Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

105results about How to "Avoid process complexity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength light foam ceramic plate and manufacturing method thereof

InactiveCN102627469AEasy accessLow priceConstruction waste recoverySolid waste disposalEnvironmental resistanceSodium bicarbonate

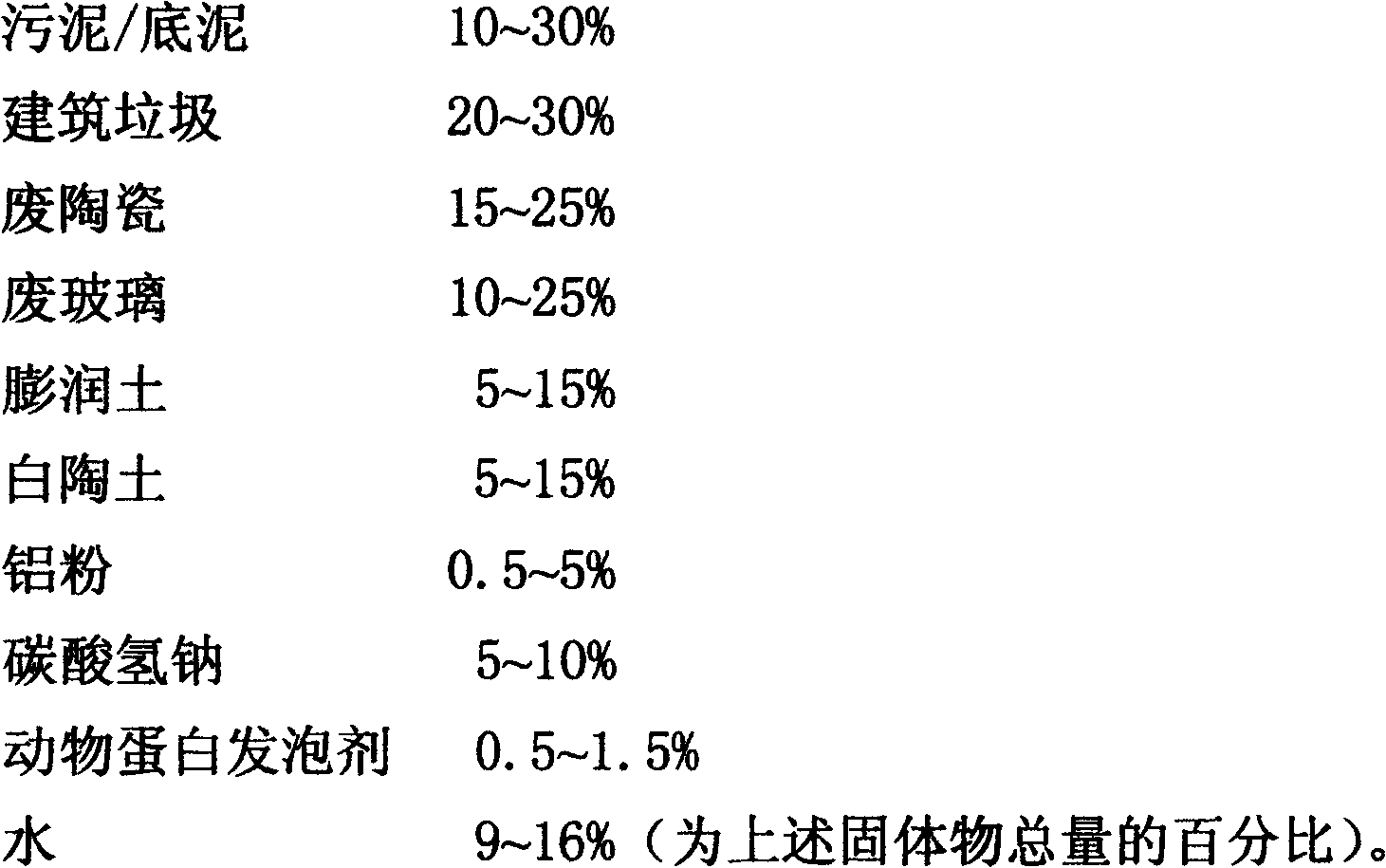

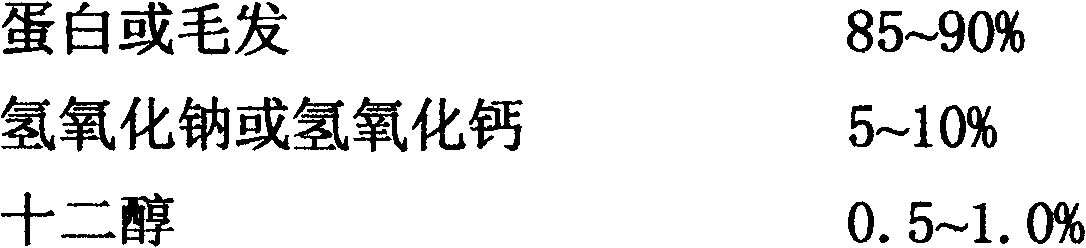

The invention discloses a high-strength light foam ceramic plate and a manufacturing method thereof, and belongs to the field of building material manufacturing. The ceramic plate comprises the following materials in percentage by weight: 10-30 percent of sludge / bottom mud, 20-30 percent of building waste, 15-25 percent of waste ceramic, 10-25 percent of waste glass, 5-15 percent of bentonite, 5-15 percent of kaolin, 0.5-5 percent of aluminum powder, 5-10 percent of sodium bicarbonate, 0.5-1.5 percent of animal albumen foaming agent and 9-16 percent (percentage of total amount of the solid matters) of water. The manufacturing method comprises the following steps of: mixing and crushing the main raw material; adding the animal albumen foaming agent and water; granulating; filling a granular material into a refractory combined mould; leveling; filling in a kiln; firing; and performing cold processing to produce a ceramic plate finished product. The high-strength light foam ceramic plate has the advantages of high product strength, small volume weight, fire proofing, excellent freeze proofing, long-term water proofing, readily available main raw material which basically comes from environmental solid waste, has a wide source and is low in cost and adoption of the animal albumen foaming agent of small using amount and wide source; the manufacturing process has the advantages of simplicity, high efficiency, energy conservation, environmental friendliness, no secondary pollution; and the high-strength light foam ceramic plate can be used as thermal insulation decorative materials, fire barriers and the like of exterior walls of buildings.

Owner:SICHUAN UNIV

Non-curing rubber asphalt waterproof material and preparation method thereof

ActiveCN105542496AAdapt to deformation requirementsImprove performancePlastic recyclingBuilding insulationsCross-linkBituminous waterproofing

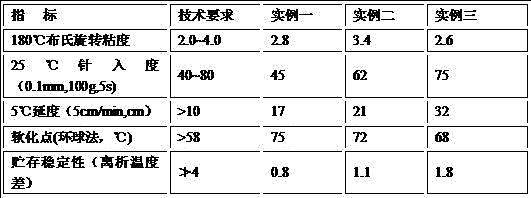

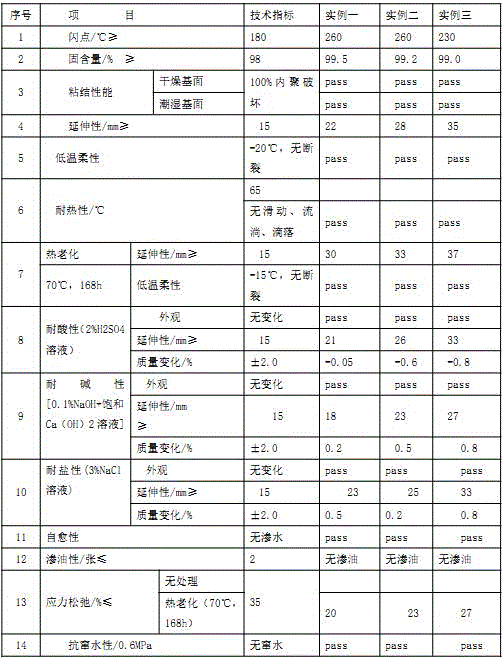

The invention discloses a non-curing rubber asphalt waterproof material and a preparation method thereof. The non-curing rubber asphalt waterproof material comprises raw materials in parts by weight as follows: 30-70 parts of base asphalt, 15-40 parts of waste tire rubber powder, 0.25-1.0 part of a desulfurizing agent, 0.8-4 parts of a composite modifier, 0.5-5 parts of a softening agent, 0.25-3 parts of a cross-linking agent and 5-15 parts of filler, wherein the grain size of the waste tire rubber powder is 20-80 meshes. The preparation method comprises steps as follows: raw material preparation, hot melting and mixture homogenization are performed; finally, the cross-linking agent and the filler in parts by weight are sequentially added to a storage tank and are stirred and mixed for 15-20 min, and the non-curing rubber asphalt waterproof material is formed. The waste tire rubber powder is directly subjected to circular shearing desulfurization by a high-shear homogenizer under the action of the desulfurizing agent in a high-temperature asphalt medium, rubber molecules are uniformly dispersed in an asphalt system in a linear structure manner and then form a stable stereoscopic meshed rubber structure with the filler under the action of the cross-linking agent, and the product performance is more stable.

Owner:河北交投特种材料科技有限公司 +1

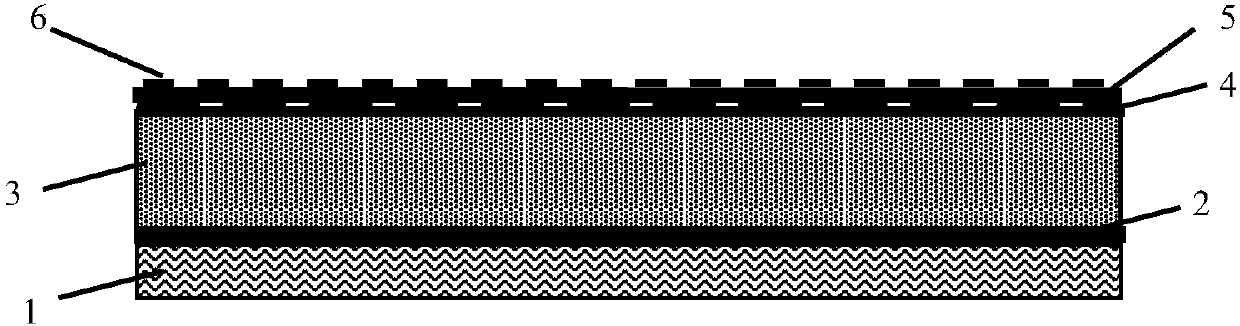

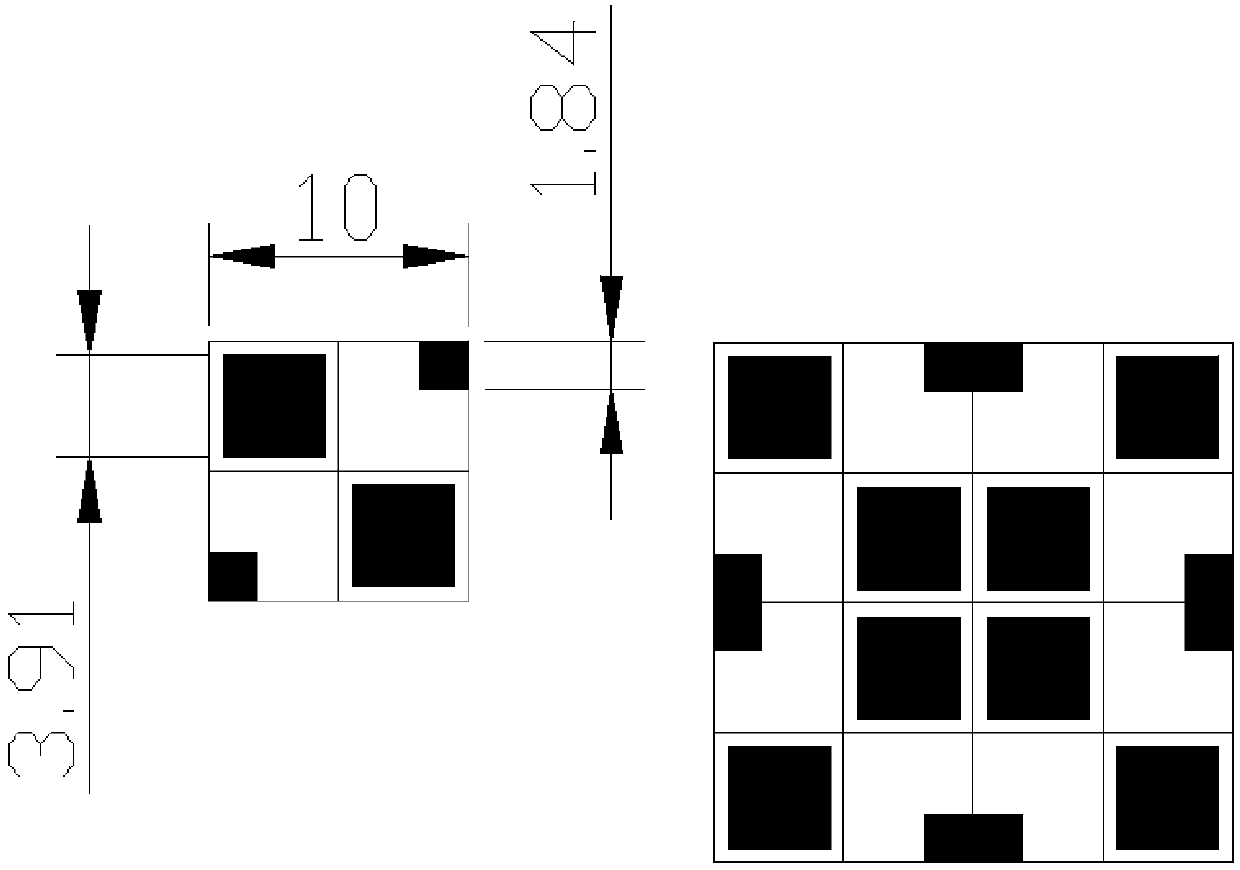

A radar/infrared compatible invisible coating resistant to 600 DEG C and a preparing method thereof

ActiveCN107747080AImprove absorbing performanceHigh radar bandMolten spray coatingMagnetic/electric field screeningElectrical conductorHigh reflectivity

A radar / infrared compatible invisible coating resistant to 600 DEG C is disclosed. The invisible coating is on the surface of a metal substrate, and includes an adhesive layer, a 8YSZ-Al2O3 ceramic bottom layer, a high-temperature resistance coating, a 8YSZ isolating layer and a high-temperature conductor coating in order from bottom to top form the surface of the metal substrate. The high-temperature resistance coating and the high-temperature conductor coating are in paster forms, and pasters are arranged periodically. A preparing method of the invisible coating is also disclosed. The structure of the invisible coating has a radar / infrared compatible stealth function. A resistance type periodic structure is introduced so that the invisible coating has a good wave absorbing function, anda defect that traditional wave absorbing coatings need absorbents so as to cause unsatisfied wave absorbing performance, big influences on processes and instable performance is solved. A conductor periodic structure is introduced to the surface layer, and the radar / infrared compatible stealth function is achieved by utilizing a high reflectivity characteristic for the infrared waveband and a hightransmittance characteristic for the radar waveband.

