Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "Reduce the probability of scratches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

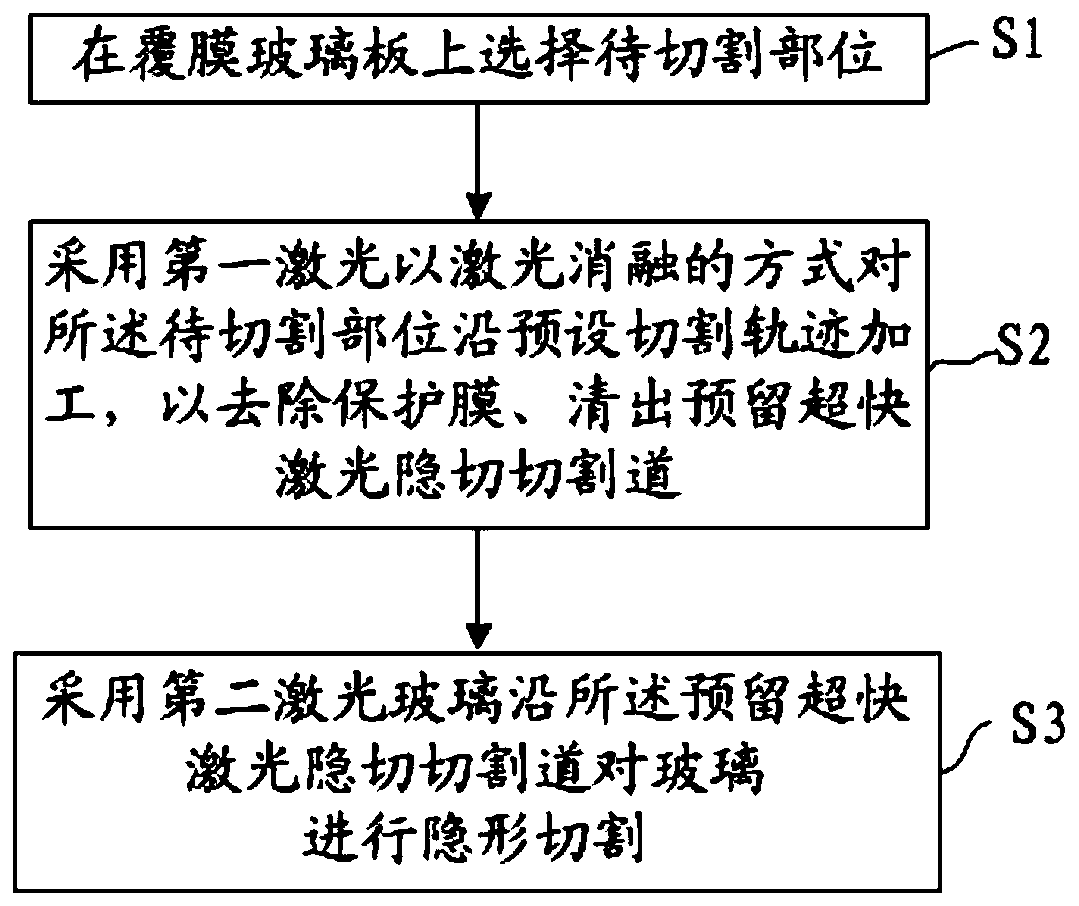

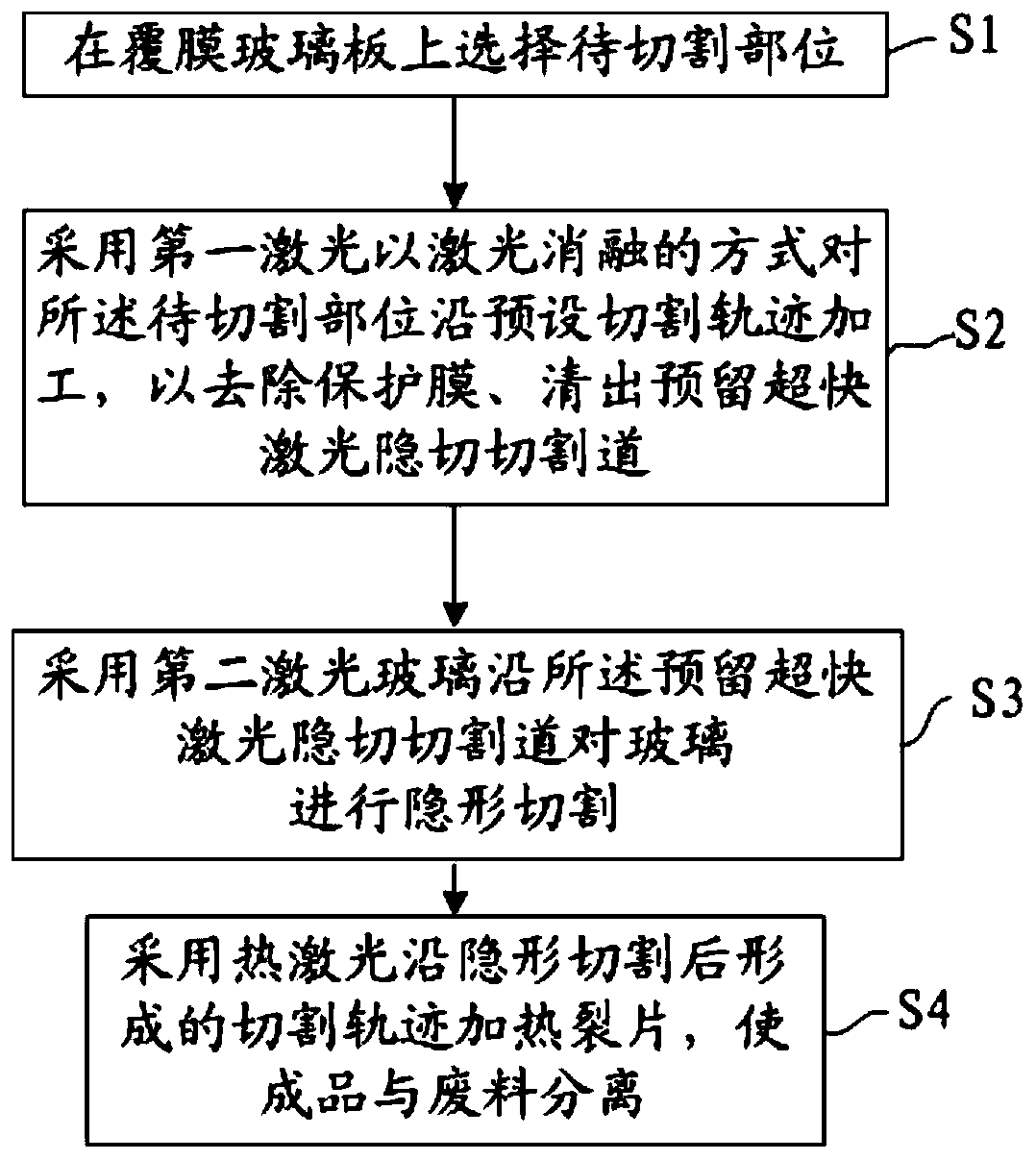

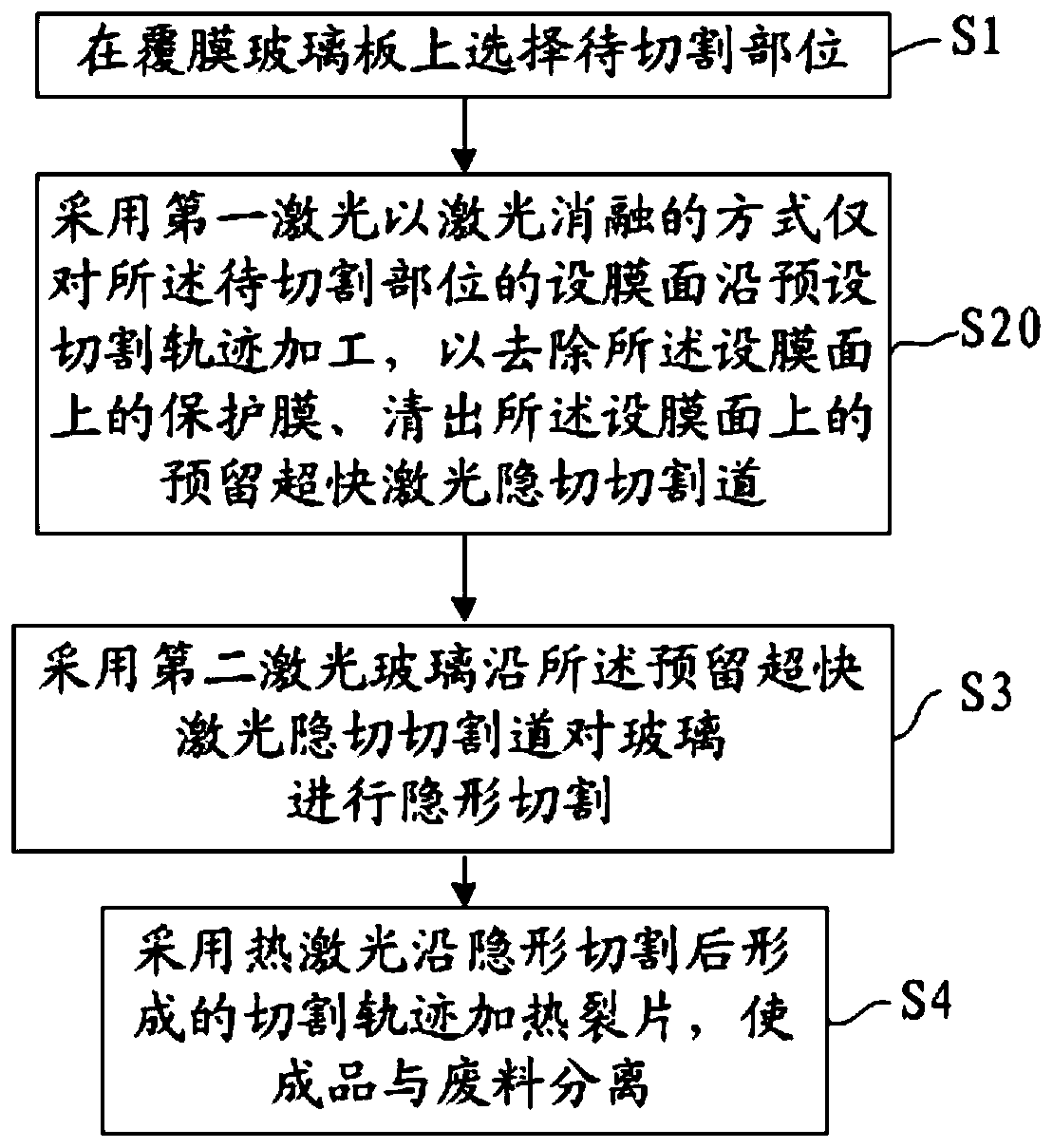

Method for laser-cutting glass covered with protective film

InactiveCN109702356AAvoid damageReduce the probability of scratchesLaser beam welding apparatusTectorial membraneCutting glass

