Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Simplify the polishing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

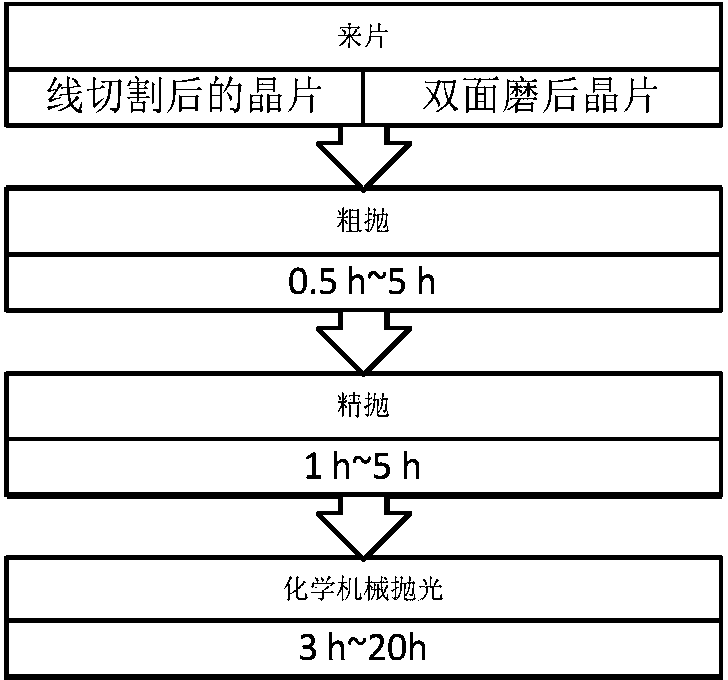

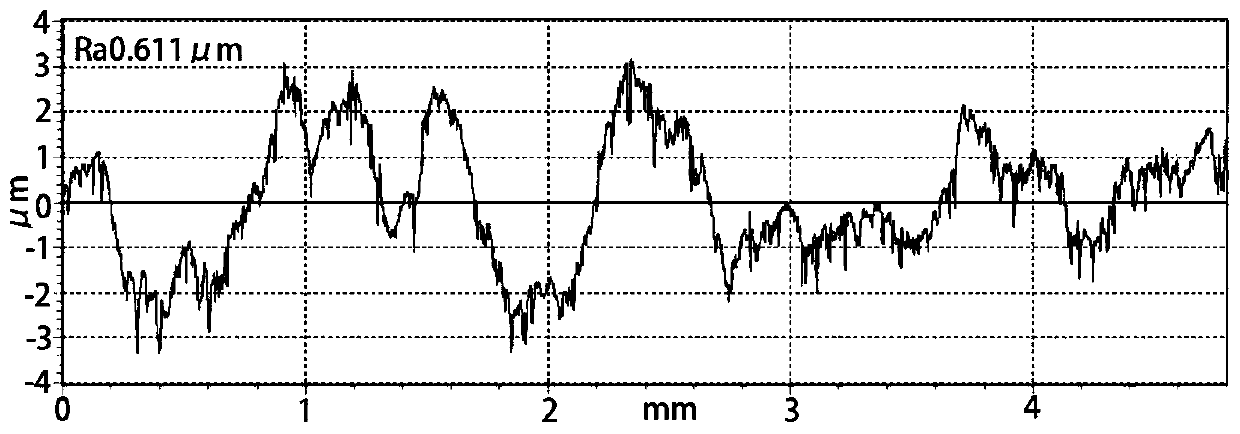

Super-hard semiconductor material polishing method

ActiveCN103506928ASimplify the polishing processKeep shapePolishing machinesSemiconductor/solid-state device manufacturingSuperhard materialSemiconductor materials

The invention relates to a super-hard semiconductor material polishing method. According to the method, a machined super-hard semiconductor material can be extremely low in surface roughness and have an atomic stepped surface through three polishing process flows with very approximate parameters, including rough polishing, fine polishing and chemico-mechanical polishing. Due to the fact that only the three processes are used, the method simplifies the super-hard material polishing flows greatly, lowers cost, guarantees the consistency and stability of machining quality and improves the rate of finished products.

Owner:安徽微芯长江半导体材料有限公司

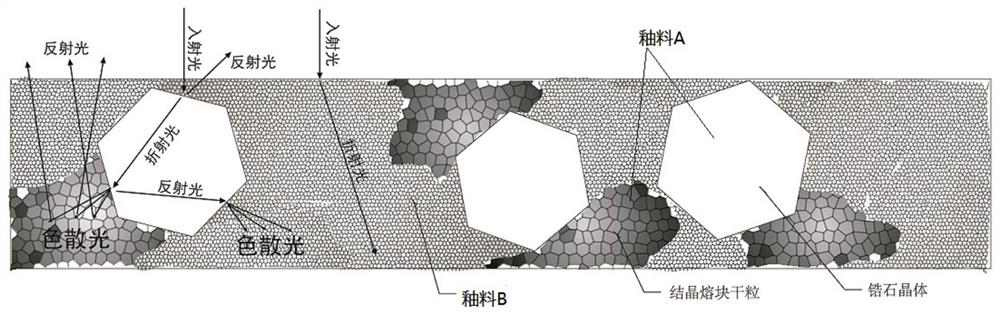

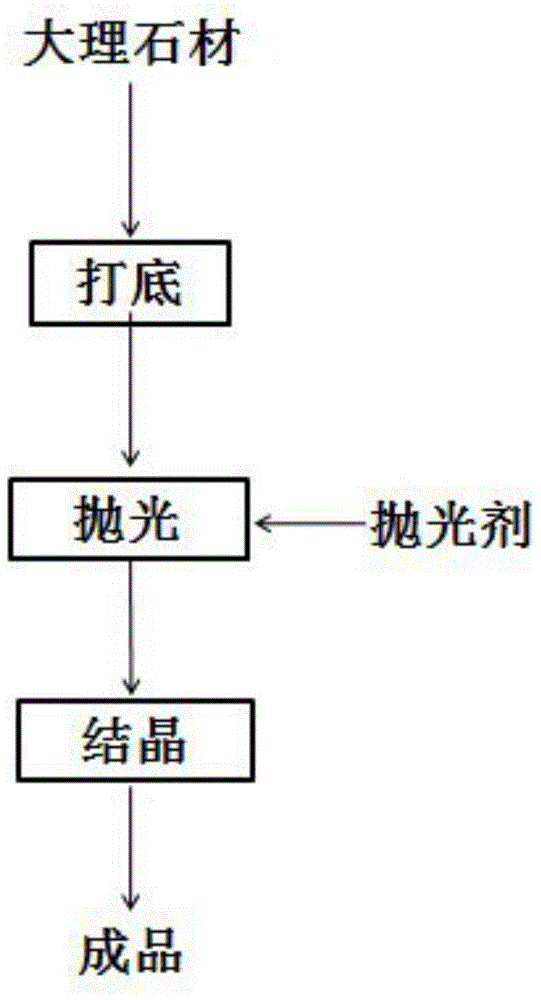

Preparation method of polished porcelain glazed tile with flashing effect

InactiveCN111923193AGood flash effectSimplify the polishing processCovering/liningsCeramic shaping apparatusGreen bodyKiln

The invention discloses a preparation method of a polished porcelain glazed tile with a flashing effect. The preparation method comprises the following steps of S1, mixing high-purity zircon sand andcrystallized frit dry particles to obtain glaze A; S2, taking marble polished glaze or transparent dry granular glaze as glaze B, and mixing the glaze A and the glaze B to obtain mixed glaze; S3, preparing a porcelain tile green body, and drying the porcelain tile green body; S4, applying a cover glaze to the porcelain tile green body dried in the step S3, performing ink-jet printing, and then sequentially applying a protective glaze and the mixed glaze; S5, drying the porcelain tile green body coated with the protective glaze and the mixed glaze in S4 in a drying kiln at 150-200 DEG C, and firing the porcelain tile green body by using a conventional porcelain tile firing method to obtain a semi-finished porcelain tile; and S6, polishing the semi-finished porcelain tile prepared in the S5.The preparation method adopts multiple reflection, dispersion and refraction methods of crystals in the glaze to realize the flashing effect, and meets the market demand.