Owner:NAT UNIV OF DEFENSE TECH

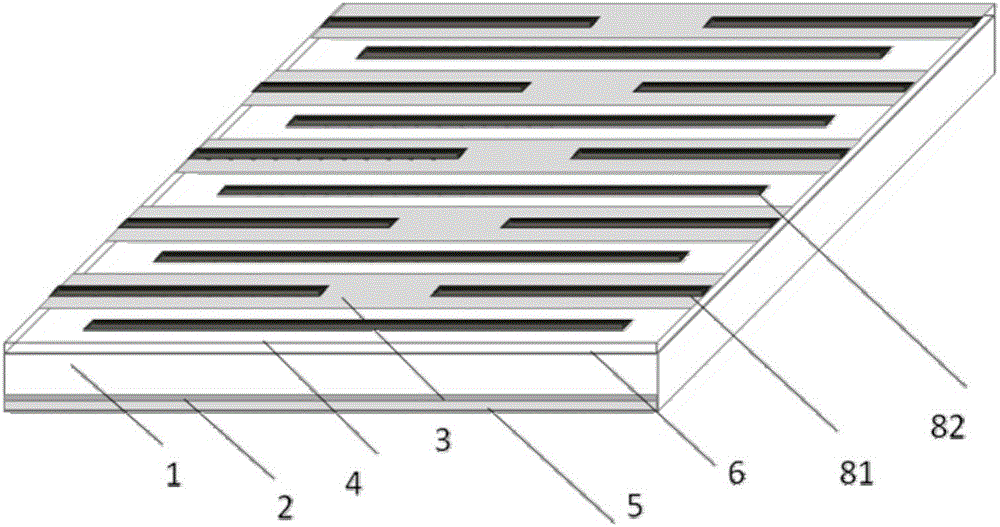

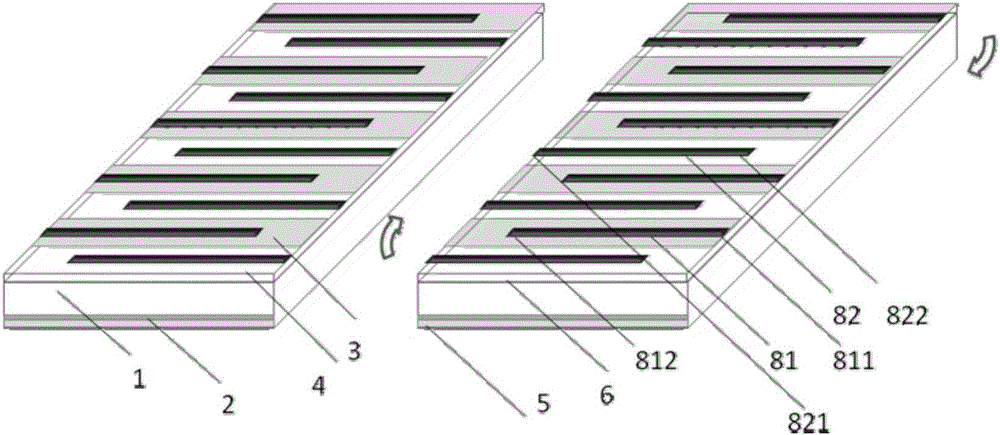

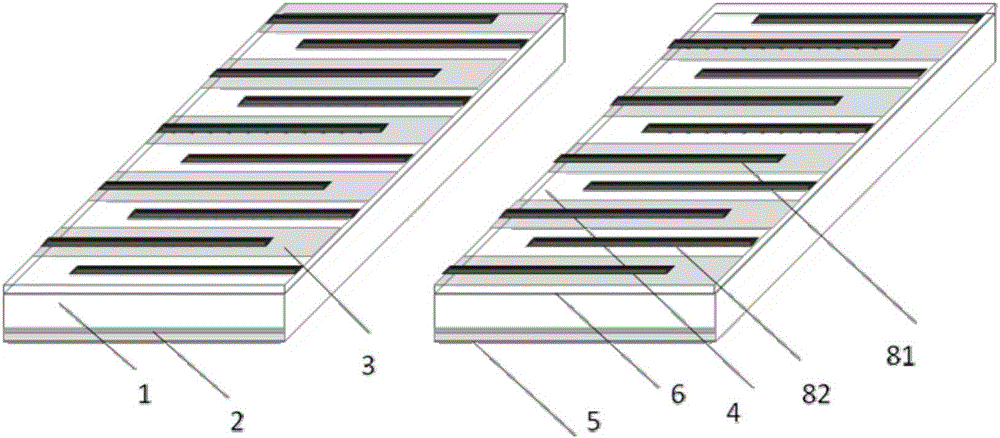

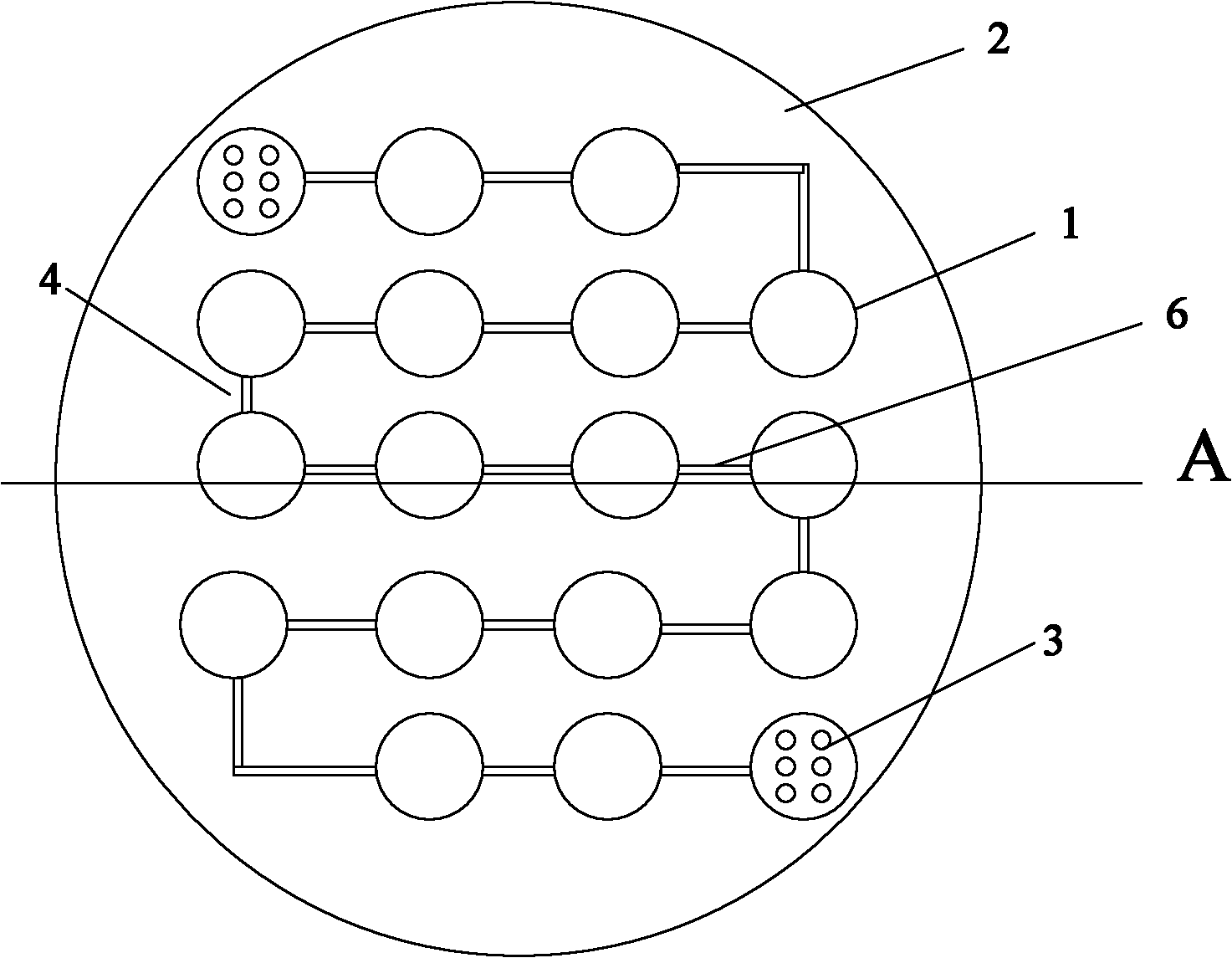

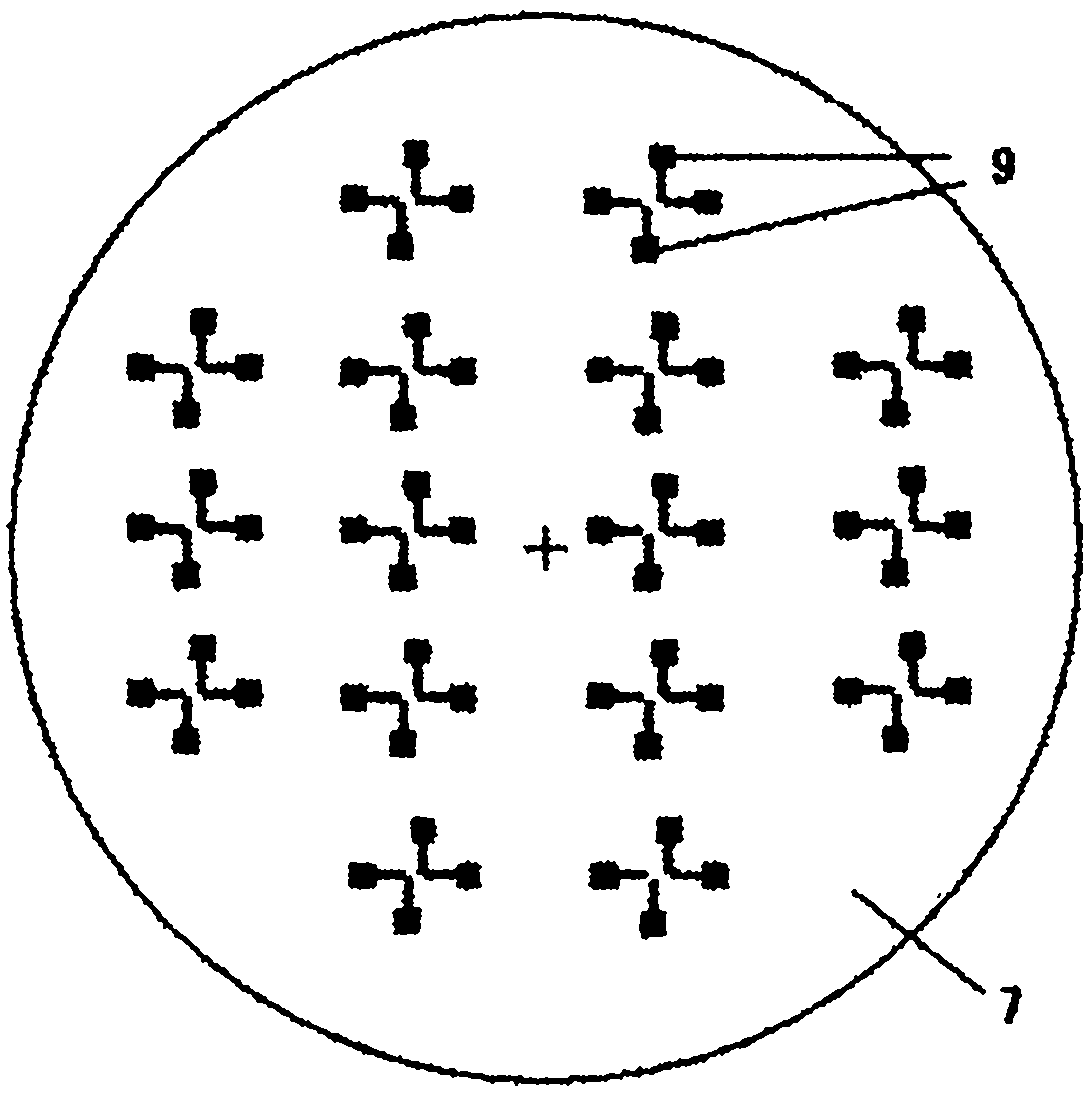

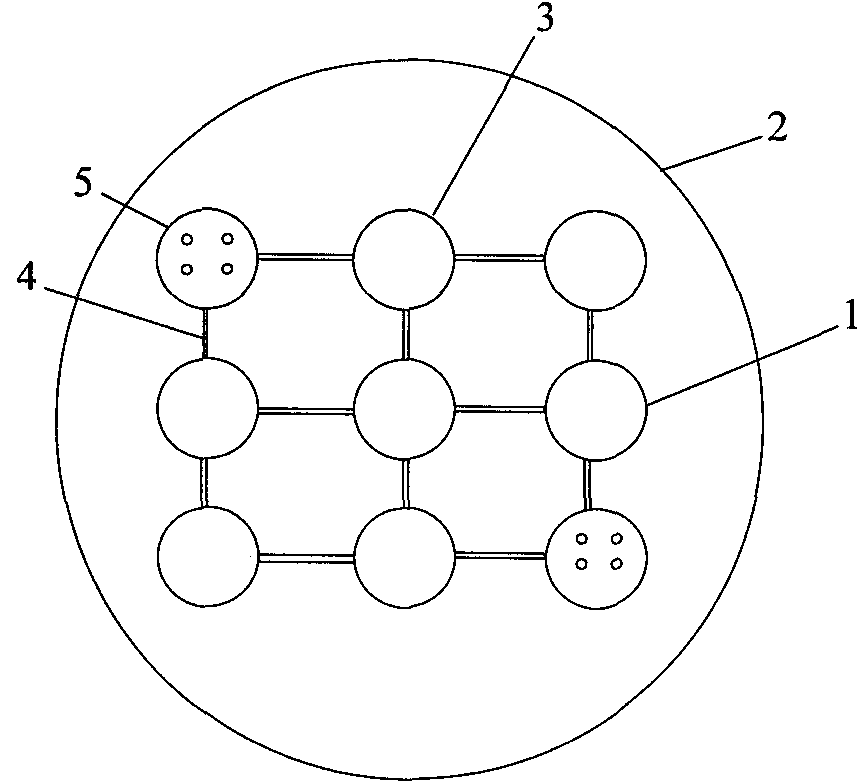

Main grid-free full-back contact solar cell module

ActiveCN106409929ALow costAvoid efficiency lossPhotovoltaic energy generationSemiconductor devicesLine resistanceSilver paste

The invention discloses a main grid-free full-back contact solar cell module. The solar cell module comprises a plurality of series back contact small solar cell sheets, the back contact small solar cell sheet is formed after cutting the back contact solar cell sheet, a protruding end of a fine grid of one back contact small solar cell sheet is serially connected with the protruding end of the fine grid with opposite polarity of the adjacent back contact small solar sheet to manufacture a series cell string and then to manufacture the cell module; the cell module avoids the efficiency loss and process complexity caused by the main grid line setting of the full-back contact solar cell and saves the main grid line cost; since a plurality of cell units are cut, the current of each string of cell sheet group string is lowered, thereby reducing the influence of the fine grid line resistance loss; the consumption of the silver paste can be lowered, and the fill factor of the battery and the module are improved at the same time; based on two above points, the cell module can improve the efficiency of the full-back contact battery module, and can lower the process difficulty and manufacturing cost thereof.

Owner:晶澳(扬州)新能源有限公司

Preparation method of flaky nano-cerium oxide

InactiveCN103991891ANo pollution in the processEasy to prepareNanotechnologyRare earth metal compoundsStationary conditionsCerium

The invention relates to a preparation method of flaky nano-cerium oxide, comprising the following steps: preparing an aqueous solution of water-soluble cerium salt and an aqueous solution of a precipitant carbonate; adding the aqueous solution of carbonate into the aqueous solution of cerium salt within the temperature range of 0-50 DEG C under the condition of stirring; continuously stirring to react for 0.2-2 h so as to obtain a precipitate solution; aging the precipitate solution for 0-48 h under stationary condition and at the temperature of 0-50 DEG C; collecting a precipitate from the precipitate solution; and washing, drying and roasting to obtain flaky nano-cerium oxide. Hydrothermal / alcohol-thermal processes are not required. Flaky nano-cerium oxide is synthesized at one step of solution precipitation reaction at low temperature. Problems of many required raw materials, complex process, harsh production conditions and the like by a hydrothermal / alcohol-thermal method, sol-gel method, micro-emulsion method or traditional liquid phase method are avoided. Technological conditions are mild and easy to control, and the preparation method is environmentally friendly and pollution-free.

Owner:EAST CHINA UNIV OF SCI & TECH

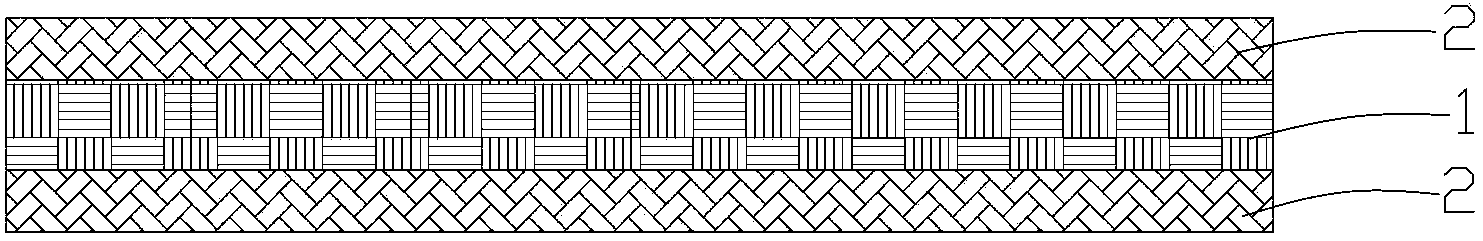

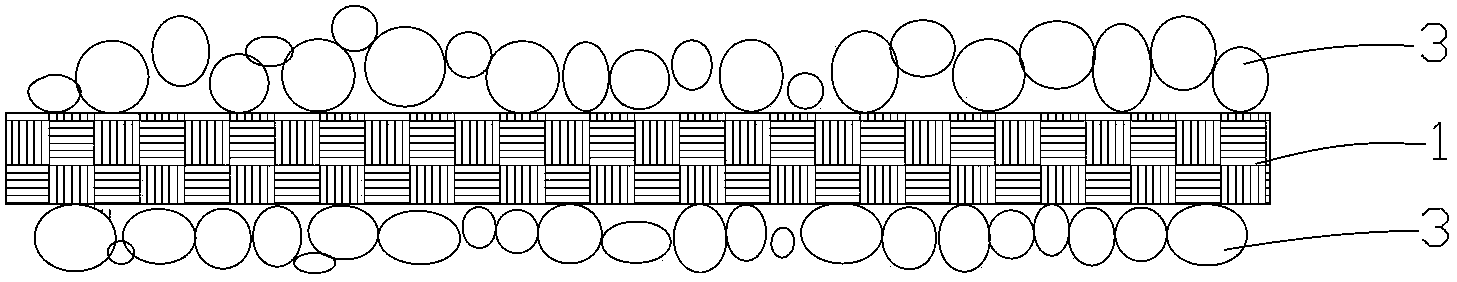

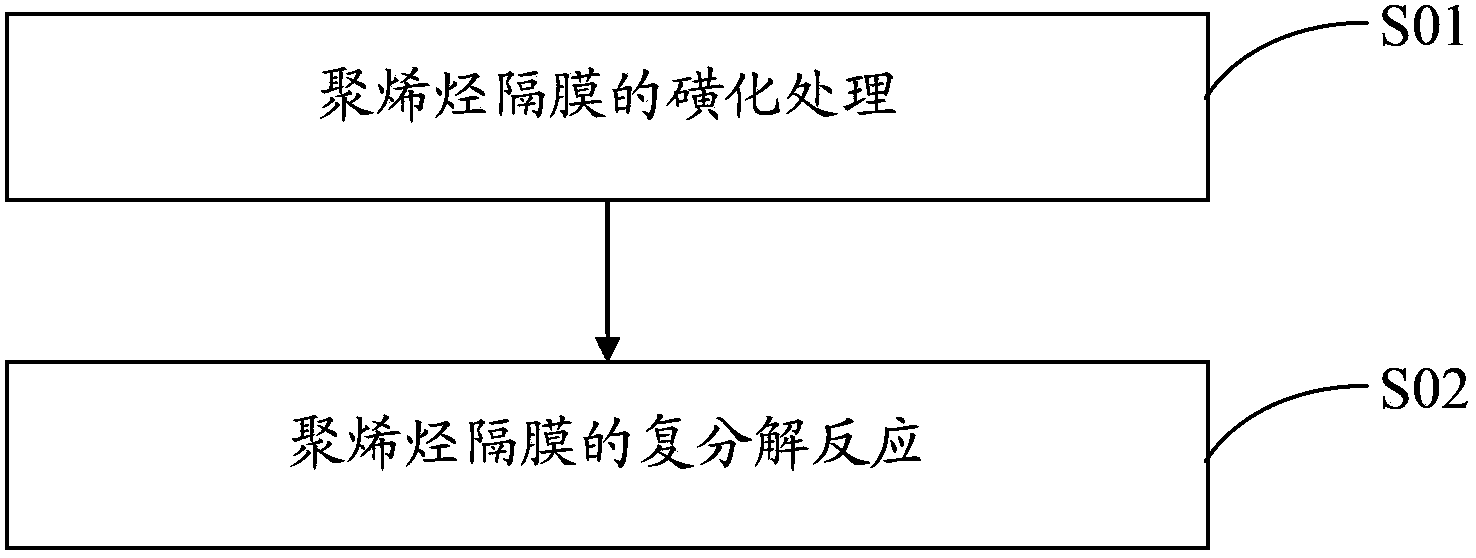

Battery diaphragm and preparation method thereof, lithium ion battery and communication equipment

