Weather-resistant anti-corrosion polyester powder coating containing glass fiber and clay minerals

A technology of glass fiber powder and clay minerals, which is applied in the field of anti-corrosion coatings and polymers with high weather resistance. It can solve the problems of endangering the normal operation of key motor parts of the inner layer materials, easy to be damaged, and short life, and achieve excellent chemical resistance. Good corrosion performance, electrical performance, heat resistance, and improved scrubbing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

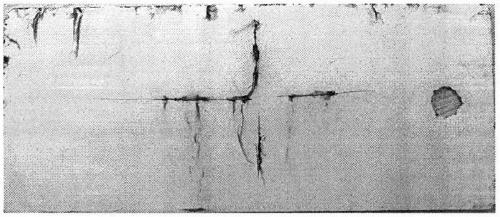

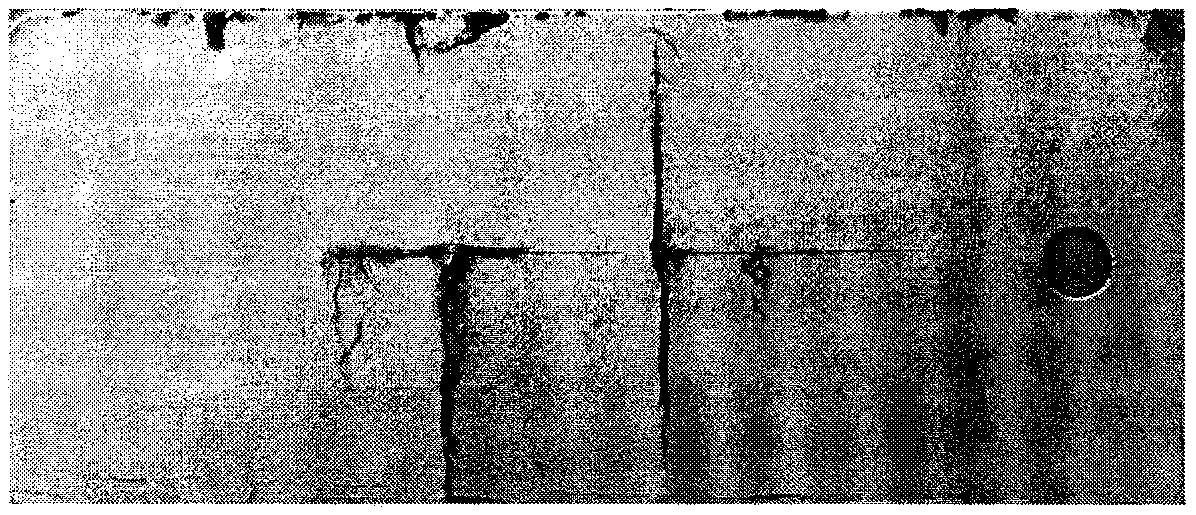

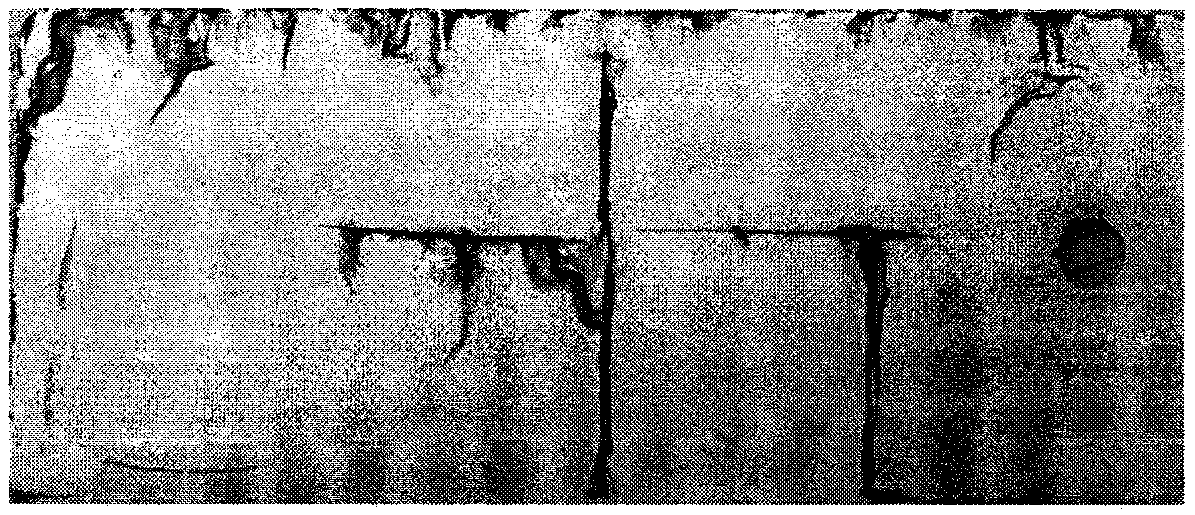

Image

Examples

Embodiment 1

[0029] A highly weather-resistant and anti-corrosion polyester / TGIC powder coating with glass fibers and clay minerals as fillers, characterized in that the preparation method comprises the following steps:

[0030] 1), ingredients pre-mixed

[0031] Premix the components in the following proportions:

[0032] Carboxyl-terminated polyester (new Chinese method P9335ATG) 370 parts

[0033] GMA type acrylic resin (Guangzhou Kebei Nuo Chemical Technology Co., Ltd. Almatex PD7610) 12 parts

[0034] 196# unsaturated polyester resin (Xinyang Technology Group) 20 parts

[0035] 0.2 parts by weight of tert-butyl peroxybenzoate

[0036] Triglycidyl isocyanurate (TGIC) 16 parts

[0037] 0.5 parts by weight of 2-methylimidazole

[0038] Titanium dioxide 100 parts

[0039] Leveling agent 6 parts

[0040] Benzoin 1.5 parts

[0041] 701B 4 copies

[0042] Polyethylene wax (Nanjing Tianshi New Material Technology Co., Ltd.) 10 parts

[0043] Barium sulfate 60 parts

[0044] 1 part ...

Embodiment 2

[0059] A highly weather-resistant and anti-corrosion polyester powder coating with glass fibers and clay minerals as fillers, characterized in that the preparation method comprises the following steps:

[0060] 1), ingredients pre-mixed

[0061] Premix the components in the following proportions:

[0062] Carboxyl-terminated polyester (new Chinese method P9335ATG) 370 parts

[0063] GMA type acrylic resin (Guangzhou Kebei Nuo Chemical Technology Co., Ltd. Almatex PD7610) 10 parts

[0064] 196# unsaturated polyester resin (Xinyang Technology Group) 20 parts

[0065] 0.3 parts by weight of tert-butyl peroxybenzoate

[0066] Triglycidyl isocyanurate (TGIC) 16 parts

[0067] 0.5 parts by weight of zinc acetylacetonate

[0068] Titanium dioxide 100 parts

[0069] Leveling agent 6 parts

[0070] Benzoin 1.5 parts

[0071] 701B 4 copies

[0072] Polyethylene wax (Nanjing Tianshi New Material Technology Co., Ltd.) 15 parts

[0073] Barium sulfate 55 parts

[0074] Glass fiber...

Embodiment 3

[0089] A highly weather-resistant and anti-corrosion polyester powder coating with glass fibers and clay minerals as fillers, characterized in that the preparation method comprises the following steps:

[0090] 1), ingredients pre-mixed

[0091] Premix the components in the following proportions:

[0092] Carboxyl-terminated polyester (new Chinese method P9335ATG) 370 parts

[0093] GMA type acrylic resin (Guangzhou Kebei Nuo Chemical Technology Co., Ltd. Almatex PD7610) 10 parts

[0094] 196# unsaturated polyester resin (Xinyang Technology Group) 20 parts

[0095] 0.3 parts by weight of tert-butyl peroxybenzoate

[0096] Triglycidyl isocyanurate (TGIC) 16 parts

[0097] Tetrabutylammonium bromide 0.5 parts by weight

[0098] Titanium dioxide 100 parts

[0099] Leveling agent 6 parts

[0100] Benzoin 1.5 parts

[0101] 701B 4 copies

[0102] Polyethylene wax (Nanjing Tianshi New Material Technology Co., Ltd.) 5 parts

[0103] Barium sulfate 65 parts

[0104] 1 part ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com