Owner:佛山市蓝瓷创陶科技有限公司

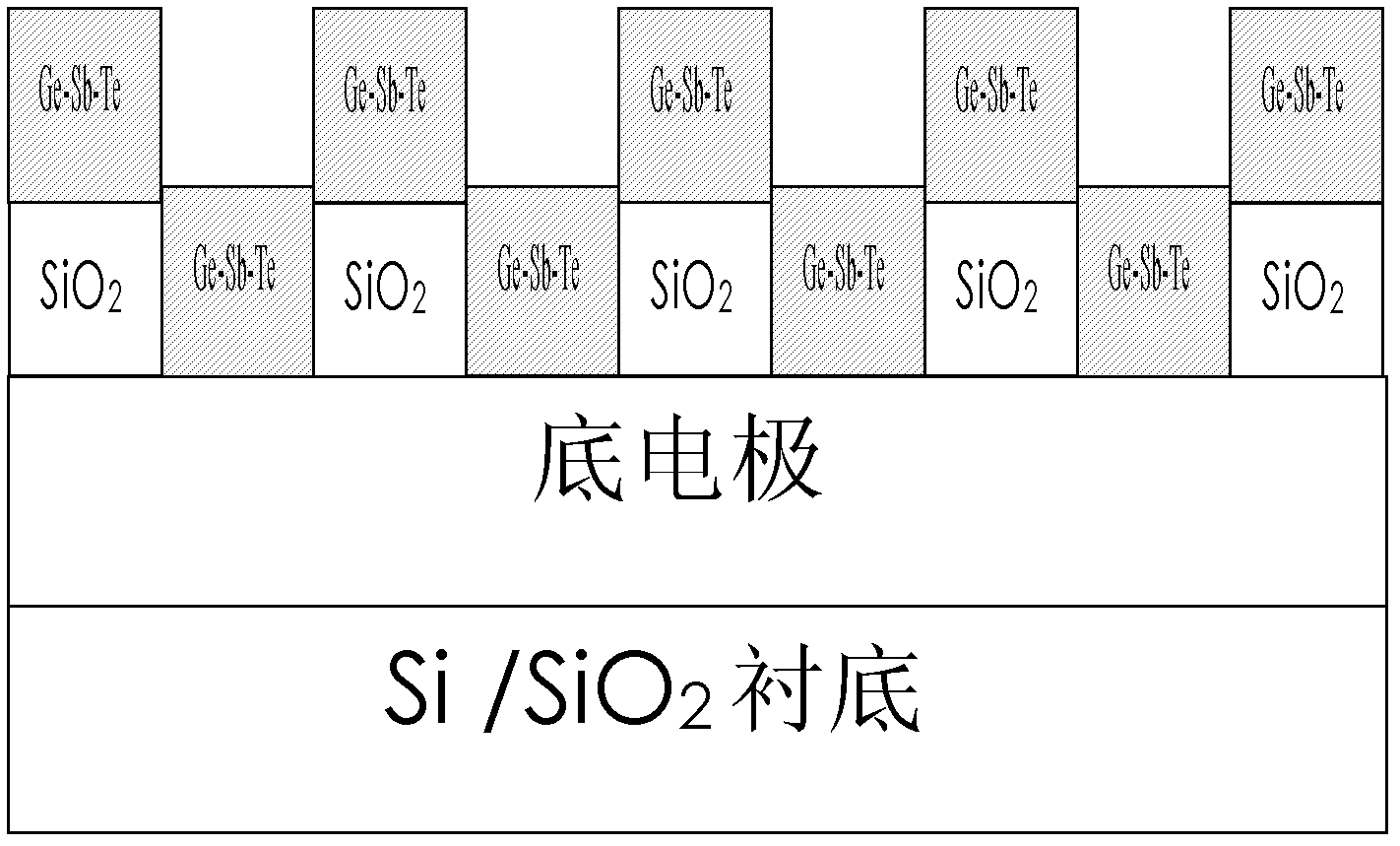

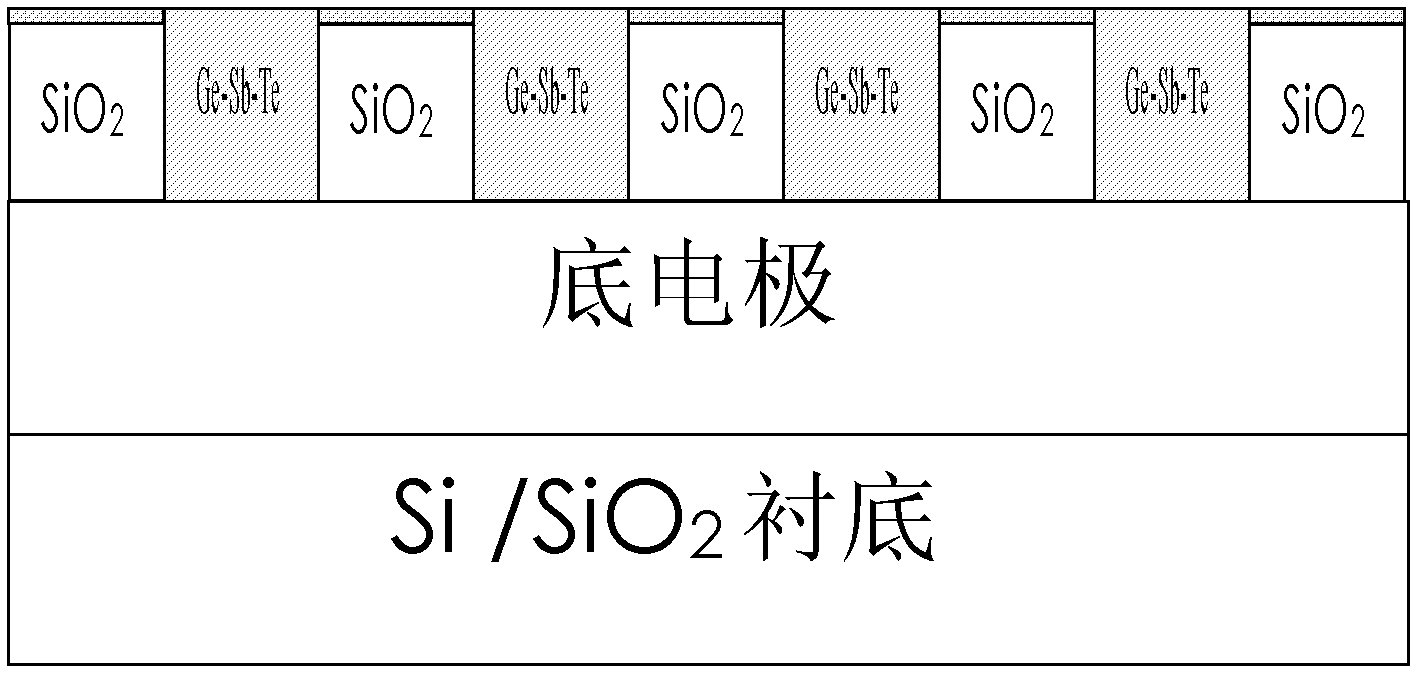

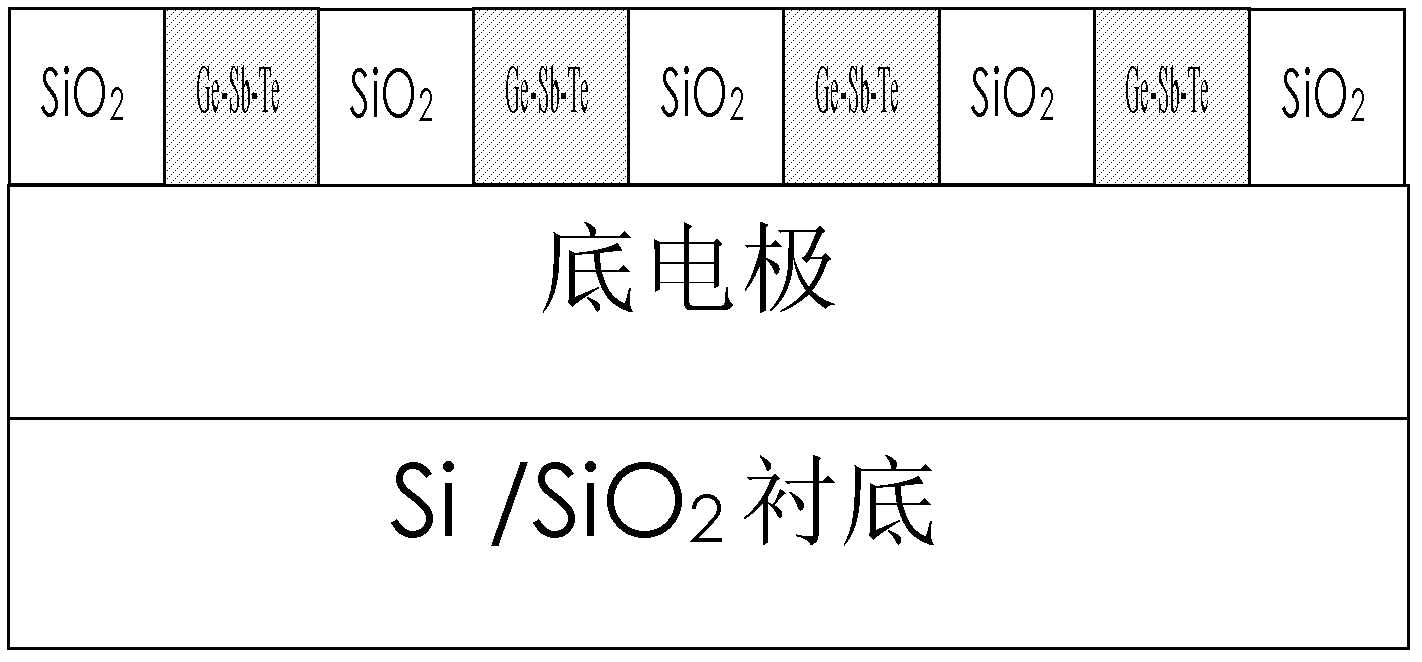

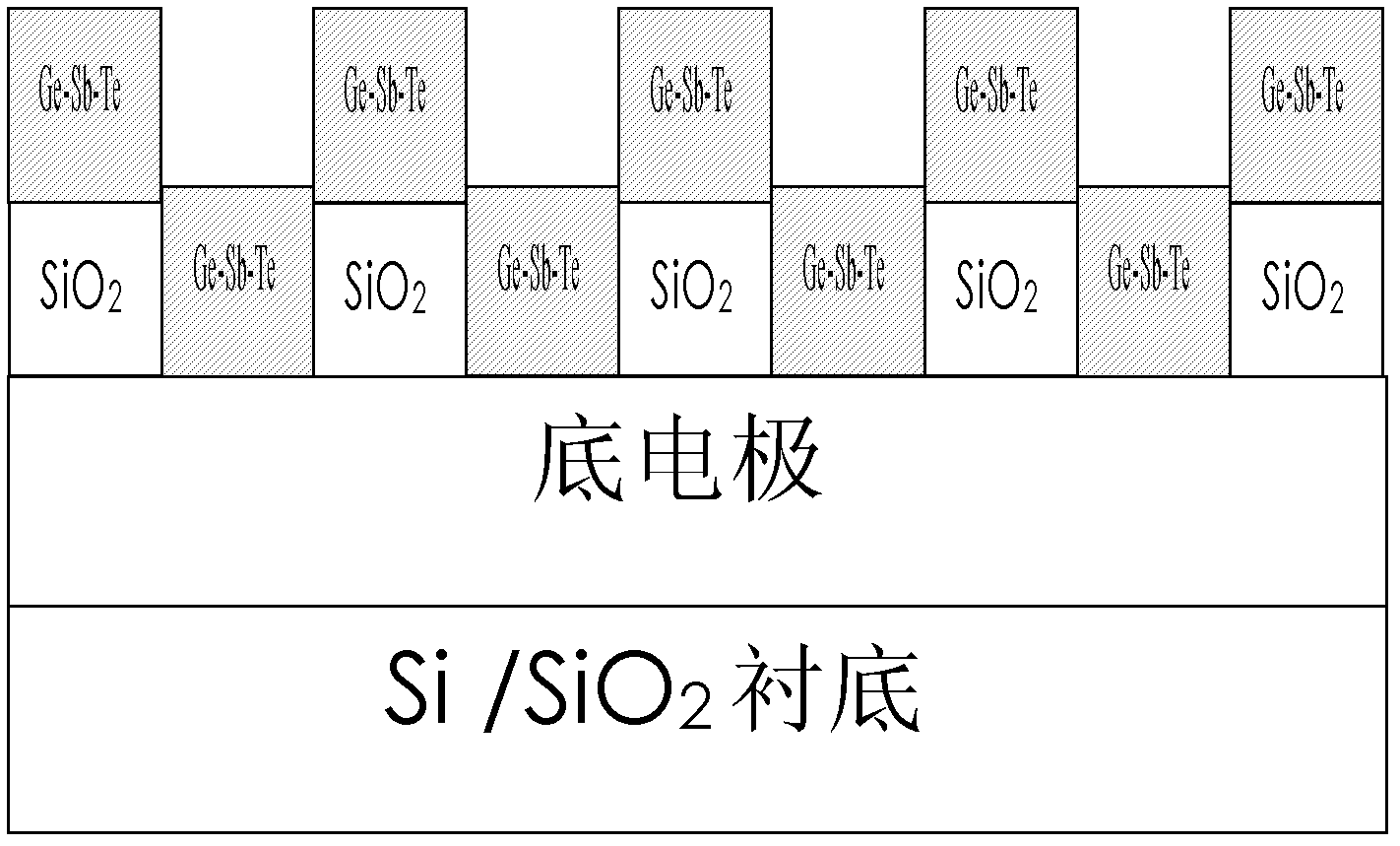

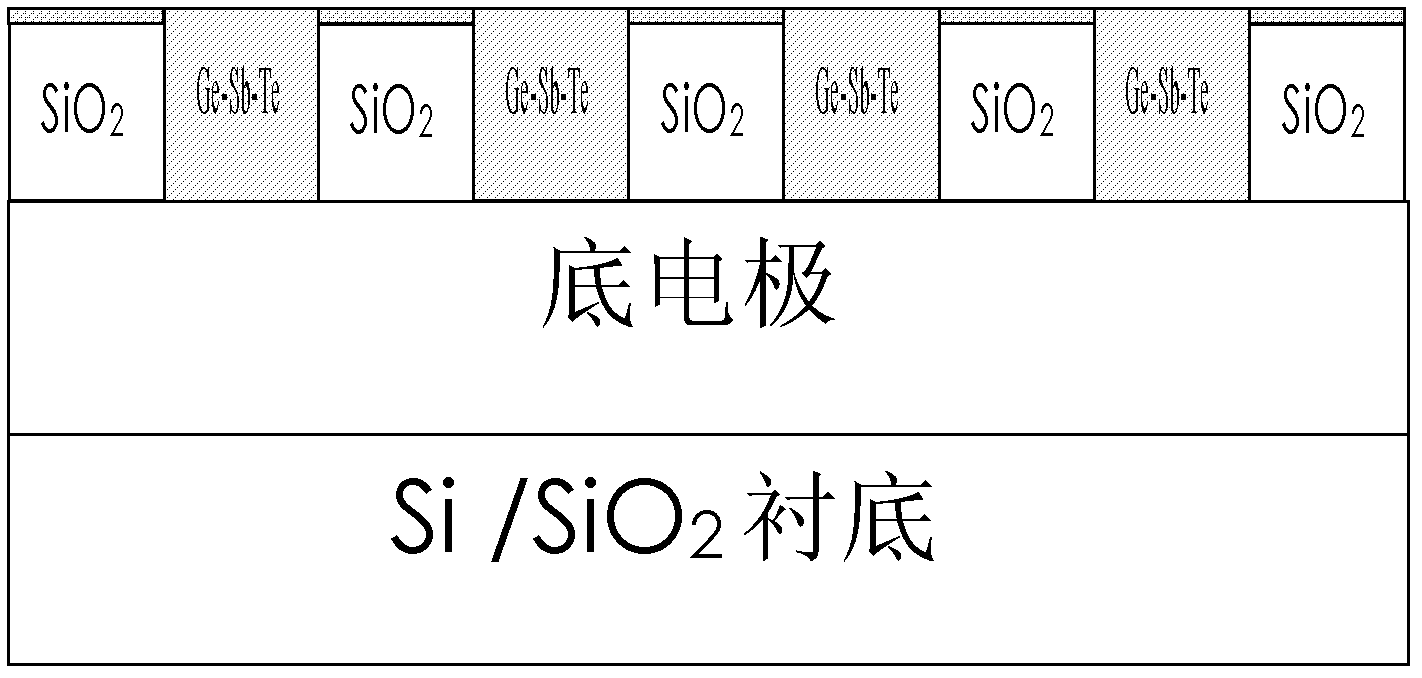

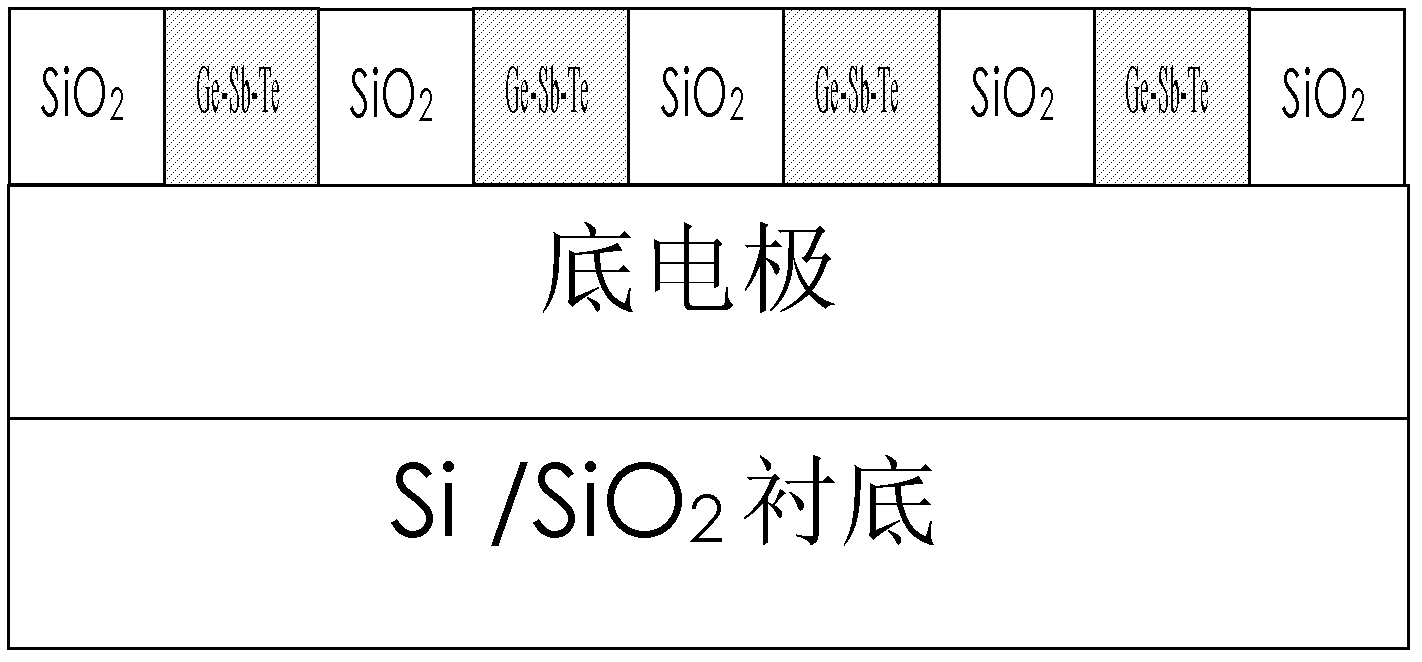

Chemical and mechanical polishing method and solution for sulfur phase-change material

ActiveCN102441819AAvoid damageEasy to cleanPolishing compositions with abrasivesPhase-change memorySulfur

A chemical and mechanical polishing method for a sulfur phase-change material comprises the following steps: 1) roughly polishing the sulfur phase-change material to quickly remove most of sulfur compound outside through holes in an inlaid structure; and 2) performing ultrafine polishing on the sulfur phase-change material which is roughly polished to remove the rest sulfur compound outside the through holes and expose a final through hole array structure. A polishing solution used in the polishing method comprises a polishing solution A for rough polishing and a polishing solution B for ultrafine polishing, and is prepared by mixing a nano grinding agent, a pH regulating agent, a surfactant, a defoaming agent, a bactericide, an assistant cleaning agent and a solvent. The chemical and mechanical polishing method for the sulfur phase-change material has the advantages of high polishing efficiency and simple and feasible process; a polished surface is smooth and has no scratch; over polishing can be prevented well, so that the stability of the performance of a phase-change memory which is manufactured on the base of the inlaid structure and the good rate of products are improved, and the cost is reduced.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

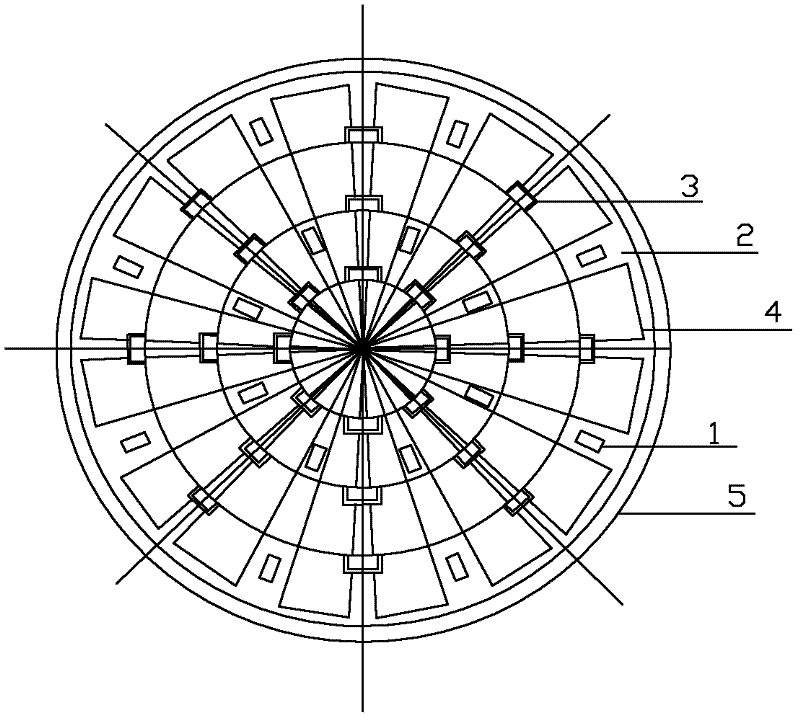

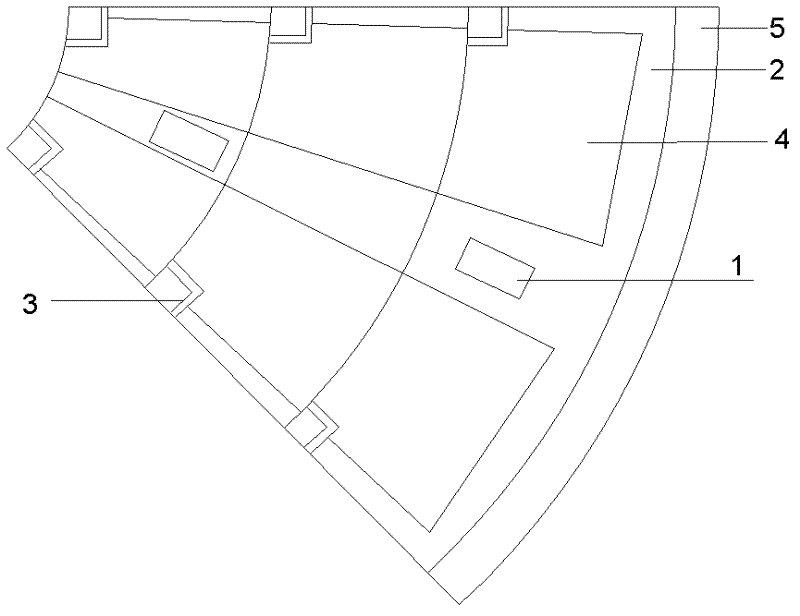

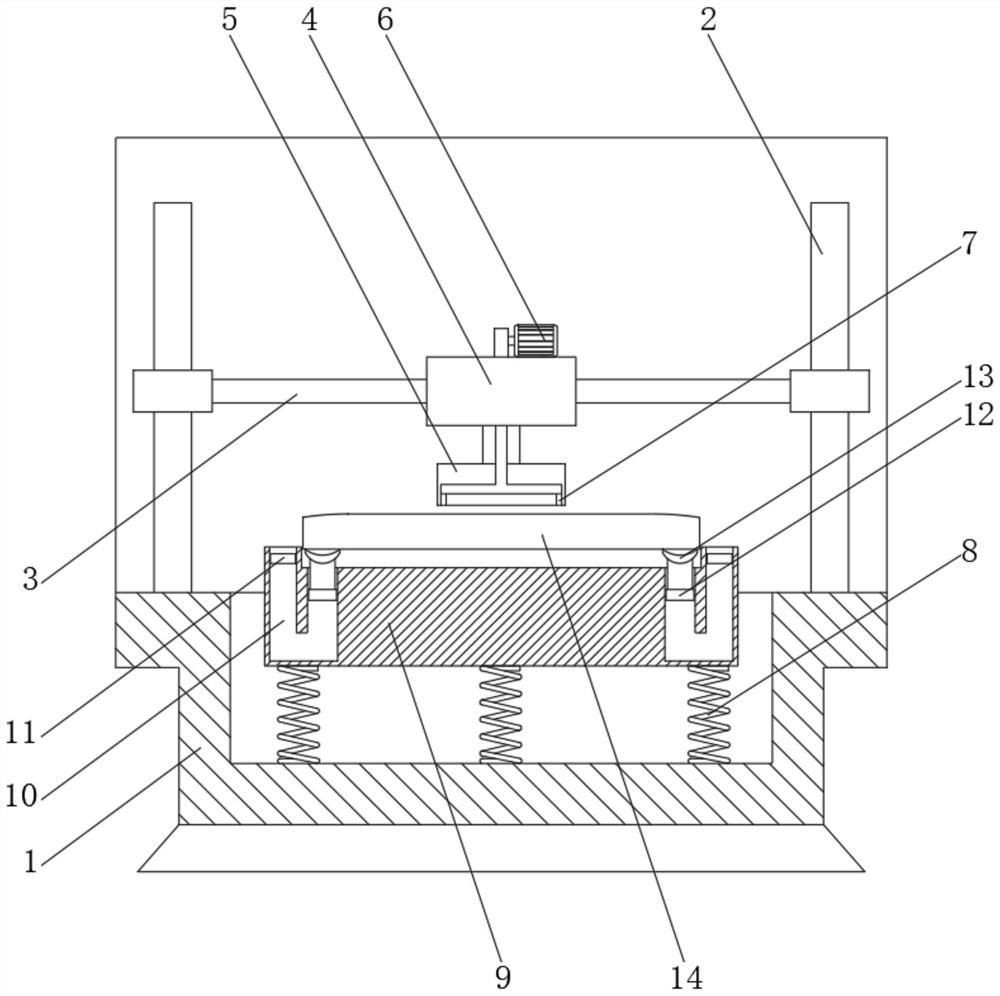

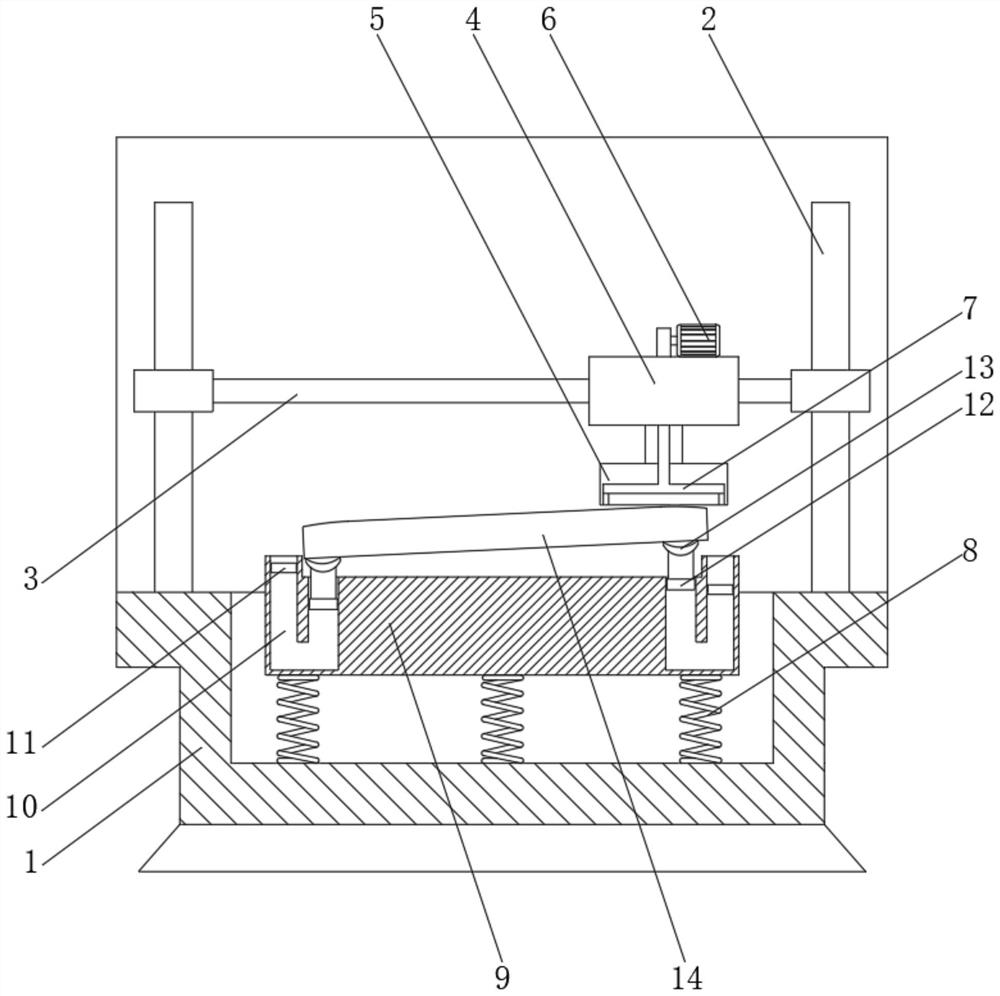

Polishing disk capable of adjusting regional pressure

InactiveCN102501187AUneven processing remains goodGuaranteed convergenceFlexible-parts wheelsLapping toolsEngineeringMechanical engineering

A polishing disk capable of adjusting regional pressure is disclosed, which relates to a mechanical polishing tool. The polishing disk capable of adjusting regional pressure is provided with a piezoelectric sensor, a polishing disk, slide block and slide groove pairs, polyurethane polishing plates and a circular chuck, wherein at least two circular rings are disposed on the polishing disk and divided into fan-shaped blocks; the slide block and slide groove pairs are disposed on the fan-shaped blocks; two polyurethane polishing plates are attached to the surface of each fan-shaped block; an inward groove for placing the piezoelectric sensor is disposed between the two polyurethane polishing plates; and the circular chuck for fixing the fan-shaped blocs is disposed on the outer edge of the polishing disk.

Owner:XIAMEN UNIV

Method for anhydrous polishing of KDP crystals

InactiveCN112139859AEasy to operateSimplify the polishing processPolishing machinesGrinding work supportsCarbide siliconMethyl oleate

The invention provides a method for anhydrous polishing of KDP crystals. High-precision and high-efficiency polishing of a KDP crystal material is realized. The anhydrous polishing process is dividedinto rough polishing and fine polishing, and a anhydrous polishing solution comprises methyl oleate, silicon carbide / aluminum oxide mixed abrasive particles and anhydrous sodium carbonate and is divided into an anhydrous rough polishing solution and an anhydrous fine polishing solution; and the difference between the anhydrous rough polishing solution and the anhydrous fine polishing solution is embodied in the viscosity of methyl oleate, the ratio, particle size and concentration of silicon carbide / aluminum oxide mixed abrasive particles, and the particle size and concentration of anhydrous sodium carbonate. Compared with other KDP crystal polishing methods, the method for anhydrous polishing of the KDP crystals has the advantages that a polishing liquid chemical reagent used in the method is non-toxic, low in harm and environmentally friendly, the phenomenon that the KDP crystals are deliquesced in contact with water to be damaged is effectively avoided in the polishing process, andthe processing quality of the surfaces of the KDP crystals is effectively improved.