ActiveCN103579560AImprove electrolyte affinityStable chemical propertiesCell seperators/membranes/diaphragms/spacersWound/folded electrode electrodesPolyolefinIon transfer

The invention provides a battery diaphragm and a preparation method thereof, a lithium ion battery and communication equipment. The battery diaphragm comprises a polyolefin diaphragm, and polyolefin molecules of the polyolefin diaphragm contain -SO3Li and -COOLi groups. The preparation method of the battery diaphragm comprises the following steps of a sulfonation step of the polyolefin diaphragm and a replacement reaction step of the polyolefin diaphragm. The lithium ion battery contains the battery diaphragm prepared by the method. The communication equipment contains the lithium ion battery. The battery diaphragm has good electrolyte affinity and increases the capacity for electrolyte retention and ionic conductivity. Lithium ions form a clear lithium ion transfer channel in the polyolefin diaphragm, so that the lithium ion battery has the large-current charging and discharging capacity. The preparation method has the advantages that the process is simple, conditions are easily controlled, the production efficiency is high and the production cost is reduced.

Owner:江苏三正新能源有限公司

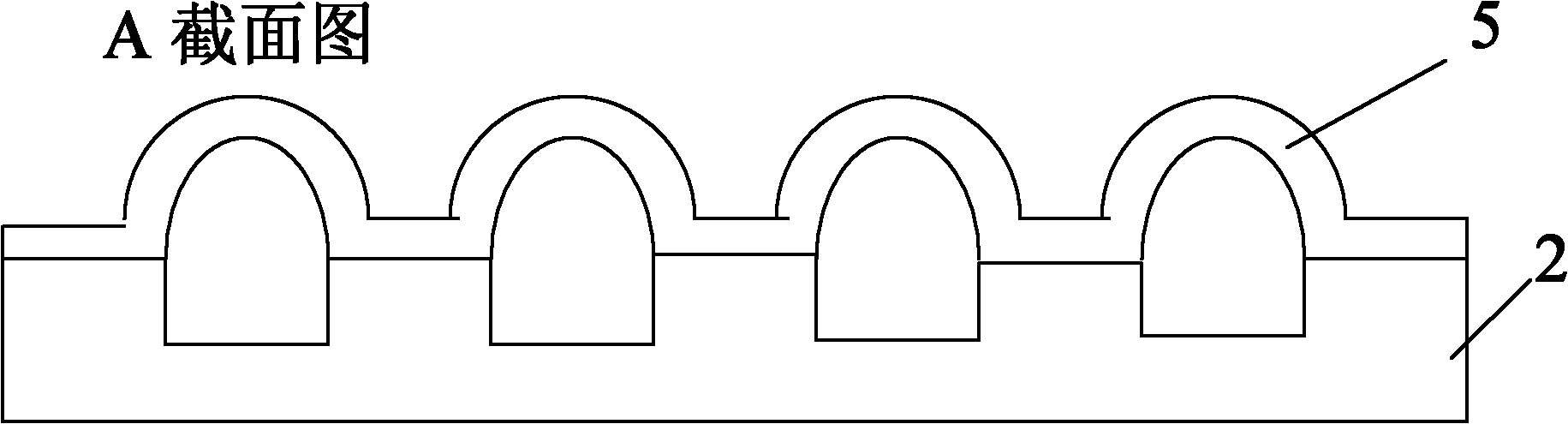

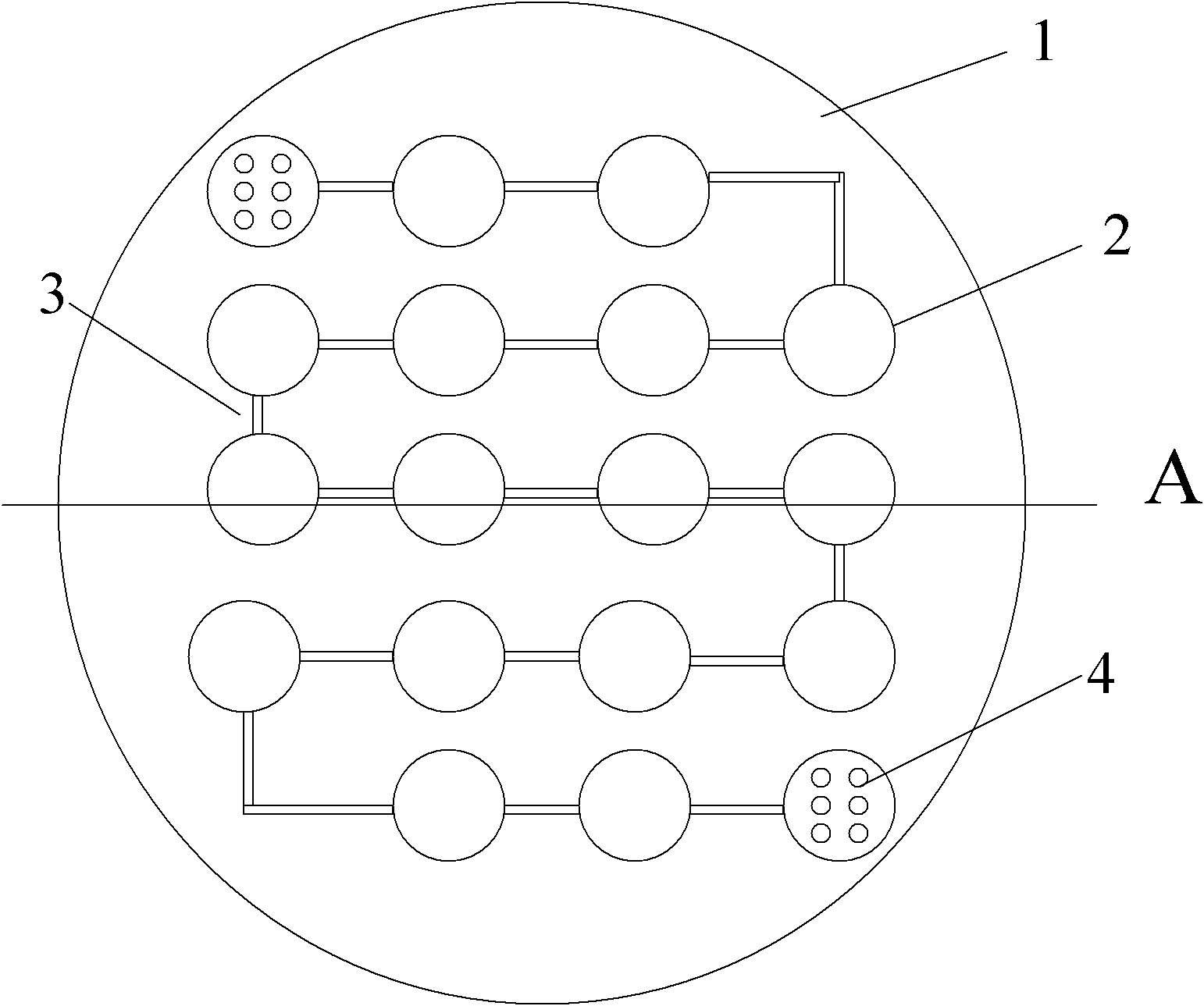

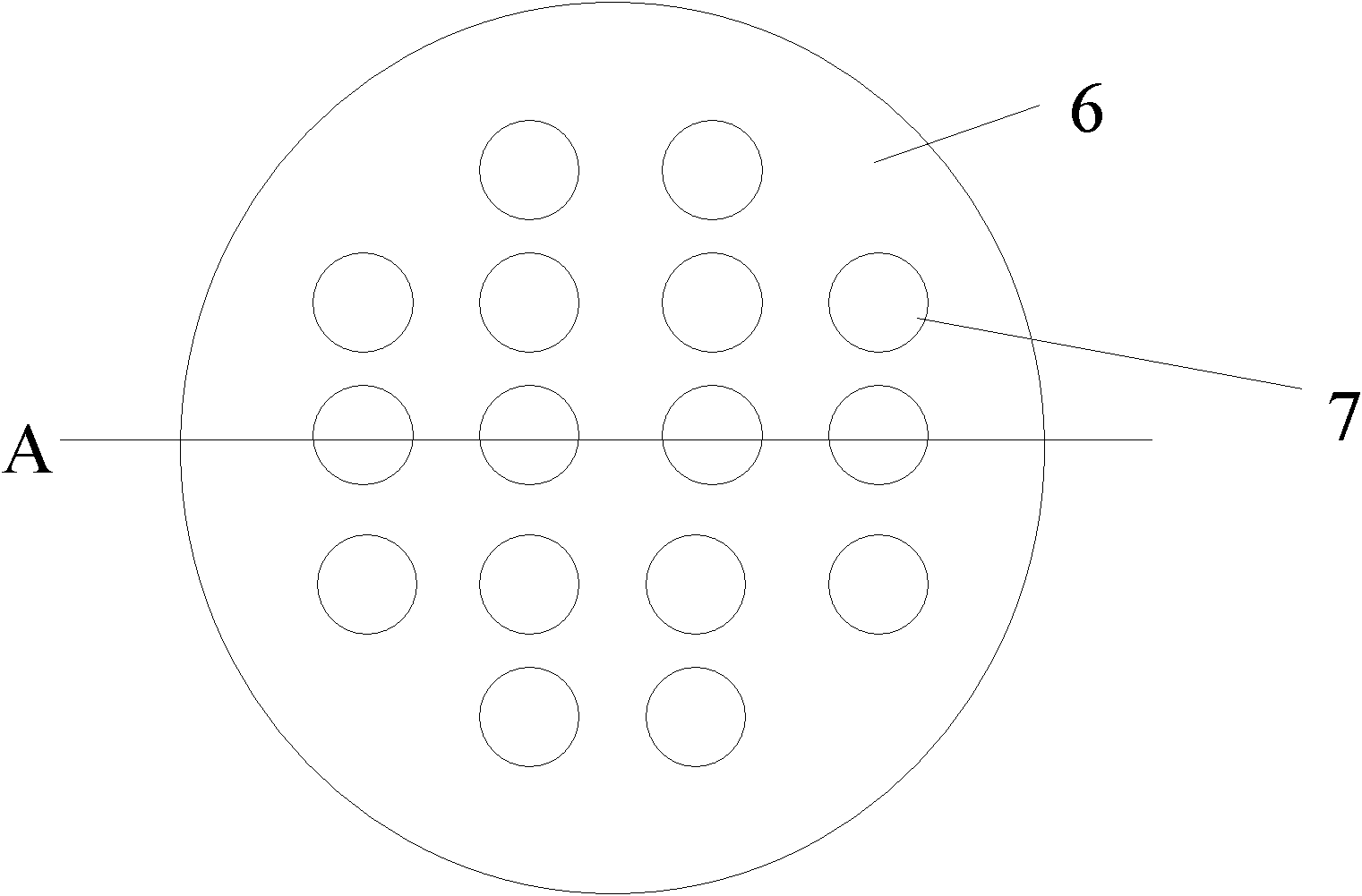

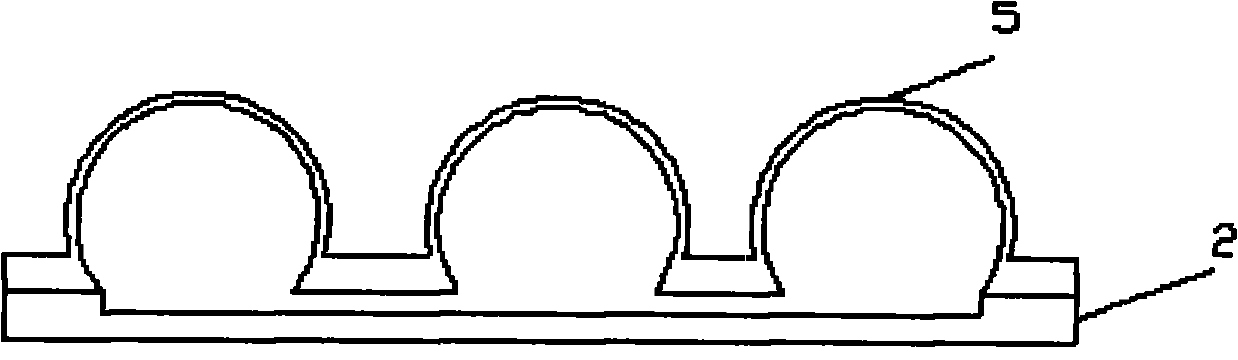

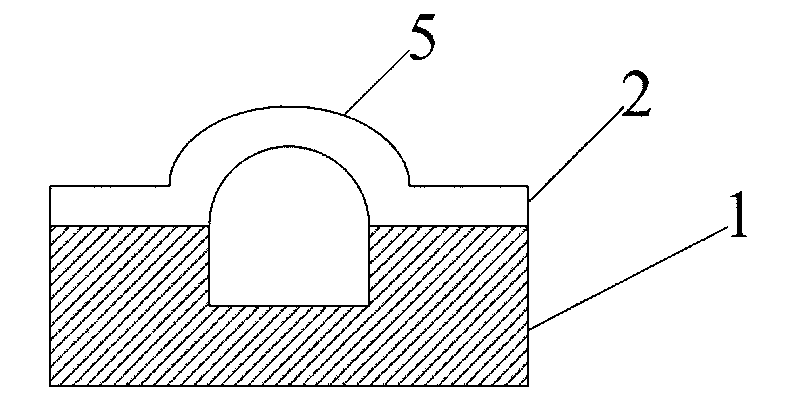

Method for packaging wafer level glass micro-cavity of light-emitting diode (LED)

ActiveCN102110750AReduce optical interfaceGood optical performanceSolid-state devicesSemiconductor devicesLed arrayLight beam

The invention discloses a method for packaging a wafer level glass micro-cavity of a light-emitting diode (LED), and the method comprises the following steps: (1) etching a micro-slot array corresponding to the pattern of a packaged LED array on a silicon wafer, wherein the micro-slots are communicated through a micro-channel, and a proper amount of heat gas releasing agent is arranged inside the micro-slots; (2) forming a closed cavity; (3) heating the bonded wafer in the air to form a spherical glass micro-cavity and a cylindrical glass micro-channel connected with the spherical glass micro-cavity, cooling to room temperature, annealing, and removing silicon to obtain a wafer level glass micro-cavity; (4) sputtering a metal layer on the silicon wafer, and preparing a metal lead through photolithography, so as to obtain a lead substrate, wherein the position of the metal lead corresponds to the position of the micro-channel of the glass micro-cavity; (5) mounting an LED chip on the lead substrate, and leading; (6) bonding the wafer level glass micro-cavity with the substrate to form a bonded wafer; and (7) filling the gap between the LED chip and the wafer level glass micro-cavity with silicone through the glass micro-channel. According to the invention, the light emitting efficiency is high, and a packaged glass lens realizes beam collimation.

