Synthetic rubber seal ring material and preparation method thereof

A synthetic rubber and sealing ring technology, applied in the field of rubber materials, can solve problems such as short life, no long-term reliable products, and lower customer loyalty, achieve super wear resistance, avoid frequent replacement, and save resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

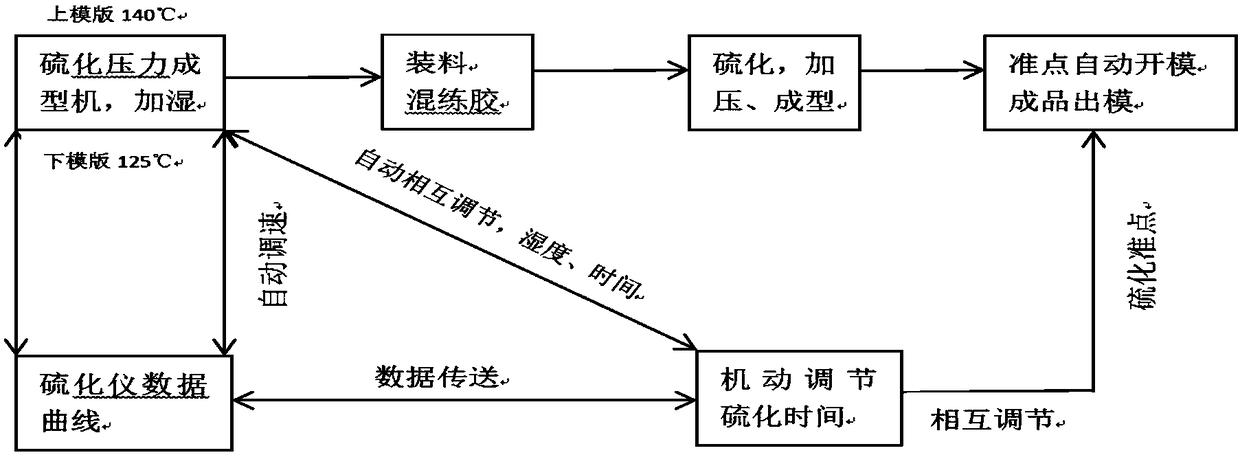

Method used

Image

Examples

Embodiment 1

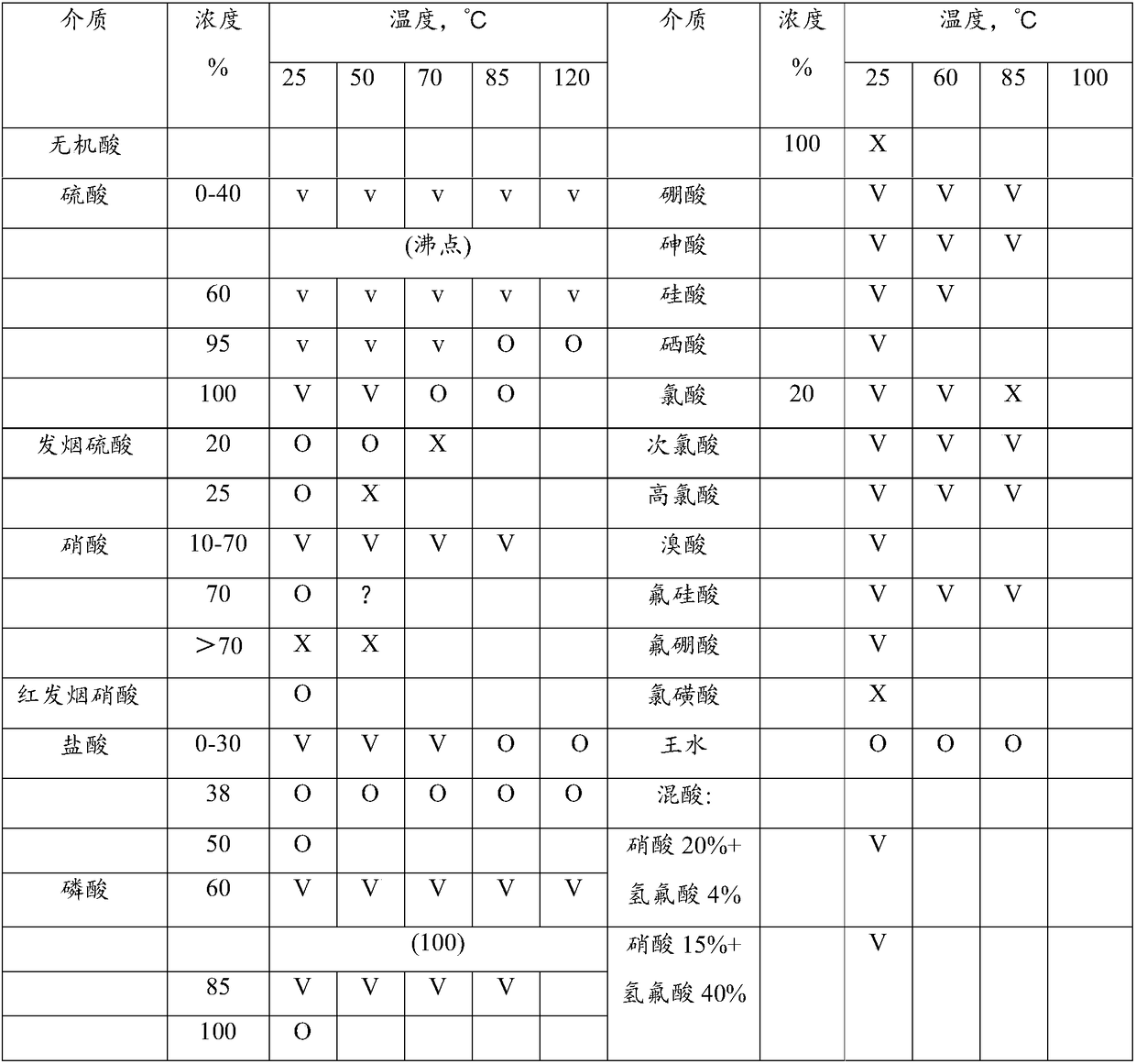

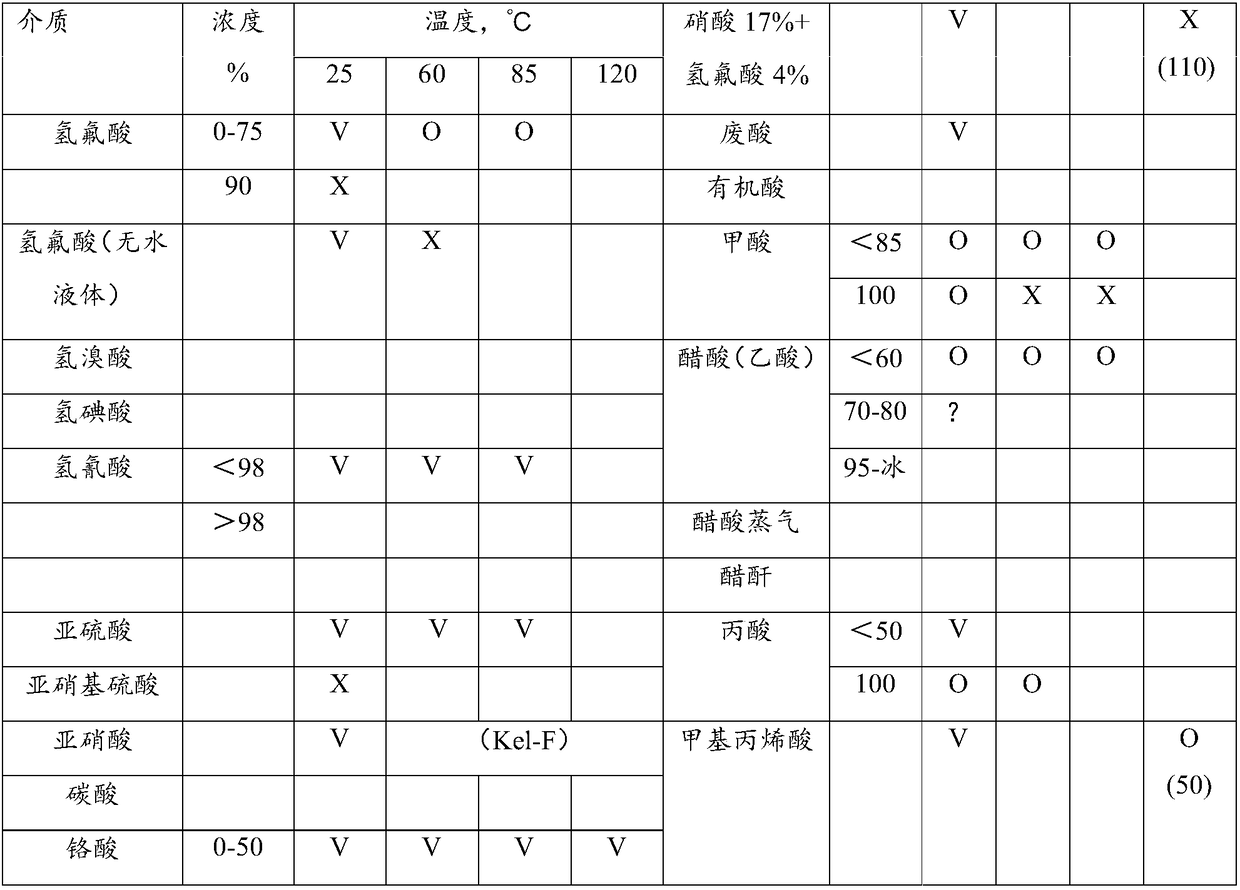

[0024] A synthetic rubber sealing ring material, mainly including the following components and their parts by weight: fluorine rubber 10, 3F fluorine rubber 10, bisphenol AF 0.1, N,N'-biscinnamaldehyde acetal-1,6-hexamethylenediamine 0.1 , Accelerator BPP0.1, Magnesium Oxide 1, Calcium Hydroxide 1, Barium Sulfate 1, Calcined Diatomite 1, Tetrafluoro Micropowder TP300 1, Organosiloxane Component / Inert Filler (75% / 25%) 0.1 , Palm wax 0.1, Luo green powder 1, iron green powder 0.1, fluorine rubber polymer 0.1. The molecular formula of bisphenol AF is C 15 h 10 f 6 o 2 ; The Chinese name of the accelerator BPP is benzyl triphenylphosphine