Owner:DALIAN UNIV OF TECH

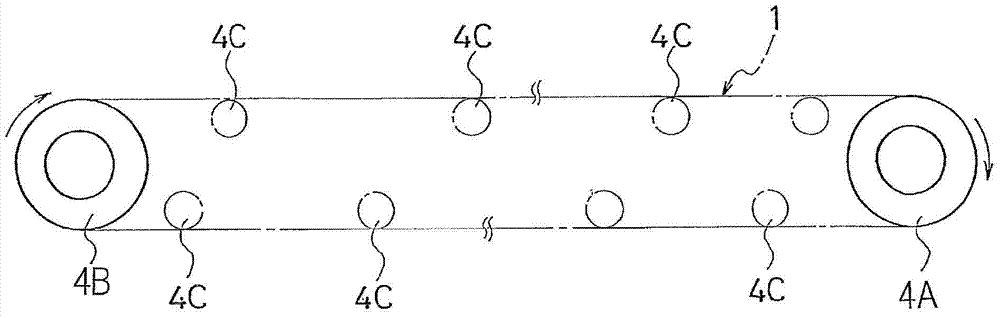

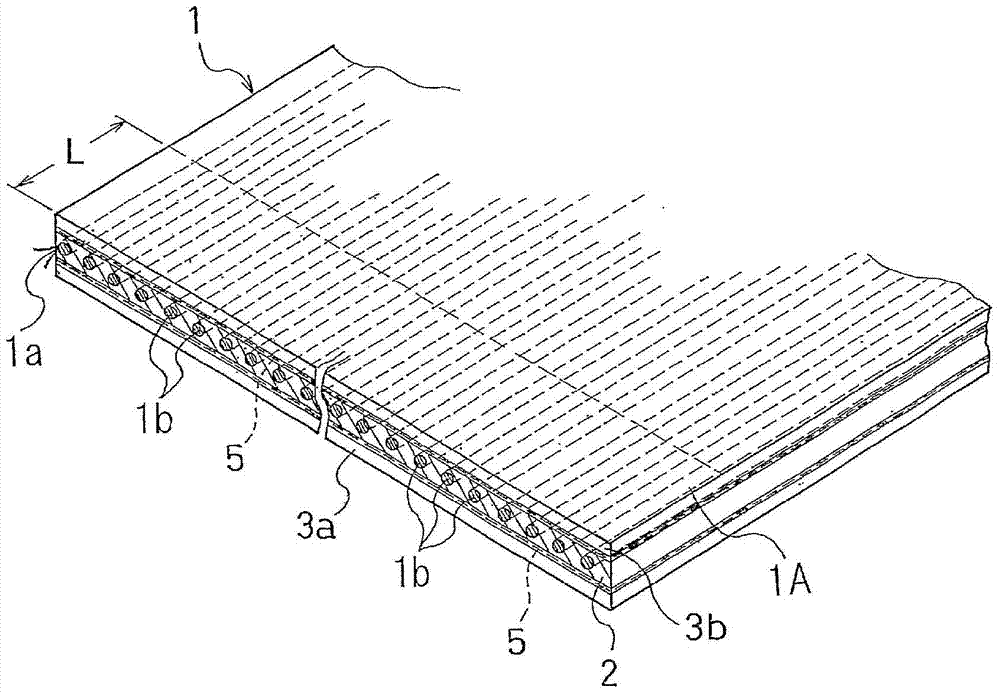

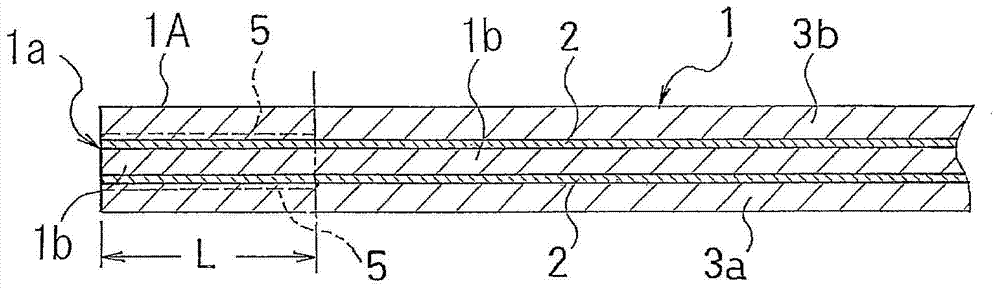

Method for joining conveyer belt

ActiveCN104520213AReduce cut-out workQuality improvementConveyorsBelt fasteningsEngineeringConveyor belt

Provided is a method that is for joining a conveyor belt having as a core layer a steel cord and that can increase the quality of the join and reduce the joining work time for the ends in the lengthwise direction of the belt. The core layer (1a) is formed in a manner so as to be exposed ahead of time at the ends (1A) in the lengthwise direction of the belt main body (1), the top of the core layer (1a) is covered by a peeling member (5), and a cover rubber (3a, 3b) is laminated to the top of the peeling member (5), in which state the belt main body (1) is vulcanized / molded; the peeling member (5) is peeled, eliminating the cover rubber (3a, 3b) laminated onto the peeling member (5) and exposing the core layer (1a); the steel cord (1b) of the core layer (1a) to which to join to is inserted into the steel cord (1b) that is of the exposed core layer (1a) and of which alternate strands in the belt width direction have been severed to a predetermined length; and after laminating a cushion rubber (2) and a cover rubber (3a, 3b), the result is vulcanized, thus joining the core layers (1a) to each other.

Owner:THE YOKOHAMA RUBBER CO LTD

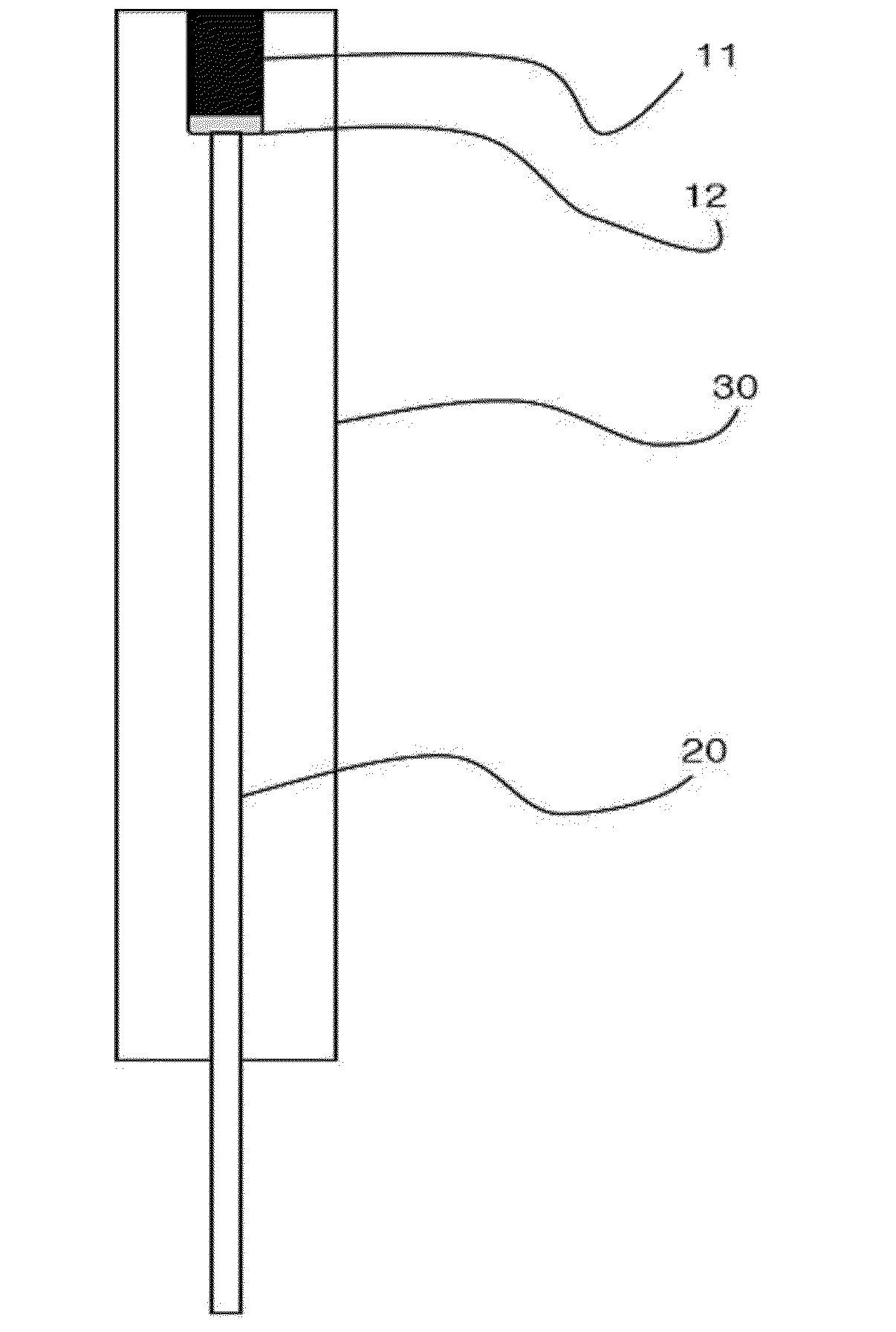

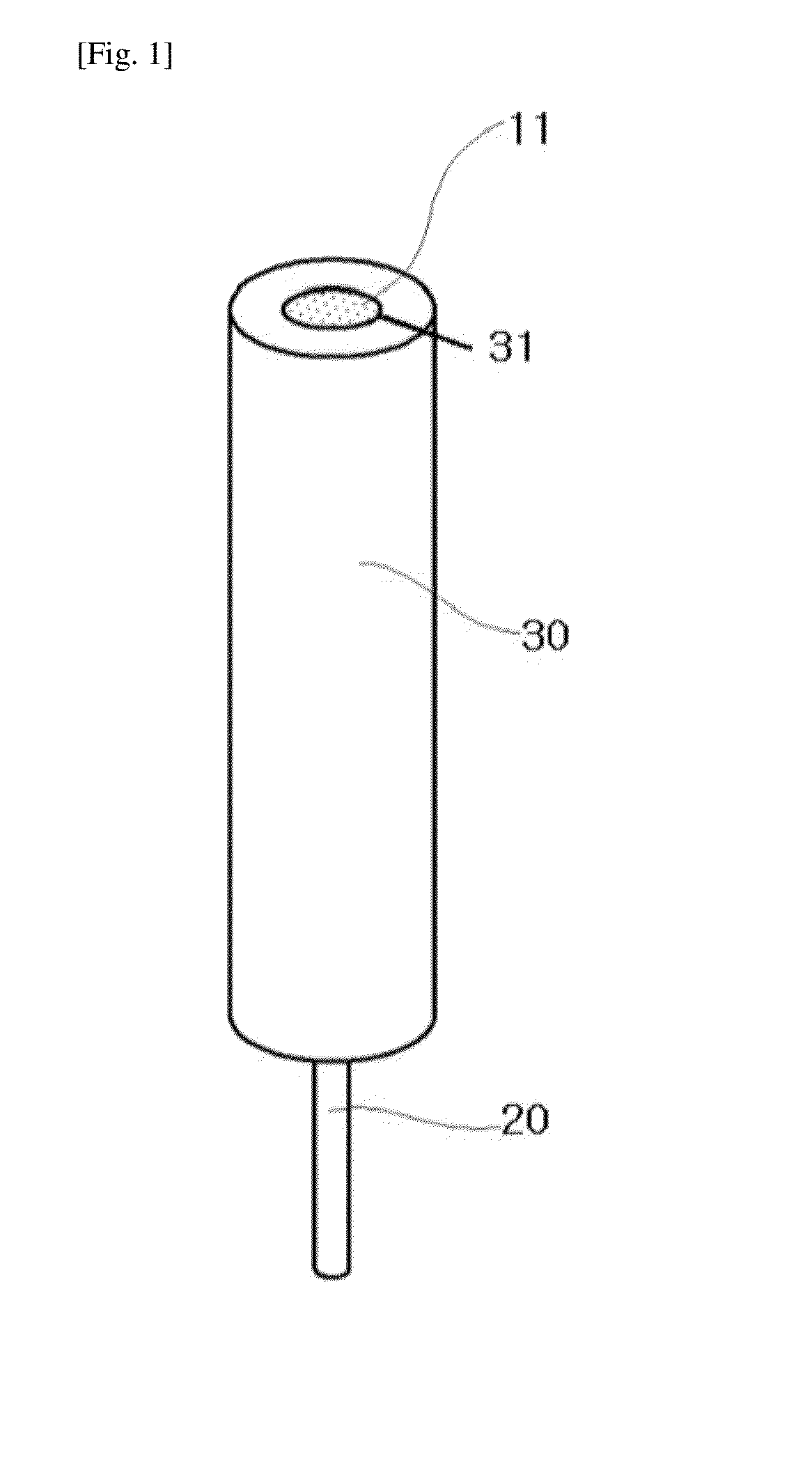

Hydrogen ion electrode composed of composite material of NANO iridium oxide and polymer resin and enabling surface regeneration, ph sensor using same, and method for manufacturing same

InactiveUS20160187281A1High reproducibilityHigh physical strengthMaterial nanotechnologyLine/current collector detailsPhysical strengthResin matrix

Provided are a hydrogen ion electrode composed of a composite material of polymer resin and nano iridium oxide, the composite material containing 1-10 nm sized nano iridium oxide particles and / or aggregates thereof which are dispersed to be electrically connected to each other in a moldable, thermoplastic, and hydrophobic polymer resin matrix; a pH sensor using the same; and a method for manufacturing the same. The surface of the hydrogen ion electrode shows very fast pH sensitivity when exposed to a sample solution, and the pH sensitivity is approximate to biphasic characteristics. Furthermore, regardless of high reproducibility of pH sensitivity, abrupt pH change, and repetitive use, very low hysteresis, durability due to high physical strength, and high surface regeneration due to polishing are exhibited, and thus, the lifetime of the electrode can be extended and various sizes and shapes of electrodes can be easily manufactured.

Owner:EZ SENSING

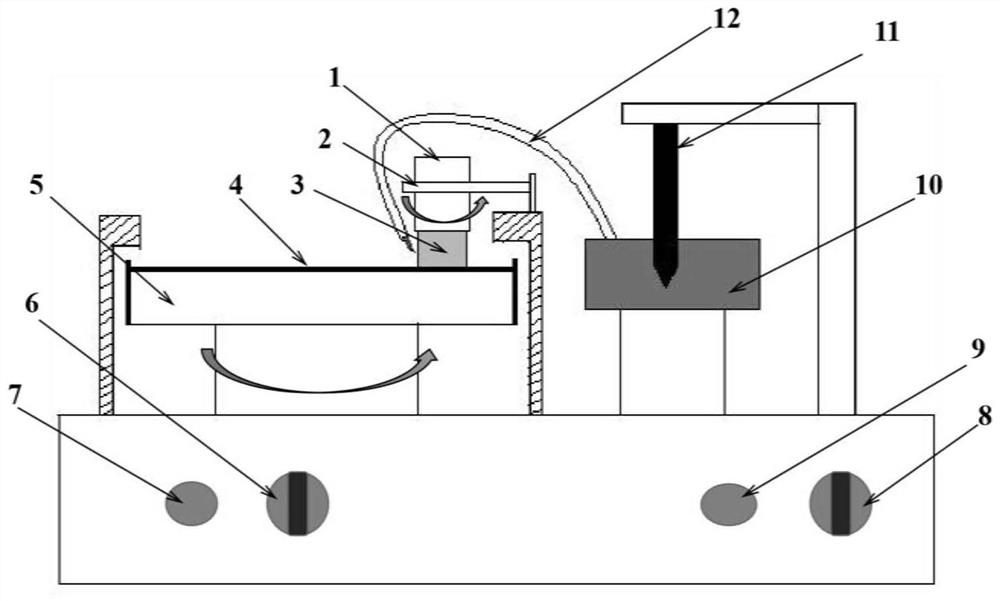

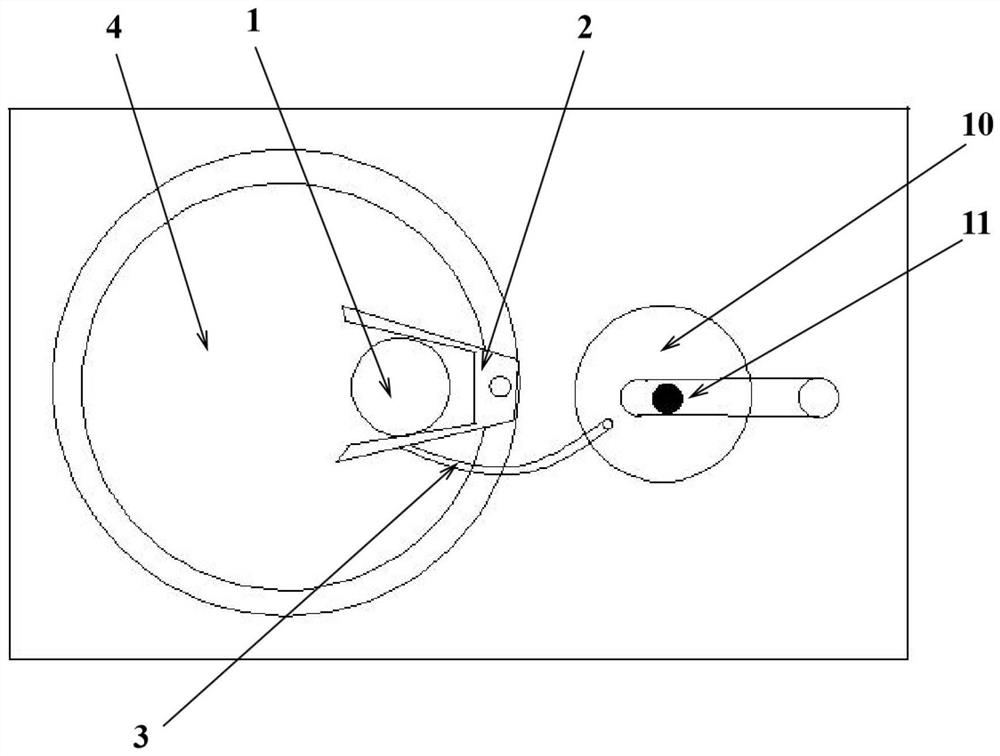

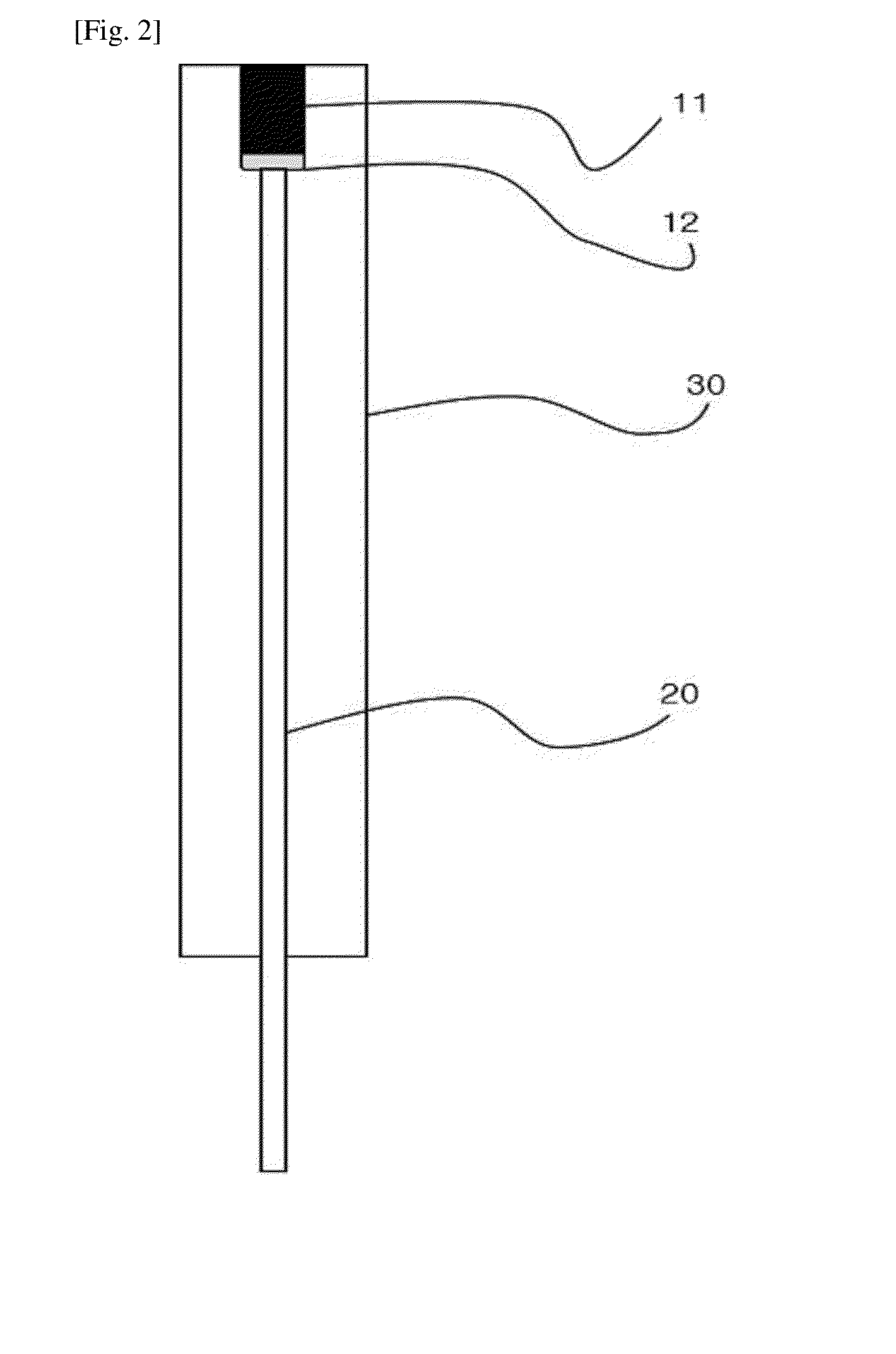

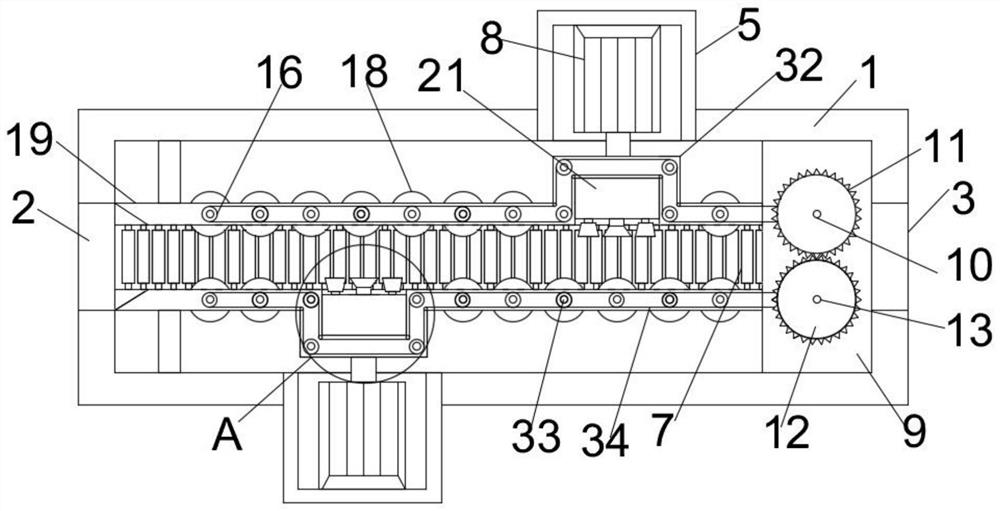

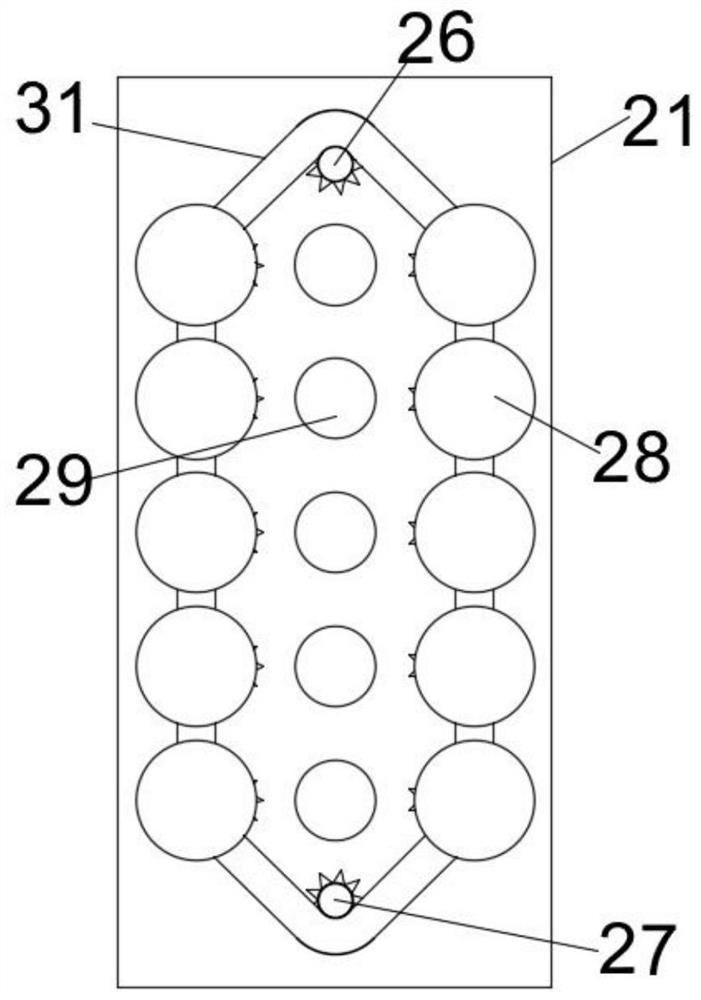

Multi-station vertical rotary abrasive flow polishing device and working method thereof

