Surface contact magneto-rheological flat polishing device and method with uniform magnetic field

A uniform magnetic field and polishing device technology, applied in the field of magnetorheological polishing, can solve the problems of fast magnetic field attenuation, difficulty in uniform polishing, and difficult degaussing, etc., and achieve the effects of simplifying equipment structure, improving polishing efficiency, and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

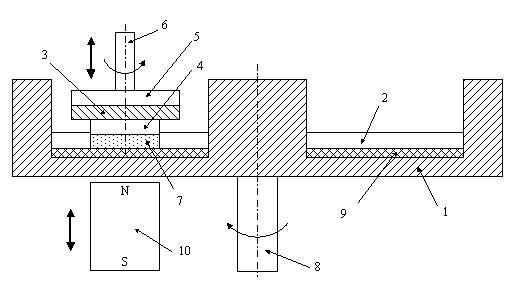

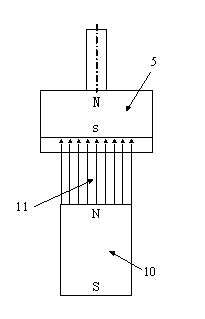

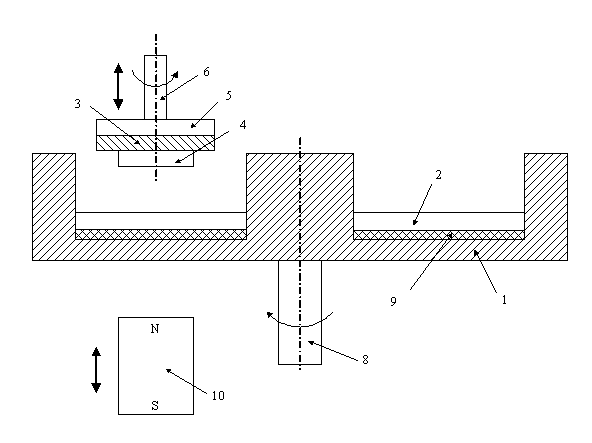

[0032] See figure 1 with image 3 , The uniform magnetic field surface contact magnetorheological plane polishing device includes a polishing head, a polishing groove 1 fixed on the main shaft 8, a magnetic pole 10 arranged below the polishing groove 1, and the polishing head includes a workpiece shaft 6 fixed on The non-magnetic holder 3 at the lower end of the workpiece shaft 6 is provided with a soft magnetic plate 5 between the non-magnetic holder 3 and the workpiece shaft 6; the polishing head is located above the polishing tank 1; the magnetic pole 10 and the soft magnetic There is a uniform magnetic field 11 between the plates 5, that is, the magnetic poles 10 and the soft magnetic plate 5 are aligned; the polishing tank 1 contains a magnetorheological fluid 2.

[0033] Wherein, a polishing pad 9 is provided at the bottom of the inner side of the polishing tank 1. The magnetic pole 10 is a permanent magnet. The workpiece shaft 6 is fixed on the vertical moving platform. ...

Embodiment 2

[0035] See figure 1 with image 3 , The uniform magnetic field surface contact magnetorheological plane polishing device includes a polishing head, a polishing groove 1 fixed on the main shaft 8, a magnetic pole 10 arranged below the polishing groove 1, and the polishing head includes a workpiece shaft 6 fixed on The non-magnetic holder 3 at the lower end of the workpiece shaft 6 is provided with a soft magnetic plate 5 between the non-magnetic holder 3 and the workpiece shaft 6; the polishing head is located above the polishing tank 1; the magnetic pole 10 and the soft magnetic There is a uniform magnetic field 11 between the plates 5, that is, the magnetic poles 10 and the soft magnetic plate 5 are aligned; the polishing tank 1 contains a magnetorheological fluid 2.

[0036] Wherein, a polishing pad 9 is provided at the bottom of the inner side of the polishing tank 1. The magnetic pole 10 is an electromagnet. The workpiece shaft 6 is fixed on the vertical moving platform. Th...

Embodiment 3

[0038] See Figure 1 to Figure 3 , A polishing method based on the polishing device described in Example 1, comprising the following steps:

[0039] (1) Install the work piece 4 on the lower surface of the non-magnetic holder 3, start the spindle 8 so that the spindle 8 drives the polishing groove 1 to rotate;

[0040] (2) The polishing head moves vertically downwards, and the permanent magnet moves vertically upwards. Adjust the distance between the soft polishing head and the permanent magnet so that the workpiece 4 is in contact with the magnetorheological fluid 2; when the polishing head is close to the permanent magnet, the soft magnetic The plate 5 is close to the permanent magnet, and the soft magnetic plate 5 is magnetized by the permanent magnet. A uniform magnetic field 11 with a magnetic field strength of 2000-5000 Gauss and a magnetic pole gap of 30 mm is formed between the soft magnetic plate 5 and the permanent magnet; The magnetorheological fluid 2 between the workpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com