Preparation method of polished porcelain glazed tile with flashing effect

A technology of glazed tiles and porcelain tiles, which is applied in the manufacture of tools, ceramic molding machines, construction, etc. It can solve the problems of affecting the surface pattern effect of products, not being suitable for fully polished products, and unable to perform full polishing processing, etc., to achieve good flash effect, simplification of the polishing process, and the effect of meeting market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method for polished porcelain glazed tiles with flash effect, comprising the following steps:

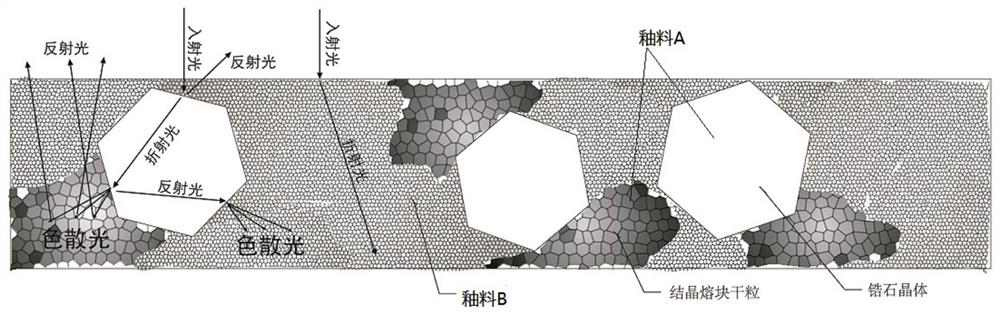

[0031] S1. Mix high-purity zircon sand and dry crystalline frit to obtain glaze A;

[0032] S2, using marble glaze as glaze B, mixing glaze A and glaze B according to a mass ratio of 1:4 to obtain a mixed glaze;

[0033] S3. Evenly spread the porcelain tile powder in the mold cavity of the brick press and press the porcelain tile powder into a porcelain tile green body, and then dry the porcelain tile green body at 200°C in a drying kiln ,spare;

[0034] S4. Apply top glaze to the green body of porcelain tile after drying in S3, then carry out inkjet printing, then apply protective glaze, then add water, carboxymethyl cellulose and wollastonite to the mixed glaze and mix thoroughly, The glaze is applied by glaze or spray glaze, and the amount of glaze is 800 grams per square meter;

[0035] S5. Place the green body of the porcelain tile after applying protect...

Embodiment 2

[0040] A preparation method for polished porcelain glazed tiles with flash effect, comprising the following steps:

[0041] S1. Mix high-purity zircon sand and dry crystalline frit to obtain glaze A;

[0042] S2, using marble glaze as glaze B, mixing glaze A and glaze B according to a mass ratio of 1:4 to obtain a mixed glaze;

[0043] S3. Evenly spread the porcelain tile powder in the mold cavity of the brick press and press the porcelain tile powder into a porcelain tile green body, and then dry the porcelain tile green body in a drying kiln at 180°C ,spare;

[0044] S4. After applying surface glaze on the green body of porcelain tile after drying in S3, inkjet printing is carried out, and then protective glaze is applied, and then the mixed glaze is fully mixed with water, bentonite and calcite, and glazed by pouring glaze or spraying glaze Apply glaze by means of 600 grams / square meter of glaze;

[0045]S5. Place the green body of the porcelain tile after applying prote...

Embodiment 3

[0050] A preparation method for polished porcelain glazed tiles with flash effect, comprising the following steps:

[0051] S1. Mix high-purity zircon sand and dry crystalline frit to obtain glaze A;

[0052] S2, using marble glaze as glaze B, mixing glaze A and glaze B according to a mass ratio of 1:4 to obtain a mixed glaze;

[0053] S3. Evenly spread the porcelain tile powder in the mold cavity of the brick press and press the porcelain tile powder into a porcelain tile green body, and then dry the porcelain tile green body in a drying kiln at 220°C ,spare;

[0054] S4. Apply surface glaze on the green body of porcelain tile after drying in S3, then carry out inkjet printing, and then apply protective glaze, then add the mixed glaze to water, kaolin and magnesium oxide, mix thoroughly, and spray glaze or spray glaze. The way of glazing is to apply glaze, and the amount of glazing is 1000 grams per square meter;

[0055] S5. Place the green body of the porcelain tile afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com