ActiveCN112497043ARealize the whole process of polishingSolve the problem of uneven polishing qualityEdge grinding machinesGrinding carriagesPolishingElectric machine

The invention discloses a multi-station vertical rotary abrasive flow polishing device and a working method thereof, and belongs to the technical field of machining. According to the multi-station vertical rotary abrasive flow polishing device, a plurality of planetary rotary discs are evenly distributed on a rotary disc assembly in the annular direction to correspond to stations of loading, unloading, rough polishing, fine polishing and the like, and a polishing motor drives a workpiece installed below the planetary rotary discs and a polishing medium evenly mixed in a charging basket to rotate relatively to achieve polishing of the workpiece, after certain procedure is finished, the rotary disc assembly drives the workpiece to enter the polishing of the next procedure, so that the whole-process polishing of the workpiece is circularly realized. A planetary rotary disc mechanism is matched with a charging basket assembly internally provided with a fixed flow guide mechanism, so that rotation and revolution of the workpiece are achieved, and the speed required by polishing is achieved; and the polishing medium rotates and overturns up and down along with the charging basket, is uniformly mixed and is prevented from settling and layering. The multi-station vertical rotary abrasive flow polishing device is provided with a plurality of stations, one-time clamping of the workpieceis achieved, multi-station and multi-procedure polishing is conducted at the same time, the polishing process is greatly simplified, and then the overall polishing efficiency is improved.

Owner:DALIAN UNIV OF TECH +1

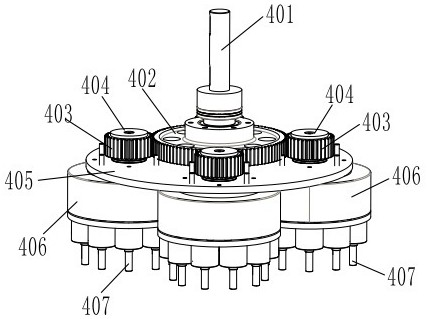

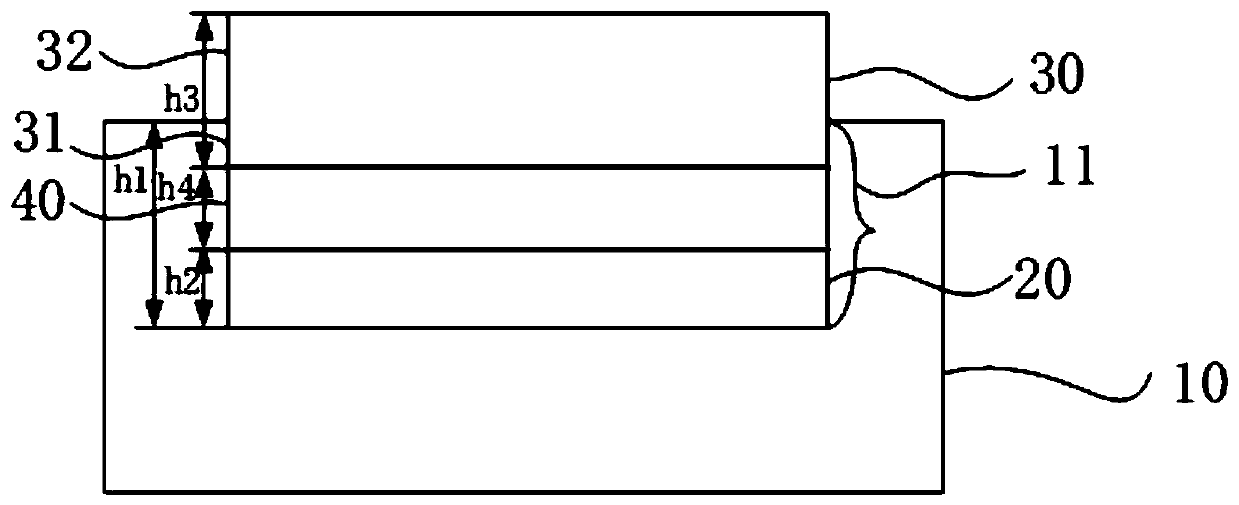

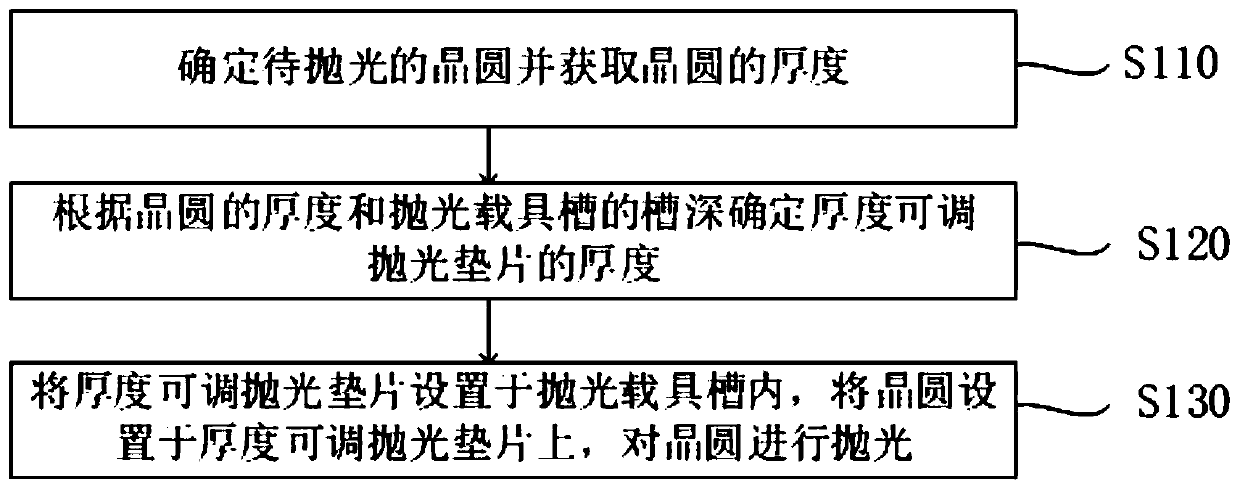

Wafer polishing device and method

InactiveCN110900438AImprove flatnessAvoid life shorteningSemiconductor/solid-state device manufacturingLapping machinesWaferPolishing

The invention discloses a wafer polishing device and method. The wafer polishing device comprises a polishing carrier and a thickness-adjustable polishing gasket, the polishing carrier comprises a polishing carrier groove, in the wafer polishing process, the thickness-adjustable polishing gasket is arranged in the polishing carrier groove, and a wafer is arranged on the thickness-adjustable polishing gasket; the groove depth h1 of the polishing carrier groove, the thickness h2 of the thickness-adjustable polishing gasket and the thickness h3 of the wafer meet the formula that h2+h3>h1. The wafer polishing device has the advantages that the service life of the wafer polishing device is prolonged, the flatness of the wafer can be improved, and the polishing process is simple and easy to implement.

Owner:SHANGHAI ADVANCED SILICON TECH CO LTD +1

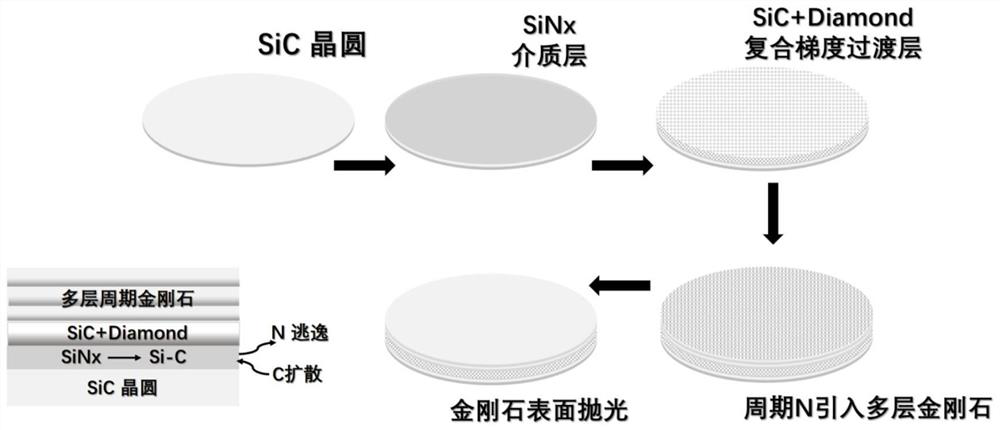

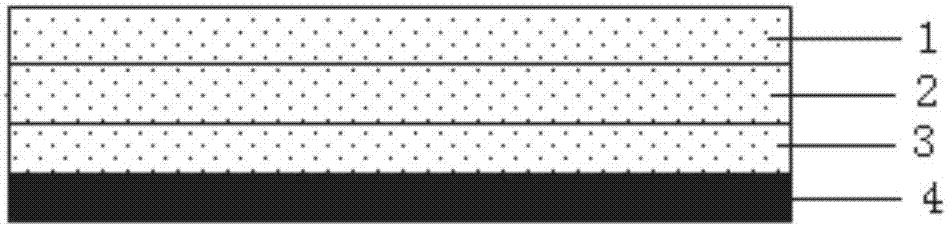

Preparation method of diamond reinforced silicon carbide composite wafer

ActiveCN114717540AAvoid process complexityImprove adhesionSolid state diffusion coatingChemical vapor deposition coatingCarbide siliconSemiconductor materials

The invention discloses a preparation method of a diamond reinforced silicon carbide (SiC) composite wafer, and belongs to the field of semiconductor material preparation. The method comprises the following steps: plating a 5-20nm SiNx thin layer on a SiC carbon polar surface subjected to vacuum heat treatment at 800-1000 DEG C; and after microwave hydrogen plasma treatment is carried out for 1-5 min, methane with the hydrogen flow proportion being 5-10% is introduced, the operation lasts for 5-15 min, and diamond high-density nucleation and C-Si bond formation are achieved based on nitrogen atom escape and carbon atom permeation. And then, silane with the hydrogen flow proportion being 0.1-1% is introduced while methane is reduced to 3%-5% for growing diamond, the silane flow is slowly reduced within 10-30 min till closing, and the SiC / diamond composite gradient transition layer is deposited. And then repeating the circulation process of introducing nitrogen with the hydrogen flow proportion of 1-5% every 5-20 min in diamond growth and keeping for 1-5 min, closing the nitrogen and methane after the diamond reaches a certain thickness, slowly cooling to 600 DEG C or below in hydrogen plasma, then raising the temperature to 800-1000 DEG C, treating for 0.5-5 h, and slowly cooling, and finally, the diamond / SiC composite wafer material with low stress and strong combination is realized by polishing the diamond surface.

Owner:广东奔朗新材料股份有限公司 +2

Solar cell silicon wafer polishing method

InactiveCN103779442AReduce weight lossImprove efficiencyFinal product manufacturePhotovoltaic energy generationTetramethylammonium hydroxideOverall efficiency

The invention relates to a solar cell silicon wafer polishing method. The method comprises the steps that PSG on the back of a silicon wafer after phosphorus diffusion is removed; the silicon wafer is immersed in a tetramethylammonium hydroxide polishing agent; and polishing is carried out on the back of the silicon wafer. The method provided by the invention has the advantages that the weight loss of the polished silicon wafer is reduced through single side polishing; without affecting the sheet resistance of the diffused silicon wafer and a front PN junction, a polishing technology process is simplified; the back of the silicon wafer is smooth through polishing; the reflectivity is between 50% and 60%; and a back passivation technology is combined, thus the overall efficiency of a cell is improve by 0.15% to 0.25%.

Owner:TRINA SOLAR CO LTD

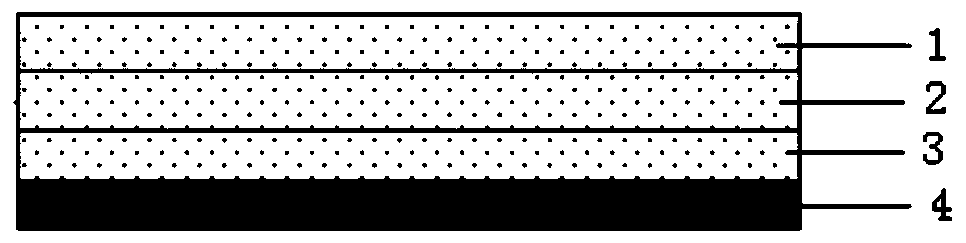

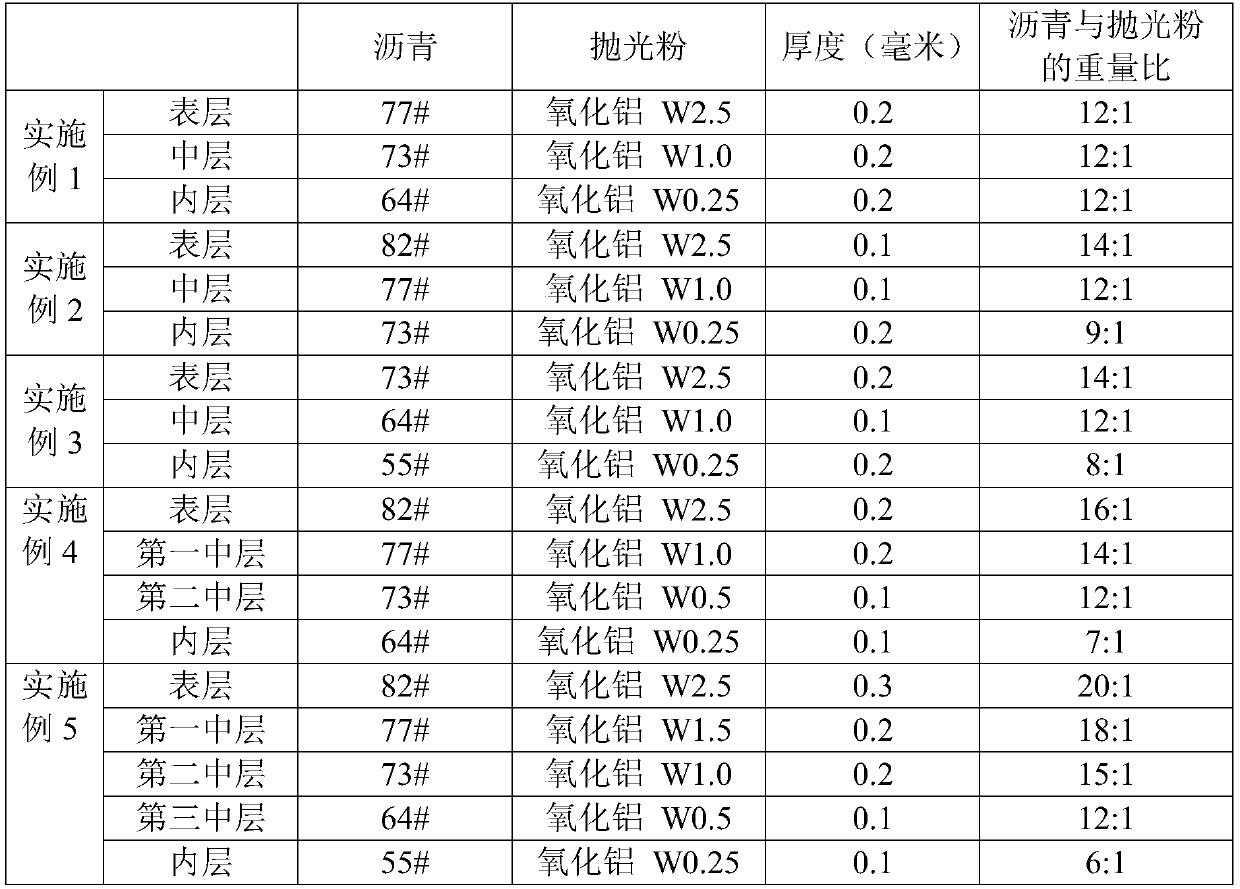

Multilayer polishing glue and preparation method and application thereof

ActiveCN107971875ASimplify the polishing processSmall particle sizeOptical surface grinding machinesAbrasion apparatusSurface layerChalcogenide glass

The invention relates to a multilayer polishing glue and a preparation method and an application thereof. The multilayer polishing glue at least comprises a surface-layer polishing glue, a middle-layer polishing glue and an inner-layer polishing glue which are sequentially arranged, wherein the surface-layer polishing glue, the middle-layer polishing glue and the inner-layer polishing glue all comprise asphalt and polishing powder; and , from the surface-layer polishing glue to the inner-layer polishing glue, the penetration of the asphalt is kept unchanged or gradually increased, and the grain diameters of the polishing powder are sequentially reduced. According to the multilayer polishing glue, the technical difficulty that the surface roughness, surface defects and the surface precisionof soft and brittle infrared material, especially chalcogenide glass are difficult to converge at the same time in the precise polishing process is overcome, and accurate control of various machiningquality parameters in the batch precision polishing process is realized.