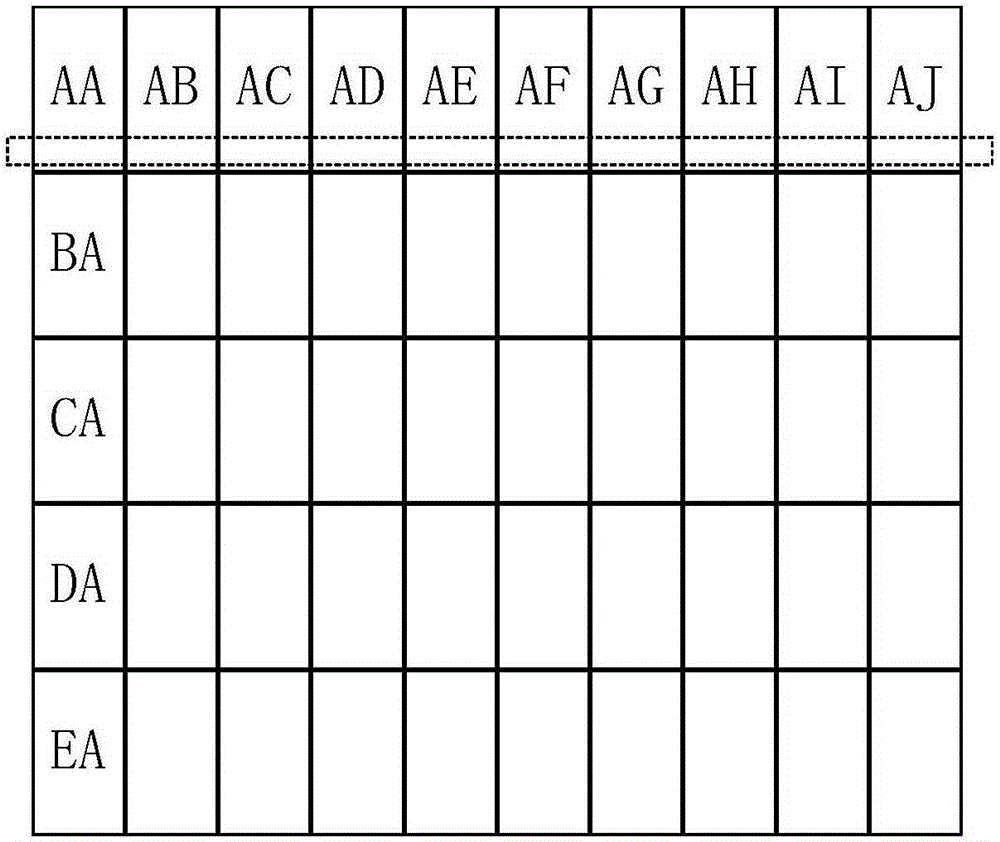

The invention discloses a method for laser-cutting glass covered with a protective film. The method comprises the following steps of selecting a to-be-cut part on a coated glass plate; machining the to-be-cut part along a preset cutting trajectory in a laser ablation mode by a first laser so as to remove the protective film and reveal a reserved ultrafast laser invisible cutting channel; and adopting a second laser to perform invisible cutting on the glass along the reserved ultrafast laser invisible cutting channel. In the method, laser cutting is adopted to replace mechanical cutting in theprior art, the protective film is removed in the laser ablation mode by the first laser before the glass is cut, so that damage to the surface of the glass in the cutting process can be avoided, the scratch rate and the pollution rate of the glass surface can be reduced, and the production yield is improved; and when the glass is cut, the energy of the laser beam cuts the glass in a non-contact manner, so that debris, fragments and micro cracks can be prevented from being generated, the strength of cutting edges by the laser is higher than that of a traditional scribing and segmentation mode,and subsequent finish machining is not needed to be carried out.

Owner:LANS INTELLIGENT ROBOT CHANGSHA CO LTD

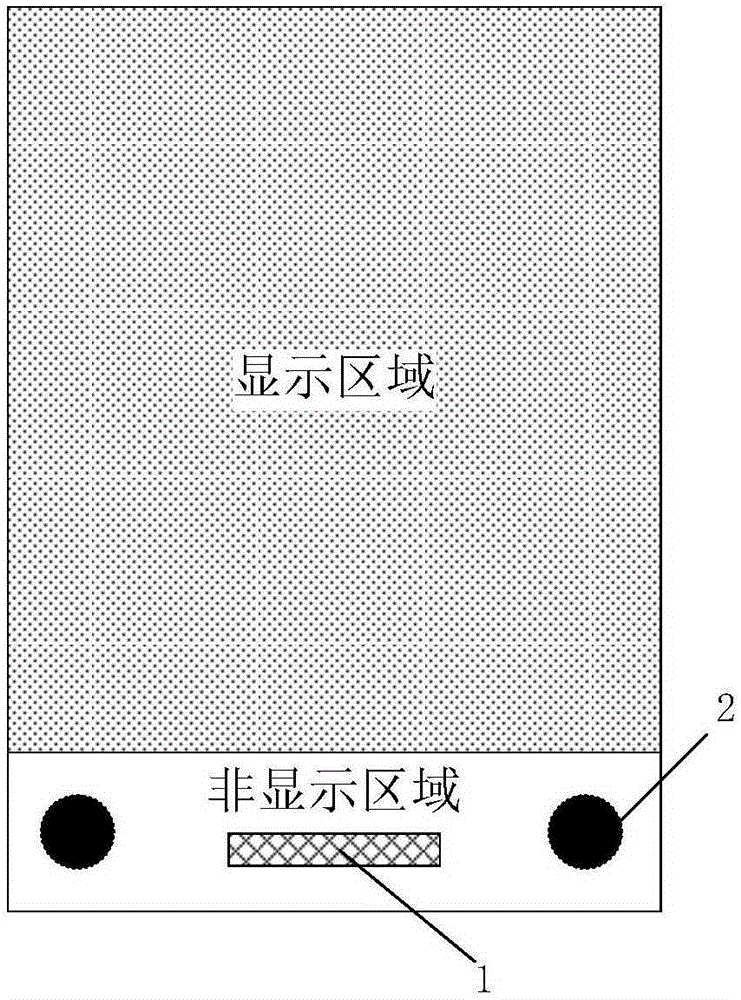

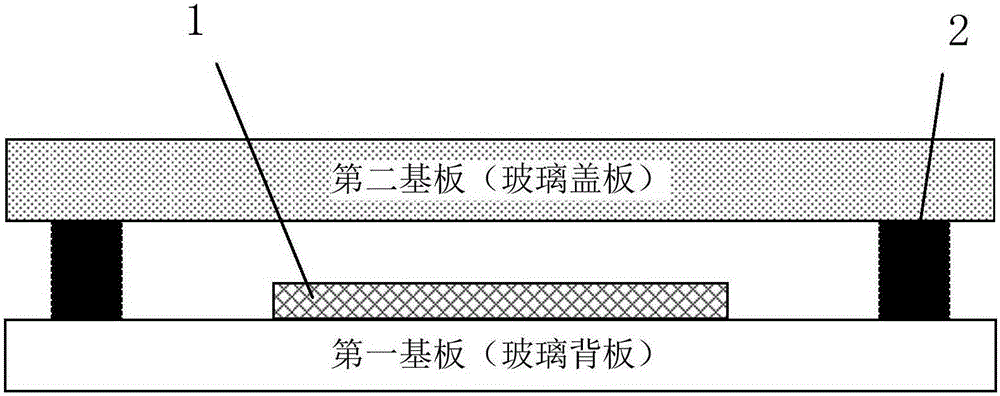

Display panel and manufacturing method thereof

InactiveCN105225608AReduce the probability of scratchesReduce bad ratioSemiconductor/solid-state device detailsNon-linear opticsEngineeringIntegrated circuit

The invention discloses a display panel and a manufacturing method thereof. The display panel comprises a first substrate and a second substrate, and the first substrate and the second substrate are in opposite arrangement. An IC (integrated circuit) is arranged in a non-display region of the first substrate, and supporting parts higher than the IC are arranged in an area, except for the area with the IC, of the non-display region. Therefore, the IC can be protected from being scratched to the maximal extent, and yield of a whole backlight module is increased.

Owner:BOE TECH GRP CO LTD +1

Device for plastic punching

InactiveCN105437313AImprove stabilityReduce the probability of driftMetal working apparatusHydraulic cylinderPunching

The invention relates to a punching device, and discloses a device used for plastic punching comprising a punching rod, a chute and two clamping plates, wherein the punching rod is connected in the chute in a sliding way, a hydraulic cylinder is connected to the left end of the punching rod, a slide rail is arranged at the right side of the punching rod, the two clamping plates are sequentially connected to the slide rail in a sliding way from left to right, a fixed block is arranged at the right end of the slide rail, a spring is connected between the clamping plate on the right and the fixed block, the two clamping plates abut against each other, an opening for the tip end of the punching rod to pass is formed in the clamping plate on the left, abutting blocks are arranged above the two clamping plates, a rack is fixedly connected with the upper portions of the abutting blocks, and the rack is meshed with a gear. Compared with the prior art, due to match of the abutting blocks and the two clamping plates, a plastic board can be steadily fixed, so that the stability of the plastic board can be enhanced, and the possibility that the tip end of the punching rod scratches the surface of the plastic board is reduced.