Owner:SOUTHEAST UNIV

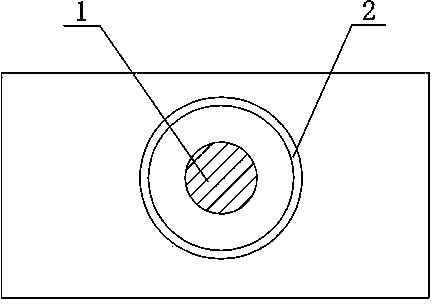

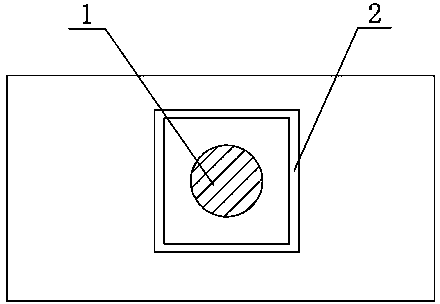

Method for reducing stress on peripheral region of silicon through hole

InactiveCN103824758AExtended service lifeImprove job stabilitySemiconductor/solid-state device manufacturingStress concentrationStress relieving

The invention relates to a method for reducing stress on the peripheral region of a silicon through hole. The silicon through hole can be subjected to etching, side wall insulation, seed layer deposition, through hole filling and other process steps in a preparation process to generate process residual stress; in addition, the thermal expansion coefficient of copper is greatly different from that of a peripheral material, therefore, a certain stress concentration phenomenon is generated on the periphery region of the silicon through hole, and the stress can bring adverse effects on the performances and reliabilities of semiconductor devices around the silicon through hole. The invention provides a solution for processing a stress eliminating structure with a certain depth and specific shape within a certain region at the periphery of the silicon through hole in order to overcome the limitation of reducing the stress at the periphery of the hole and the stress influence range in an annealing way adopted at present. Compared with the prior art, the method has the beneficial effects that the process complexity of the annealing way for eliminating the stress is lowered, the area of a stress influence region is greatly reduced, the service life of the silicon through hole can be remarkably prolonged and the working stability of peripheral devices can be remarkably improved through arranging the specific stress eliminating structure within a certain region at the periphery of the silicon through hole by using the traditional etching way, and the method has the advantages of simple and reliable process and easiness for realization.

Owner:NAT CENT FOR ADVANCED PACKAGING

Method for packaging glass-silicon wafer-grade chiponboard (COB) of light emitting diode (LED)

ActiveCN102097545AReduce luminous attenuationImprove performanceSolid-state devicesSemiconductor devicesHeat resistanceSilica gel

The invention discloses a method for packaging a glass-silicon wafer-grade chiponboard (COB) of a light emitting diode (LED). The method comprises the following steps: 1, etching a silicon micro slot array with the micro slots communicated with each other through micro channels, and placing a proper amount of heat outgas agent in the micro slots; 2, performing anodic bonding on the Si wafer with patterns and the heat outgas agent and borosilicate glass wafer in air or in vacuum to form a sealed cavity; 3, heating and preserving heat to form a spherical glass micro cavity, cooling the cavity to normal temperature, annealing and removing silicon to obtain a wafer-grade glass micro cavity; 4, preparing a lead substrate; 5, mounting a chip and leading a wire; 6, carrying out wafer-grade bonding; and 7, filling silica gel to realize the wafer-grade packaging of the LED. By achieving the integration with the wafer-grade LED reflecting cup, the method reduces heat resistance and cost.

Owner:SOUTHEAST UNIV

Method for preparing wafer-level uniform-dimension glass microcavity by positive pressure thermal forming

ActiveCN101905859ANot easy to expandLow costPrecision positioning equipmentSoldering apparatusPhysical chemistrySilicon

The invention discloses a method for preparing a wafer-level uniform-dimension glass microcavity by positive pressure thermal forming. The method comprises the following steps of: etching an array consisting of microgrooves on a silicon wafer, and etching microchannels connecting the microgrooves, wherein the minimum groove width of the microgrooves is 5 times more than the runner width; and putting a proper amount of thermal outgassing agent into at least one microgroove, correspondingly bonding the plurality of microgrooves to form a sealed cavity by using a glass wafer, heating to soften the glass, making the thermal outgassing agent heated to release gases to generate positive pressure, acting the positive pressure on the softened glass corresponding to the plurality of microgrooves which are connected through the microchannels so as to form a spherical microcavity with uniform dimension, and cooling the microcavity. By connecting the same microgrooves through the microchannel, the inside air pressure of the microgrooves is substantially consistent, and the formed glass microcavity has uniform dimension. When the dimension of the microgrooves is far greater than that of the microchannel, the microchannels with smaller radius hardly expand due to higher additional pressure. Therefore, the glass corresponding to the microchannels can keep smooth.

Owner:SOUTHEAST UNIV

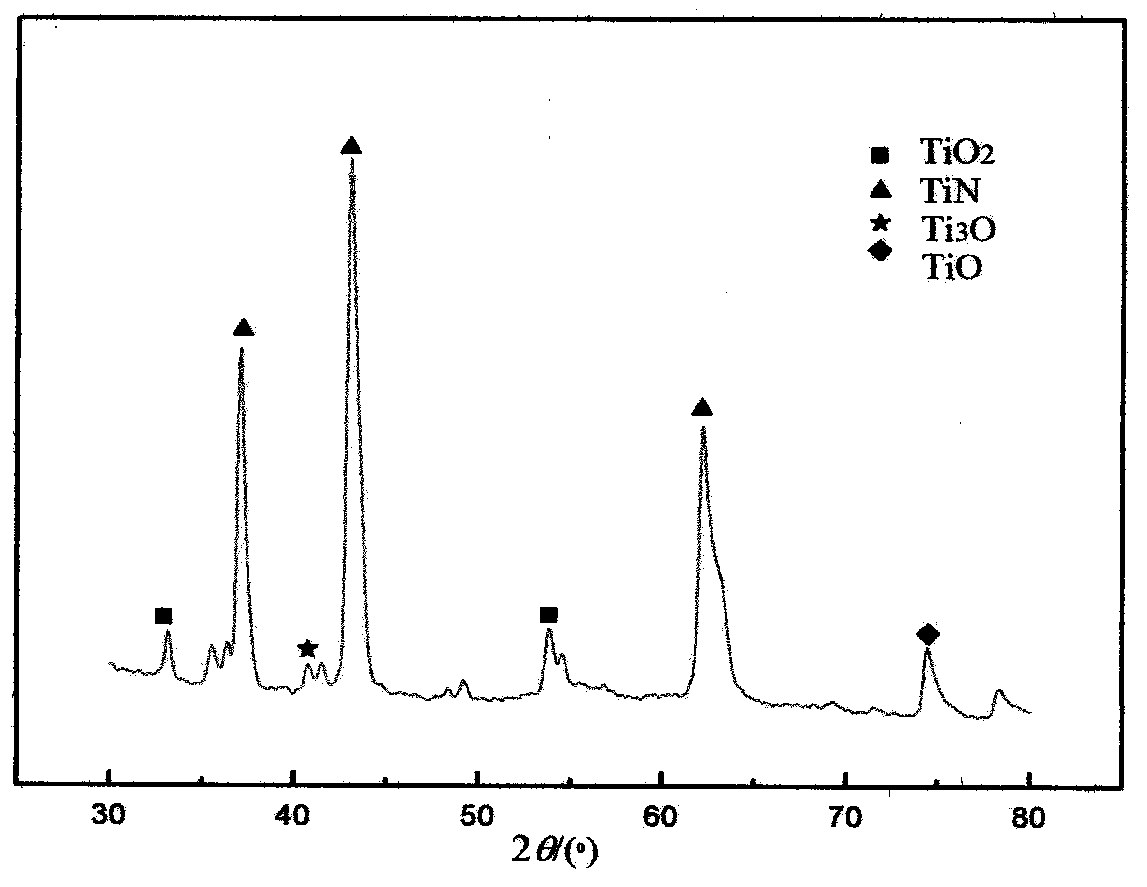

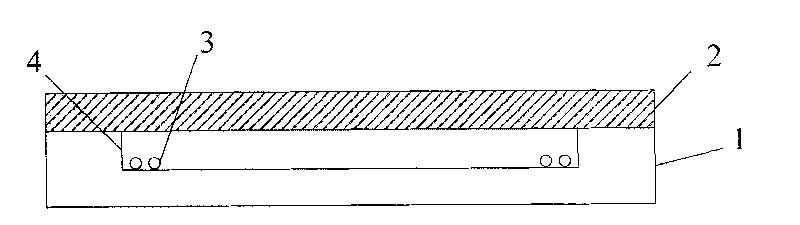

TiN-coat-coated mold

InactiveCN104342613AImprove toughnessAvoid brittlenessMolten spray coatingBearing componentsHigh fractureFracture mechanics

The invention discloses a mold of which the surface is coated with a TiN coat, wherein the surface is coated with a TiN coat, and the three-strong-peak phase of the coat is a TiN phase and also has partial TiO, TiO2 and Ti3O oxide phases. The coat has laminar distribution of dark-and-light phases, and the joint of the laminar structure inside and laminar structure is provided with a small amount of pores. The joint of the coat and base does not have crack or any other microdefect, is well combined. By using ultrasonic plasma to spray the TiN coat, the coat has higher hardness (up to 1210HV0.1), and the high hardness can enhance the wear resistance of the coat; the coat has higher fracture toughness which can enhance the interior fracture mechanical properties of the coat and prolong the fatigue life of the coat.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

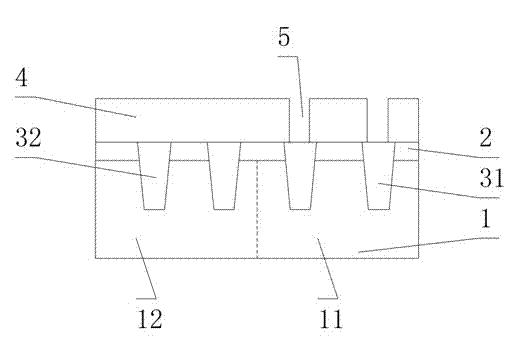

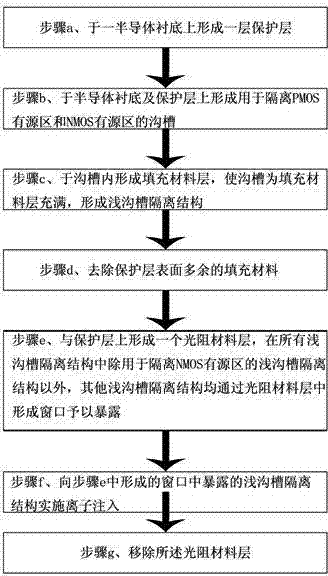

Manufacture method of shallow trench isolation structure for adjusting stress of isolation oxide by ion implantation

ActiveCN102412184AAvoid process complexityImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesPhysical chemistryIon implantation

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Power battery as well as power battery cover plate and manufacturing method thereof

InactiveCN107658394AAvoid process complexityAvoid process costsCell lids/coversElectric connector introductionPower batteryElectrical battery

The application relates to a power battery as well as a power battery cover plate and a manufacturing method thereof. The power battery cover plate comprises a cover plate body, an insulation protective layer covered on an inner layer of the cover plate body, and a post terminal penetrating through the cover plate body, wherein an injection molding layer for realizing a sealed connection between the post terminal and the cover plate body is arranged between the post terminal and the cover plate body, and the injection molding layer and the post terminal are molded through an injection moldingmode and form a chemical bond connection. According to the application, a chemically bonded injection molding layer is molded and formed on the surface of the post terminal by adopting an injection molding mode, the sealed connection between the post terminal and the cover plate body can be achieved by using the injection molding layer, and thus the problems of complex process, higher cost, low structural strength, lower reliability of the power battery and the like caused by adopting a riveting or snap spring structure for sealing in the prior art can be effectively avoided; and according tothe application, the complexity of a manufacturing process can be reduced through the injection molding mode, a low cost can be achieved, and the structural strength and the equipment reliability canbe ensured.

Owner:SHENZHEN EVERWIN PRECISION TECH

Method for preparing high-silicon steel sheet by powder compression sintering

The invention discloses a method for preparing a high-silicon steel sheet by powder compression sintering, and belongs to the technical field of powder metallurgy. According to the method, gas atomized Fe-6.5 wt.% Si powder is used as a raw material, the powder is in a compact state through powder presetting, the powder is placed in a vacuum sintering furnace to be metallurgically bonded through high-temperature sintering, multi-passes hot rolling are carried out to a certain thickness and then 1-4 times of cold rolling are carried out, and finally annealing is carried out at high temperatureto obtain the high-silicon steel sheet with excellent performance. Compared with adopting water atomized powder, gas atomized high-silicon steel powder is adopted and oxide inclusions of an alloy system are greatly reduced, meanwhile, the problem that spherical gas atomized powder is difficult to form is solved by adopting a direct compression sintering method, so that the process complexity and the subsequent problems of degumming and carbon residue caused by adding a forming agent are avoided, and the method has the advantages of being simple to operate, high in production efficiency, high in product precision, short in process flow, free of pollution and inclusions, excellent in performance and the like.