Owner:CHINA BUILDING MATERIALS ACAD

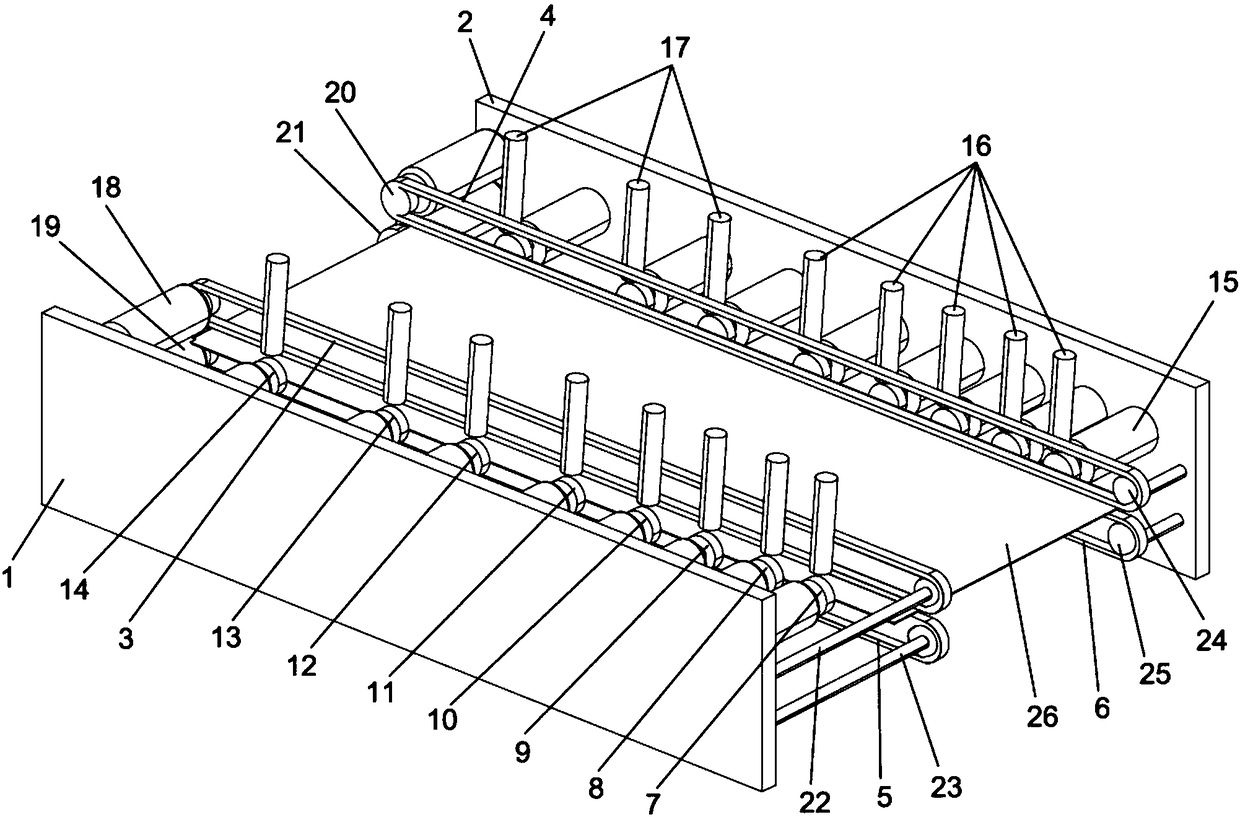

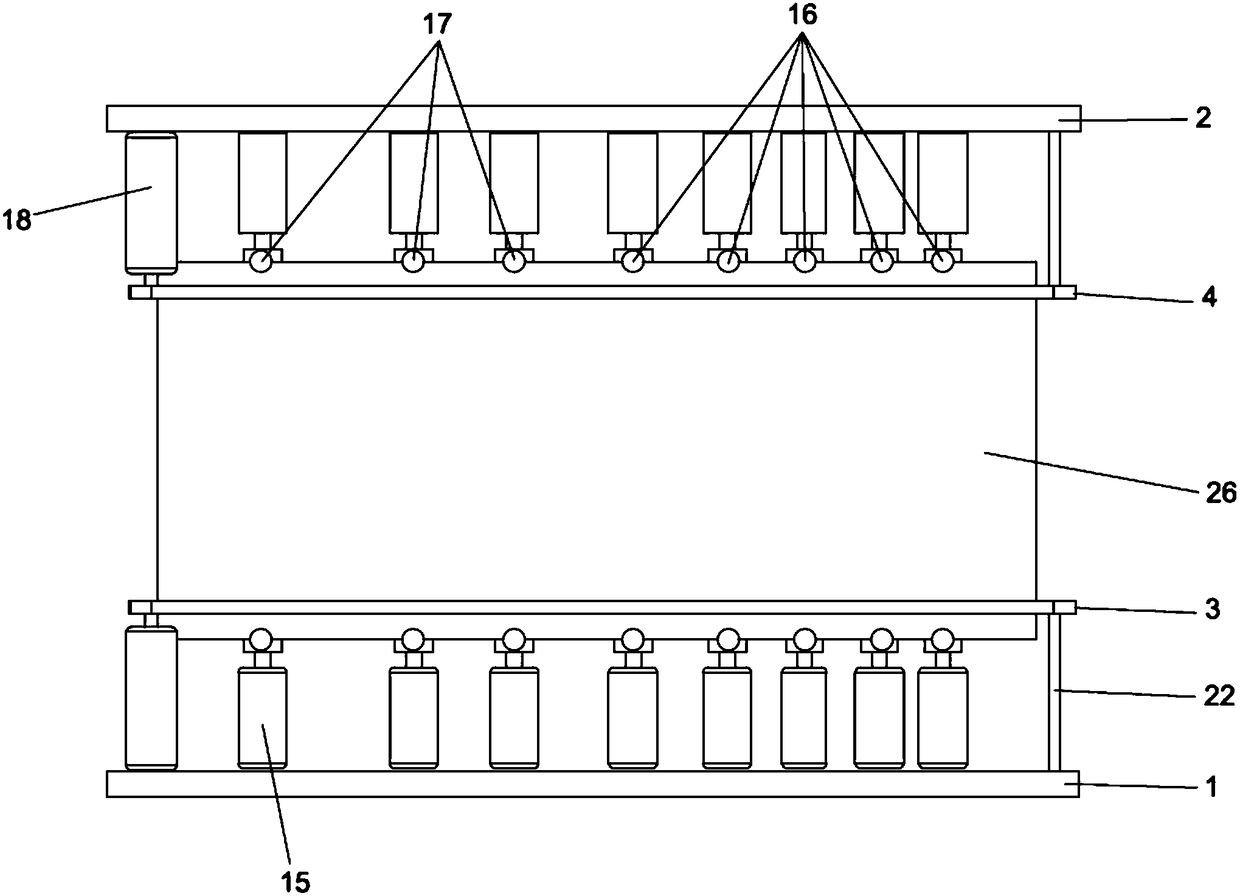

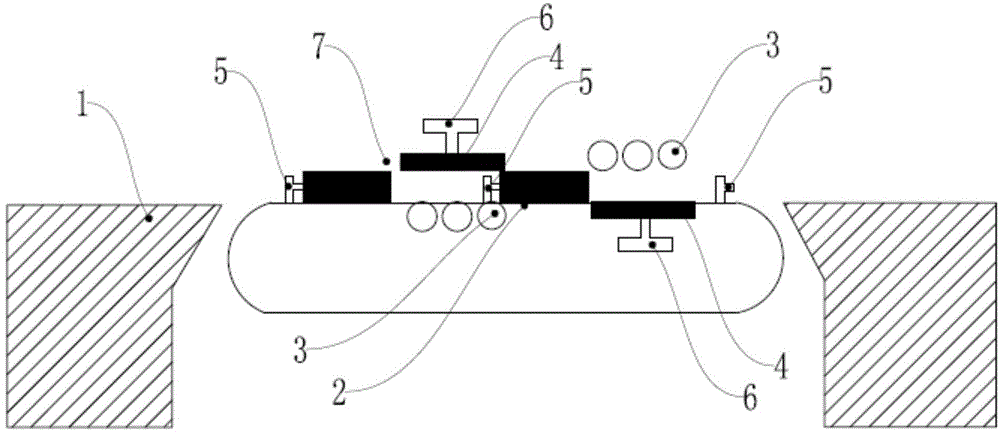

Side surface polishing device for glass light guide plate

ActiveCN108466125AImprove polishing brightnessSimplify the polishing processGrinding feedersPlane surface grinding machinesLight guideEngineering

The invention provides a side surface polishing device for a glass light guide plate. The side surface polishing device comprises an upper conveyor belt A, an upper conveyor belt B, a lower conveyor belt A and a lower conveyor belt B, wherein the upper conveyor belt A and the upper conveyor belt B are arranged relatively, and the lower conveyor belt A and the lower conveyor belt B are arranged relatively. First polishing wheels, second polishing wheels, third polishing wheels, fourth polishing wheels, fifth polishing wheels, sixth polishing wheels, seventh polishing wheels and eighth polishingwheels which are driven by motors A to rotate are sequentially arranged on one side between the upper conveyor belt A and the lower conveyor belt A and one side between the upper conveyor belt B andthe lower conveyor belt B. Liquid transfer tubes A used for inputting clear water are arranged on one sides of the first polishing wheels, the second polishing wheels, the third polishing wheels, thefourth polishing wheels and the fifth polishing wheels, and liquid transfer tubes B used for inputting polishing liquid are arranged on one sides of the sixth polishing wheels, the seventh polishing wheels and the eighth polishing wheels. The polishing process is carried out during the transmission of the light guide plate to improve the polishing efficiency and the degree of finish of the polished surface.

Owner:DONGGUAN YINTAIFENG OPTICAL TECH CO LTD

A dust-removing aluminum veneer polishing equipment

ActiveCN111113247BSimplify the polishing processImprove work efficiencyGrinding carriagesPolishing machinesDrive wheelPolishing

Owner:安徽墙煌科技股份有限公司

Chemical mechanical polishing solution and polishing method for propeller

InactiveCN110434680AImprove polishing effectAchieve precision polishingPolishing compositions with abrasivesNumerical controlMetallurgy

The invention belongs to the technical field of mechanical manufacturing, and discloses chemical mechanical polishing solution and polishing method for a propeller. The polishing method comprises thefollowing steps of rotating the propeller in chemical mechanical polishing solution, enabling the surfaces of propeller blades to be correspondingly subjected to alternating cycles of chemical corrosion and mechanical scraping removal effects with chemical reagents and abrasive particles in the polishing solution, and realizing precise polishing of all parts of the surfaces of the propeller blades. The polishing solution comprises an oxidizing agent, a dissolving agent, a corrosion inhibitor, composite additive, abrasive particles and water. Compared with traditional numerical control polishing and manual polishing, the polishing method is simple, high in polishing precision and good in flexibility, and particularly the polishing of propeller blade roots and impeller hub parts can be realized.

Owner:DALIAN UNIV OF TECH

Silicon wafer polishing manufacture procedure method

InactiveCN102773790AReduce investmentEliminate the phenomenon of "white fog"Lapping machinesPressure reductionSilicon

The invention discloses a silicon wafer polishing manufacture procedure method, which comprises the following steps of: S1) pre-cleaning; S2) pasting; S3) roughly polishing; S4) moderately polishing; S5) finely polishing; S6) peeling; and S7) dewaxing and cleaning, wherein the steps of roughly polishing, moderately polishing and finely polishing respectively comprise the following steps of: S1.1) carrying out pre-pressure reduction water polishing; S1.2) pressurizing, and polishing grinding fluid; and S1.3) carrying out post-pressure reduction water polishing; and a step of polishing a pressure reduction surfactant is added after the steps of post-pressure reduction water polishing in the steps of roughly polishing and finely polishing. According to the silicon wafer polishing manufacture procedure method disclosed by the invention, the polishing manufacture procedure is simplified, the input of fixed assets is effectively lowered, and the phenomenon of ''rime fog'' on the wafer surface is effectively eliminated by adding the step of ''polishing the pressure reduction surfactant''. After the wafer is peeled by high-quality flowing pure water, according to the short-period storage of the wafer, the particle problem is alleviated, the operations of replacing and preparing the solution are omitted, the operation burden is lightened, and the manufacture procedure percent of pass is improved.

Owner:SHANGHAI SHENHE THERMO MAGNETICS ELECTRONICS CO LTD

Formula and applications of granite polishing agent

InactiveCN105567096ANon-slipRestores polished colorPolishing compositionsActive agentSurface-active agents

The present invention discloses a formula and applications of a granite polishing agent, wherein the component in the formula is obtained by carrying out physical mixing on a first solid mixture, a first material liquid, a second material liquid and a third material liquid according to a weight ratio of 23:27:5:5 or 23:27:10:10 or 23:27:15:15 or 46:54:35:35, the first solid mixture comprises 89% of nanometer silica, 4% of a sulfide and 7% of a macromolecule polymer, the first material liquid comprises 3.7% of a surfactant, 1.8% of silicone oil and 94.5% of deionized water, the second material liquid comprises 4.6-20% of diethylene glycol monoethyl ether and 5.6-22% of ethoxylated C12-13 alcohol, and the third material liquid comprises 22-48% of an acrylic acid copolymer. The granite polishing agent of the present invention has characteristics of slip resistance, polishing color recovery, gloss increasing, no yellowing on the surface after the treating, and polishing step simplifying.

Owner:罗松全

High-efficiency and low-cost polishing and grinding equipment for green bricks

InactiveCN105773333ASimple structureSimplify the polishing processGrinding machine componentsCeramic shaping apparatusBrickEngineering

The invention discloses high-efficiency and low-cost polishing and grinding equipment for green bricks. The high-efficiency and low-cost polishing and grinding equipment comprises a bench, wherein a conveying device for conveying the green bricks is arranged on the bench; at least two sets of polishing and grinding devices driven by an external power mechanism are arranged along the driving direction; each polishing and grinding device consists of a surface polishing mechanism and a grinding disc arranged at the opposite side of the surface polishing mechanism; and in two sets of adjacent polishing and grinding devices, the positions of the surface polishing mechanisms and the grinding discs are opposite separately. According to the high-efficiency and low-cost polishing and grinding equipment disclosed by the invention, the grinding discs are arranged right above the corresponding surface polishing mechanisms, so that polishing and grinding of two surfaces can be realized while green brick bodies are split, and the polishing and grinding of two times is changed into the polishing and grinding of one time, so that the working procedures of the polishing and grinding are simplified; and a polishing and grinding line structure is simpler, and double-faced polishing and grinding can be realized without two sets of equipment, so that the cost is reduced.

Owner:FOSHAN BAOHANG MACHINERY EQUIP IND INTPROP SERVICES

Hydrogen ion electrode composed of composite material of nano iridium oxide and polymer resin and enabling surface regeneration, pH sensor using same, and method for manufacturing same

InactiveUS9810655B2Fast and near-theoretical pH sensitivityIncrease physical strengthMaterial nanotechnologyNanostructure manufactureHysteresisPolymer resin

Provided are a hydrogen ion electrode composed of a composite material of polymer resin and nano iridium oxide, the composite material containing 1-10 nm sized nano iridium oxide particles and / or aggregates thereof which are dispersed to be electrically connected to each other in a moldable, thermoplastic, and hydrophobic polymer resin matrix; a pH sensor using the same; and a method for manufacturing the same. The surface of the hydrogen ion electrode shows very fast pH sensitivity when exposed to a sample solution, and the pH sensitivity is approximate to biphasic characteristics. Furthermore, regardless of high reproducibility of pH sensitivity, abrupt pH change, and repetitive use, very low hysteresis, durability due to high physical strength, and high surface regeneration due to polishing are exhibited, and thus, the lifetime of the electrode can be extended and various sizes and shapes of electrodes can be easily manufactured.

Owner:EZ SENSING

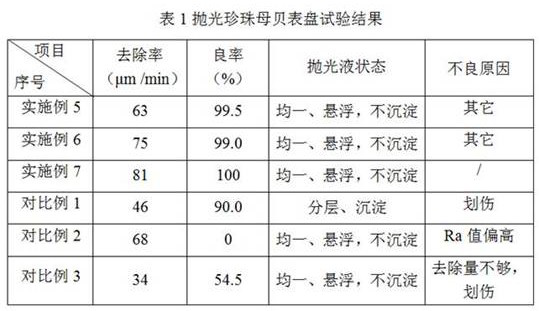

Aluminum oxide polishing solution for polishing mother pearl shellfish and preparation method of aluminum oxide polishing solution

ActiveCN113943534AImprove surface conditionHigh removal ratePolishing compositions with abrasivesSuspending AgentsAluminium oxides

The invention discloses an aluminum oxide polishing solution for polishing mother pearl shellfish and a preparation method of the aluminum oxide polishing solution, and belongs to the technical field of grinding and polishing. The aluminum oxide polishing solution is prepared from the following raw materials in parts by weight: 15 to 30 parts of plate-shaped aluminum oxide powder, 0.5 to 10 parts of sphere-like aluminum oxide powder, 0.3 to 1.0 part of a dispersing agent, 0.2 to 10 parts of a suspending agent, 0.1 to 1 part of a pH regulator and 50 to 80 parts of water. The aluminum oxide powder adopted by the invention is plate-shaped aluminum oxide powder and sphere-like aluminum oxide powder, and the adopted suspending agent is BYK LAPONITER-RDS sol-level flaky silicate. The aluminum oxide polishing solution adopted by the invention has better dispersity, uniformity and suspension property; and when the prepared polishing solution is used for polishing mother pearl shellfish, the grinding step and the polishing step can be combined into a whole, the processing flow is simplified, and the high removal rate, the low surface roughness and the perfect surface state can be achieved.