chloride. The performance of barium sulfate is shown in Table 1, the average particle size is 5.5um; the whiteness is 91.5, and the false specific gravity is 0.42. The calcined diatomite is shown in Table 2, choose FP3.

[0025] The preparation method mainly includes:

[0026] (1) Take each component in proportion;

[0027] (2) Pre-mix fl...

Embodiment 2

[0032] A synthetic rubber sealing ring material, mainly including the following components and their parts by weight: fluorine rubber 100, 3F fluorine rubber 100, bisphenol AF 100, N,N'-biscinnamaldehyde acetal-1,6-hexamethylenediamine 5 , Accelerator BPP5, Magnesium Oxide 50, Calcium Hydroxide 50, Barium Sulfate 30, Calcined Diatomite 100, PTFE Micropowder TP30030, Organosiloxane Component / Inert Filler (75% / 25%) 5, Beauty Brown Wax 5, Luo green powder 30, iron green powder 20, fluororubber polymer 10.

[0033] The molecular formula of bisphenol AF is C 15 h 10 f 6 o 2 ; The Chinese name of the accelerator BPP is benzyl triphenylphosphine chloride. The performance of barium sulfate is shown in Table 1, the average particle size is 5.5um; the whiteness is 91.5, and the false specific gravity is 0.42. The calcined diatomite is shown in Table 2, choose FP22.

[0034] The preparation method mainly includes:

[0035] 1) take each component in proportion;

[0036] (2) Pre-mi...

Embodiment 3

[0041]A synthetic rubber sealing ring material, mainly including the following components and their parts by weight: Fluorine rubber 100, 3F Fluorine rubber 10, bisphenol AF 100, N,N'-biscinnamaldehyde acetal-1,6-hexamethylenediamine 0.1 , Accelerator BPP5, Magnesium Oxide 1, Calcium Hydroxide 50, Barium Sulfate 30, Calcined Diatomite 100, Tetrafluoro Micropowder TP3001, Organosiloxane Component / Inert Filler (75% / 25%) 0.1, Beauty Brown Wax 5, Luo green powder 30, iron green powder 0.1, fluorine rubber polymer 10.

[0042] The molecular formula of bisphenol AF is C 15 h 10 f 6 o 2 ; The Chinese name of the accelerator BPP is benzyl triphenylphosphine chloride. The performance of barium sulfate is shown in Table 1, the average particle size is 5.5um; the whiteness is 91.5, and the false specific gravity is 0.42. The calcined diatomite is shown in Table 2, choose FP4.

[0043] The preparation method mainly includes:

[0044] 1) take each component in proportion;

[0045] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com