Owner:CHONGQING HUARUI STANDARD COMPONENT MFG CO LTD

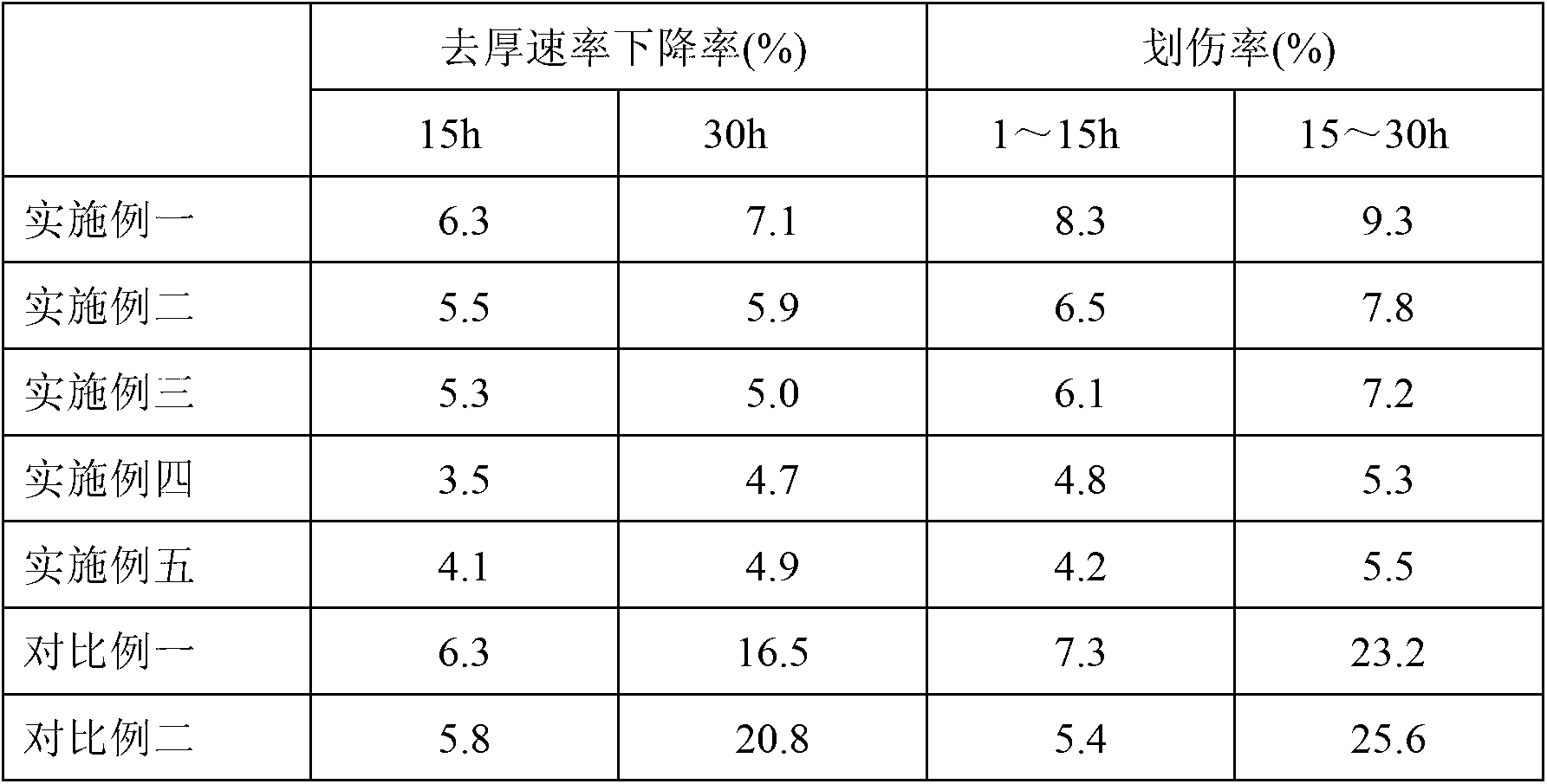

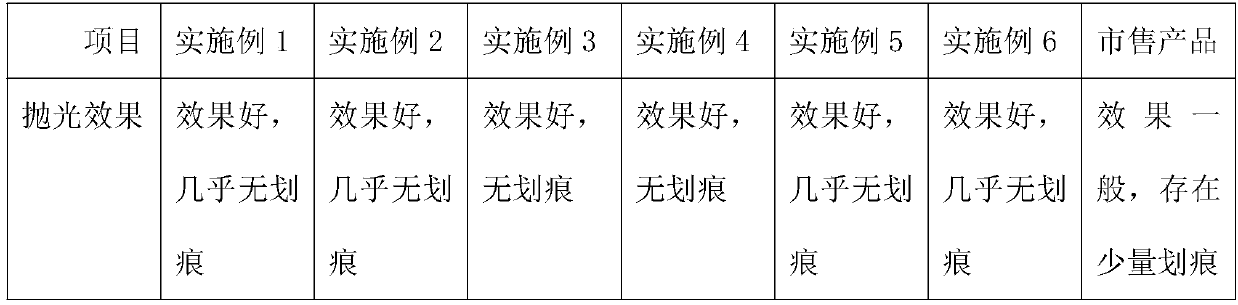

Polishing pad cleaning solution and use method thereof

InactiveCN103074175AWith adsorptionRemove in timeInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsHydrogenSurface-active agents

The invention discloses a polishing pad cleaning solution and a use method thereof, and belongs to the field of silicon wafer polishing pad cleaning technology. The cleaning solution comprises a polyoxyethylene ether non-ionic surface active agent, a cleaning addition agent, a blocking prevention agent, a solubilizing agent, a wetting agent and a PH (potential of hydrogen) conditioning agent, and the pH value of the cleaning solution ranges from 8.0 to 10.0. In a circularly polishing process, after the polishing, the polishing pad cleaning solution is diluted for 20-40 times, and then a polishing pad is scrubbed with a flow rate of 5L / min (maximum flow) for 1 min. With the adoption of the cleaning solution and the cleaning method, residual fouling and ion residues accumulated on the polishing pad in the circularly polishing process can be effectively removed, so that the moisture retention of the polishing pad can be increased, and the service life of the polishing pad is prolonged. The cleaning solution can be recycled, the price and the cost are low, and the cleaning solution has the advantages of simple processing, controllability and the like when used in cleaning.

Owner:SHENZHEN LEAGUER MATERIAL +2

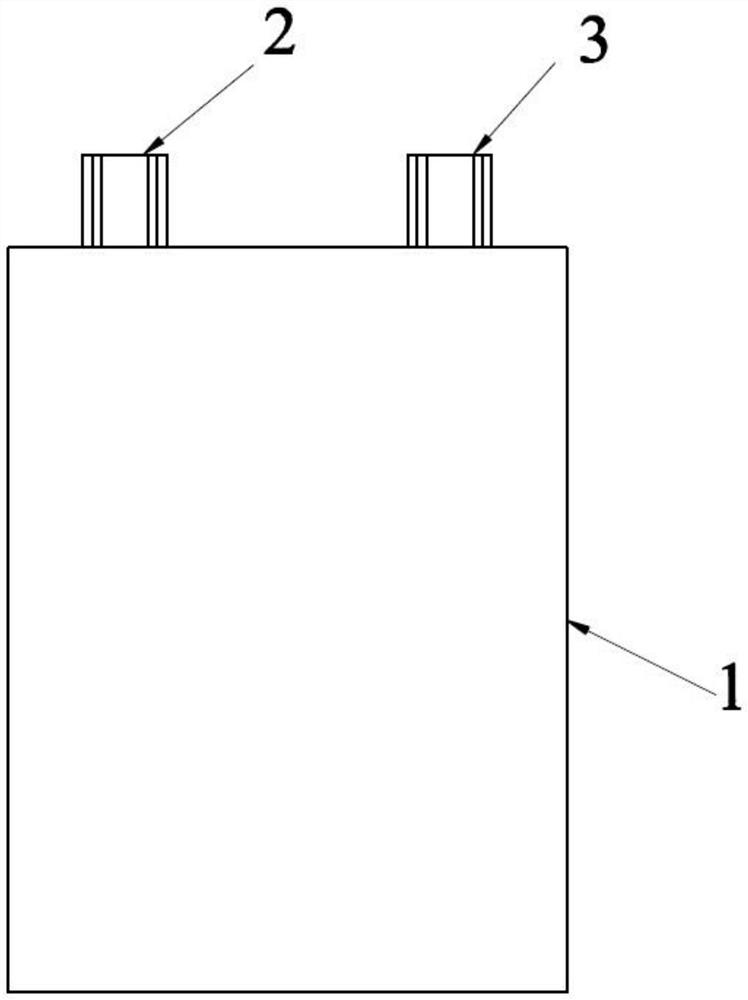

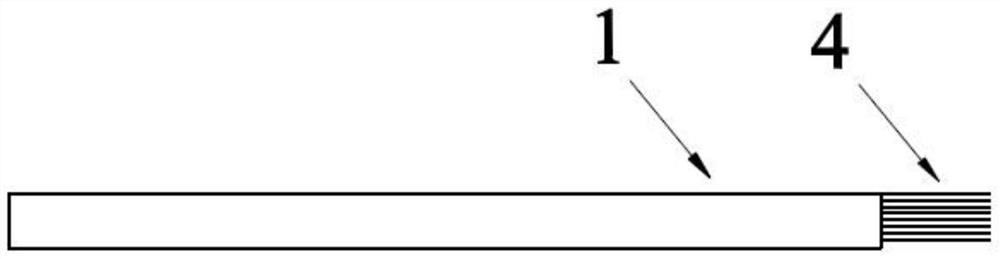

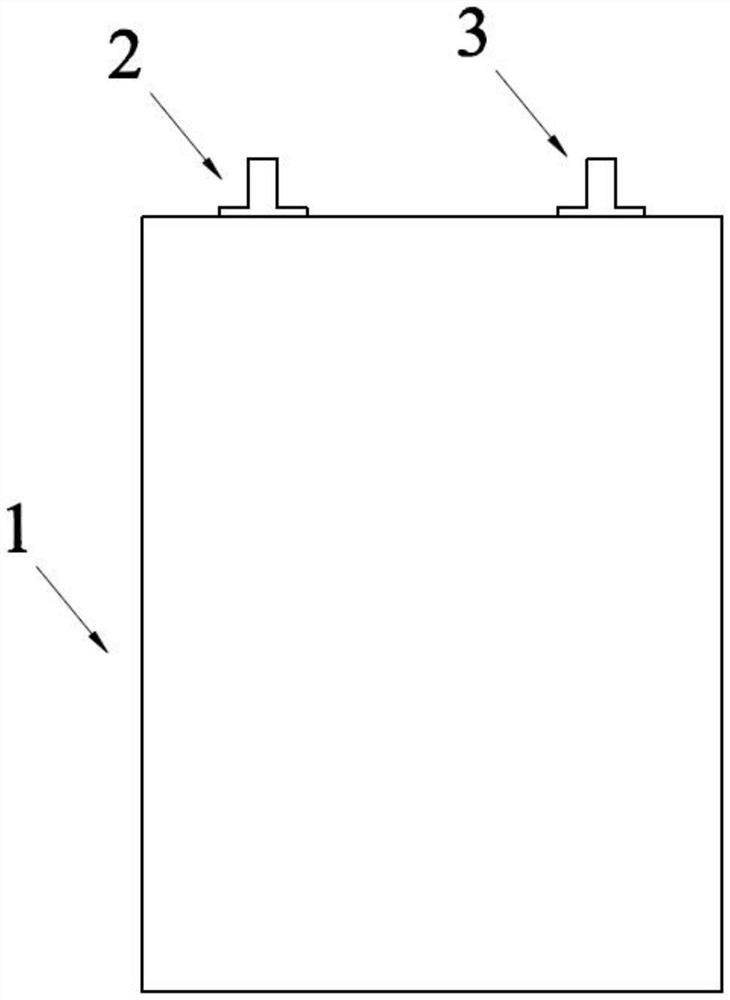

Tab bending method for multi-tab battery cell

ActiveCN113571845AImprove consistencyEasy to pass throughFinal product manufactureSecondary cellsElectrical polarityEngineering

The invention belongs to the technical field of batteries, and particularly relates to a tab bending method of a multi-tab battery cell. The method comprises the following steps of 1, respectively cutting tabs on two pole pieces, and sequentially winding the two pole pieces and a diaphragm to prepare a naked battery cell with a multi-tab structure; 2, overlapping a plurality of tabs with the same polarity and then cutting, hot-pressing and bending into a foil tab group with a preset shape, meanwhile, bending a metal strap tab with a through hole by a preset angle, wherein tab glue is pasted to the surface of the metal strap tab; 3, enabling the foil tab group to pass through the through hole, wrapping the root of the metal strap tab, and then fixedly connecting the foil tab group with the metal strap tab; and 4, pasting protective adhesive paper on the foil tab group and the metal strap tab. By optimizing the multi-tab process, the stability of the multi-tab structure is improved, and the position consistency of the bent tabs can be improved.

