Polishing machine

A polishing machine and polishing tool technology, applied in the field of polishing machines, can solve the problems of low polishing efficiency, cumbersome operation steps, and high polishing cost, and achieve the effects of improving polishing efficiency, simplifying the polishing process, and increasing the operating range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

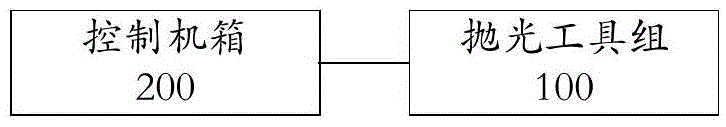

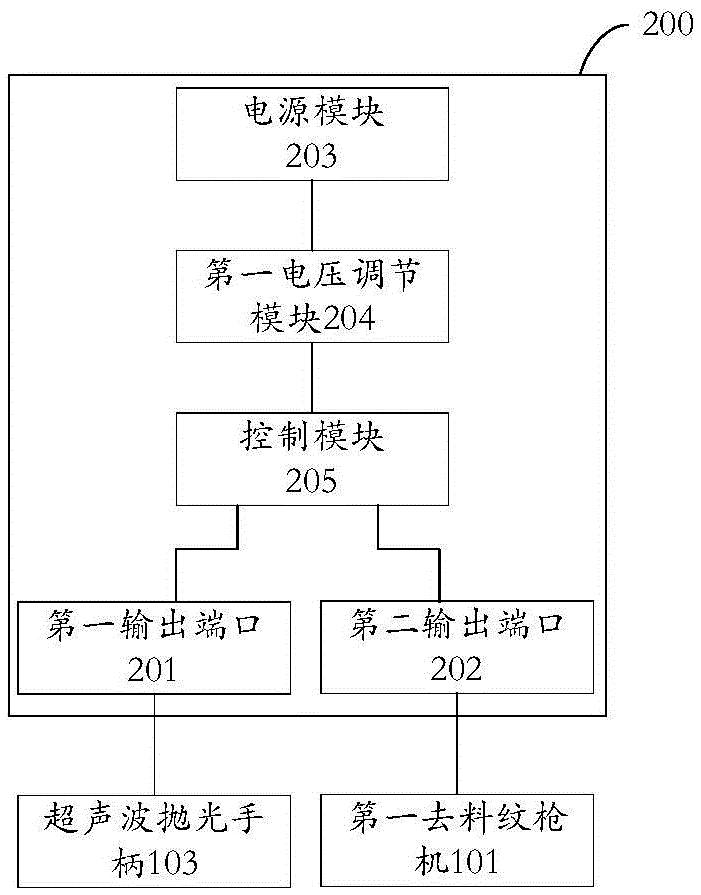

[0079] A polishing machine, including a polishing tool set 100 and a control cabinet 200 for controlling the polishing tool set 100, the polishing tool set 100 includes a first grain removal gun 101, a rotary polishing handle 102 and an ultrasonic wave Polishing handle 103, the control cabinet 200 is provided with a first output port 201 and a second output port 202, the first output port 201 is used to connect the ultrasonic polishing handle 103, and the second output port 202 is used to connect The first grain removal bolt 101 or the rotary finishing and polishing handle 102, the control cabinet 200 includes a power supply module 203, a first voltage regulation module 204 and a control module 205, the first voltage regulation module 204 respectively connected to the power supply module 203 and the control module 205, the output terminals of the control module 205 are respectively connected to the first output port 201 and the second output port 202, and the first voltage regu...