Owner:UNIV OF SCI & TECH BEIJING

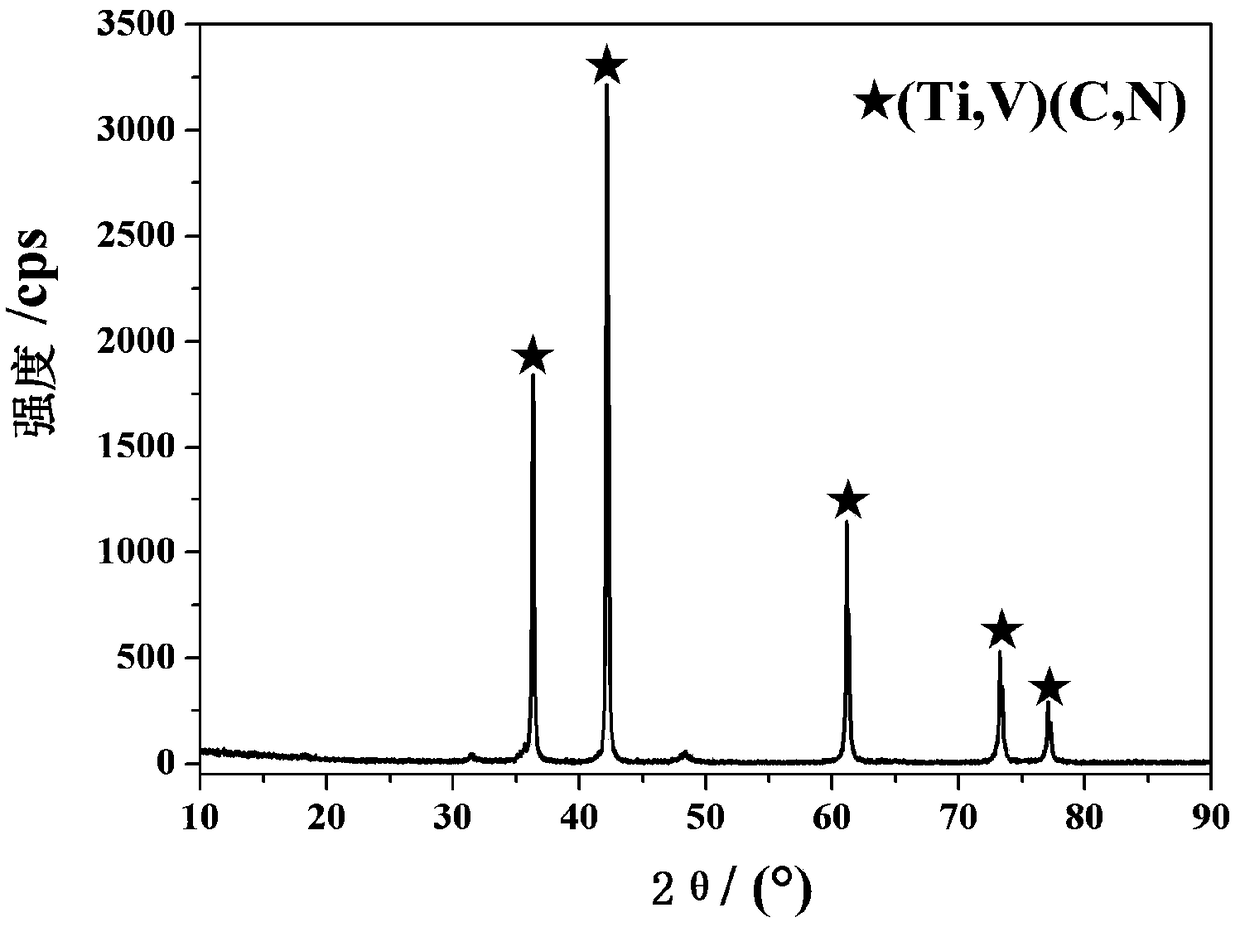

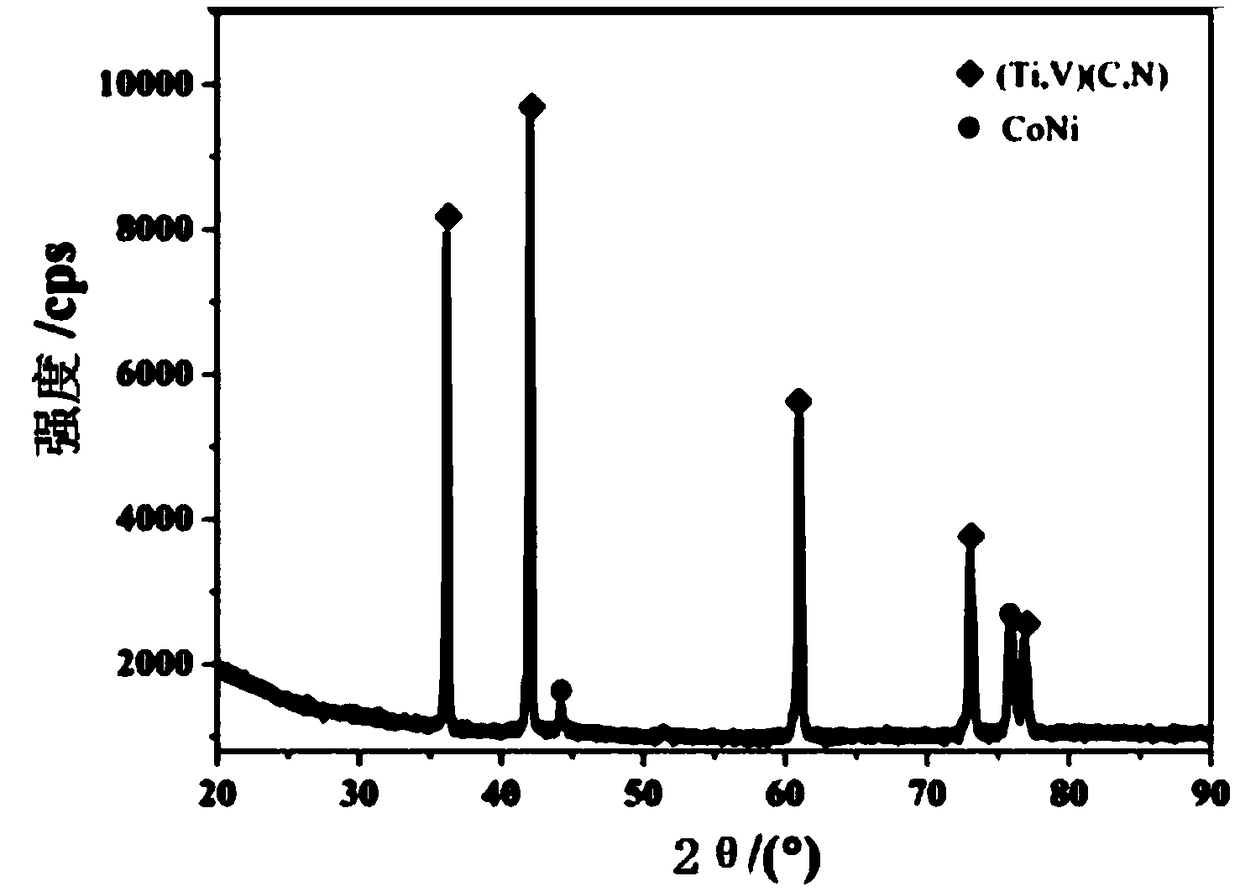

Production method of carbon vanadium nitride solid melt and hard alloy thereof

InactiveCN109136709AEasy to operateEasy to controlNitrogen and non-metal compoundsFiltrationCarbonization

The invention relates to a production method of a carbon vanadium nitride solid melt and a hard alloy thereof, belongs to the technical field of hard alloys and aims to solve the technical problem ofproviding a production method which is low in cost and easy in process control for the carbon vanadium nitride solid melt and the hard alloy thereof. The production method of the carbon vanadium nitride solid melt comprises the following steps: a, carrying out ball milling, namely putting solid powder into absolute ethyl alcohol in a liquid-solid ratio of (4-8):1, and carrying out ball milling mixing with a ball material ratio of (5-10):1, wherein the solid powder is carbon vanadium nitride powder and carbon nitriding metallic powder, and the carbon nitriding metallic powder is titanium carbonitride powder or carbon vanadium nitride powder; b, carrying out filtration and drying; c, carrying out pressing molding; d, carrying out reductive carbonization, thereby obtaining the carbon vanadiumnitride solid melt. Ti(C, N) or V(C, N) made by using a common carbon thermal reduction method provided by the invention is a nitrogen source produced carbon vanadium nitride solid melt and a corresponding hard alloy, the content of N in the melt is easy to control, and the production process is simple and feasible, convenient to control and low in cost.

Owner:PANZHIHUA UNIV

Manufacture method of ultra-large-diameter pipeline extruded nozzles

InactiveCN103286153AReduce the amount of processingAvoid process complexityExtrusion control devicesSteel pipelinePhysical property

The invention relates to a manufacture method of ultra-large-diameter pipeline extruded nozzles. The method comprises the following steps of: straightening and finishing a stainless steel tube blank, so as to ensure that the straightness and the size of the stainless steel tube blank is uniform, rapidly heating the treated stainless steel tube blank through an induction coil, so as to ensure that the temperature of the stainless steel tube blank reaches 1,150 to 1,200 DEG C, preheating a die, keeping the preheating temperature at 100 to 200 DEG C, conveying the heated stainless steel tube blank into the die, ensuring that the temperature of the stainless steel tube blank is more than 1,100 DEG C, inserting a core rod into the stainless steel tube blank, applying force to the guide section side of the core rod from the extrusion side of the core rod, and performing one-way extrusion, so as to ensure that steel is filled in die holes of the die and to extrude a nozzle shape. By adopting the method, not only can nozzles be produced in ultra-large-diameter stainless steel pipelines, but also the nozzles have good physical properties, material is also saved, and the operability is high.

Owner:ZHONGXING ENERGY EQUIP

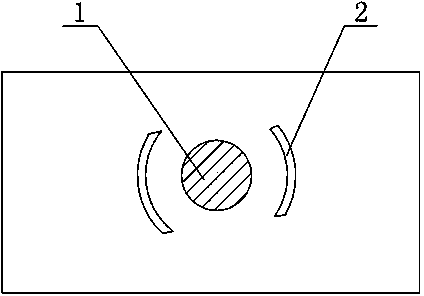

Glass vacuum cavity device of atom interferometer

InactiveCN106932997AImprove reliabilityHigh Optical Intervention QualityNon-linear opticsIndiumEdge structure

The invention relates to a glass vacuum cavity device of an atom interferometer. The glass vacuum cavity device comprises a square cavity, a transition circular pipe, a glass circular ring, a pressing piece and an adapter flange. A glass vacuum cavity structure is composed of the square cavity and the transition circular pipe. The transition circular pipe and the glass circular ring are sealed by using the optical cement technology. The glass circular ring is uniformly and tightly pressed in a polished groove at one side of the adapter flange by the pressing piece. A Teflon gasket is disposed between the pressing piece and the glass circular ring. The glass circular ring and the adapter flange are sealed by using indium wires. The other side of the adapter flange is of a general edge structure and can be conveniently sealed with a stainless steel vacuum cavity. The disadvantages that a traditional cavity is required to be sealed by metal and glass, the sintering technology is complex, and the traditional cavity is large in size and easy to crack are solved, and the glass vacuum cavity device has the advantages of high reliability, simple manufacture and high optical intervention quality, and can be used as a key structure of an integrated atom interferometer vacuum cavity.

Owner:BEIHANG UNIV

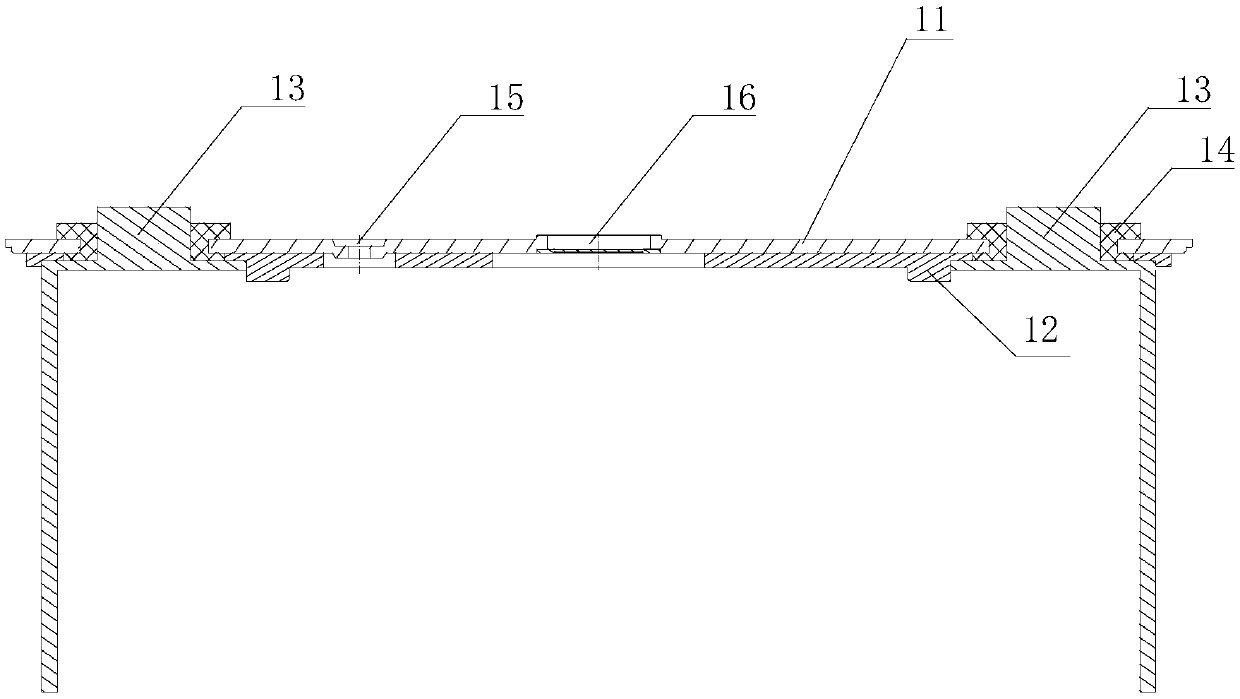

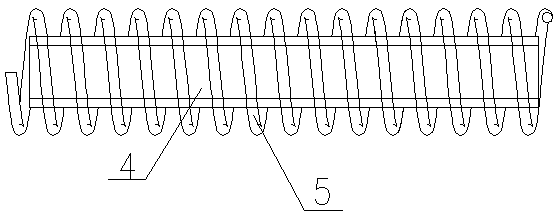

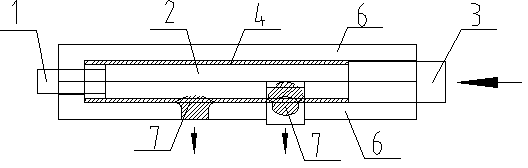

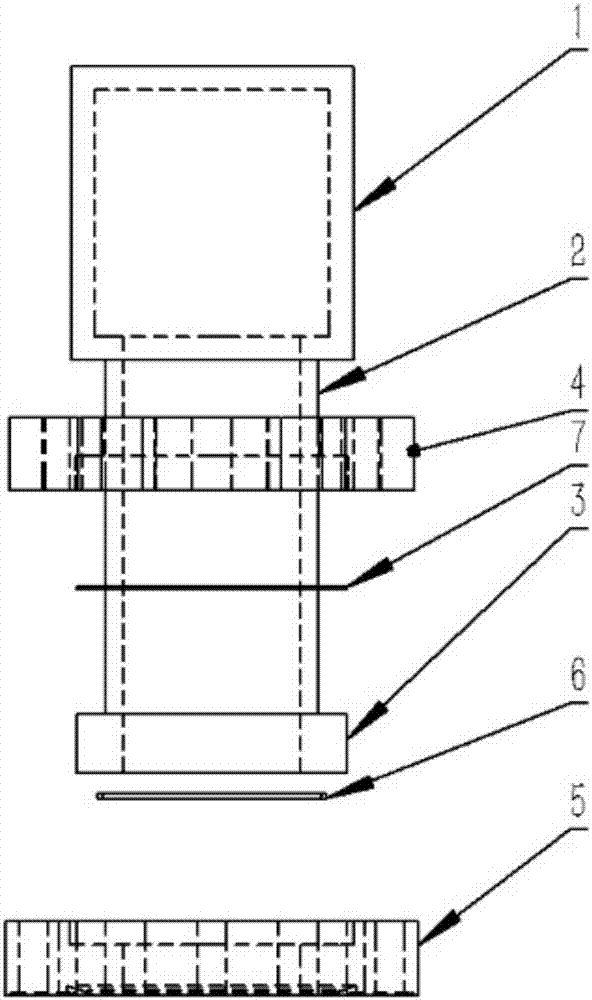

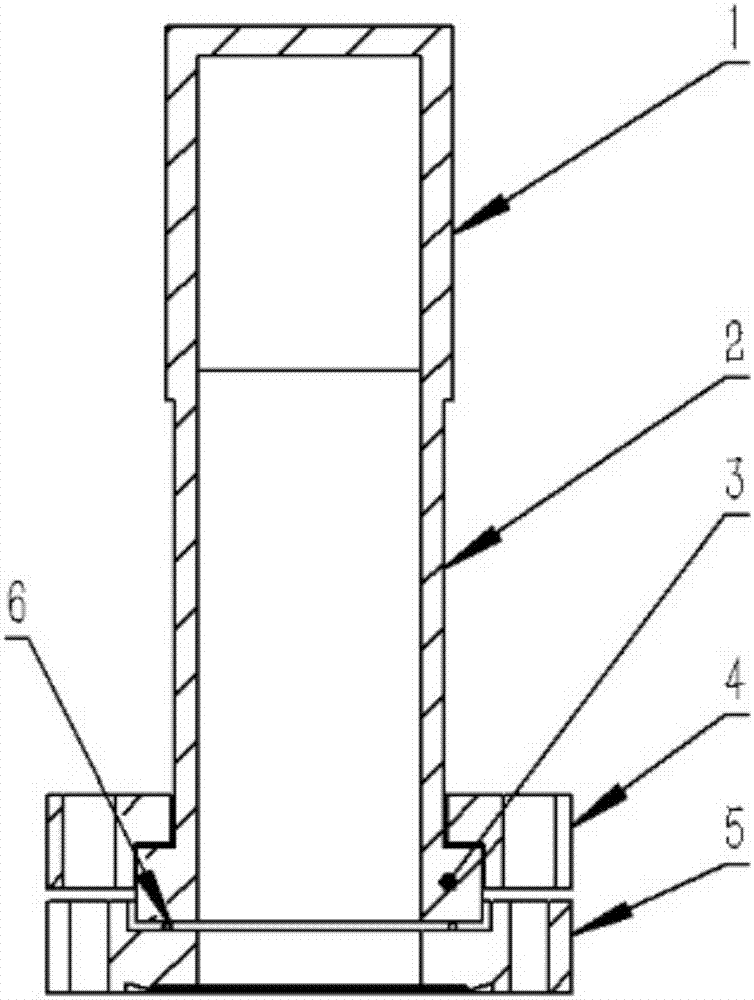

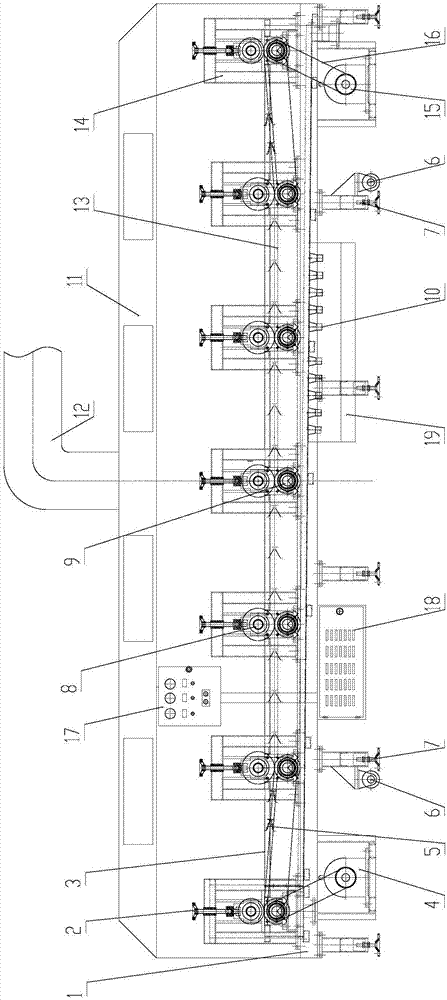

Continuous impregnation and pressing ultrasonic gluing machine

ActiveCN107362936AReduce surface tensionLow viscosityLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses a continuous impregnation and pressing ultrasonic gluing machine comprising a frame, an impregnation tank, an ultrasonic unit, multiple groups of rolling mechanisms and driving units. The impregnation tank is arranged on the frame. The ultrasonic unit is arranged on the lower portion of the impregnation tank. The rolling mechanisms are arranged along the length direction of the impregnation tank in a spaced manner, and each rolling mechanism comprises a support, an upper press roller and a lower press roller. The driving units drive the lower press rollers of the rolling mechanisms to rotate. The continuous impregnation and pressing ultrasonic gluing machine can improve working efficiency.