Owner:HUIZHOU LIWINON NEW ENERGY TECH CO LTD

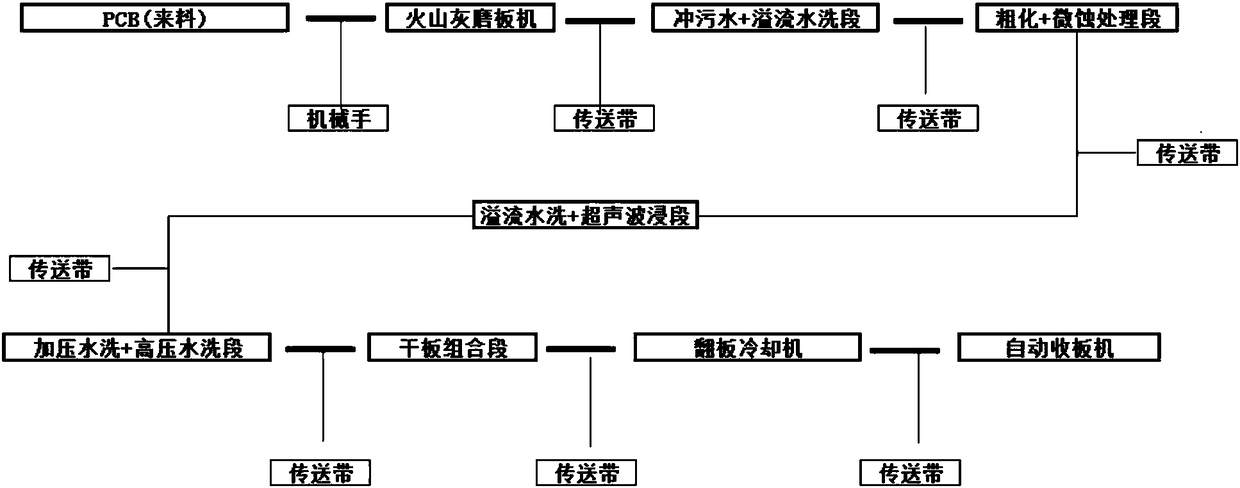

PCB (printed circuit board) resistance welding pretreatment process

ActiveCN108282966AReduce scratchesReduce the probability of scratchesProcessing steps orderNon-metallic protective coating applicationSolder maskSurface cleaning

The invention discloses a PCB (printed circuit board) resistance welding pretreatment process. The PCB resistance welding pretreatment process includes the steps of automatic feeding, volcanic-ash board grinding, roughening, microetching, surface cleaning, board drying, cooling and automatic board collecting. The process is high in automation degree, feeding and receiving are operated automatically, the step of carrying boards manually is omitted, processing efficiency is improved, and labor cost is lowered; in the steps of roughening and microetching, copper surfaces and holes of the PCBs aretreated by adopting a roughening solution and a microetching solution, the copper surface roughening effect is controlled by controlling of copper surface roughness and cleanliness, the roughness anduniformity of the copper surfaces can be optimized by roughening and microetching treatment, the binding force of the copper surfaces and the holes of the PCBs with resistance welding ink is improved, problems of bubbling and ink coming off the resistance welding layer are solved, and in addition, automatic board collecting operation also reduces the probability of friction on the board surfaces.

Owner:江西景旺精密电路有限公司

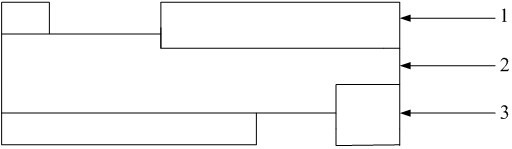

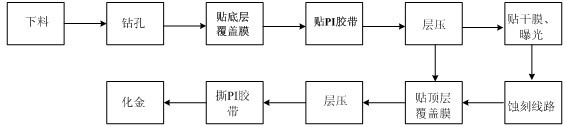

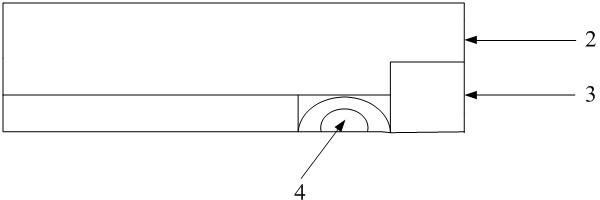

Manufacturing process of single panel gold finger

ActiveCN102427680AAvoid deformationAvoid wrinklesPrinted element electric connection formationStripping membraneAdhesive

The invention provides a manufacturing process of a single panel gold finger. The gold finger comprises: a top cover membrane layer arranged on an upper layer, a pure copper foil layer arranged in the middle and a bottom cover membrane layer arranged on the bottom. An opening is arranged on the bottom cover membrane layer. The manufacturing process comprises the following steps: a joint step: sticking a PI adhesive tape which is larger than the opening on the opening of the cover membrane layer; a laminated step: laminating the gold finger and the PI adhesive tape together, sticking the top cover membrane layer on the laminated product and then carrying out lamination; an evulsion step: evulsing the laminated PI adhesive tape; a processing step: processing on the top cover membrane layer and the opening of the bottom cover membrane layer. By using the manufacturing process of the invention, deformation and corrugation of the hollow finger during a process of after etching line stripping membrane to laminated top cover membrane in this kind of products can be avoided. A production yield rate of the products can be substantially increased.

