Flat ultra-thin heat pipe with thermal superconductivity

A thermal superconducting, ultra-thin technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of low yield, unstable thermal conductivity, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

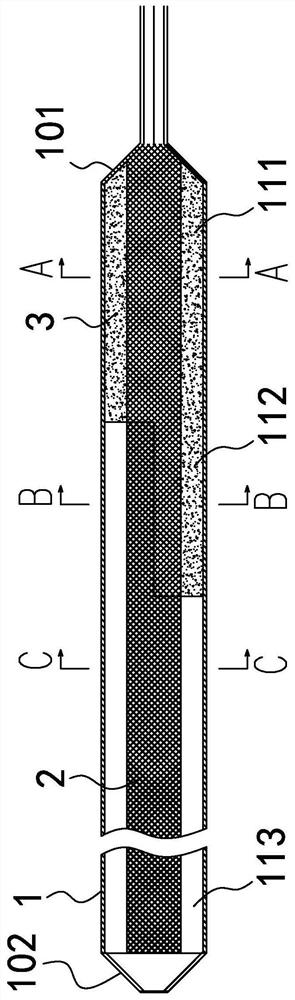

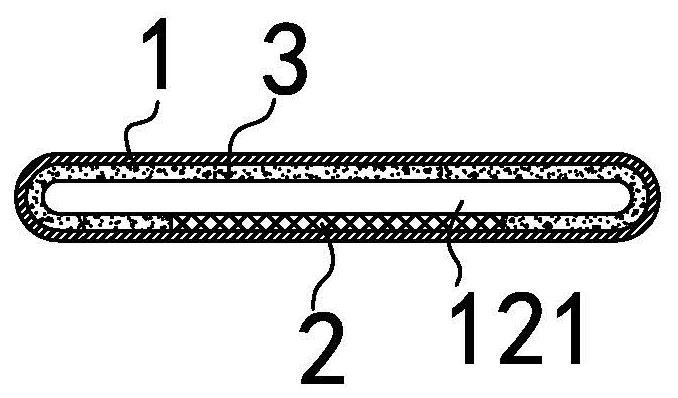

[0052] as attached figure 1 to attach Figure 10 As shown, Embodiment 1 of the present invention proposes a flat and ultra-thin heat pipe with thermal superconductivity, including a tube body 1, one end of the tube body 1 is an evaporation end 101, and the other end is a condensation end 102, and the tube body 1 There is a sealed hollow flat space in the hollow flat space, and the working liquid is encapsulated in the hollow flat space. The first capillary structure 2 and the second capillary structure 3 are arranged in the hollow flat space, and the first capillary structure 2 is copper wire bundle or Copper wire braid, the second capillary structure 3 is a sintered copper powder, and the remaining space in the hollow flat space except the first capillary structure 2 and the second capillary structure 3 forms a steam space, wherein:

[0053] The steam flow path of the pipe body 1 extending from the evaporation end 101 to the condensation end 102 is sequentially provided wit...

Embodiment 2

[0062] as attached Figure 10 As shown, Embodiment 2 of the present invention proposes a flat and ultra-thin heat pipe with thermal superconductivity, including a tube body 1, one end of the tube body 1 is an evaporation end 101, and the other end is a condensation end 102, and the tube body 1 There is a sealed hollow flat space in the hollow flat space, and the working liquid is encapsulated in the hollow flat space. The first capillary structure 2 and the second capillary structure 3 are arranged in the hollow flat space, and the first capillary structure 2 is copper wire bundle or Copper wire braid, the second capillary structure 3 is a sintered copper powder, and the remaining space in the hollow flat space except the first capillary structure 2 and the second capillary structure 3 forms a steam space, wherein:

[0063] The steam flow path extending from the tube body 1 along the evaporation end 101 to the condensation end 102 is sequentially defined as a full section 111 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com