Manufacture method of shallow trench isolation structure for adjusting stress of isolation oxide by ion implantation

A technology for isolating oxides and isolation structures, applied in the field of preparation of shallow trench isolation structures, which can solve problems such as complexity and low yield, and achieve the effects of improving performance, overcoming process complexity, and making the process simple and feasible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

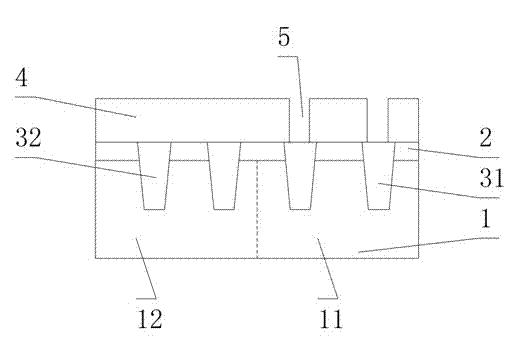

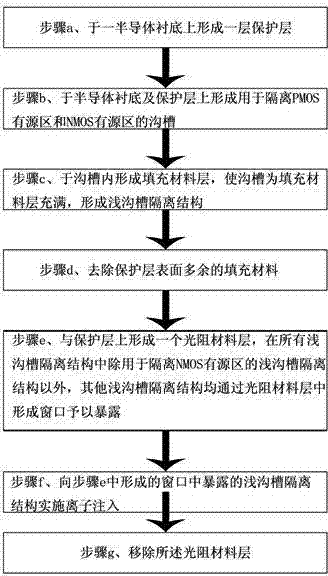

[0029] Such as figure 1 , figure 2 As shown, the preparation method of the shallow trench isolation structure for adjusting the stress of the isolation oxide by ion implantation of the present invention includes the following steps:

[0030] Step a, forming a layer of protective layer 2 on a semiconductor substrate 1, where the semiconductor substrate is single crystal silicon, and the protective layer 2 is a silicon nitride film formed by chemical vapor deposition or physical vapor deposition .

[0031] Step b, forming the trench 31 for isolating the PMOS active region 11 and the trench 32 for isolating the NMOS active region 12 on the semiconductor substrate 1 and the protective layer 2, the method for forming the trench 31 and the trench 32 here For example, a patterned hard mask layer is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com