthophosphoric acid, and isopropanol is 10:5:5:1, and the ratio of the volume of isopropanol to the mass of urea is preferably 1mL:1.8g), and then Sonicate in acetone and ethanol for 2 minutes respectively, and finally immerse in deionized water several times for rinsing, and blow dry with nitrogen;

[0093] Put the pretreated copper plate on the quartz boat, put it into the high-temperature reaction furnace, turn on the mechanical pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com