Aluminum oxide polishing solution for polishing mother pearl shellfish and preparation method of aluminum oxide polishing solution

A technology of alumina and polishing fluid, which is applied in the field of grinding and polishing, can solve the problems that the alumina polishing fluid is difficult to exert the grinding and polishing effect, and is easy to agglomerate, delaminate, precipitate, and agglomerate, so as to improve the surface state of the workpiece and reduce scratches The effect of high removal rate and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

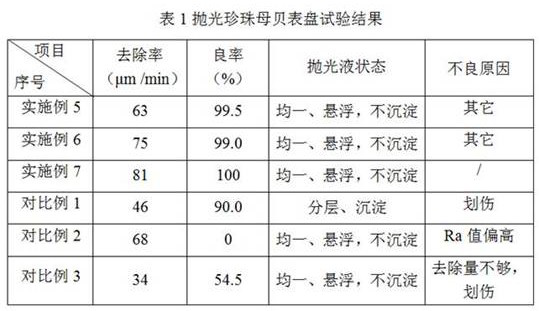

Examples

Embodiment 1

[0020] An alumina polishing solution for polishing mother-of-pearl, comprising the following raw materials in parts by weight: 15-30 parts of plate-shaped alumina powder, 0.5-10 parts of spherical alumina powder, and 0.3-10 parts of dispersant 1.0 parts, 0.2-10 parts of suspending agent, 0.1-1 part of pH regulator, 50-80 parts of water.

Embodiment 2

[0022] An alumina polishing solution for polishing mother-of-pearl, comprising the following raw materials in parts by weight: 15-30 parts of plate-shaped alumina powder, 0.5-10 parts of spherical alumina powder, and 0.3-10 parts of dispersant 1.0 parts, 0.2-10 parts of suspending agent, 0.1-1 part of pH regulator, 50-80 parts of water.

[0023] Wherein, the weight of the quasi-spherical alumina powder is 5% to 30% of the weight of the plate-shaped alumina powder.

Embodiment 3

[0025] An alumina polishing solution for polishing mother-of-pearl, comprising the following raw materials in parts by weight: 15-30 parts of plate-shaped alumina powder, 0.5-10 parts of spherical alumina powder, and 0.3-10 parts of dispersant 1.0 parts, 0.2-10 parts of suspending agent, 0.1-1 part of pH regulator, 50-80 parts of water.

[0026] Wherein, the crystal phase of the spherical alumina powder is one of α phase, γ phase or a combination thereof, and the purity of the spherical alumina powder is >99.9%.

[0027] Among them, the dispersant is SN-5040, sodium methylene dinaphthalene sulfonate, ammonium polyacrylate, AMP-95 or a combination thereof; the suspending agent is BYK LAPONITE-RDS sol grade sheet silicate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com