Multi-station vertical rotary abrasive flow polishing device and working method thereof

A polishing device and vertical rotation technology, applied in grinding drive devices, grinding/polishing equipment, machine tools for surface polishing, etc. Simplify polishing process and improve polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

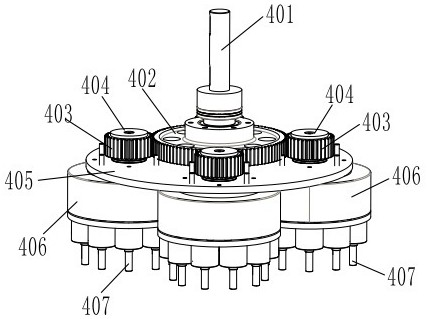

[0032] Such as Figure 1 to Figure 4As shown, a multi-station vertical rotary abrasive flow polishing device includes a planetary rotary disk 4 and a bucket assembly. A column 2 is installed vertically at the center of the base 1 of the device, and a turntable assembly 3 is fixedly installed above the column 2, and the turntable assembly 3 distributes planetary rotary disks 4 evenly along the circular direction. The bucket assembly adopts the automatic rotating lifting bucket assembly 5 arranged directly below the planetary rotary table 4. The lifting bucket assembly 5 is set on the lifting frame 55, and the lifting frame 55 is held on the column through the linear slider 57d and the slide rail 57d. 2; the number of planetary rotary discs 4 is 3; the number of automatic rotating lifting bucket assemblies 5 is 2. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com