Owner:HENAN UNION ABRASIVES

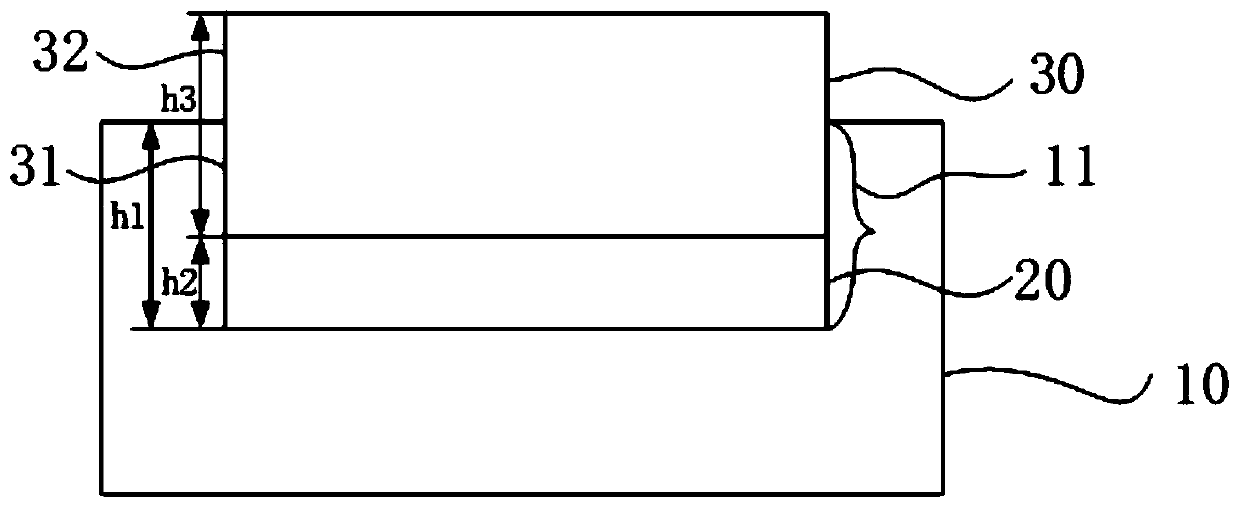

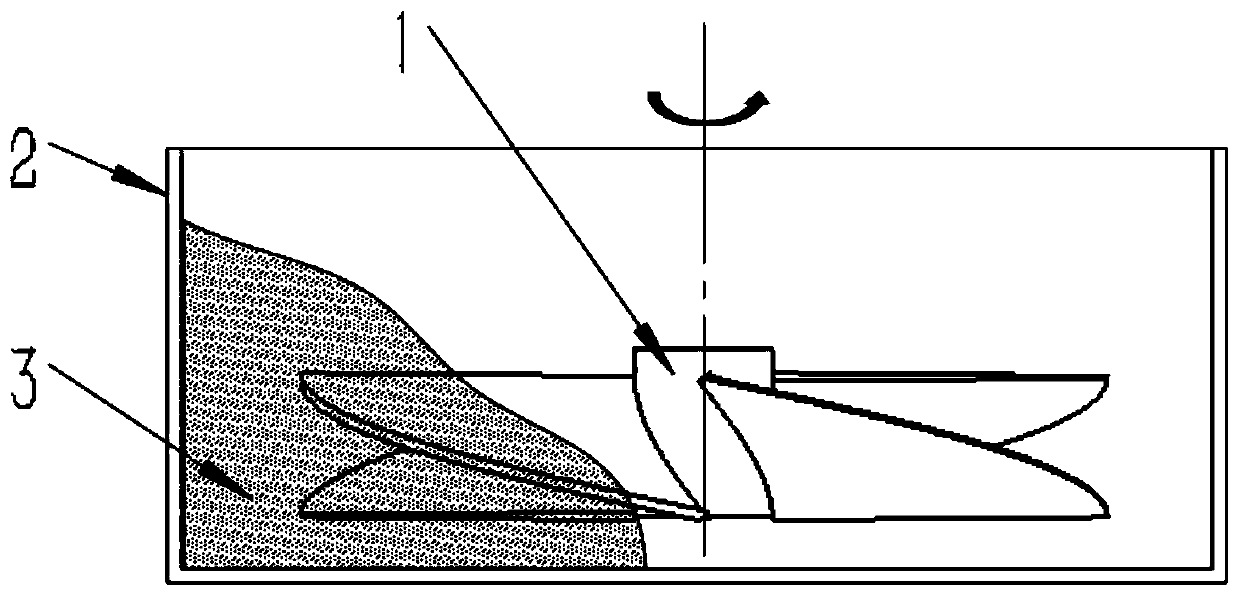

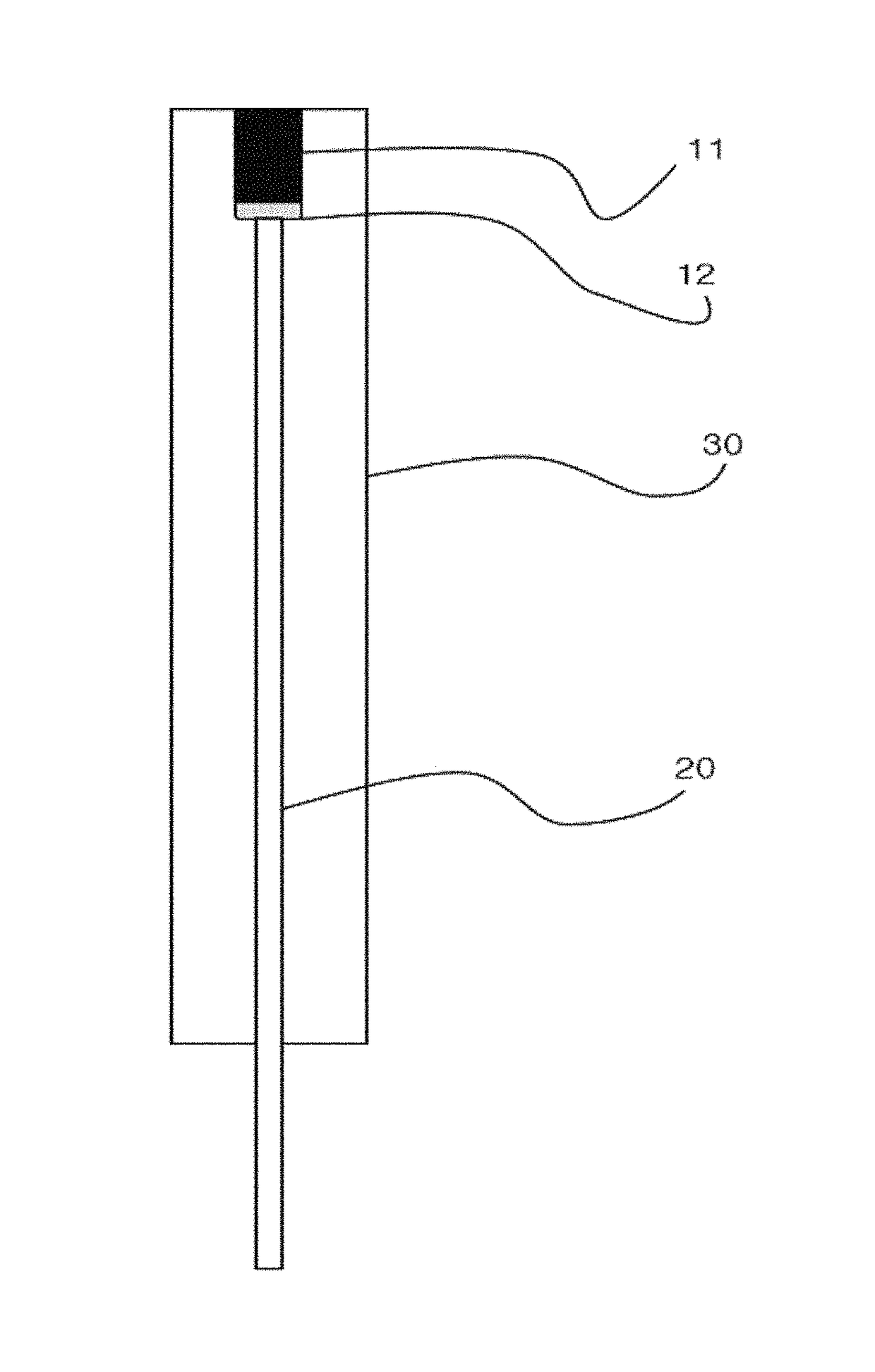

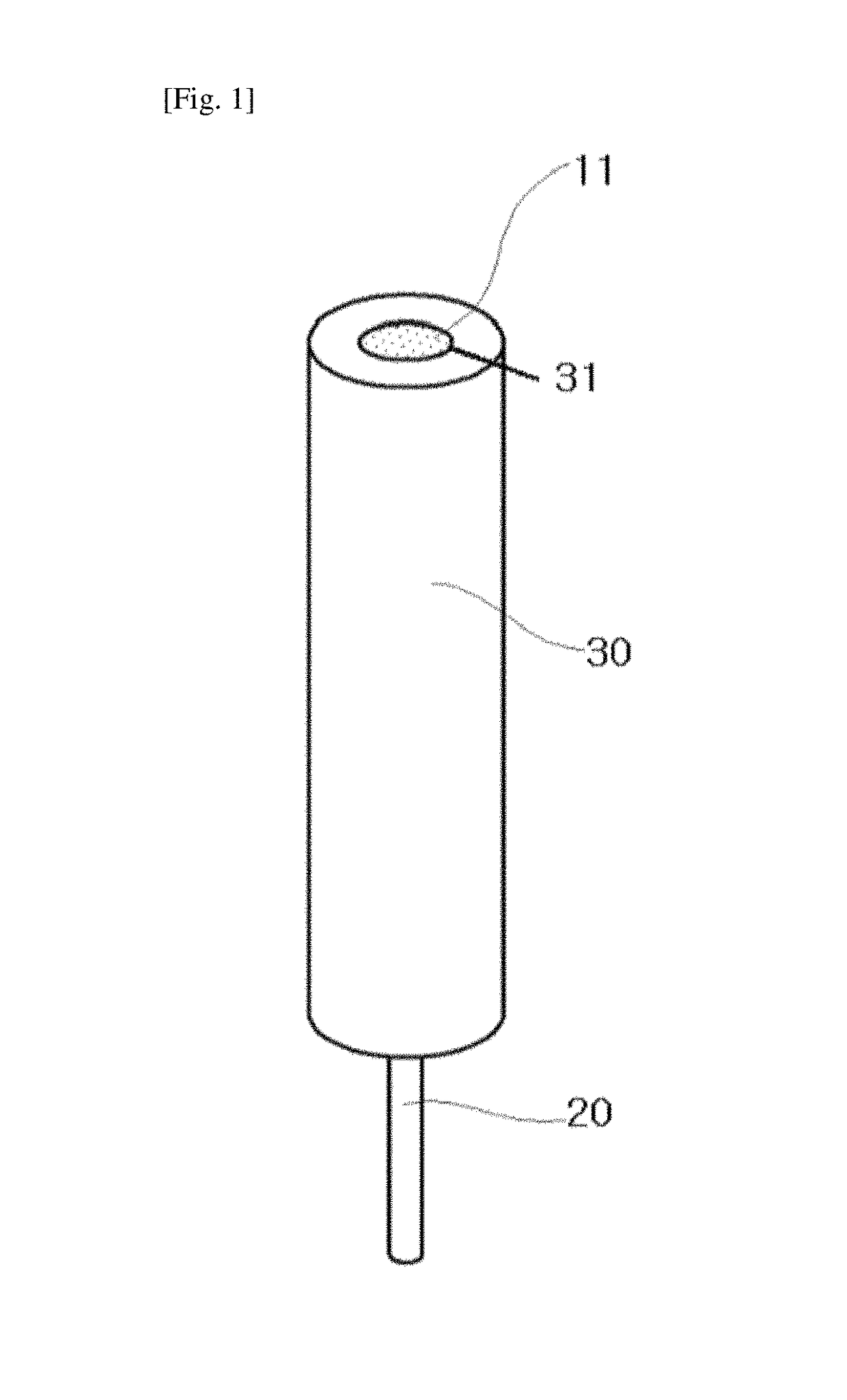

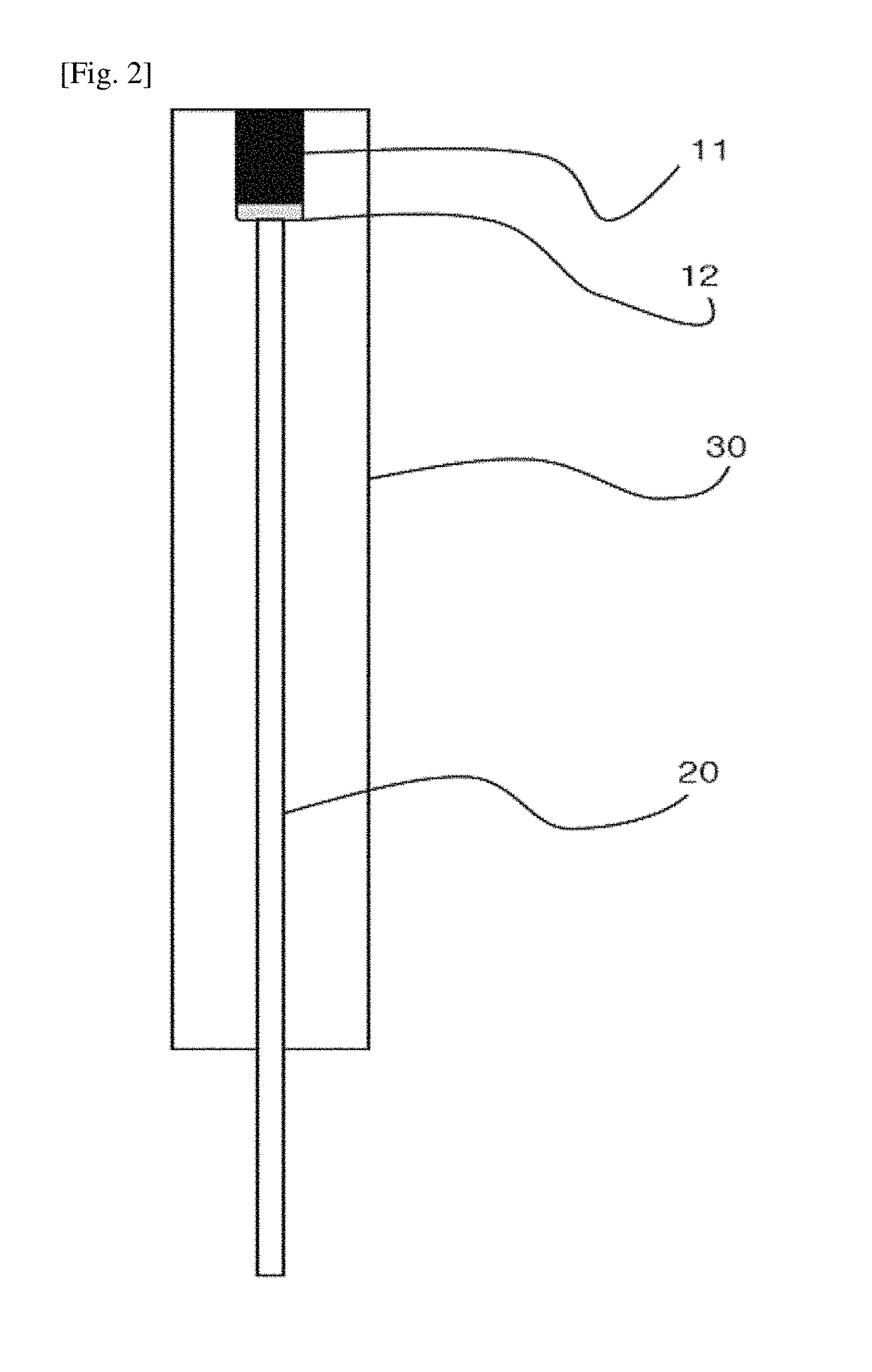

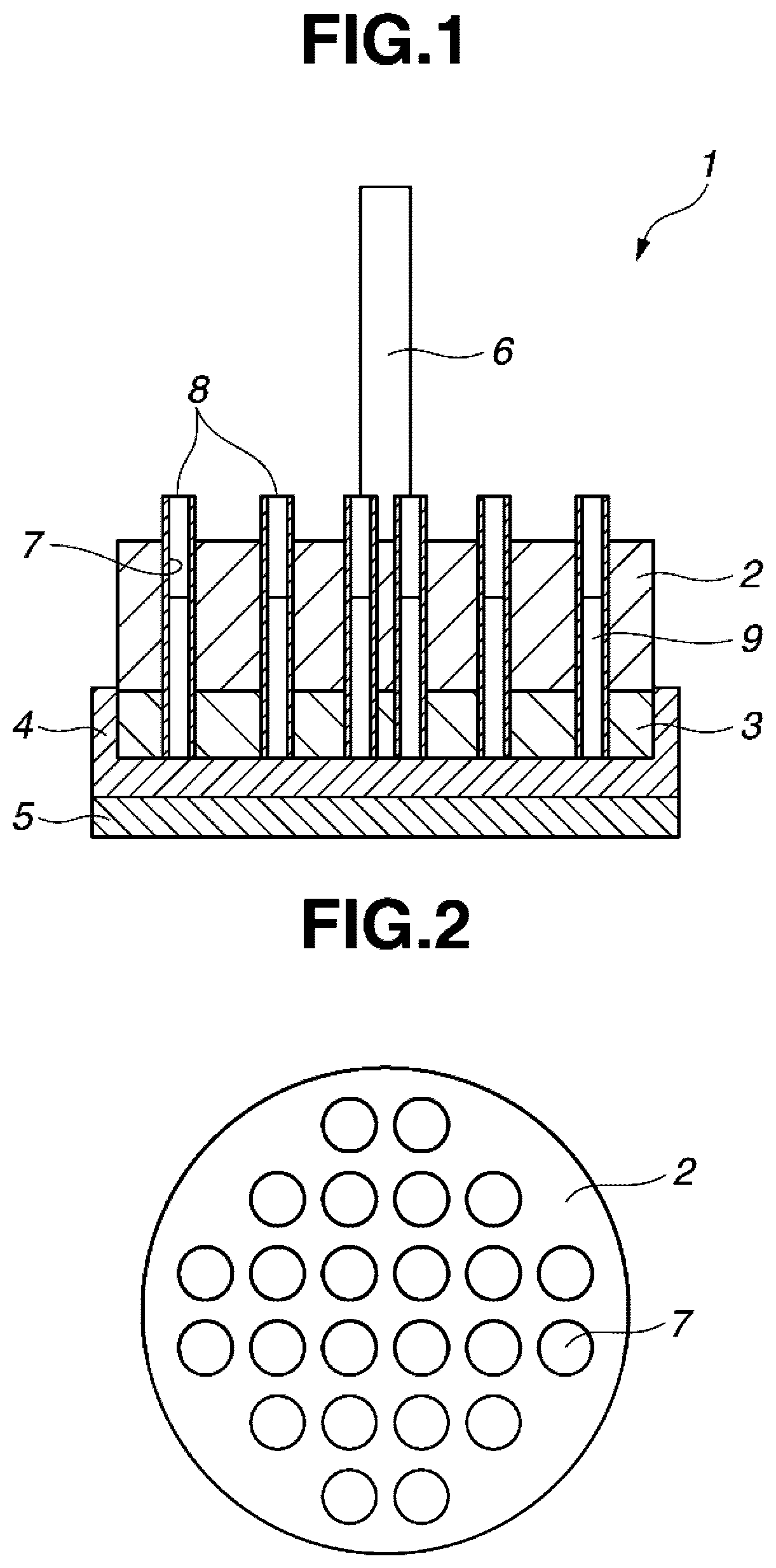

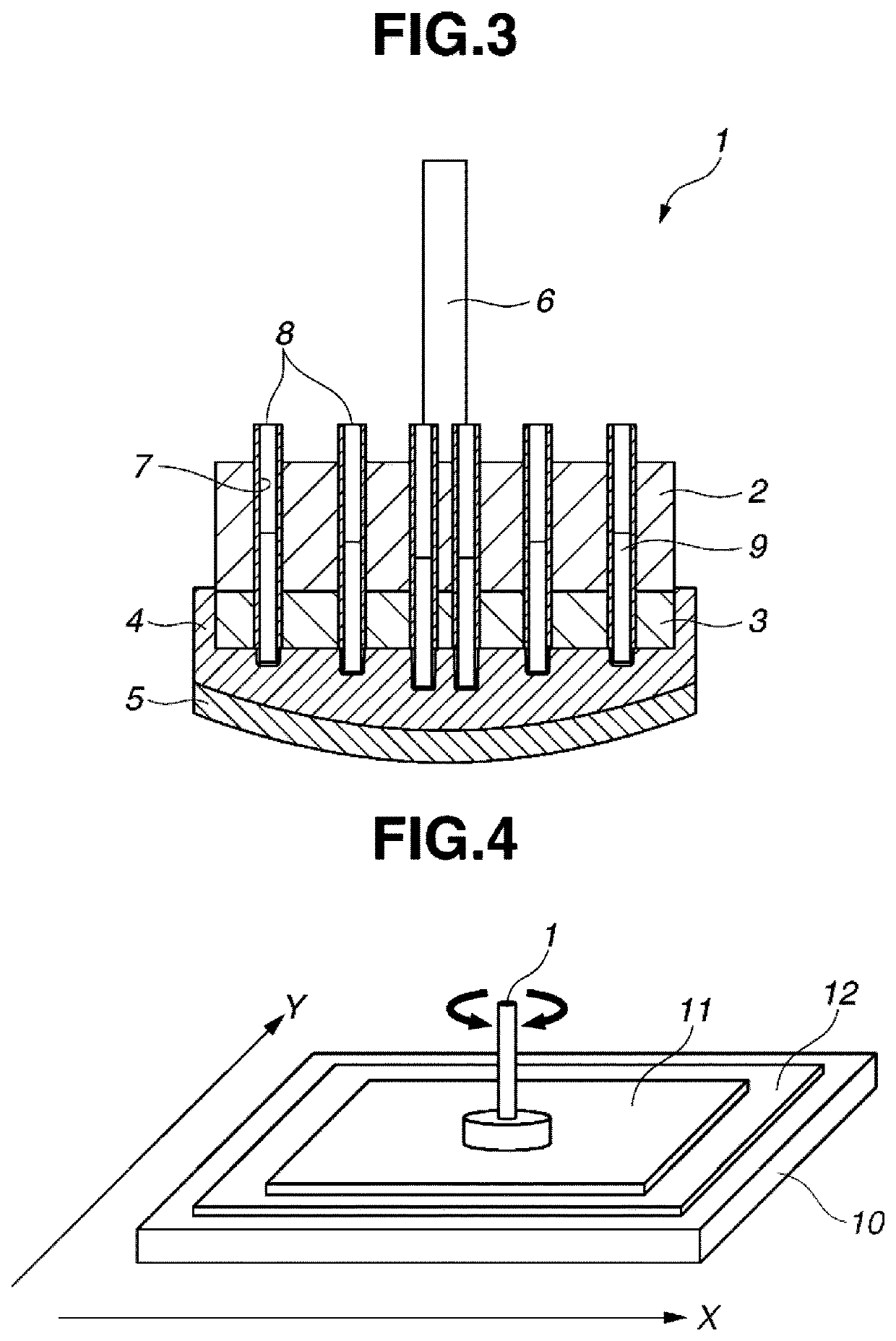

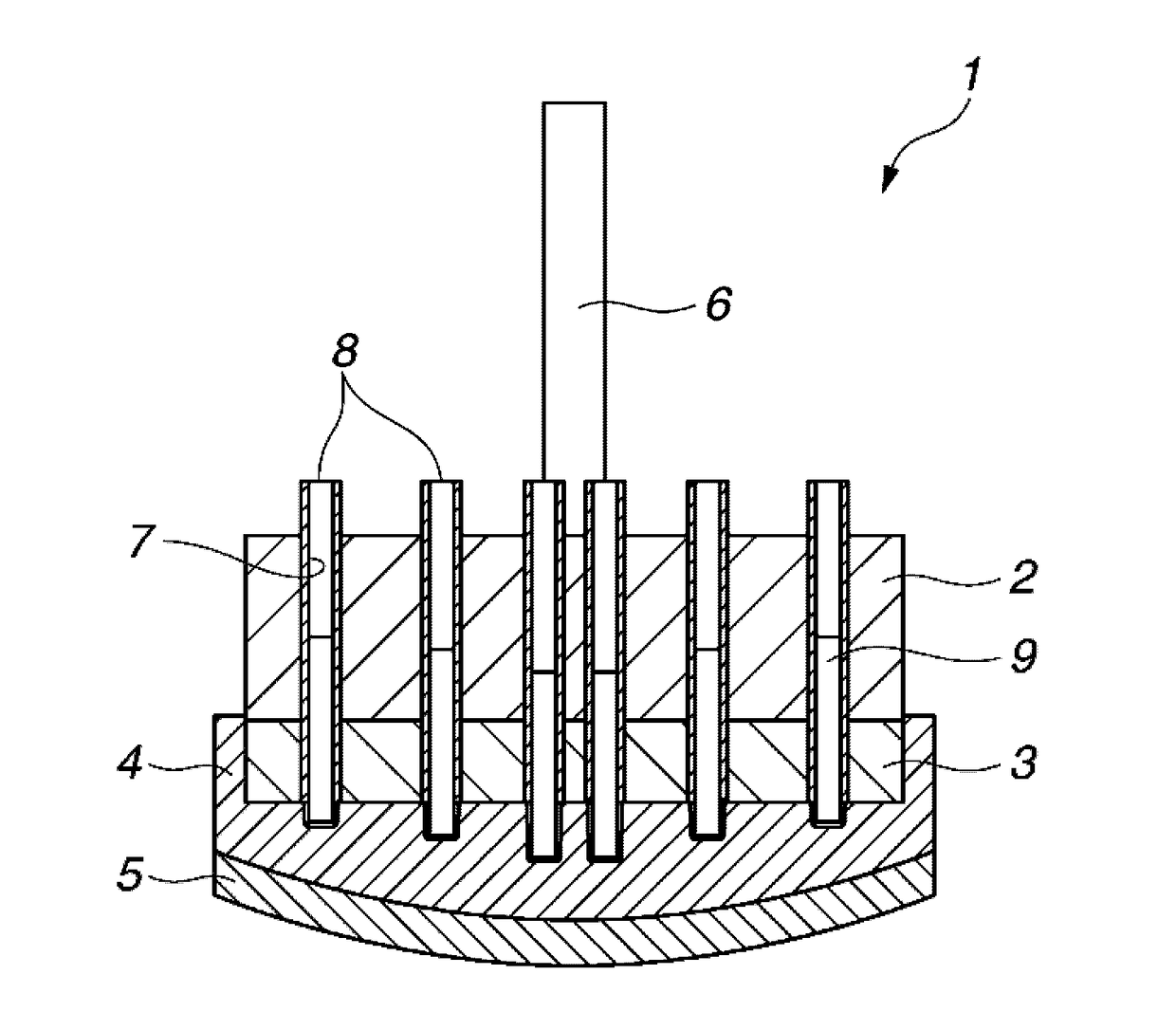

Method for producing substrate

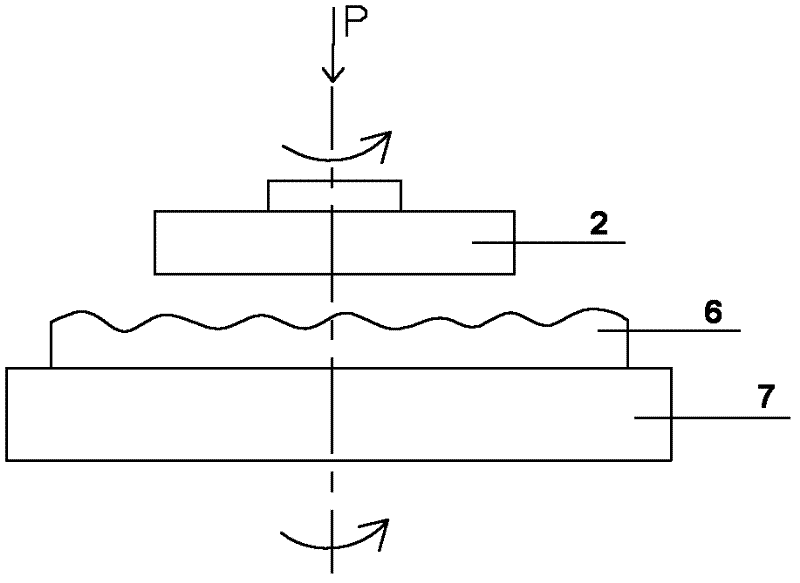

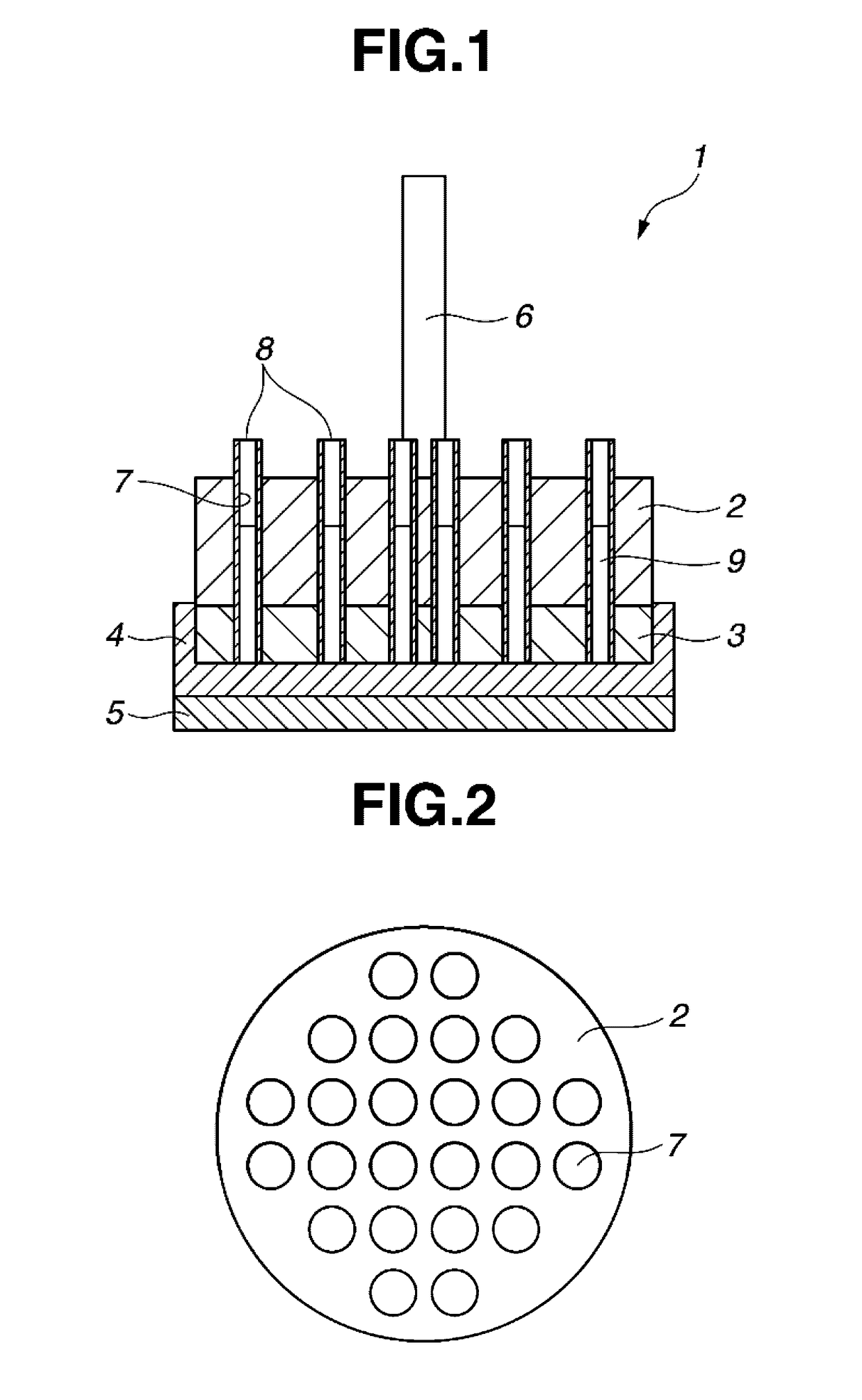

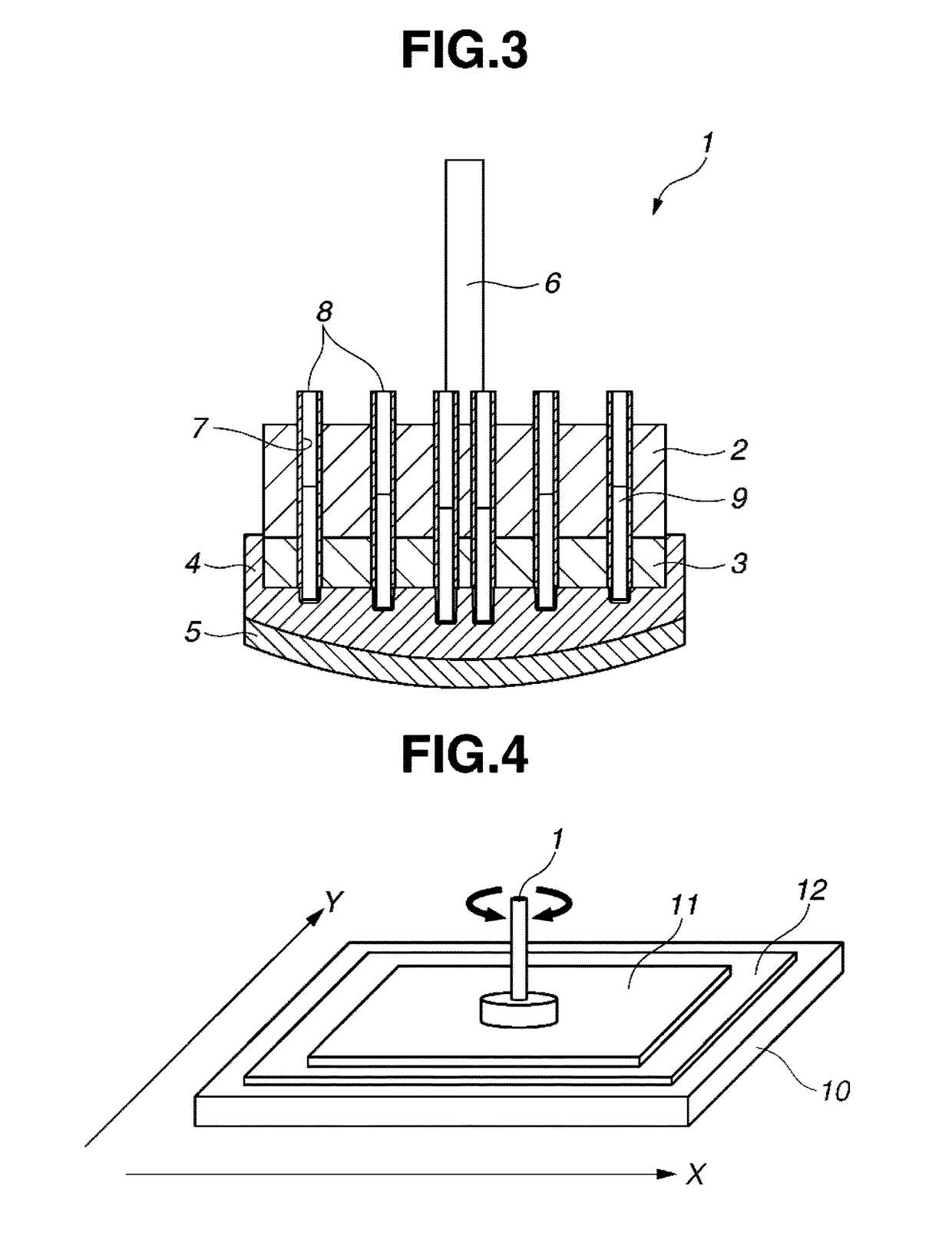

ActiveUS10646976B2Simplify the polishing processImprove productivityPolishing machinesSemiconductor/solid-state device manufacturingElastomerRotational axis

There is furnished a working tool comprising a rotating shaft (6), a polishing plate (3) mounted on the shaft, an expandable elastomer sheet (4) attached to the polishing plate (3), an abrasive cloth (5) attached to the elastomer sheet (4), and means for pressing the elastomer sheet (4) at a plurality of positions under respective predetermined different pressures such that a lower surface of the abrasive cloth (5) is deformed to the desired inverted convex shape in accordance with differences of pressing force applied to the elastomer sheet (4) at the plurality of positions. A substrate is produced by bringing the inverted convexly deformed surface of the abrasive cloth (5) in contact with a substrate stock, and rotating and moving the working tool for polishing the substrate over a selected area.

Owner:SHIN ETSU CHEM IND CO LTD

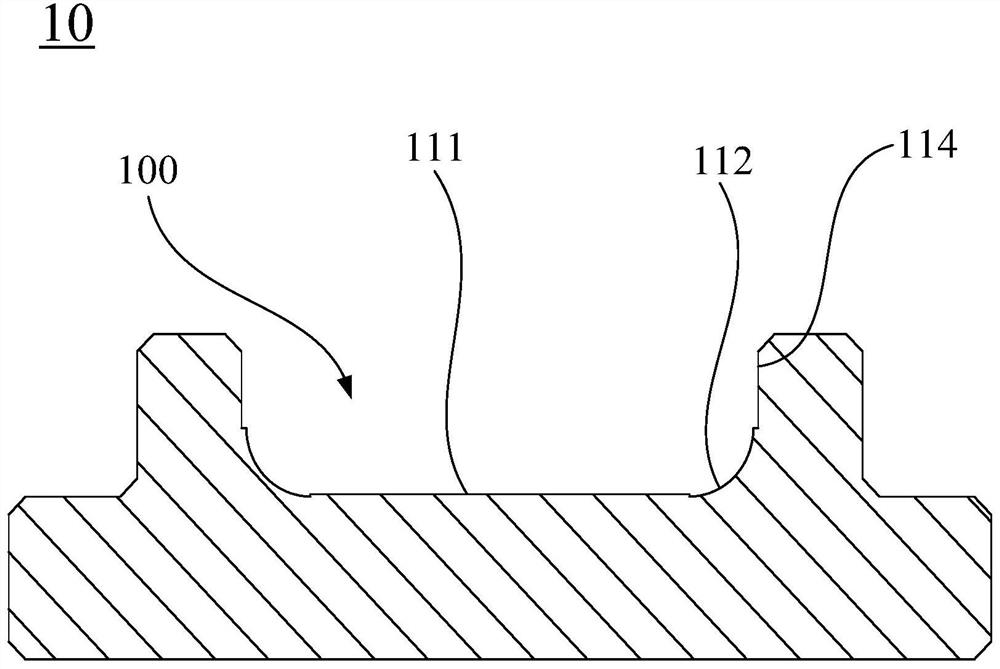

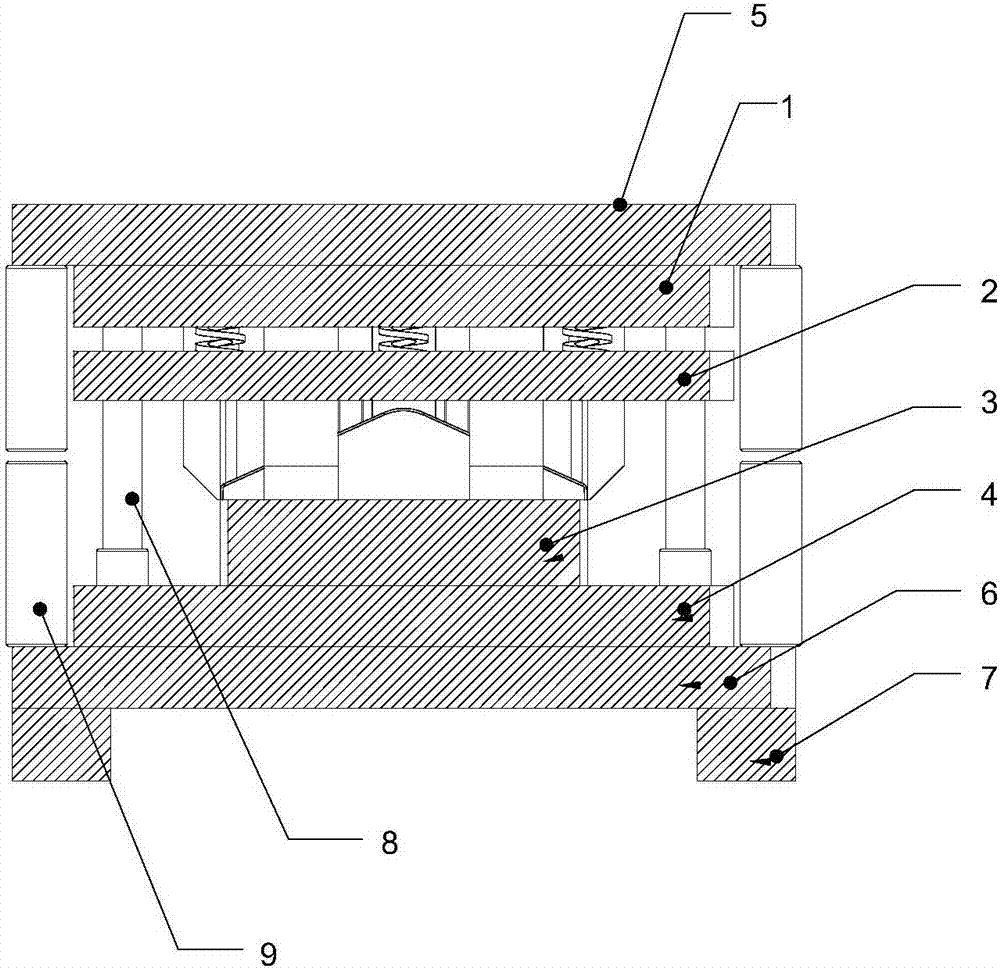

