Glass vacuum cavity device of atom interferometer

A technology of atomic interferometer and glass vacuum, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve problems such as bursting, vacuum cavity, and air leakage at the interface, so as to achieve simple production, ensure vacuum degree, and assemble simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

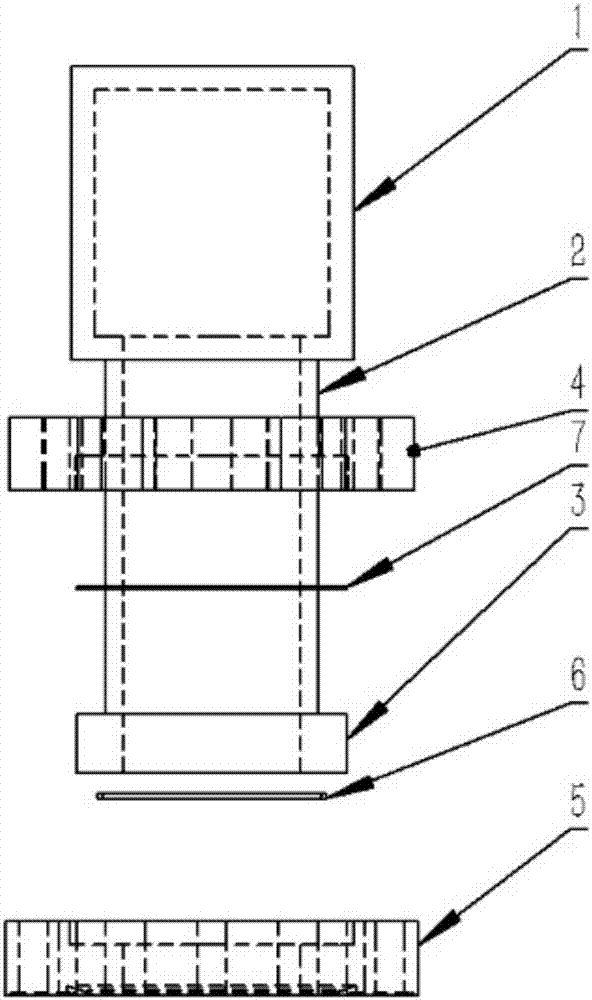

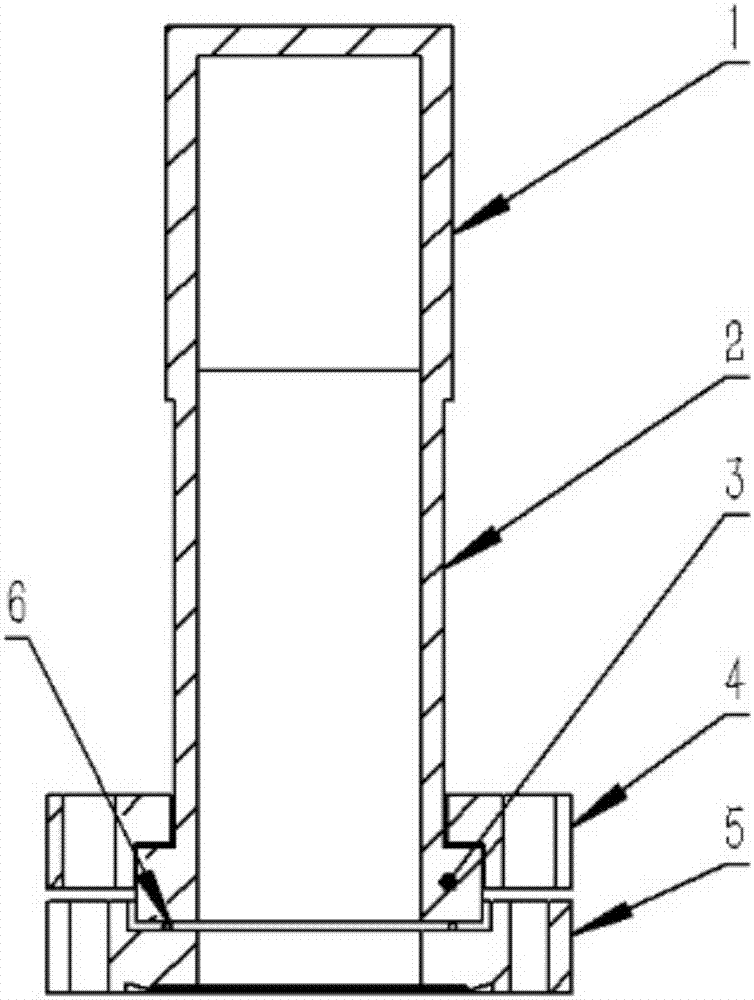

[0018] Such as figure 1 As shown, it is an exploded view of the structure of the present invention, which is composed of a square cavity 1, a transition tube 2, a glass ring 3, a pressing piece 4, and an adapter flange 5. Among them, the optical glue technology is used to seal the square cavity 1 and the transition tube 2. The name of this sealing technology is the light glue technology. It is specifically to polish the two sides of the two parts that need to be glued and keep them clean and smooth. Consistent, at high temperature (high temperature depends on the material used, for quartz material, it is about 1300-1500 degrees). Under the action, align the two sides that need to be glued and make them fully contact until the two contact surfaces are directly bonded together. At this time, the force between the two sides that need to be glued is the molecular force between the two contact surfaces.

[0019] In the past processes and devices, there is this type of glass vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com