Owner:博罗县精汇电子科技有限公司

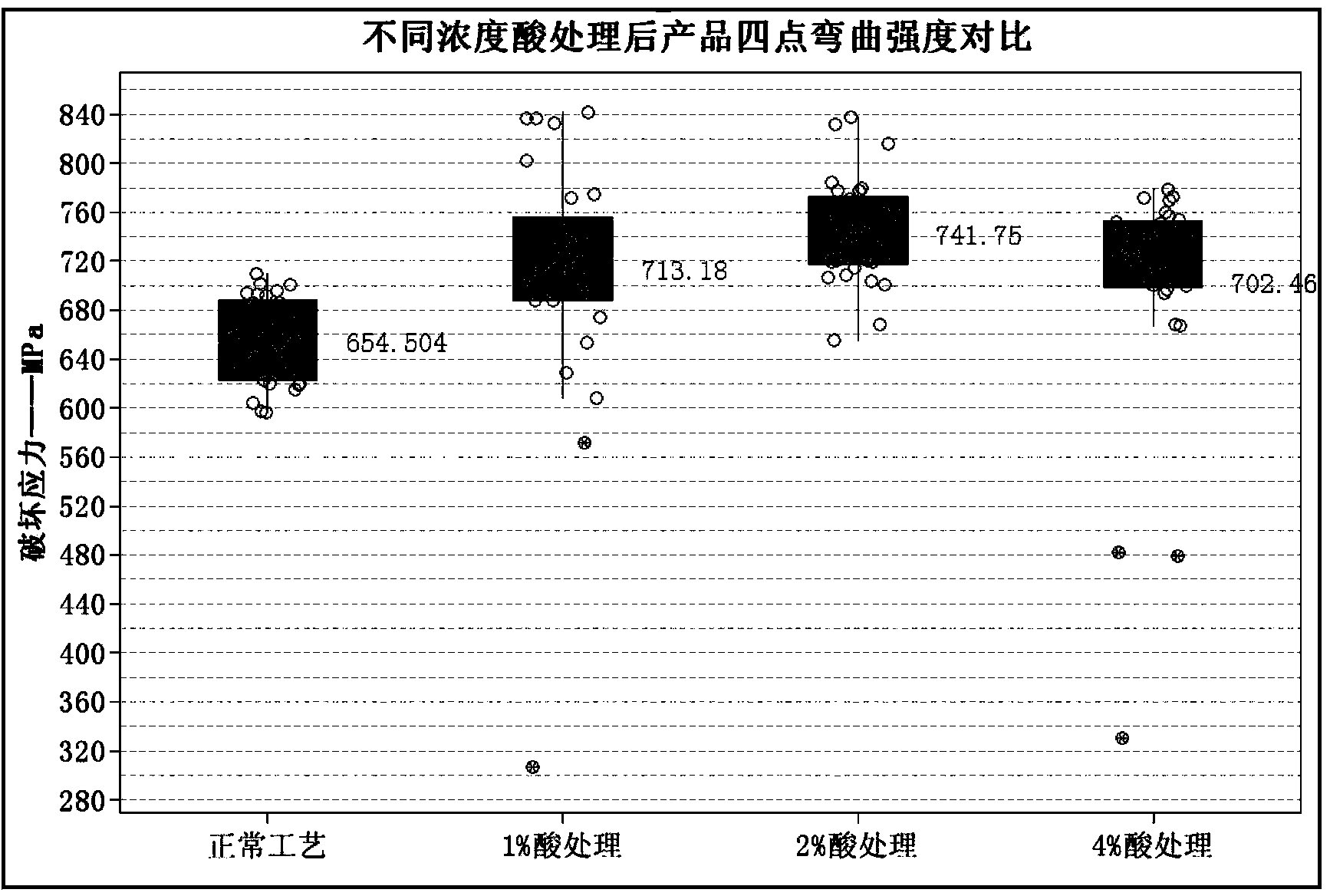

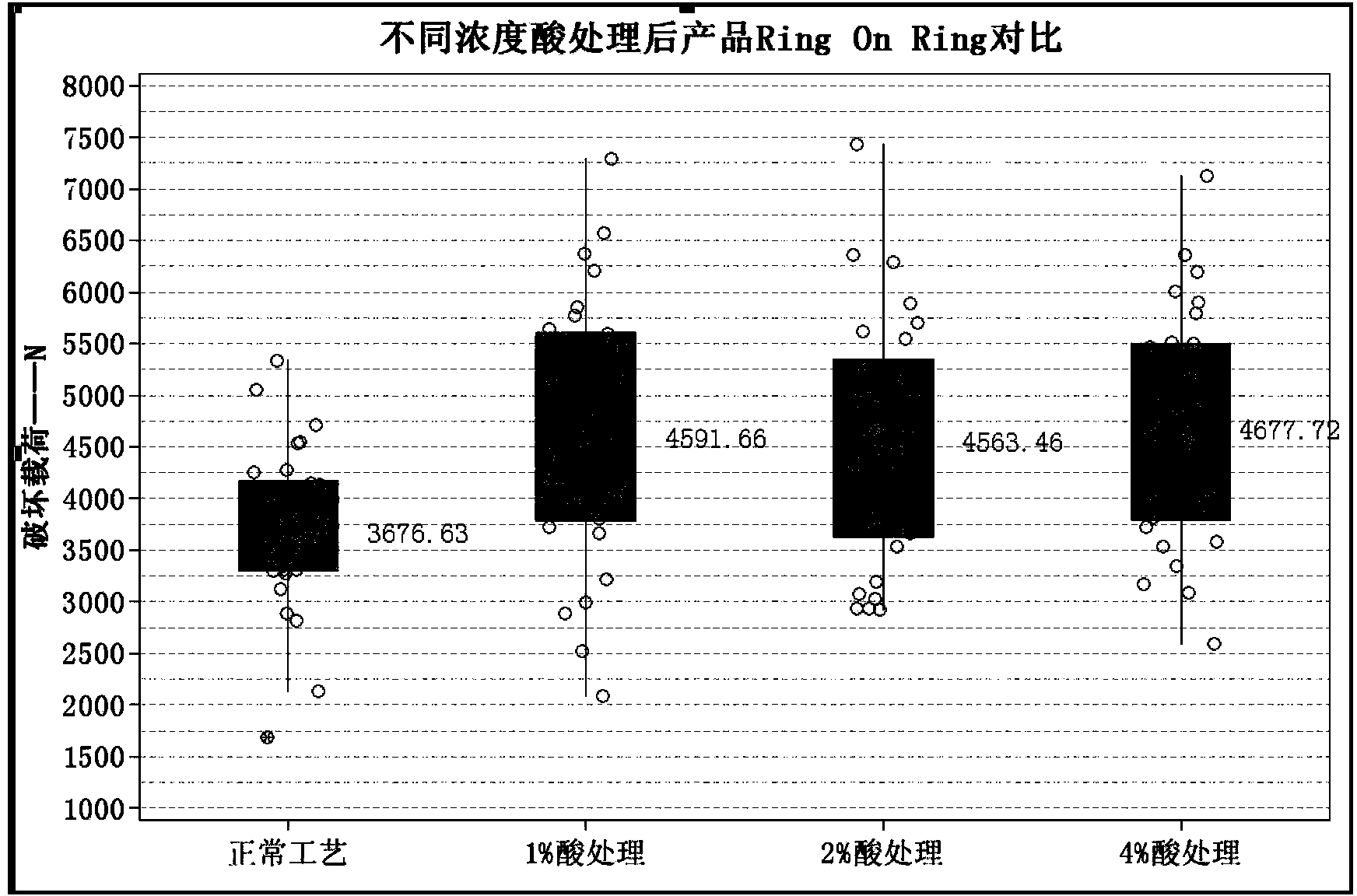

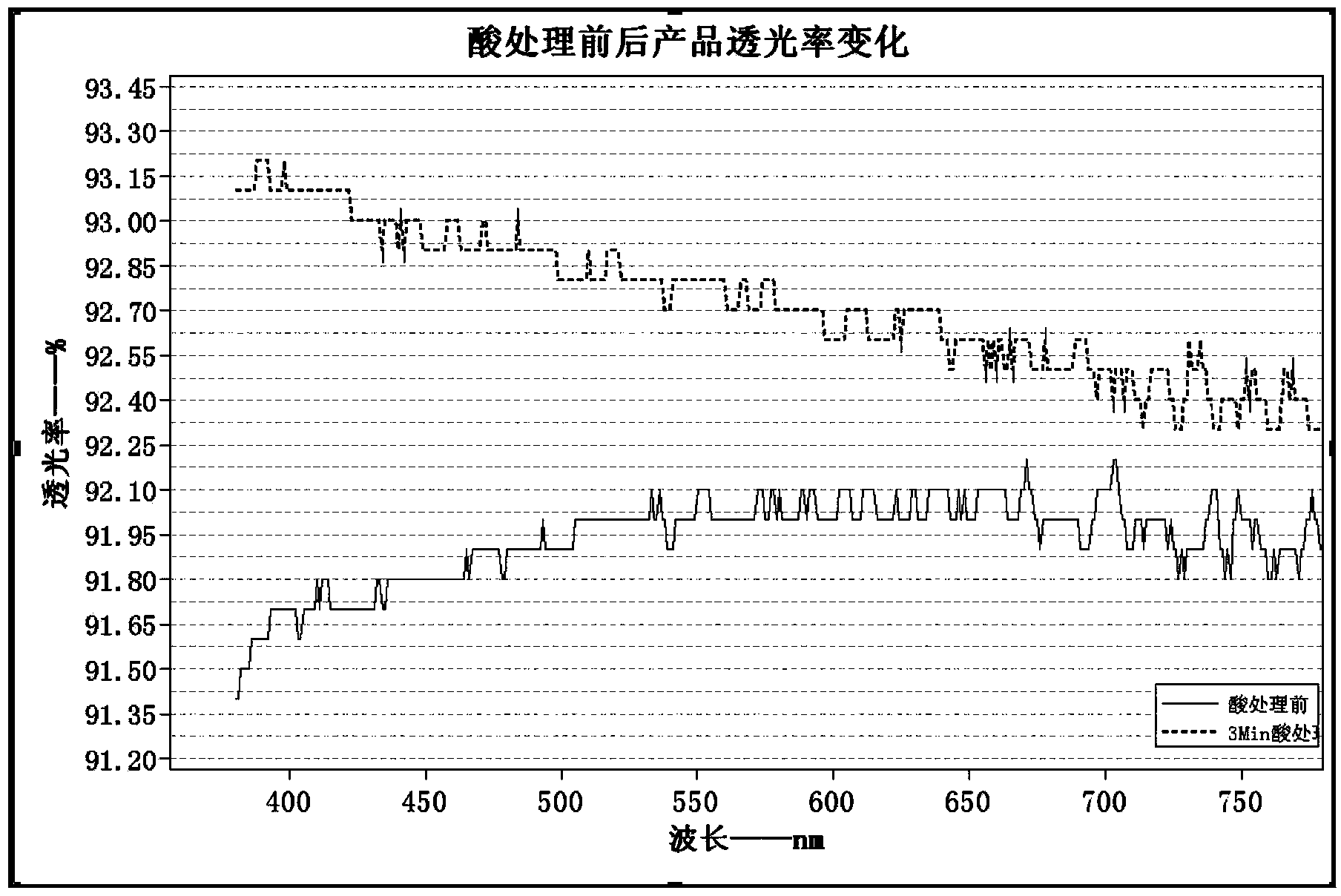

Glass lens processing method and mixed acid for processing glass lens

InactiveCN104016577AHigh strengthReduce the probability of scratchesGlass tempering apparatusHydrofluoric acidStress concentration

The invention discloses a glass lens processing method which sequentially comprises the steps of coarse grinding, elaborate polishing, reinforcing, acid treatment and after-polishing, wherein in coarse grinding, a copper disc or tin disc jumping within 0.1mm is adopted for coarse grinding; in elaborate polishing, a polishing solution with a polishing powder diameter below 1 micron is adopted for polishing the product; in reinforcing, analytically-pure fused potassium nitrate is adopted for chemically reinforcing the product; in acid treatment, the lens is soaked in mixed acid of hydrofluoric acid, sulfuric acid and water at a ratio of 1:1:50 for 2.5-3.5 minutes at 34-37 DEG C while the solution is oscillated and circulated; in after-polishing, a polishing solution with a polishing powder diameter below 0.8 micron is adopted for polishing the product. In the method, SiO2 in the glass reacts with acid, thus the stress concentration is reduced or eliminated, the glass strength is enhanced, the scratch rate of the glass is reduced, and the light transmission and appearance beauty are improved.