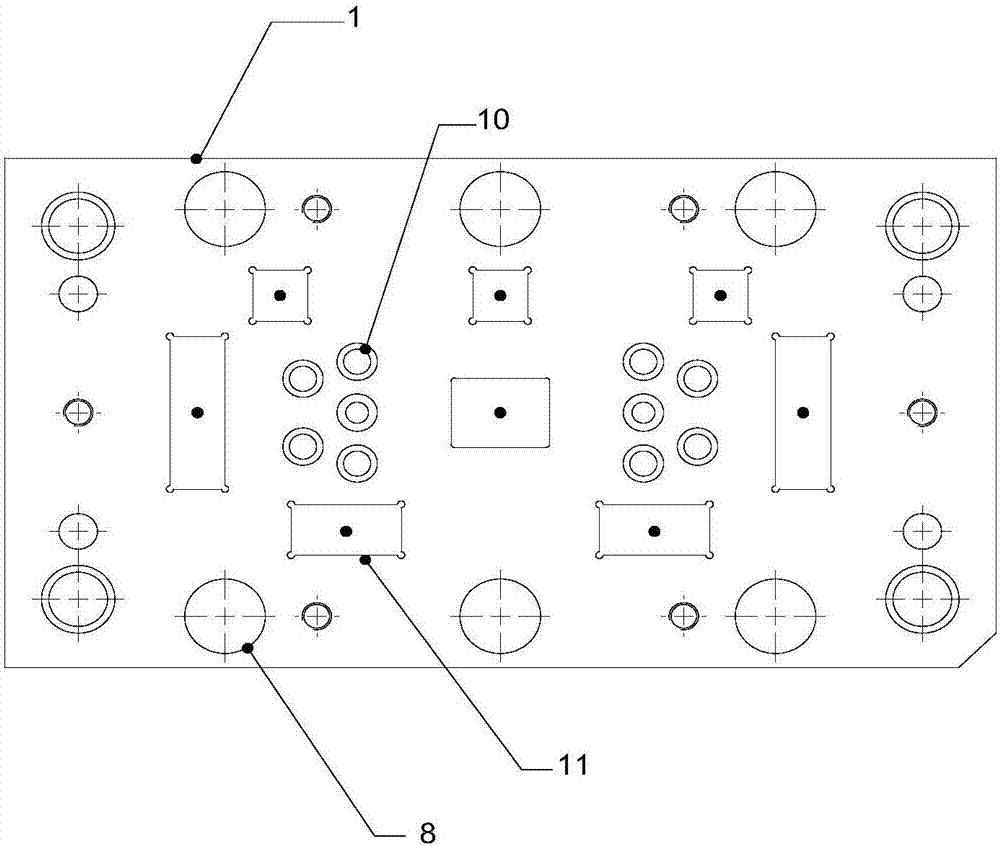

Glass forming mold, glass forming device and forming method

ActiveCN113060930AAvoid oxidation powdeAvoid the situationGlass reforming apparatusGlass productionFlat glassGlass forming

The invention provides a glass forming mold and a glass forming method. The glass forming mold comprises a shaping mold and a pressing mold which are matched for use; the shaping mold is provided with a shaping groove, and the bottom of the shaping groove is provided with a groove bottom plane area and a groove bottom curved surface area extending outwards in the groove opening direction along the edge of the groove bottom plane area; a pressing mold is provided with a shaping convex block, the top of the shaping convex block is provided with a convex block plane area and a convex block curved surface area, the convex block plane area is matched with the groove bottom plane area, the convex block curved surface area is matched with the groove bottom curved surface area, and when the shaping mold is matched with the pressing mold for use, the shaping convex block extends into the shaping groove; and the distance d1 between the groove bottom plane area and the protruding block plane area is 90%-99% of the thickness d of the plate glass to be processed, and the distance d2 between the groove bottom curved surface area and the protruding block curved surface area is larger than d. By adopting the glass forming mold, the subsequent processing and preparation time of the curved glass prepared by the glass forming mold can be remarkably shortened.

