Preparation method of wear-resistant corrosion-resistant coating

A corrosion-resistant and coating technology, applied in the field of coatings, can solve the problems of insignificant wear-resistant and corrosion-resistant properties, difficulty in controlling the thickness of the nano-metal layer, and mismatched thermal expansion coefficients, so as to improve the gas-liquid transmission efficiency and reduce cathodic stripping. Destruction, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing a wear-resistant and corrosion-resistant coating, which is made of the following raw materials in weight percentages:

[0027] E12 epoxy resin 60%, filler nano-microcrystalline stone 26%, fluorocarbon anti-shrinkage leveling agent 3%, curing agent quinazine 5%, coupling agent isobutyltriethoxysilane 3% and modifier nano-carbon fiber 3%.

[0028] Among them, the nano-microcrystalline stone powder is dried in a dryer at 60-70°C for 12 hours before use, and then ball-milled for 30 minutes with a ball mill before use. Then mix and grind the above components in a superfine powder ball mill in proportion to ensure that the final particle size is above 1200 mesh.

Embodiment 2

[0030] A method for preparing a wear-resistant and corrosion-resistant coating, which is made of the following raw materials in weight percentages:

[0031] E12 epoxy resin 55%, filler nano-microcrystalline stone 32%, fluorocarbon anti-shrinkage leveling agent 3%, curing agent quinazine 5%, coupling agent isobutyltriethoxysilane 2% and modifier nano-carbon fiber , graphene or carbon nanotubes 3%.

[0032] Among them, the nano-microcrystalline stone powder is dried in a dryer at 60-70°C for 12 hours before use, and then ball-milled for 30 minutes with a ball mill before use. Then mix and grind the above components in a superfine powder ball mill in proportion to ensure that the final particle size is above 1200 mesh.

Embodiment 3

[0034] A method for preparing a wear-resistant and corrosion-resistant coating, which is made of the following raw materials in weight percentages:

[0035] E12 epoxy resin 50%, filler nano-microcrystalline stone 37%, fluorocarbon anti-shrinkage leveling agent 3%, curing agent quinazine 5%, coupling agent isobutyltriethoxysilane 2% and modifier nano-carbon fiber 3%.

[0036] Among them, the nano-microcrystalline stone powder is dried in a dryer at 60-70°C for 12 hours before use, and then ball-milled for 30 minutes with a ball mill before use. Then mix and grind the above components in a superfine powder ball mill in proportion to ensure that the final particle size is above 1200 mesh.

[0037] According to the above-mentioned embodiment method, the filler is replaced by nano-sepiolite and nano-ceramic powder, each of 3 embodiments; then the above 9 are processed in batches, and the modifier is replaced by graphene and carbon nanotubes, each of the embodiments 9.

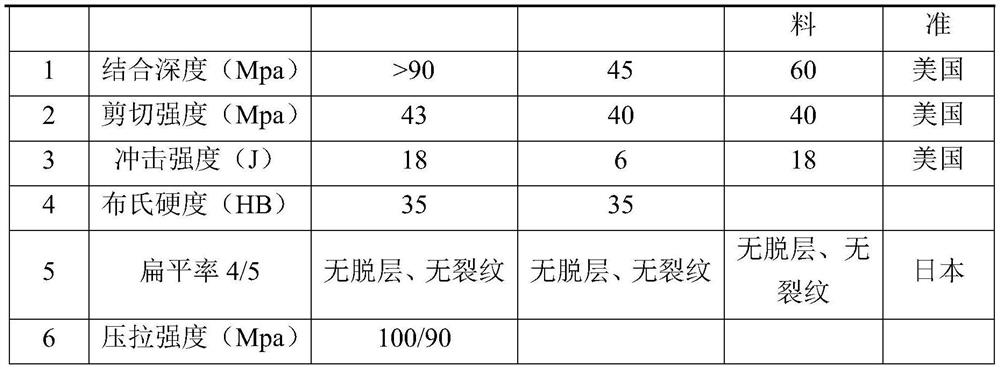

[0038] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com