Owner:LENS TECH

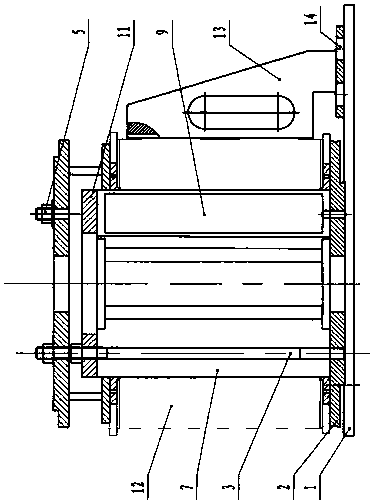

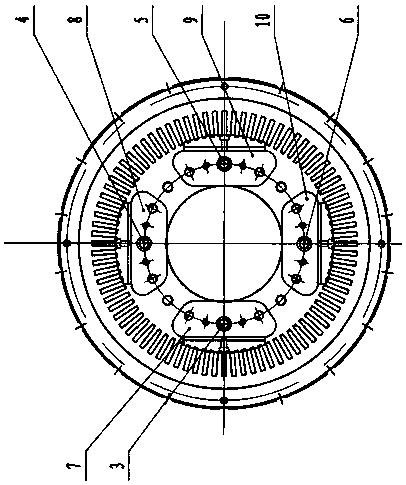

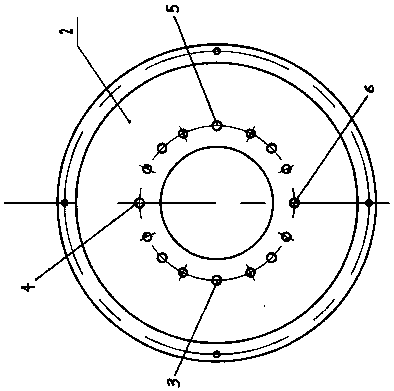

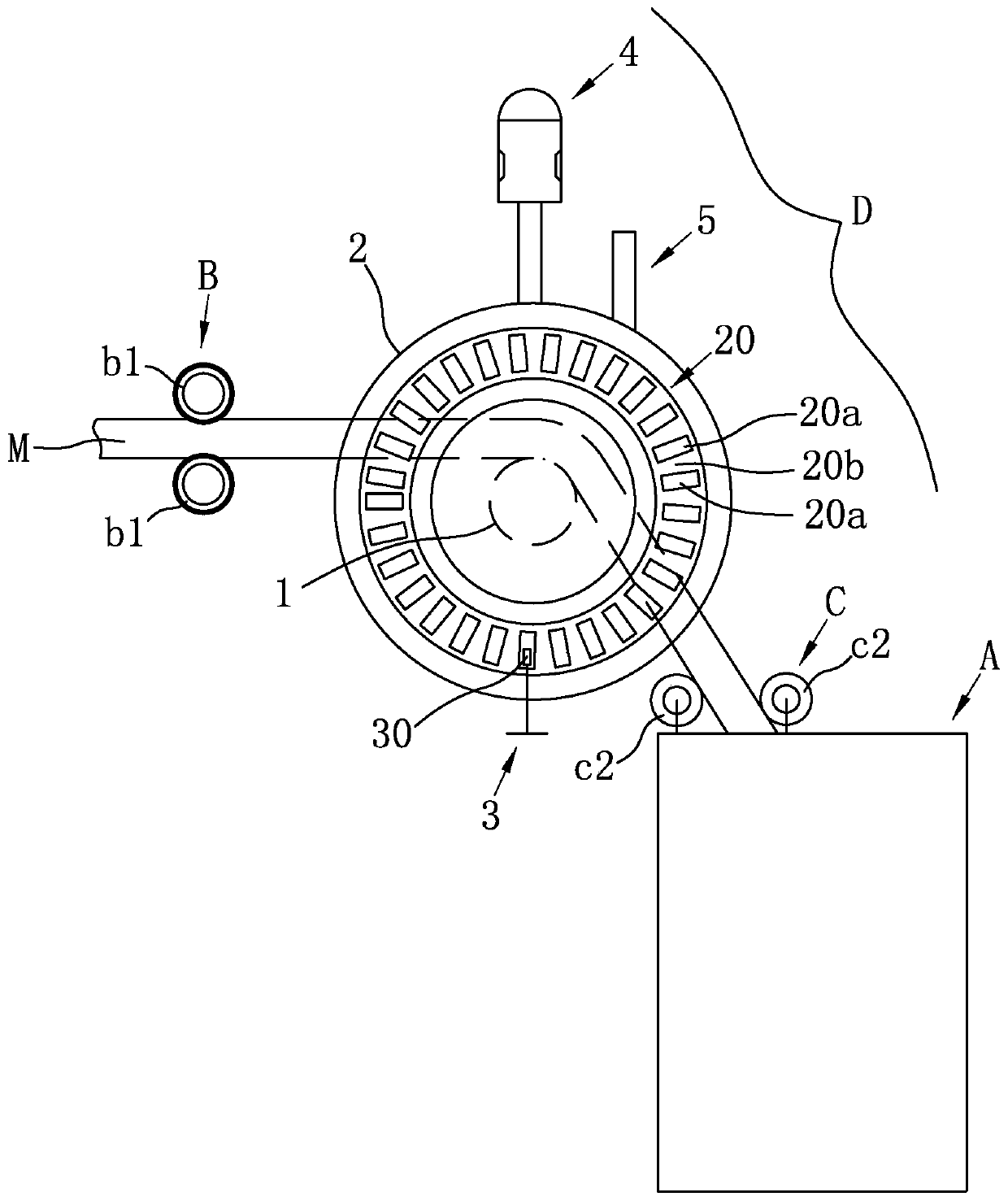

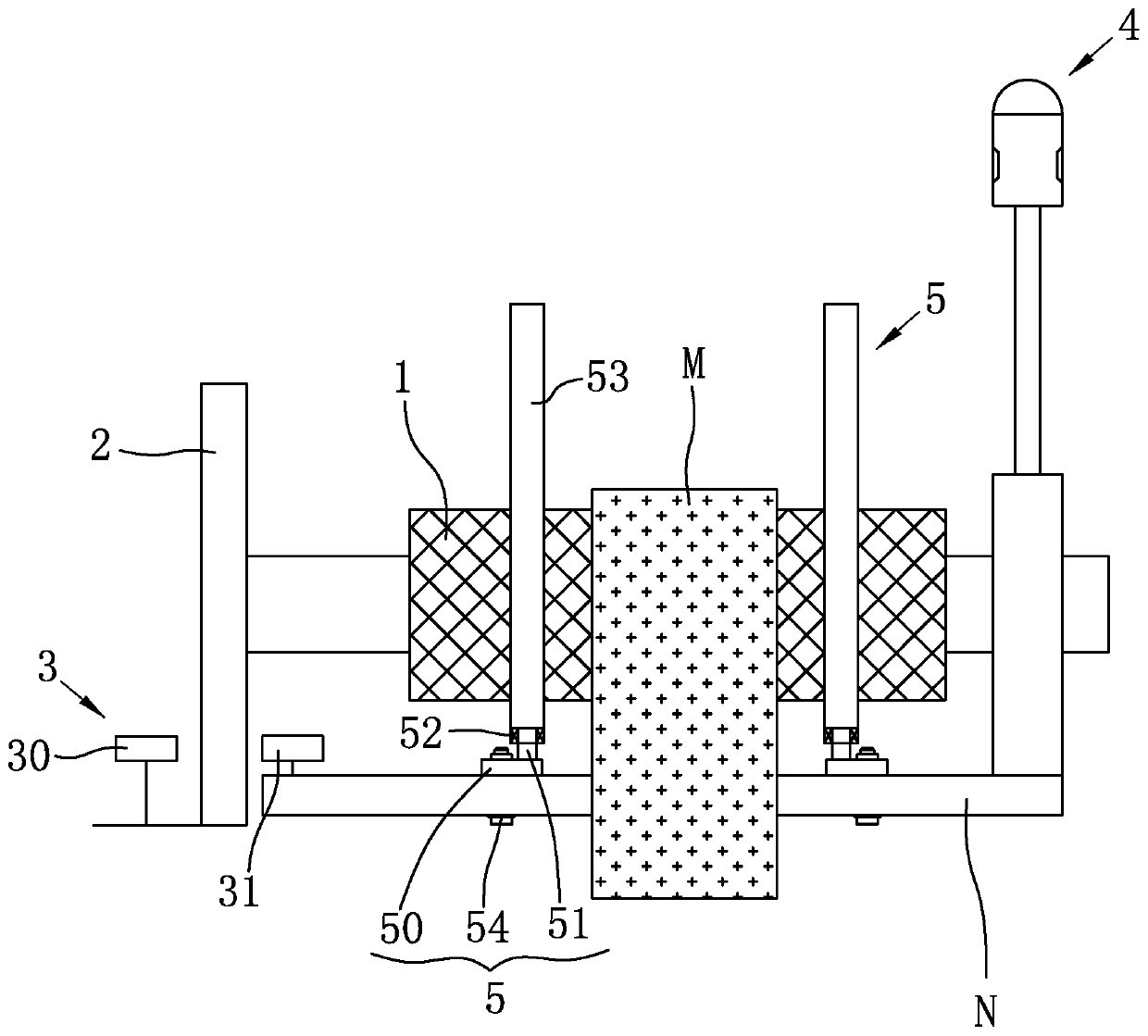

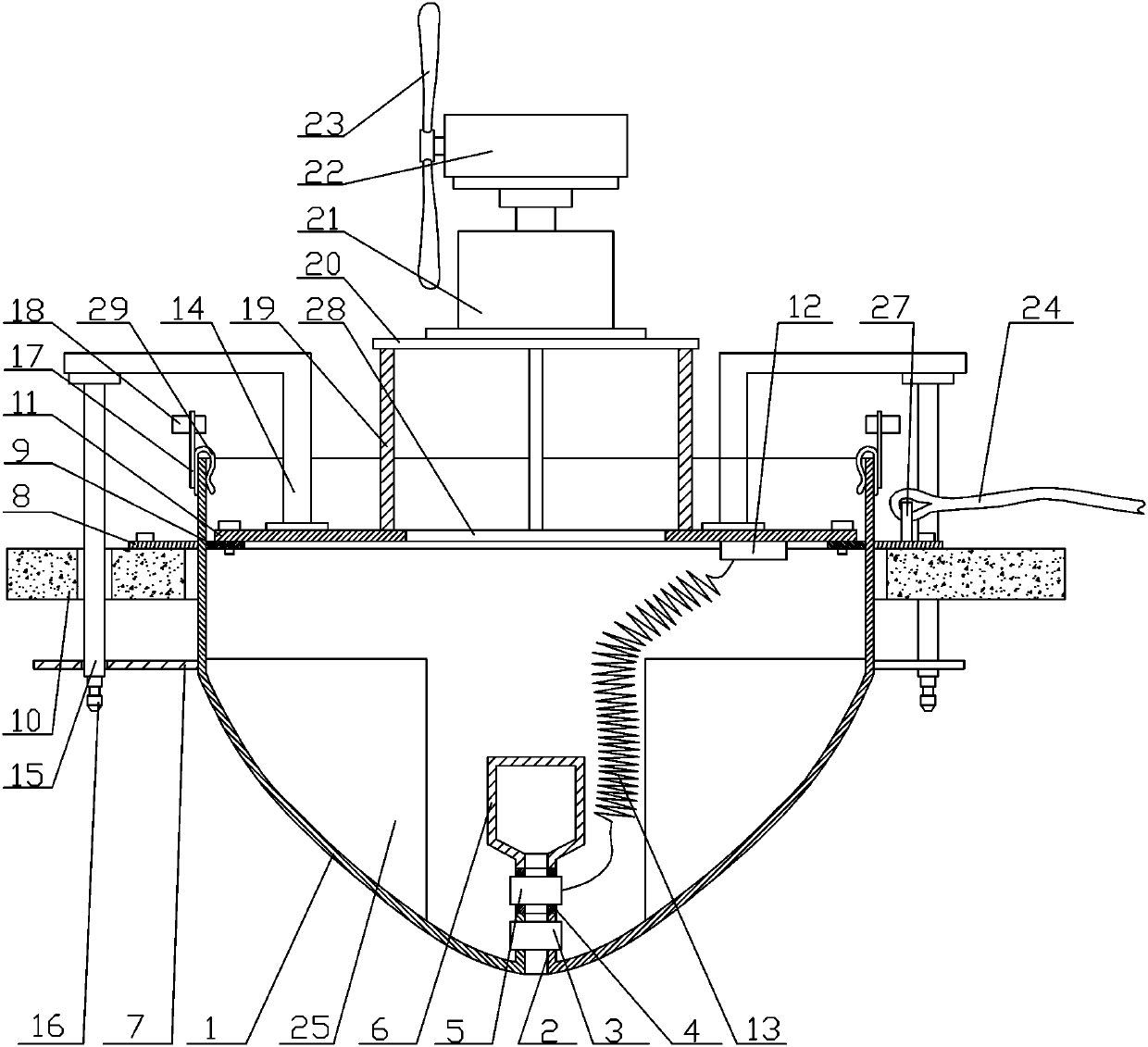

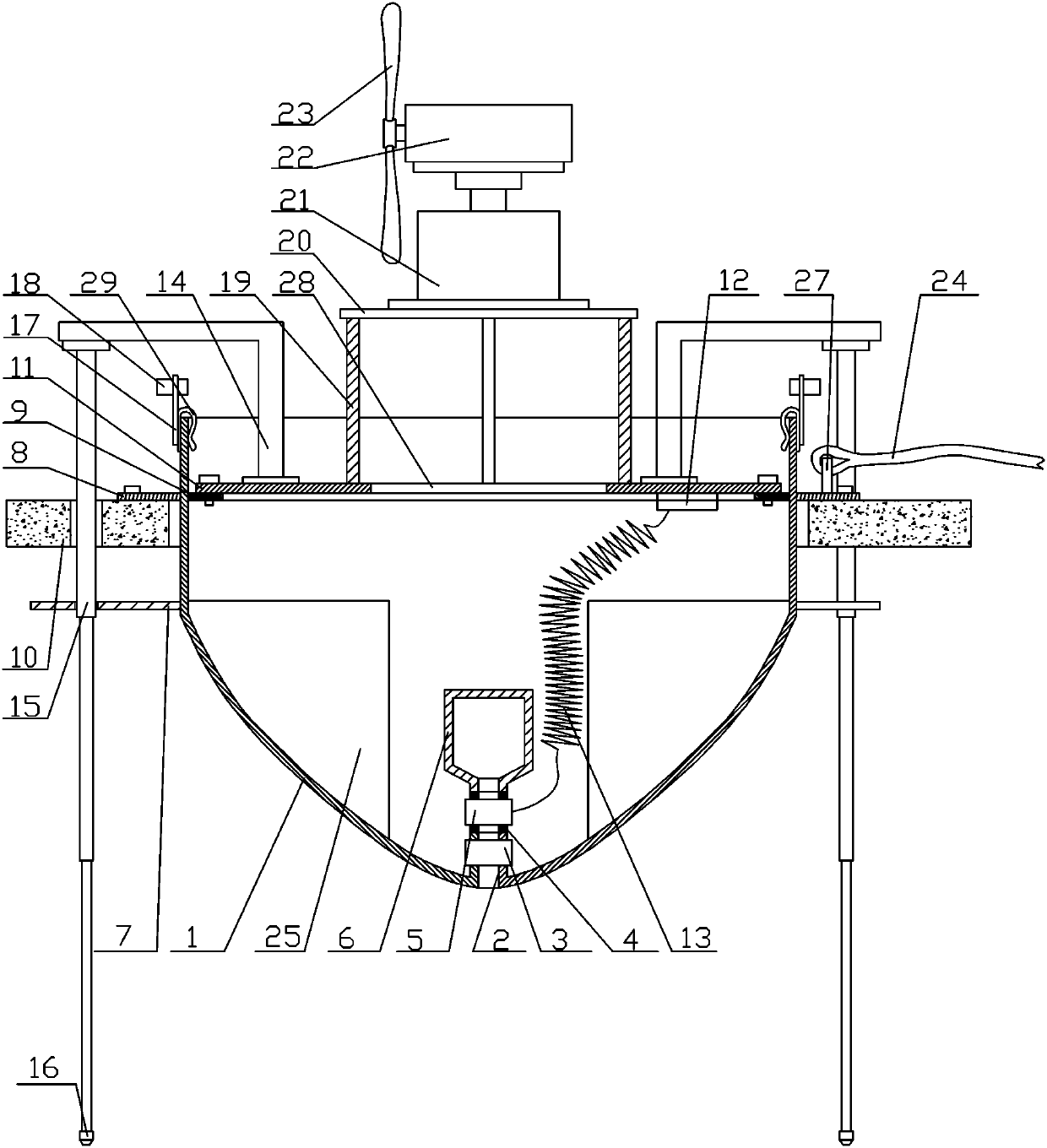

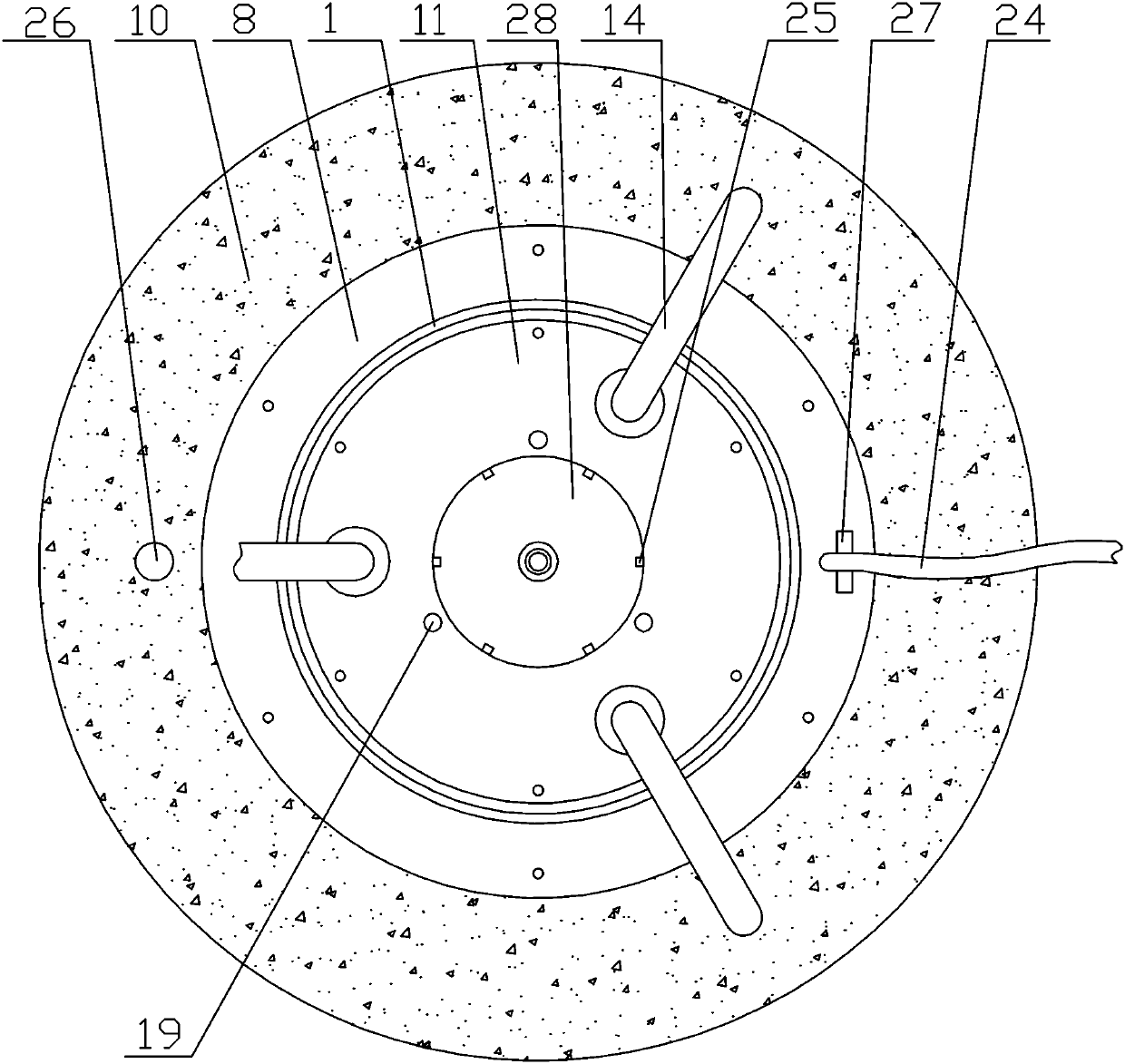

Wind driven generator stator iron core lamination forming tool and a lamination forming method

PendingCN111327165AImproving Lamination Weld Forming QualityReduce the probability of scratchesManufacturing stator/rotor bodiesEngineeringElectric generator

The invention discloses a wind driven generator stator iron core lamination forming tool and a lamination forming method, and solves the problem that an integral silicon steel sheet iron core is difficult to separate from an integral positioning support cylinder in an existing stator iron core lamination tool. An integral positioning support cylinder of a laminated silicon steel sheet iron core isdecomposed into four arc-shaped laminated positioning support plates, a spacing gap is formed between every two adjacent arc-shaped laminated positioning supporting plates, and after stator iron coresilicon steel sheets are laminated, the fixing mechanisms of the arc-shaped laminated positioning supporting plates are dismounted, so that the four arc-shaped laminated positioning supporting platesare in a movable state, and the laminated stator iron core can be conveniently separated from the stator iron core; and the silicon steel sheet excircle positioning vertical plate (13) is matched with a silicon steel sheet laminated excircle positioning groove (21) formed in the excircle of the stator core silicon steel sheet (12), so that the positioning rib embedding grooves in the laminated silicon steel sheets are aligned. The quality of the iron core is improved, and the scratching probability of the inner side wall of the iron core is reduced.