Owner:CHAMBROAD CHEM IND RES INST CO LTD +1

Method for preparing high-silicon steel sheet through powder rolling

ActiveCN110355372AGood for magnetismImprove mechanical propertiesTransportation and packagingMetal-working apparatusIron powderElectrolysis

The invention discloses a method for preparing a high-silicon steel sheet through powder rolling, and belongs to the technical field of powder metallurgy. The method comprises the following steps thatelectrolytic iron powder and silicon powder coated with iron powder are adopted, the raw materials are simply mixed through a v-shaped mixer to form Fe-6.5wt.%Si. A green sheet is formed through a powder rolling method, is subjected to high-temperature sintering so as to be subjected to metallurgical bonding, and is subjected to multi-pass hot rolling to a certain thickness and then is subjectedto cold rolling for 2-4 times, and finally annealing is carried out at a high temperature to obtain the high-silicon steel sheet with excellent performance. By adopting the powder rolling method, theprocess flow for preparing the sheet can be effectively shortened, the formability of a powder system is greatly improved by adopting the silicon powder coated with the iron powder in raw materials, so that the process complexity and the subsequent debinding residual carbon problem caused by addition of a forming agent are avoided, and the method has the advantages of being simple to operate, highin production efficiency, high in product precision, free of pollution and included foreign materials, excellent in performance and the like.

Owner:UNIV OF SCI & TECH BEIJING

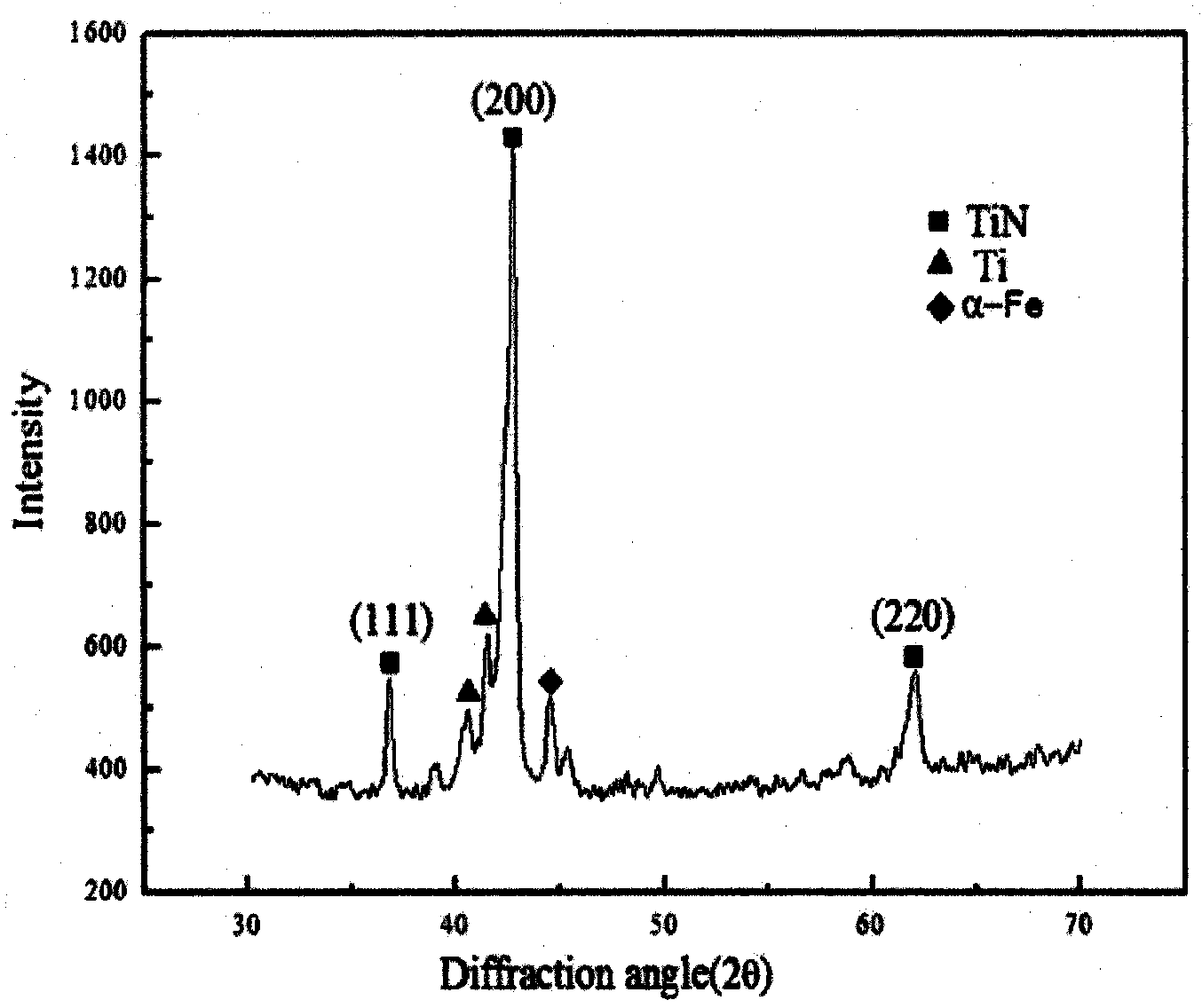

TiN coating mold with better wear resistance and fatigue performance

InactiveCN104264150AHigh hardnessImprove toughnessMetallic material coating processesMetal layered productsPorosityCrazing

The invention discloses a TiN coating mold with better wear resistance and fatigue performance. The surface of the TiN coating mold is coated with a TiN coating, and the phase composition of the coating mainly comprises a TiN phase, an alpha-Fe phase, a Ti phase and an oxide-free phase; the coating is more compact and free of holes, TiN is dispersed and distributed in the coating, microdefects such as cracks in the coating and a substrate and the like are overcome, and the coating is in metallurgical bonding with the substrate. A thicker TiN coating can be prepared in short time through in-situ synthesis by a reaction plasma cladding technology, the deposition efficiency of powder is greatly improved, and the cost is saved; and the porosity in the coating is low, the coating quality is good, the coating and the substrate can form metallurgical bonding, and the coating performance is greatly improved.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

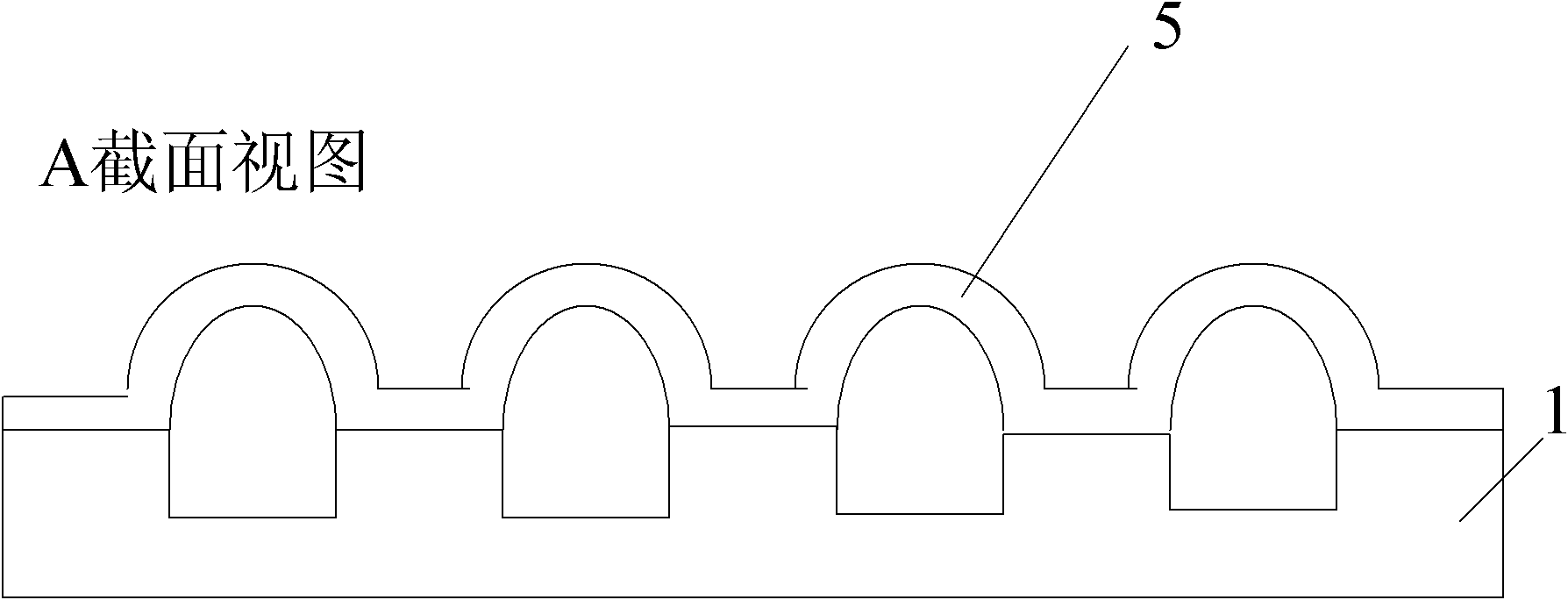

Positive pressure thermoforming manufacturing method of wafer-level glass micro-channel

ActiveCN101759138AHigh forming heightIncrease processing costDecorative surface effectsChemical vapor deposition coatingPositive pressureEngineering

The invention discloses a positive pressure thermoforming manufacturing method of a wafer-level glass micro-channel, which comprises the following steps of: 1. etching a specific silicon micro-channel shallow slot pattern on a Si wafer by utilizing a Si microprocessing process; 2. locally placing a proper amount of high-temperature gas releasing agent at both ends or a specific position of a silicon micro-channel; 3. bonding the Si wafer and a Pyrex7740 glass wafer to enable a shallow slot on Pyrex7740 glass to form a sealed cavity body; and 4. heating the bonded wafers to the temperature of 810-890 DEG C in air, preserving heat for 5-10 minutes, releasing gas by the high-temperature gas releasing agent due to heating, generating a positive pressure to enable molten glass corresponding to the sealed cavity body to deform and form a micro-channel pattern corresponding to the silicon micro-channel shallow slot pattern on the glass, and cooling to obtain the wafer-level glass micro-channel. In the invention, the gas is released by utilizing the high-temperature gas releasing agent, so that the glass can be in the shape of a hemispherical arc pipe to form the glass micro-channel.

Owner:SOUTHEAST UNIV

Image analysis device, image analysis method and program

ActiveUS20140355887A1Prevent ignored areaAvoid complex processImage enhancementImage analysisImaging processingImaging analysis

Provided is an image processing device including a corresponding pixel computation unit configured to, with respect to image data containing an image data area and an ignored area, replace a pixel in the ignored area having influence on a spatial analysis process with a pixel having no influence on the spatial analysis process.

Owner:HITACHI SOFTWARE ENG

Preparation method of tetramethyldivinyldisilazane

ActiveCN102766156ASimple production processReduce energy consumptionGroup 4/14 element organic compoundsAlkaline waterDesalination

The invention discloses a preparation method of tetramethyldivinyldisilazane. The preparation method includes the following steps: dimethylvinylchlorosilane is added in a reaction kettle, ammonia is led in to perform reaction under the stirring condition, mass ratio of the dimethylvinylchlorosilane and the ammonia is 4.30-4.40:1, reaction temperature is 110-115 DEG C, and reaction pressure is 0.15-0.18 MPa; and sodium hydroxide solution is added in the reaction kettle, and the tetramethyldivinyldisilazane is obtained after stirring. Compared with the prior art, the dimethylvinylchlorosilane and the ammonia are reacted under the solvent-free condition, production process is simplified, energy consumption is reduced, and yield is improved. The preparation method of the tetramethyldivinyldisilazane uses the sodium hydroxide solution as salt dissolving agent, adopts alkaline water desalination technology, and avoids the problems of complicated process, severe loss, environment hazards and the like caused by filtration desalination in the prior art.

Owner:XINYAQIANG SILICON CHEM JIANGSU

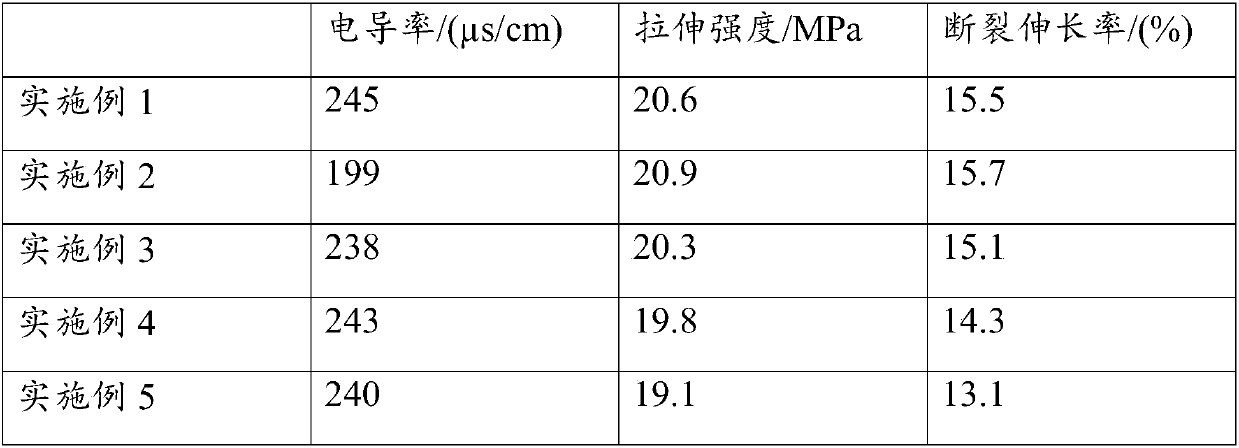

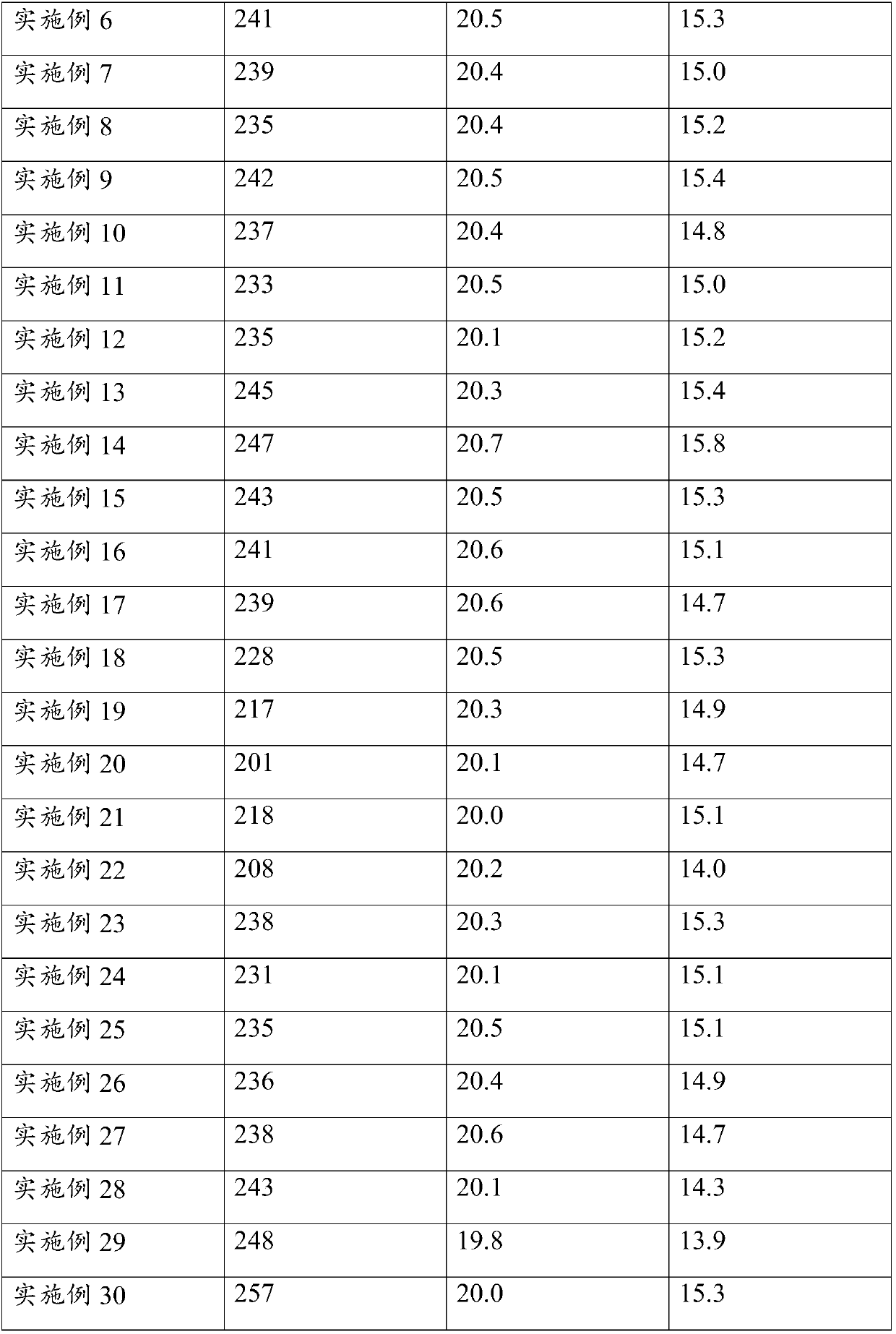

Graphene modified material as well as preparation method and application thereof

The invention provides a graphene modified material as well as a preparation method and application thereof. The preparation method of the graphene modified material comprises the following steps thata substance to be steeped is steeped in steeping liquid; then, the substance to be steeped is taken out for irradiation; the substance to be steeped comprises fiber, yarns or fabrics; the steeping liquid is mainly prepared from a graphene material, a cross-linking agent, a nanometer conducting metal wire and water. The preparation method solves the problem that the conducting performance cannot be improved since graphene and fiber and other products cannot be effectively crosslinked; the graphene modified material prepared by the method has the advantages of high electric conductivity, lightweight, antistatic performance, wide application range and the like.

