System and process for recovering dimethylacetamide from cefuroxime axetil production waste liquor

A technology of dimethylacetamide and recovery system, which is applied in the field of recovery of dimethylacetamide in cefuroxime axetil production waste liquid, and can solve problems such as unclean filtration, difficult filtration, and difficult treatment of salt slag , to achieve the effect of reducing pump equipment, increasing steam space, and speeding up solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

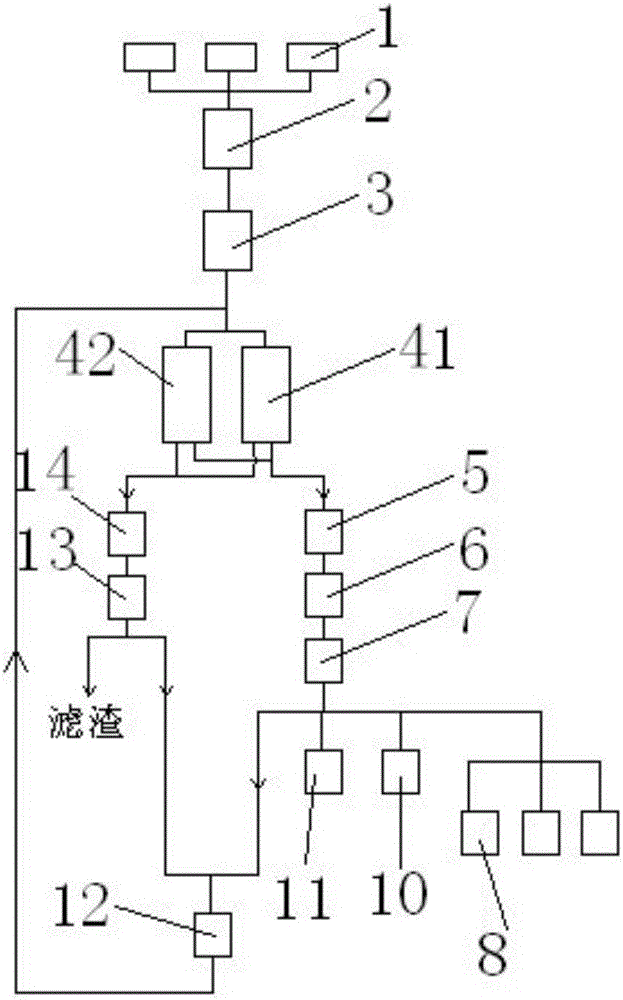

[0056] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, and the schematic embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

[0057] combine figure 1 Shown, technique of the present invention is as follows,

[0058] 1. Start-up operation of light removal distillation tower 2:

[0059] 1.1 Start the raw material pump, pump the raw material from the mother liquor tank 1 to the light removal distillation tower 2, pay attention to the feeding situation, and stop feeding when the liquid level of the tower kettle reaches the required liquid level of 1500mm;

[0060] 1.2 Open the regulating valve of the steam pipeline of the reboiler of the light removal distillation tower 2, set the temperature of the heating kettle of the light removal distillation tower 2 reboiler to 91-92°C, recover most of the low boil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com