Method for anhydrous polishing of KDP crystals

A technology of water polishing and crystal, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, polishing compositions containing abrasives, etc. It can solve the problems of reducing laser light, reducing surface quality, damage threshold, etc., and achieves simple polishing process , Easy operation and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] specific implementation plan

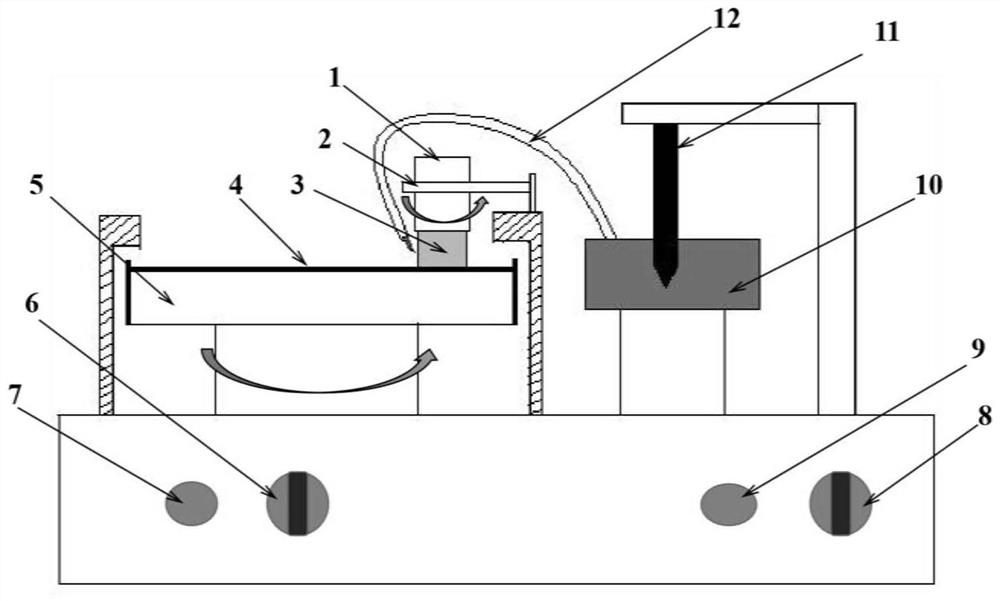

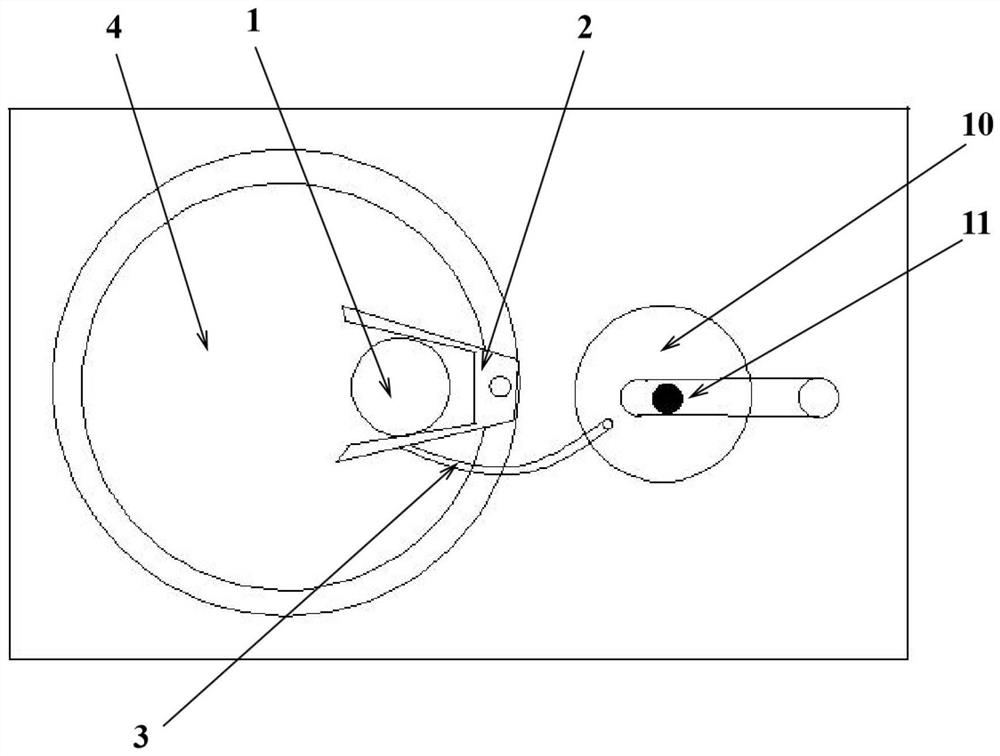

[0028] Attached below Figure 1~2 , the present invention will be further described.

[0029] A method for anhydrous polishing of KDP crystals, taking a 10×10×5mm KDP crystal block as an example, the specific operations are as follows:

[0030] 1. According to the total volume of the anhydrous polishing liquid, calculate the required volume or mass of each component of the polishing liquid in turn, wherein in the anhydrous rough polishing liquid, the viscosity of methyl oleate is 60cs, and the silicon carbide / alumina mixed abrasive grain Particle size is 1500nm, and the content in this polishing liquid is 200g / L, and the particle size of anhydrous sodium carbonate is 1500nm, and the content in this polishing liquid is 150g / L; In anhydrous fine polishing liquid, oleic acid Methyl ester viscosity is 20cs, the particle size of silicon carbide / alumina mixed abrasive grains is 800nm, the content in this polishing liquid is 150g / L, and the par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com