Owner:山东省圣泉生物质石墨烯研究院

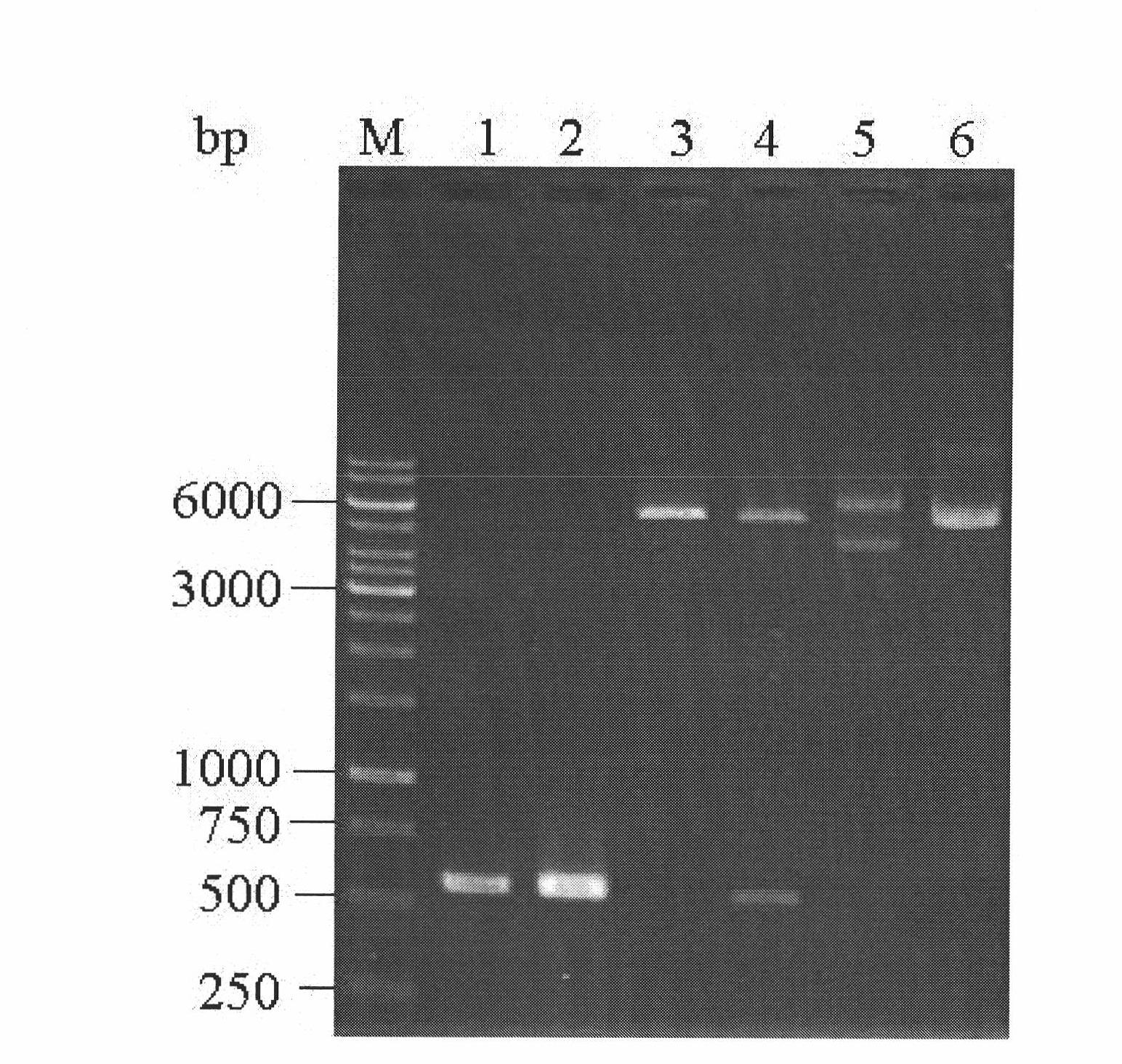

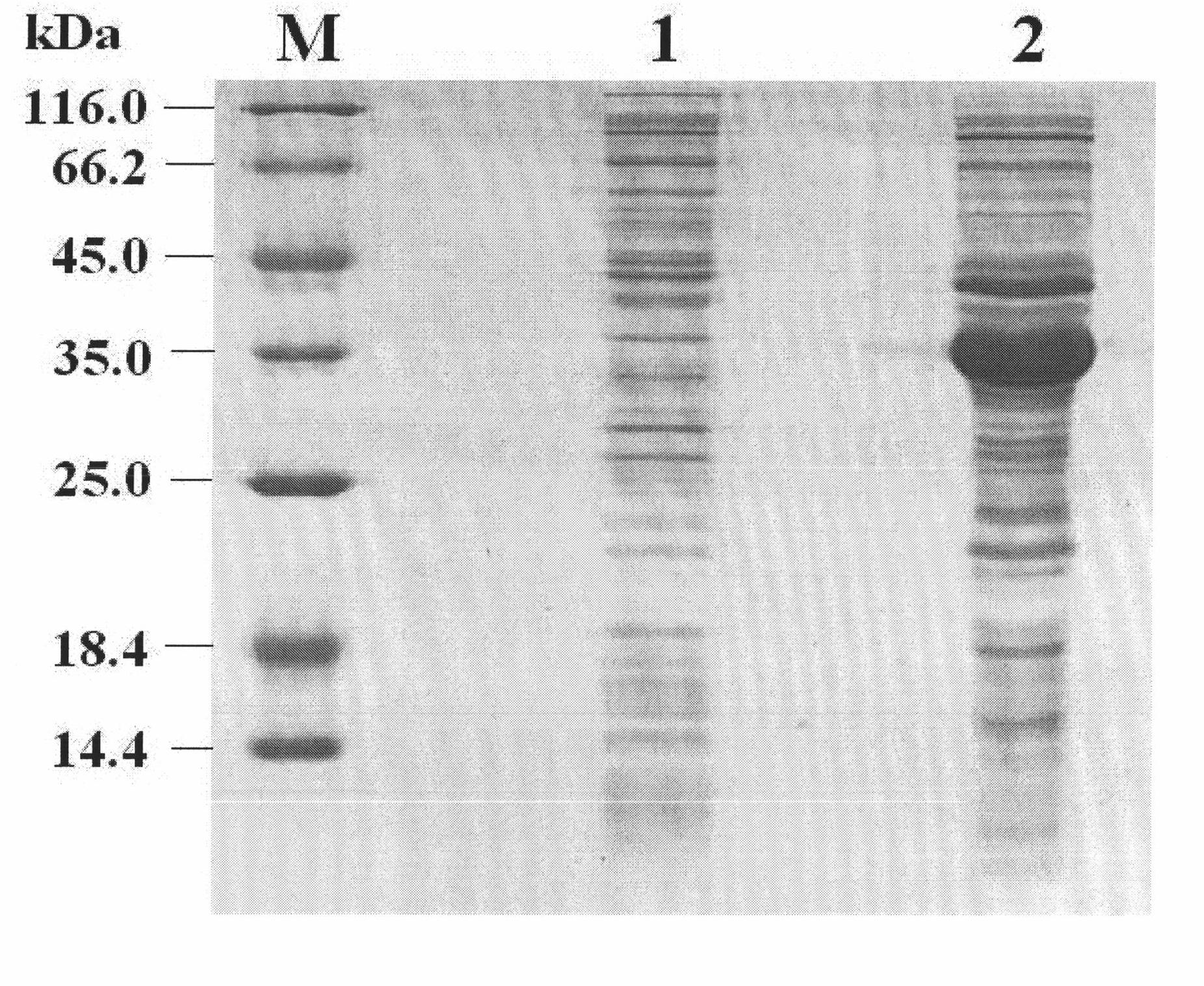

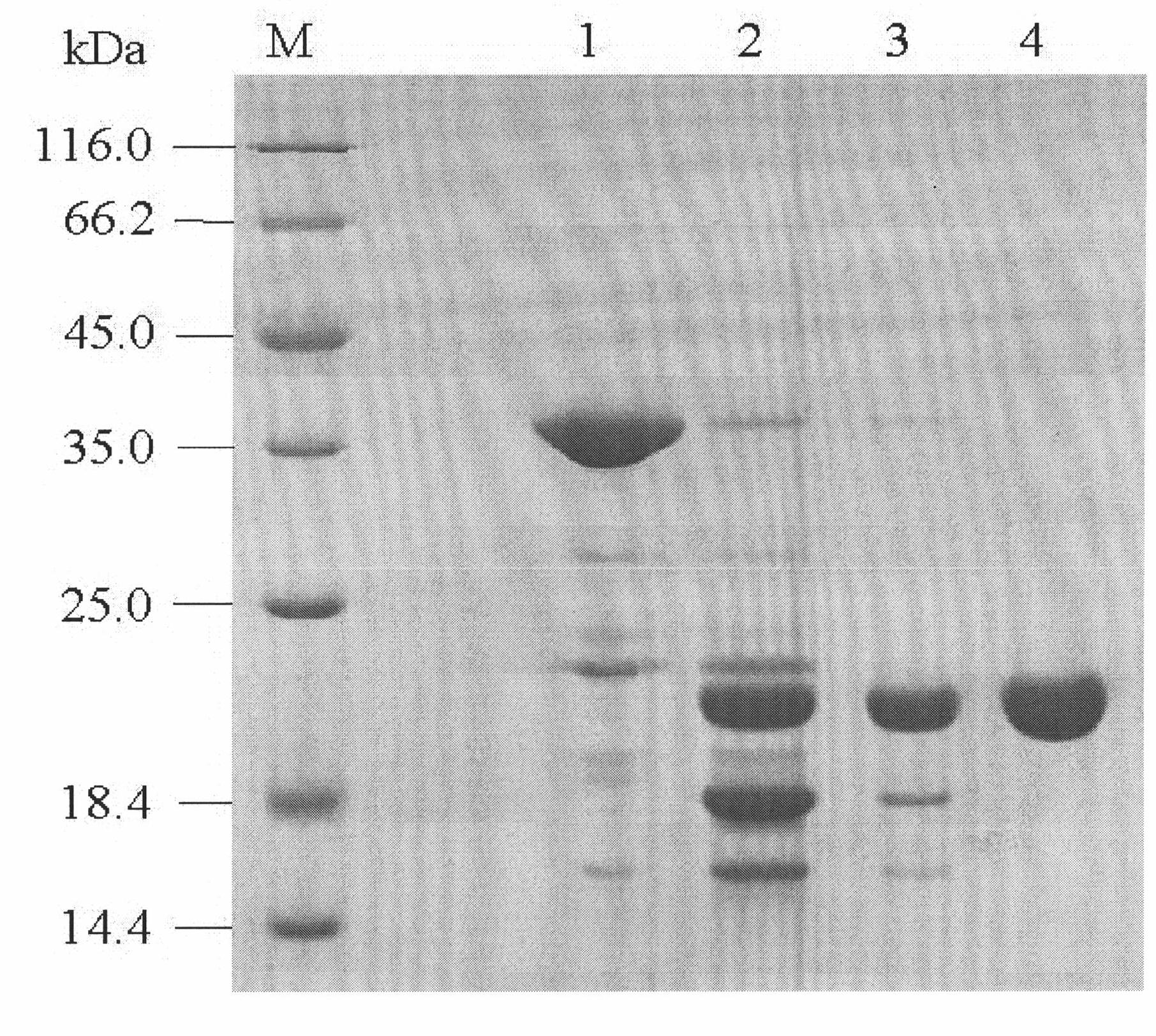

Method for preparing recombinant human interleukin-11

InactiveCN102140487ATreatment safetySafe and effective treatmentPeptide preparation methodsFermentationWhite blood cellGradient elution

The invention provides a method for preparing recombinant human interleukin-11 (rhIL). The method comprises the following steps: 1) providing a fusion protein, wherein from the N-end to the C-end, the fusion protein is thioredoxin-(His)6-proteolytic enzyme recognition site-rhIL-11 or (His)6-thioredoxin-proteolytic enzyme recognition site-rhIL-11; 2) using the proteolytic enzyme to perform enzyme cutting to the fusion protein and obtain an enzyme cutting product, wherein the enzyme cutting product contains thioredoxin and rhIL-11; and 3) using the nickel ion chelate affinity column chromatography to purify the enzyme cutting product, and performing gradient elution to the column to obtain rhIL-11, wherein the thioredoxin and the rhIL-11 are both adsorbed on the column. By adopting the method provided by the invention, the rhIL-11 can be purified rapidly, conveniently and efficiently and the recovery rate can be greatly increased.

Owner:DONGGUAN TAILI BIOTECH

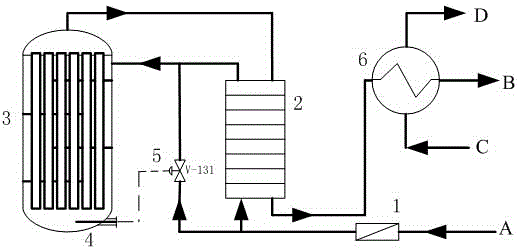

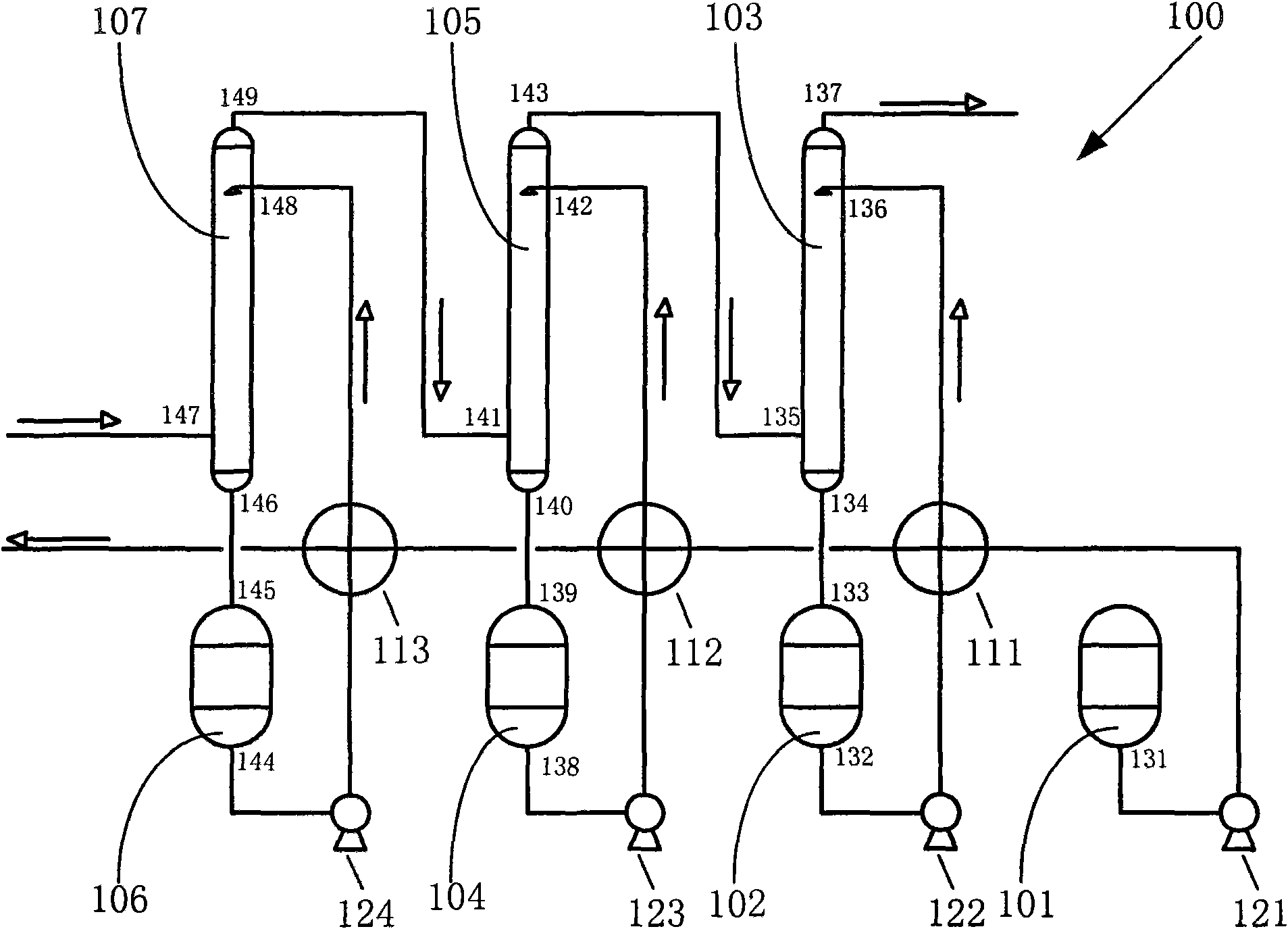

Method and equipment for deoxidizing low-concentration oxygen-containing coal bed gas

The invention discloses a method for deoxidizing a low-concentration oxygen-containing coal bed gas. The method comprises the following steps: preheating a fixed bed deoxidization reactor; feeding the oxygen-containing coal bed gas into the reactor after penetrating through a flame arrester, a preheater and a preheater bypass; carrying out deoxidization reaction when the reaction temperature is 350-650 DEG C, the operation pressure is 0-0.4MPa and the gaseous hourly space velocity is 2,000-20,000h<-1>; feeding a hot deoxidized coal bed gas into the preheater and exchanging heat with a cold oxygen-containing coal bed gas; and feeding the cooled oxygen-containing coal bed gas into a cooler, cooling and dewatering, and feeding to a coal bed gas delivery pipeline. The method has the advantages of being good in safety, good in deoxidization effect, low in investment, convenient to operate and low in operation cost.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Over-temperature protection circuit, semiconductor device and fabrication method of semiconductor device

PendingCN108109999ATimely and accurate collectionGuaranteed to workTransistorSolid-state devicesControl signalEngineering

The invention provides an over-temperature protection circuit, a semiconductor device and a fabrication method of the semiconductor device. The over-temperature protection circuit comprises a currentsource, a temperature sampling tube, a comparator, a control signal generation unit and an MOS field-effect transistor, wherein the current source is used for providing a constant-current source, thetemperature sampling tube is used for detecting a temperature, the comparator is used for generating a temperature detection signal according to the detected temperature, the control signal generationunit is used for generating a temperature control signal according to the temperature detection signal, and the MOS field-effect transistor is used for achieving over-temperature protection by switch-off or switch-on according to the temperature control signal. The real-time temperature can be timely and accurately acquired by a temperature sampling device, so that the over-temperature protectioncircuit effectively works, an error during the heat transferring process is not needed to be considered, and the design of the over-temperature protection circuit is simplified; and meanwhile, the semiconductor device and a control module are integrated in a package tube shell by a joint sealing mode to form the over-temperature protection circuit, chips based on different processed are organically combined, and process complexity and high cost brought by a single chip for achieving the same function are prevented.

