Comfortable stab resistance body armor and manufacturing method thereof

A manufacturing method and technology of stab-resistant clothing, applied in chemical instruments and methods, clothing, clothing and other directions, can solve the problems of complex preparation process, poor comfort of stab-resistant clothing, etc., achieve high comfort, eliminate flexibility, manufacture Simple and feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

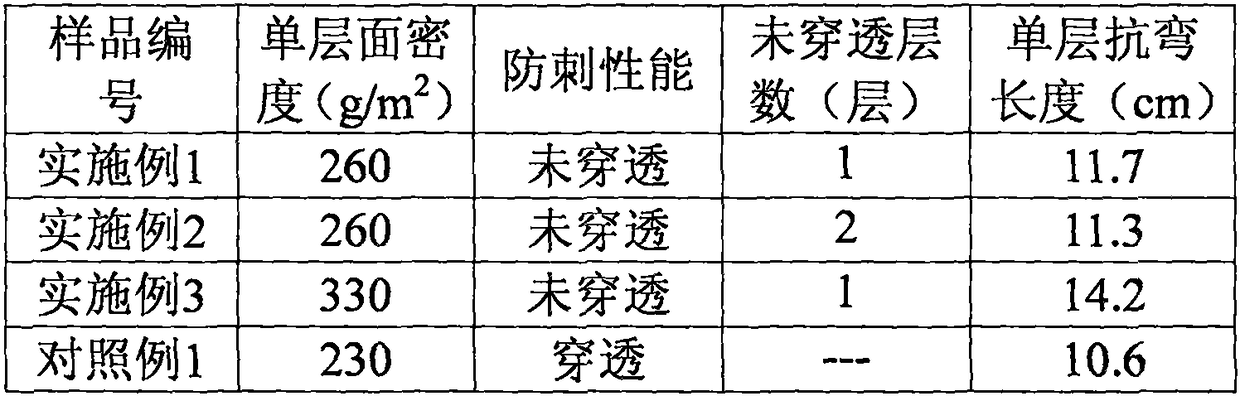

Examples

Embodiment 1

[0039] The manufacturing steps of the stab-proof clothing of the present embodiment are:

[0040] 1) Manufacture of non-weft fabric

[0041] Prepare a glue solution with a solid content of 40% from water-based polyurethane adhesive and put it into the glue tank. The aramid fiber is dipped in the glue tank, spread out, and fixed on the layout machine. At the same time, the glue solution is spread evenly with a scraper blade. After drying completely at 110°C, the first fiber cloth is obtained; rotate the first fiber cloth by 90 degrees, then spread a hot-melt adhesive film of the same size on it, and fix it with the first fiber cloth at the edge with double-sided adhesive According to the method for preparing the first fiber cloth, the second fiber cloth is prepared on a hot-melt adhesive film with a thickness of 0.08mm, the difference is that the drying temperature is 130°C; when the drying of the second fiber cloth is completed, What is obtained is the described non-weft clot...

Embodiment 2

[0049] The manufacturing steps of the stab-proof clothing of the present embodiment are:

[0050] 1) Manufacture of non-weft fabric

[0051] Prepare a glue solution with a solid content of 30% from water-based polyurethane adhesive and put it into the glue tank. The aramid fiber is dipped in the glue tank, spread out, and fixed on the layout machine. At the same time, the glue solution is spread evenly with a scraper blade. After drying completely at 110°C, the first fiber cloth is obtained; rotate the first fiber cloth by 90 degrees, then spread a hot-melt adhesive film of the same size on it, and fix it with the first fiber cloth at the edge with double-sided adhesive According to the method for preparing the first fiber cloth, the second fiber cloth is prepared on a hot-melt adhesive film with a thickness of 0.05mm, the difference is that the drying temperature is 120°C; when the drying of the second fiber cloth is completed, What is obtained is the described non-weft fabr...

Embodiment 3

[0059] The manufacturing steps of the stab-proof clothing of the present embodiment are:

[0060] 1) Manufacture of non-weft fabric

[0061] Prepare a glue solution with a solid content of 30% from water-based polyurethane adhesive and put it into the glue tank. The aramid fiber is dipped in the glue tank, spread out, and fixed on the layout machine. At the same time, the glue solution is spread evenly with a scraper blade. After drying completely at 110°C, the first fiber cloth is obtained; rotate the first fiber cloth by 90 degrees, then spread a hot-melt adhesive film of the same size on it, and fix it with the first fiber cloth at the edge with double-sided adhesive According to the method for preparing the first fiber cloth, the second fiber cloth is prepared on a hot-melt adhesive film with a thickness of 0.05mm, the difference is that the drying temperature is 120°C; when the drying of the second fiber cloth is completed, What is obtained is the described non-weft fabr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com