Embodiment approach 2

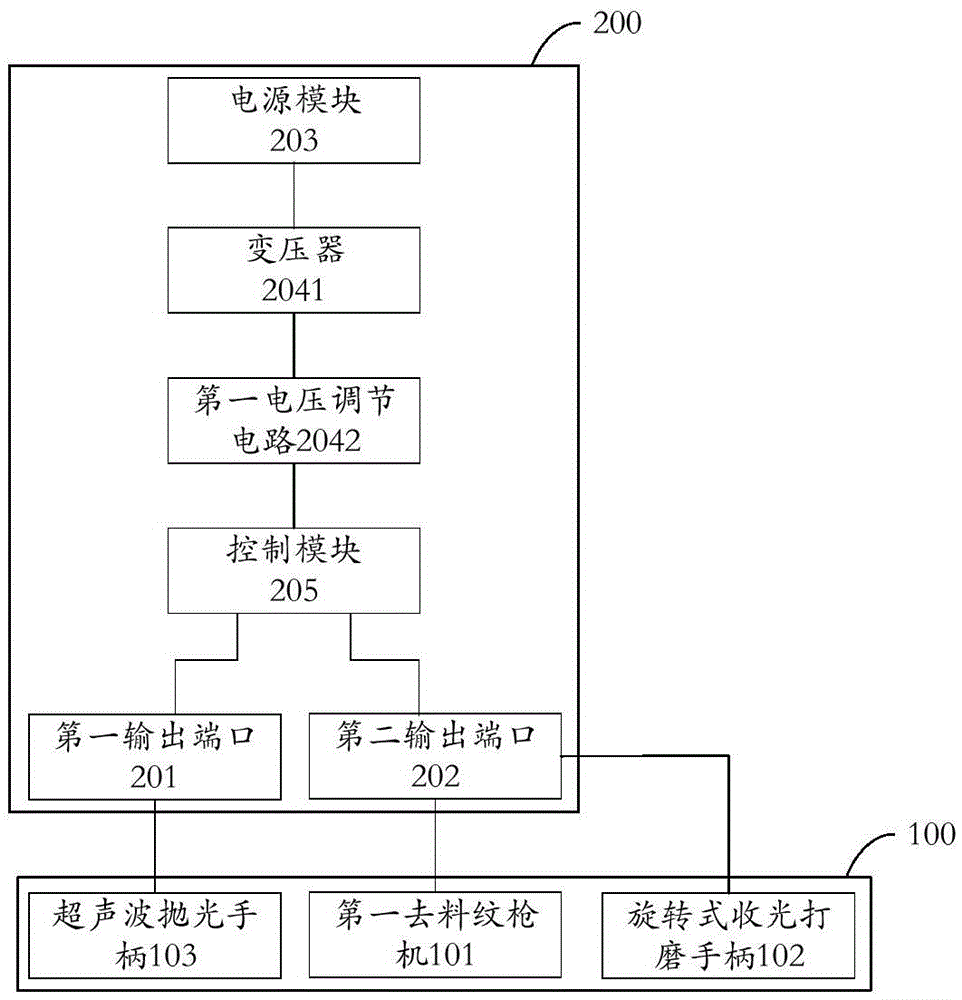

[0084] A polishing machine, including a polishing tool set 100 and a control cabinet 200 for controlling the polishing tool set 100, the polishing tool set 100 includes a first grain removal gun 101, a rotary polishing handle 102 and an ultrasonic wave Polishing handle 103, the control cabinet 200 is provided with a first output port 201 and a second output port 202, the first output port 201 is used to connect the ultrasonic polishing handle 103, and the second output port 202 is used to connect The first grain removal bolt 101 or the rotary finishing and polishing handle 102, the control cabinet 200 includes a power supply module 203, a first voltage regulation module 204 and a control module 205, the first voltage regulation module 204 respectively connected to the power supply module 203 and the control module 205, the output terminals of the control module 205 are respectively connected to the first output port 201 and the second output port 202, and the first voltage regu...

Embodiment approach 3

[0089] A polishing machine, including a polishing tool set 100 and a control cabinet 200 for controlling the polishing tool set 100, the polishing tool set 100 includes a first grain removal gun 101, a rotary polishing handle 102 and an ultrasonic wave Polishing handle 103, the control cabinet 200 is provided with a first output port 201 and a second output port 202, the first output port 201 is used to connect the ultrasonic polishing handle 103, and the second output port 202 is used to connect The first grain removal bolt 101 or the rotary finishing and polishing handle 102, the control cabinet 200 includes a power supply module 203, a first voltage regulation module 204 and a control module 205, the first voltage regulation module 204 respectively connected to the power supply module 203 and the control module 205, the output terminals of the control module 205 are respectively connected to the first output port 201 and the second output port 202, and the first voltage regu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com