Owner:SHANGHAI NATLINEAR ELECTRONICS CO LTD

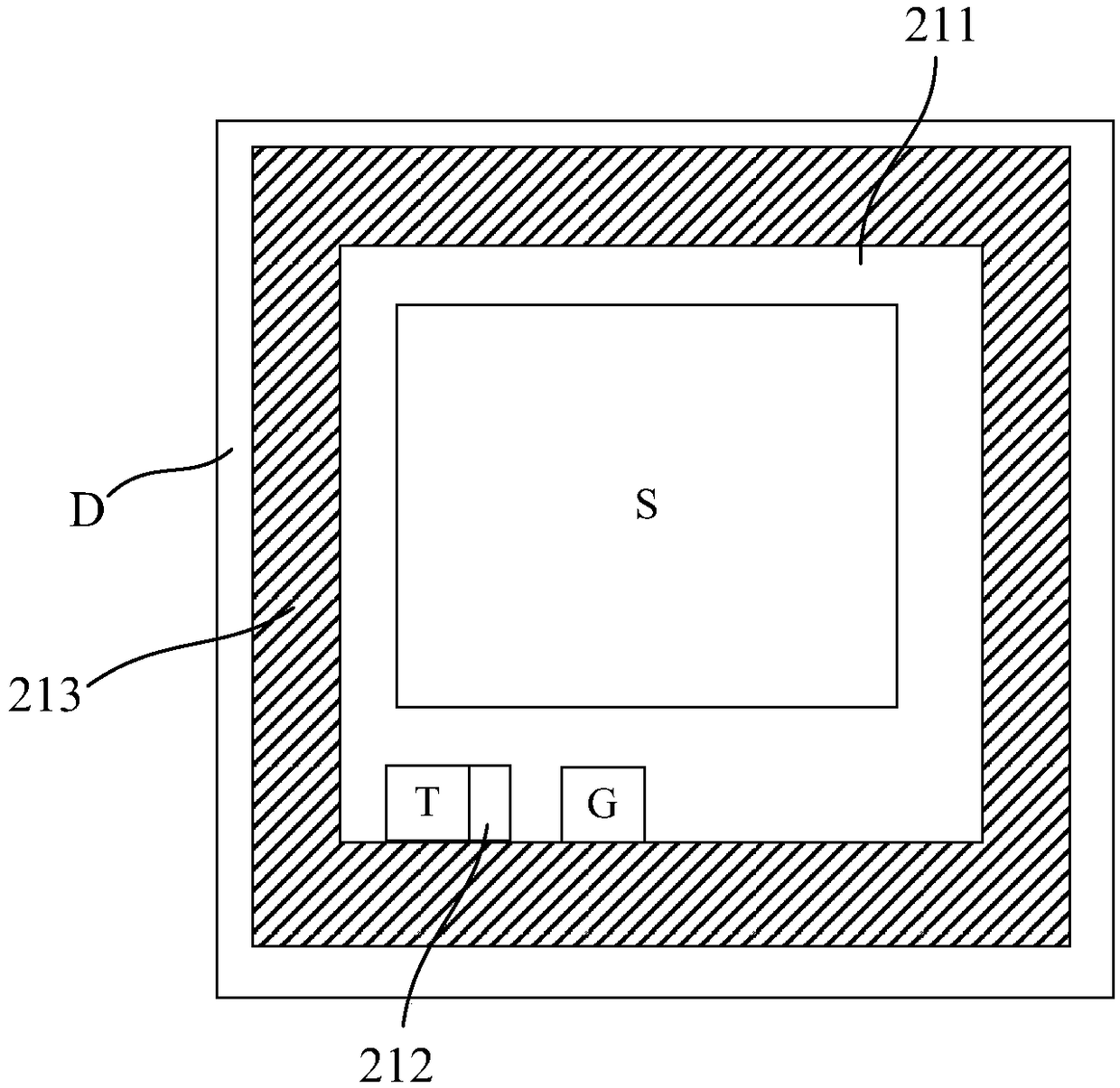

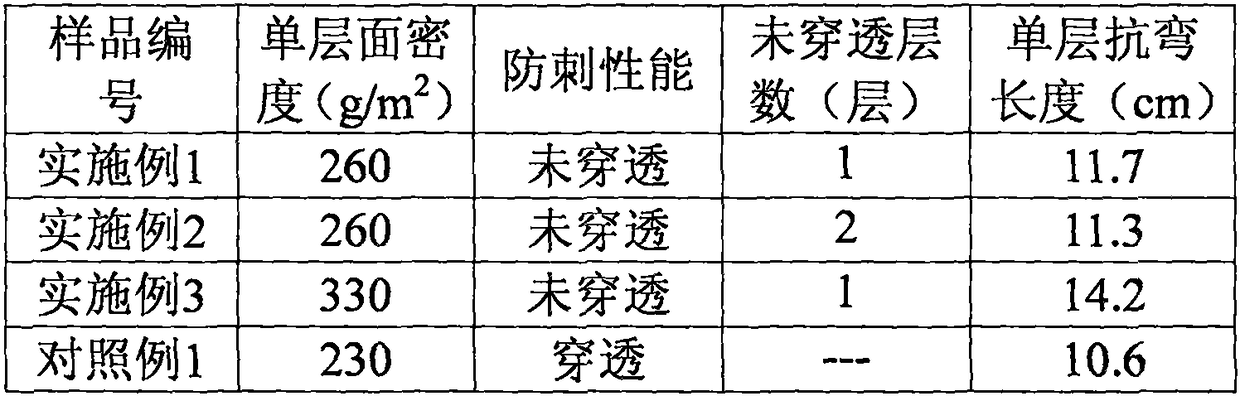

Comfortable stab resistance body armor and manufacturing method thereof

ActiveCN109357571AImprove comfortThe preparation process is simple and feasibleLamination ancillary operationsProtective equipmentFiberManufacturing technology

The invention provides comfortable stab resistance body armor and a manufacturing method thereof. The comfortable stab resistance body armor comprises a jacket and stab resistance materials arranged in the jacket, and the stab resistance materials comprise a stab resistance chip and buffer materials; the stab resistance chip is formed by overlapping at least 16 layers of laid fabric according to 0 / 90 DEG orthogonally; the laid fabric is composed of two layers of fiber cloth and a hot melt adhesive film; the hot melt adhesive film is arranged between the two layers of the fiber cloth; the two layers of the fiber cloth are overlapped according to 0 / 90 DEG orthogonally; and the fiber cloth is formed by bonding fibrils with adhesive. The stab resistance body armor is high in comfort, and the manufacturing technology is simple and practicable.

Owner:BEIJING AEROSPACE RATE MECHANICAL & ELECTRICAL ENG CO LTD +1

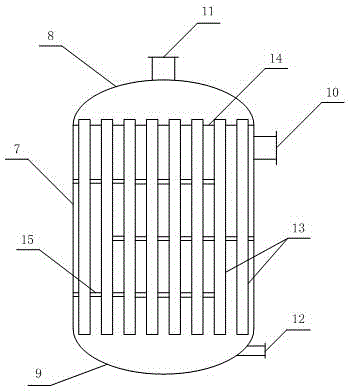

Multi-tower combined reactor

The invention relates to a multi-tower combined reactor. In the invention, a plurality of reactor groups including a polymerization tower and a polymerization kettle are connected with one another byfour-way controllers; inlets at ends of the reactor groups are added with crotonic aldehyde, and inlets at other ends thereof are added with ketene, thus being capable of converting a continuous reaction state to an intermittent reaction state according to the proceeding conditions of the reaction simultaneously when the crotonic aldehyde and the ketene react under a reverse flow direction state,so that the crotonic aldehyde can be completely reacted, and the process complexity and increased cost brought by the separation of crotonic aldehyde and sorbic acid polyester are avoided.

Owner:ZHEJIANG BOSSEN INGREDIENTS

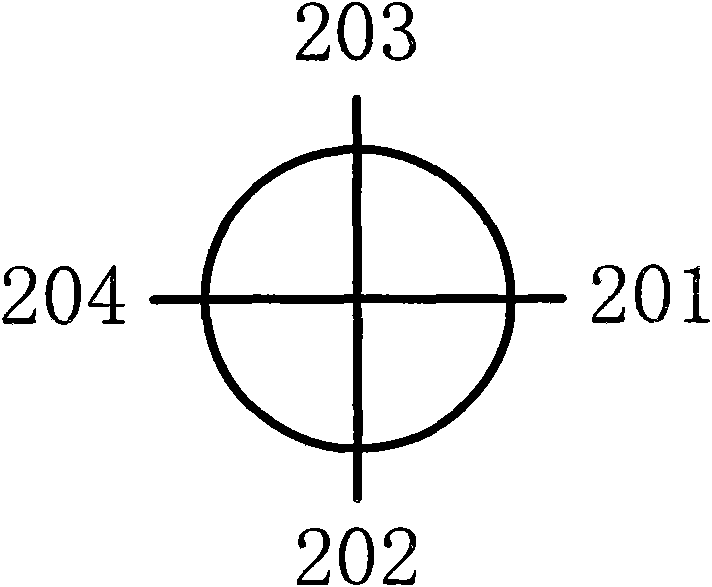

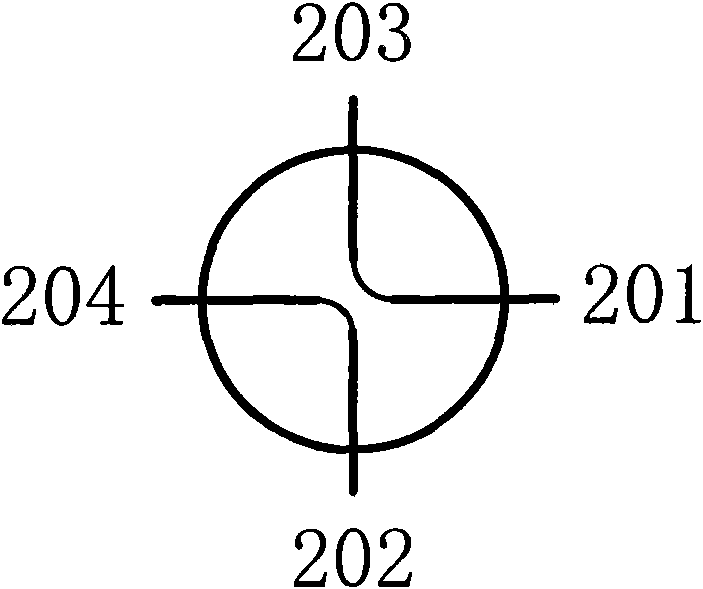

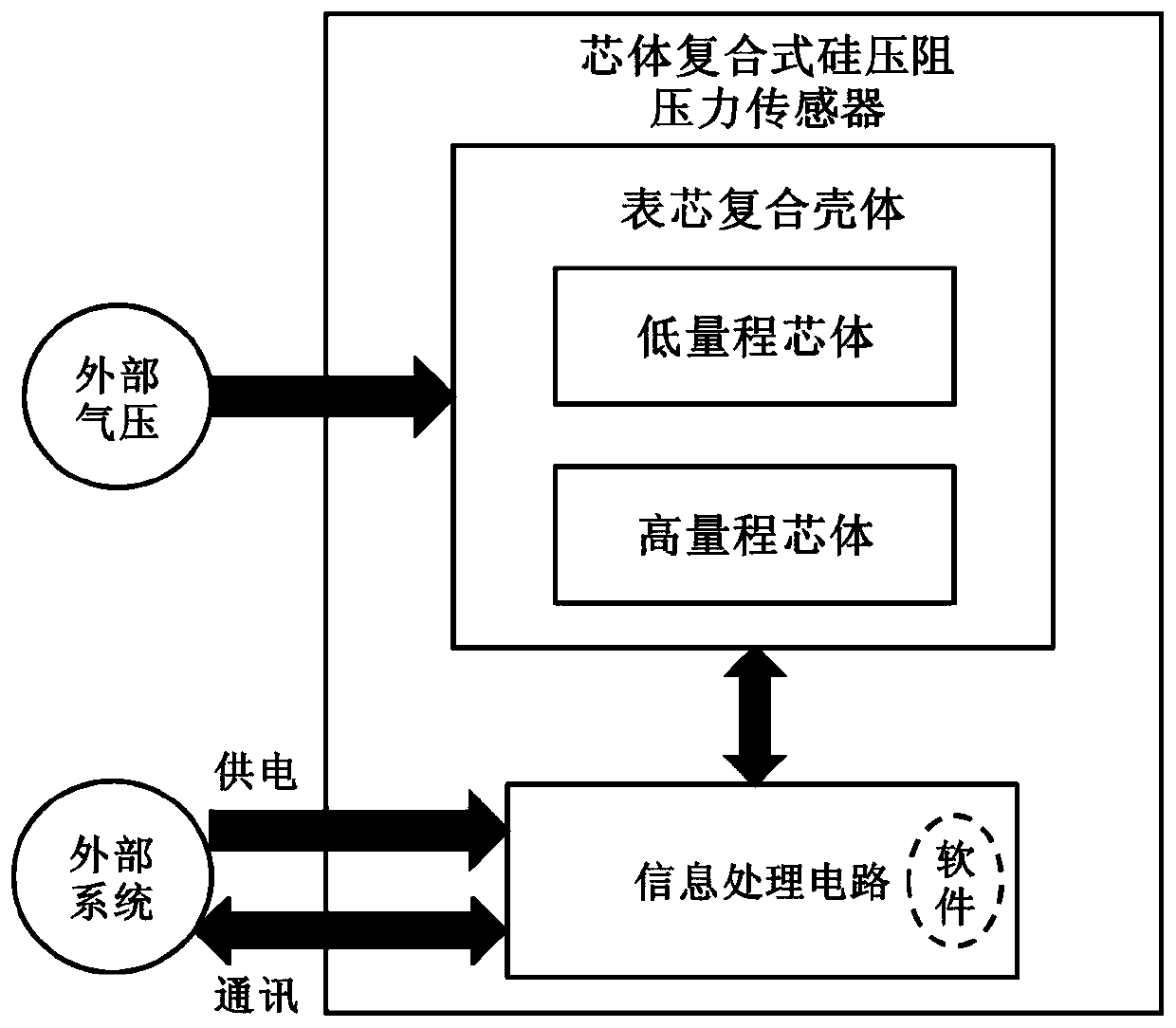

Core composite type silicon piezoresistive pressure sensor

ActiveCN110567632ASolve the problem of full-scale accuracy defectsRealize high-precision measurement requirementsFluid pressure measurement using ohmic-resistance variationForce measurement using piezo-resistive materialsPiezoresistive pressure sensorsPressure measurement

The invention provides a core composite type silicon piezoresistive pressure sensor in order to solve the problem of full-range precision defect in pressure measurement of an existing silicon piezoresistive pressure sensor. The pressure sensor comprises a plurality of silicon piezoresistive pressure sensor cores, a core composite shell and an information processing circuit board. Each silicon piezoresistive pressure sensor core comprises a silicon piezoresistive pressure sensor chip used for collecting the pressure of a to-be-measured piece. The ranges of the silicon piezoresistive pressure sensor cores are different, and the ranges of the silicon piezoresistive pressure sensor cores cover the full range of use. The core composite shell is used for packaging a plurality of silicon piezoresistive pressure sensor core assemblies and providing a unified test pressure medium for the silicon piezoresistive pressure sensor core assemblies. The information processing circuit board is arrangedon the core composite shell, and the information processing circuit board is used for controlling and realizing cooperative measurement and switching output of the silicon piezoresistive pressure sensor cores.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com