Owner:QINGYUAN CSG NEW ENERGY SAVING MATERIALS CO LTD +1

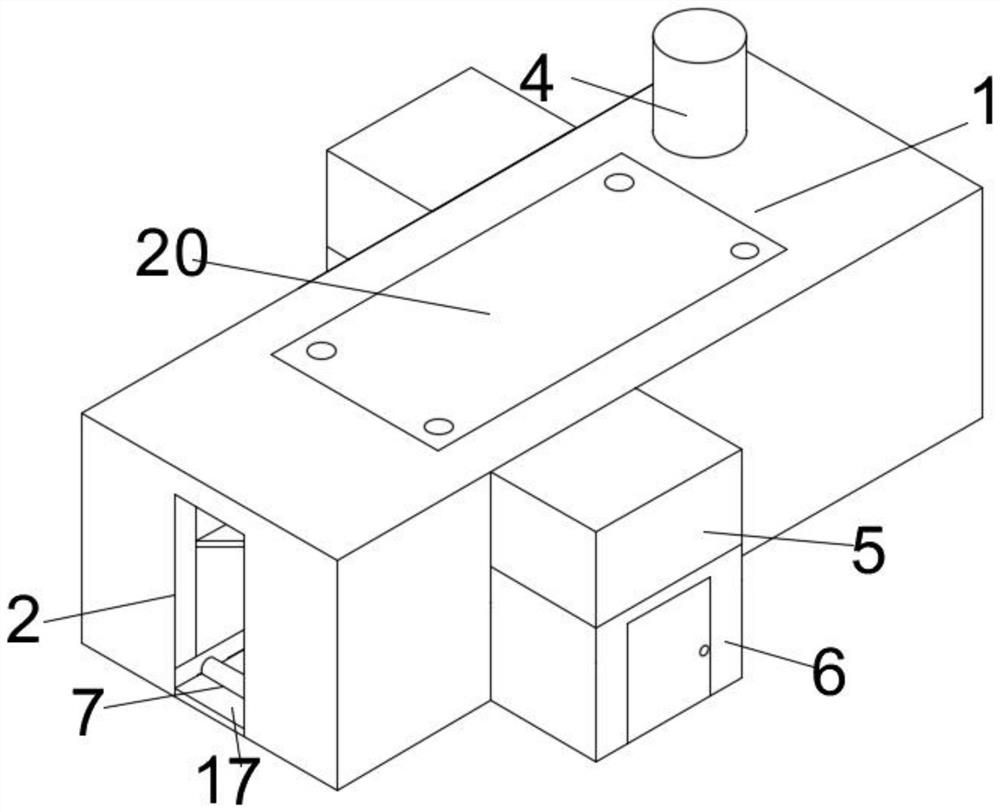

Device for removing sprues of automobile brake pedal assembly

InactiveCN107081368ASimplify the polishing processReduce manual labor intensityPunchingAutomotive engineering

The invention discloses a device for removing sprues of an automobile brake pedal assembly. The device comprises an upper fixing plate, punching knives, a lower fixing plate and a positioning die, wherein the upper fixing plate is connected to a retractable device, the punching knives are used for cutting off the sprues of the automobile brake pedal assembly and are connected to the upper fixing plate, the positioning die is arranged on the lower fixing plate, and a profiling surface used for positioning the automobile brake pedal assembly is arranged on the positioning die. According to the device, the automobile brake pedal assembly is placed on the positioning die, then the retractable device is started to enable the upper fixing plate to move downwards, the punching knives move downwards along with the upper fixing plate to cut off the sprues on the automobile brake pedal assembly, and then only fine polishing needs to be carried out on the automobile brake pedal assembly. The device has the advantages that the sprues can be automatically punched and cut, the polishing procedure is simplified, and therefore the labor intensity of workers can be reduced, the production efficiency can be improved, and the cost of products can be reduced; and in addition, punching pins can be additionally arranged to be used for punching burrs inside assembling holes.

Owner:江苏铭利达科技有限公司

Gear non-load overall immersion type chemical mechanical coupling surface polishing method

ActiveCN114247939AMeet smooth requirementsMeet high-quality processing requirementsGear teethCarbide siliconO-Phosphoric Acid

According to the non-load overall immersion type chemical mechanical coupling surface polishing method for the gear, the gear is integrally immersed during polishing, no external load is applied, ultrasonic assistance is applied, chemical and mechanical coupling and fluid and solid coupling are achieved, and the surface of the gear is efficiently and stably polished. The self-developed green and environment-friendly polishing solution mainly comprises deionized water, silicon carbide abrasive particles, hydrogen peroxide, phosphoric acid and malic acid. Compared with other surface treatment methods for gear parts, the method has the advantages that the gear can be comprehensively polished, an external load is not independently applied in the polishing process, the defects such as scratches and subsurface damage generated in the polishing process are effectively reduced, and the polished gear surface including a curved tooth profile can meet the smooth requirement. In addition, the developed polishing solution does not contain chemical reagents such as strong acid or strong alkali which are harmful to human bodies or the environment, and is green and environment-friendly.

Owner:DALIAN UNIV OF TECH

Chemical and mechanical polishing method for sulfur phase-change material

ActiveCN102441819BAvoid damageEasy to cleanPolishing compositions with abrasivesPhase-change memorySulfur

A chemical and mechanical polishing method for a sulfur phase-change material comprises the following steps: 1) roughly polishing the sulfur phase-change material to quickly remove most of sulfur compound outside through holes in an inlaid structure; and 2) performing ultrafine polishing on the sulfur phase-change material which is roughly polished to remove the rest sulfur compound outside the through holes and expose a final through hole array structure. A polishing solution used in the polishing method comprises a polishing solution A for rough polishing and a polishing solution B for ultrafine polishing, and is prepared by mixing a nano grinding agent, a pH regulating agent, a surfactant, a defoaming agent, a bactericide, an assistant cleaning agent and a solvent. The chemical and mechanical polishing method for the sulfur phase-change material has the advantages of high polishing efficiency and simple and feasible process; a polished surface is smooth and has no scratch; over polishing can be prevented well, so that the stability of the performance of a phase-change memory which is manufactured on the base of the inlaid structure and the good rate of products are improved, and the cost is reduced.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Method for producing substrate

ActiveUS20180056475A1Simplify the polishing processImprove productivityPolishing machinesSemiconductor/solid-state device manufacturingElastomerEngineering

There is furnished a working tool comprising a rotating shaft (6), a polishing plate (3) mounted on the shaft, an expandable elastomer sheet (4) attached to the polishing plate (3), an abrasive cloth (5) attached to the elastomer sheet (4), and means for pressing the elastomer sheet (4) at a plurality of positions under respective predetermined different pressures such that a lower surface of the abrasive cloth (5) is deformed to the desired inverted convex shape in accordance with differences of pressing force applied to the elastomer sheet (4) at the plurality of positions. A substrate is produced by bringing the inverted convexly deformed surface of the abrasive cloth (5) in contact with a substrate stock, and rotating and moving the working tool for polishing the substrate over a selected area.

Owner:SHIN ETSU CHEM IND CO LTD

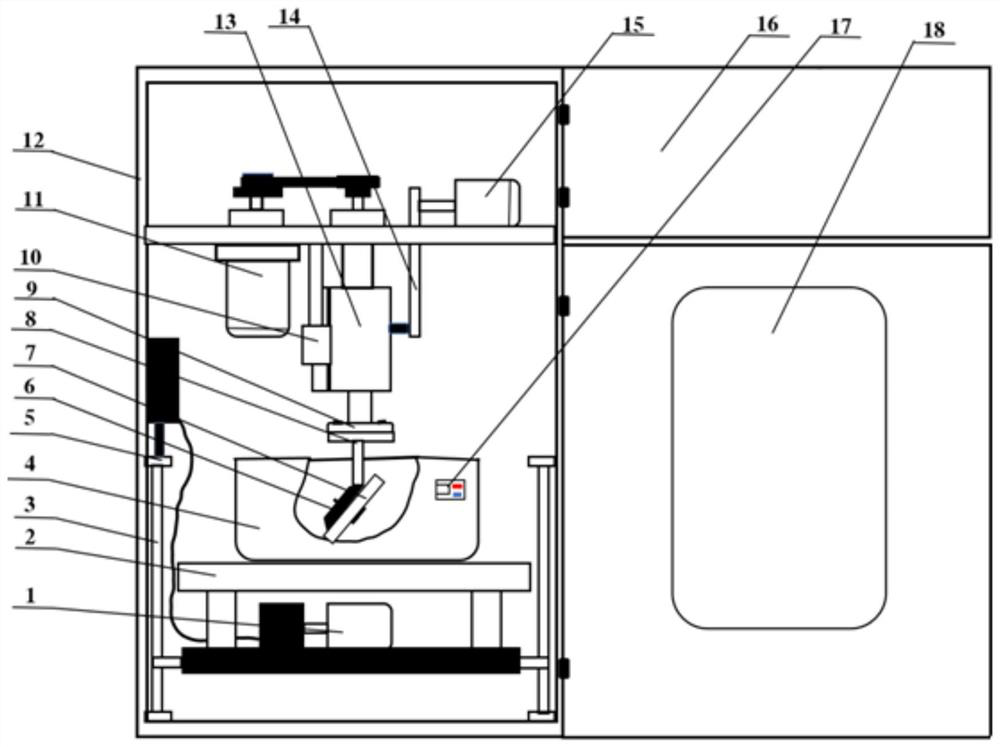

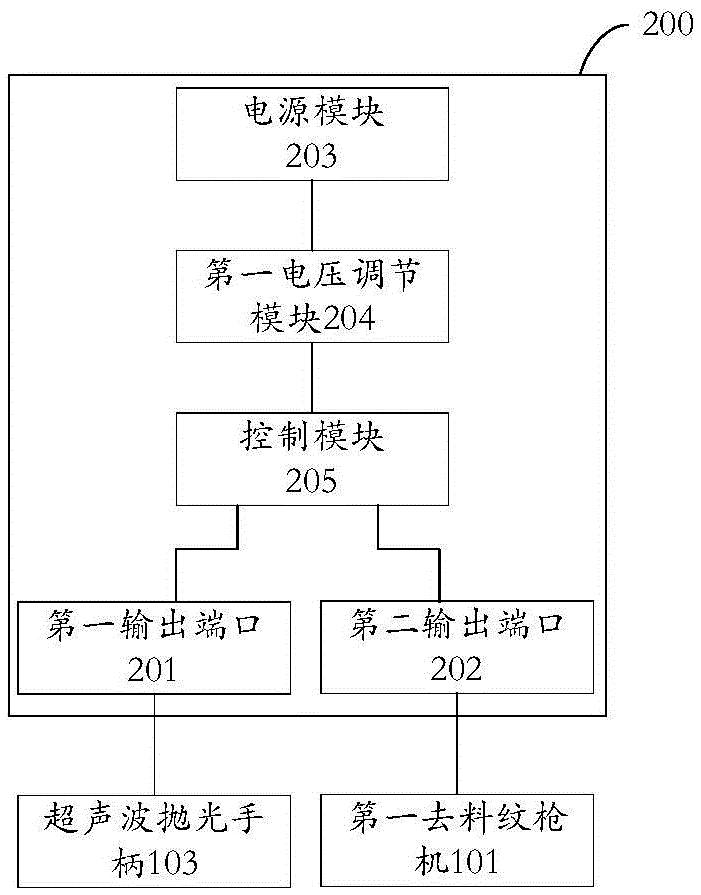

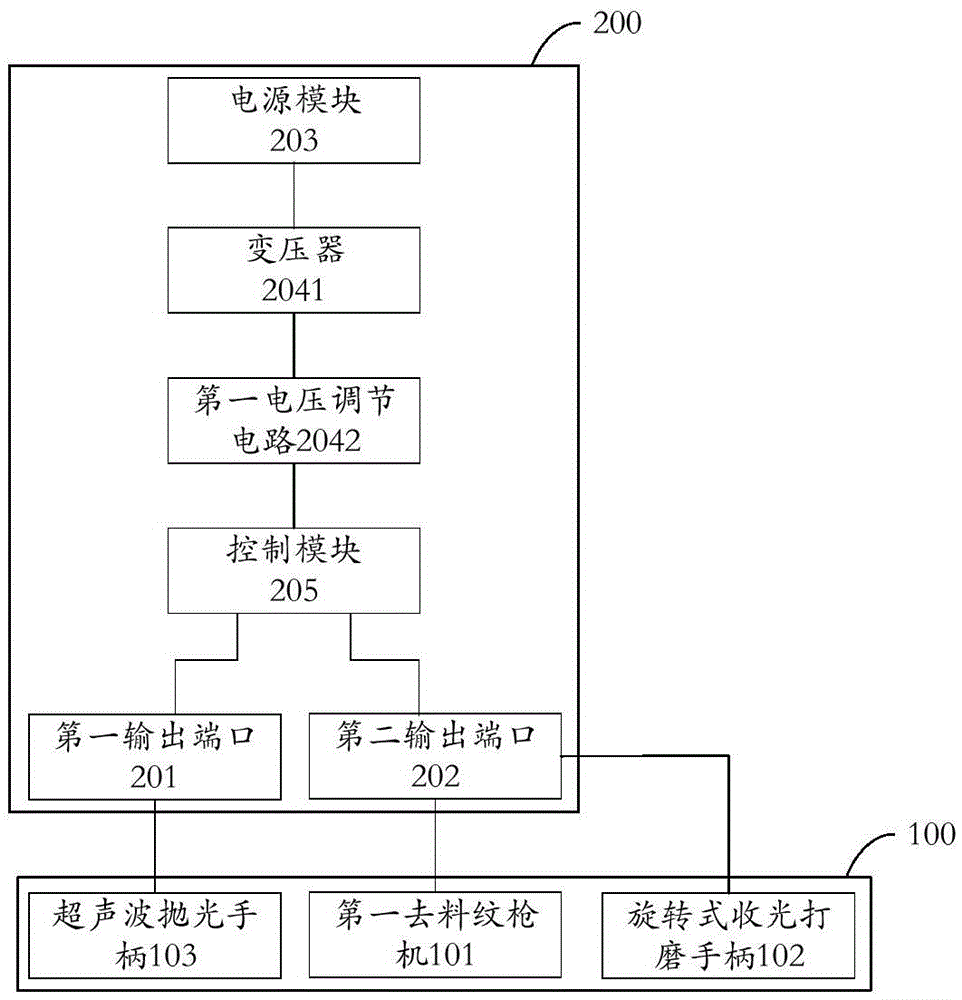

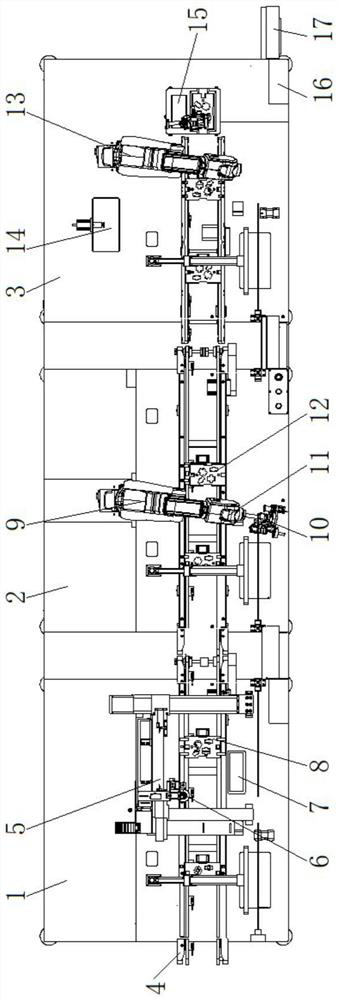

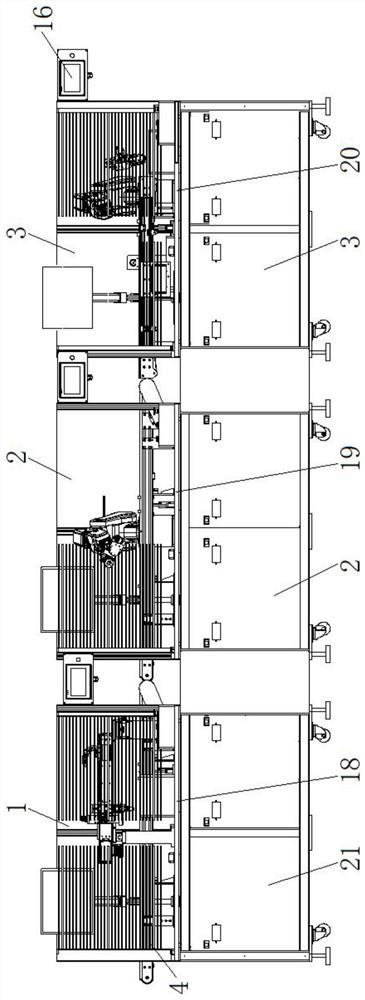

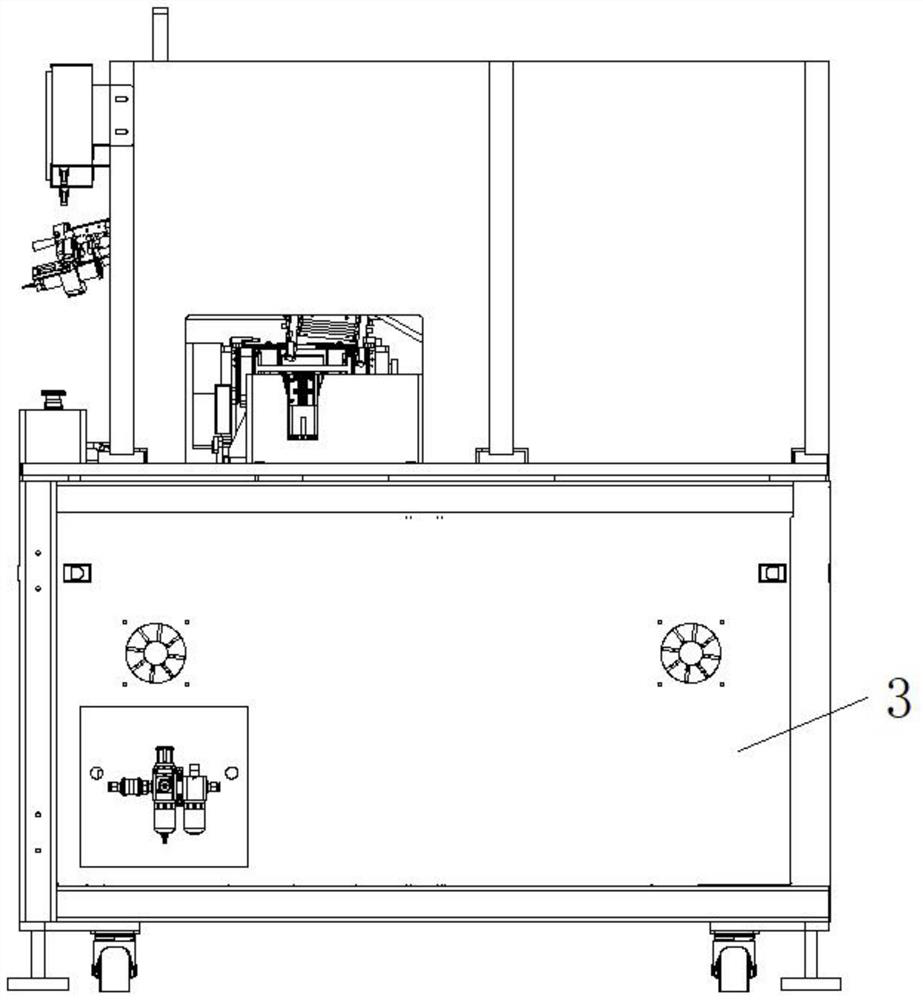

Polishing machine

InactiveCN105479312AImprove polishing efficiencySimplify the polishing processGrinding machinesAutomatic grinding controlVoltage regulator moduleVoltage regulation

The invention provides a polishing machine, and belongs to the field of die polishing equipment. The polishing machine comprises a polishing tool set and a control box. The polishing tool set comprises a first bank mark removing gun machine, a rotary sleeking and grinding handle and an ultrasonic polishing handle. The control box is provided with a first output end opening connected with the ultrasonic polishing handle and a second output end opening connected with the other two tools. The control box comprises a power module, a first voltage regulation module used for regulating the output voltage of the power module and a control module for controlling the end opening voltage of the first output end opening and the end opening voltage of the second output end opening. The first voltage regulation module is connected with the power module and the control module. The output end of the control module is connected with the two output end openings. According to the polishing machine obtained through the design, when workers carry out precision polishing on a die, polishing can be achieved without operating multiple single working polishing machines, polishing efficiency is improved, meanwhile, the polishing process is simplified, and polishing cost is reduced.

Owner:赵治军

An industrial robot that fits automatically

ActiveCN110202466BAchieve crawlingEasy to adjustLiquid surface applicatorsPolishing machinesRobot handProcess engineering

The present invention relates to the technical field of material bonding, in particular to an industrial robot for automatic bonding, including a right-angle manipulator platform, a six-axis robot dispensing platform, a six-axis robot polishing platform and a carrier conveying line. The six-axis robot dispensing The head end of the platform is fixedly connected to the tail end of the right-angle manipulator platform, the head end of the six-axis robot polishing platform is fixedly connected to the tail end of the six-axis robot dispensing platform, and the bottom of the carrier conveying line is fixedly connected to the right-angle manipulator The middle of the top of the platform, six-axis robot dispensing platform and six-axis robot polishing platform. The invention realizes the functions of material grabbing, polishing, dispensing, and automatic screwing, which saves a lot of labor, improves production efficiency, and greatly improves the quality, and uses a large number of automated equipment to simplify dispensing and polishing processes. , reduces the labor intensity, makes each production process can be closely combined, and greatly improves the intelligence of the entire equipment.

Owner:深圳市鑫锐华自动化设备有限公司

Rough-wrought workpiece polishing device for mold production

InactiveCN112405301ASimple polishing processImprove polishing efficiencyGrinding carriagesPolishing machinesPolishingAir pump

The invention relates to the technical field of production equipment, and discloses a rough-wrought workpiece polishing device for mold production. The rough-wrought workpiece polishing device comprises a device base, wherein the top end of the device base is fixedly connected with a lifting frame, the top end of the lifting frame is movably connected with a moving frame, the middle of the movingframe is movably connected with a moving block, the bottom end of the moving block is fixedly provided with a sand disc, the top end of the moving block is fixedly provided with an air pump, an air passage is formed in the sand disc, air blowing openings are formed in the two sides of the bottom end of the sand disc, and a buffer spring is fixedly arranged in the middle of the device base. According to the rough-wrought workpiece polishing device, the air blowing openings are formed in the two sides of the sand disc and are connected with the air pump through the air passage, so that the polishing device is used for continuously blowing air to the surface of the polishing surface by utilizing the air pump when polishing work is carried out, fine sand grains or other impurities on the surface of a polishing piece are cleaned, the cleaning work when the sand disc is replaced during each polishing is replaced, the polishing process is simplified, and the polishing efficiency is improved.

Owner:魏绣娟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com