Owner:CSIC ELECTRICAL MACHINERY SCI & TECH

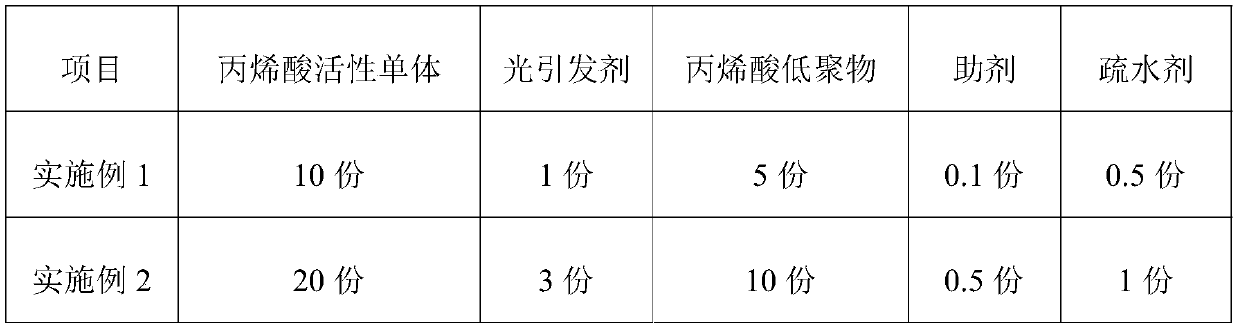

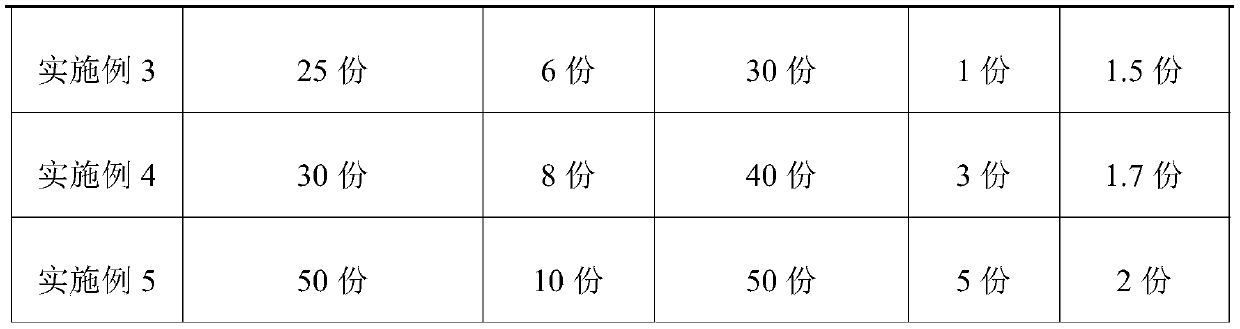

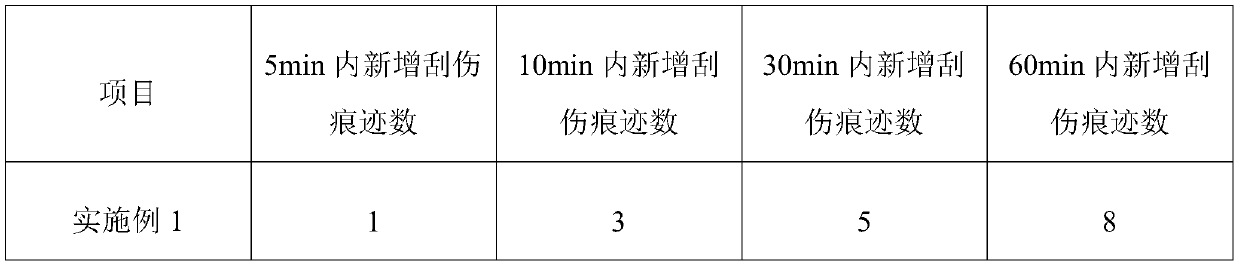

Water-resistant UV-cured resin composition, preparation method and applications thereof

InactiveCN111040619AIncrease surface tensionReduce hydrophilicityPolyurea/polyurethane coatingsEpoxy resin coatingsPolymer scienceLiquid-crystal display

The invention discloses a water-resistant UV cured resin composition, which comprises the following components in parts by weight: 10-50 parts of an acrylic acid active monomer, 5-50 parts of an acrylic acid oligomer, 1-10 parts of a photoinitiator, 0.1-5 parts of an assistant and 0.5-2 parts of a hydrophobic agent. The invention also discloses a preparation method and applications of the water-resistant UV cured resin composition. The surface tension of the water-resistant UV-cured resin composition is increased, and the hydrophilic performance is obviously reduced, so that the hydrophobic performance is obviously improved. The invention also provides a preparation method and applications of the water-resistant UV-cured resin composition. The water-resistant UV-cured resin composition isconverted into a solid sheet under the irradiation of ultraviolet light through simple and easy-to-operate preparation steps so as to be used for preparing a prismatic lens for a liquid crystal display device.

Owner:CCS (SHANGHAI) FUNCTIONAL FILMS IND CO LTD

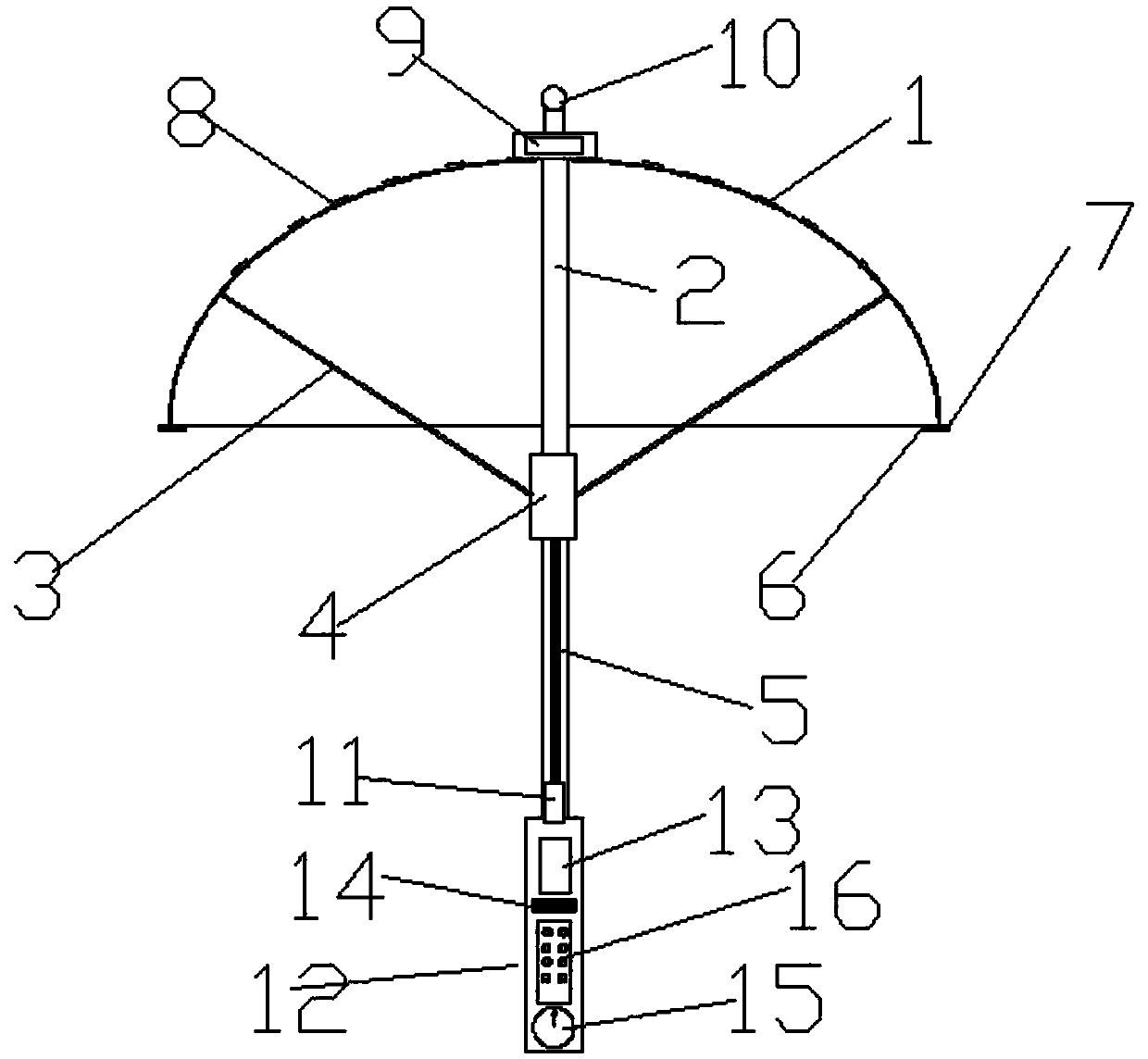

Intelligent umbrella monitoring system based on Internet of things

InactiveCN109584462ARealize centralized remote monitoringRealize centralized remote monitoring and shared use of smart umbrellasWalking sticksMeasurement devicesElectricityThe Internet

The invention discloses an intelligent umbrella monitoring system based on Internet of things. The Internet of things technology is used; the integrated remote monitoring on an intelligent umbrella can be realized; and the sharing use of the intelligent umbrella is realized. The intelligent umbrella is foldable, has a sunscreen function and can realize the self-adaptive adjustment of a support frame angle, so that the umbrella shielding range is expanded and reduced; a wind speed sensing function is set, so that an included angle between an umbrella rib and an umbrella handle can be conveniently adjusted, and the turnover probability by strong wind is reduced; a luminous vibration reminding function is also realized; luminous materials are used, so that the safety in the use process of theumbrella can be ensured; through the arrangement of an infrared sensor, the early warning on ambient vehicle conditions can be effectively realized; bluetooth mobile phone communication is used, so that simplicity and convenience are realized; the photo taking through a camera can also be realized; the functions are various; electricity is stored in a solar energy handle; a hot air drying function is realized; a GPS positioning function can also be realized, so that the position can be mastered; and the borrowing and sharing can be realized only by scanning two-dimensional through mobile phone APP control, so that the operation is simple.

Owner:SUZHOU VOCATIONAL UNIV

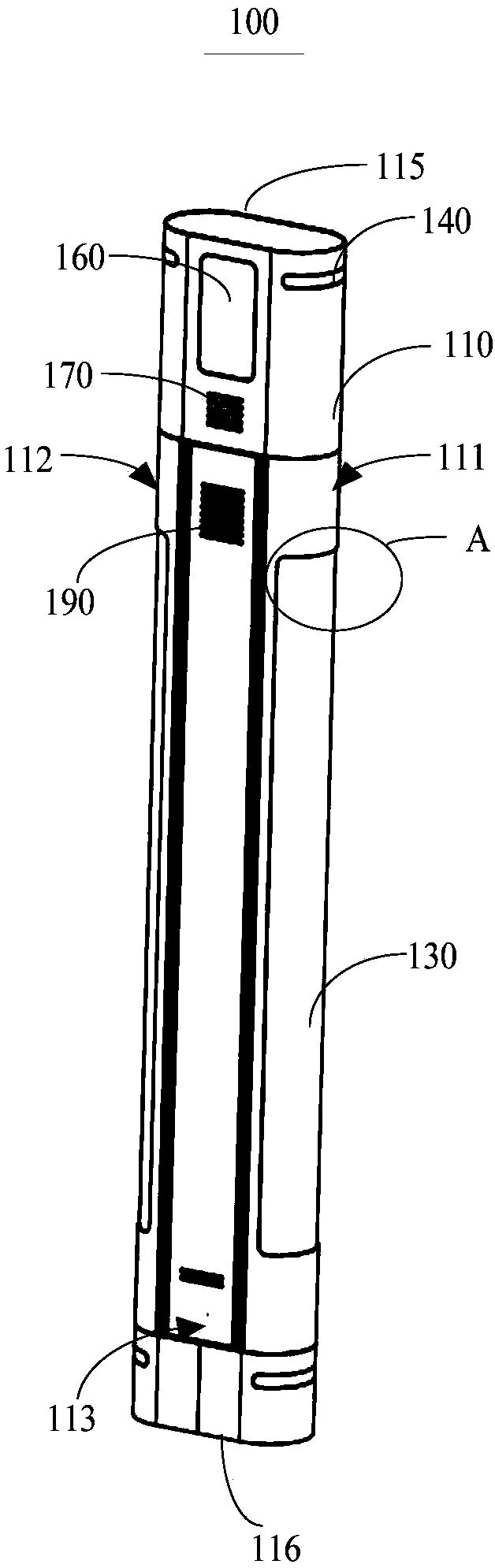

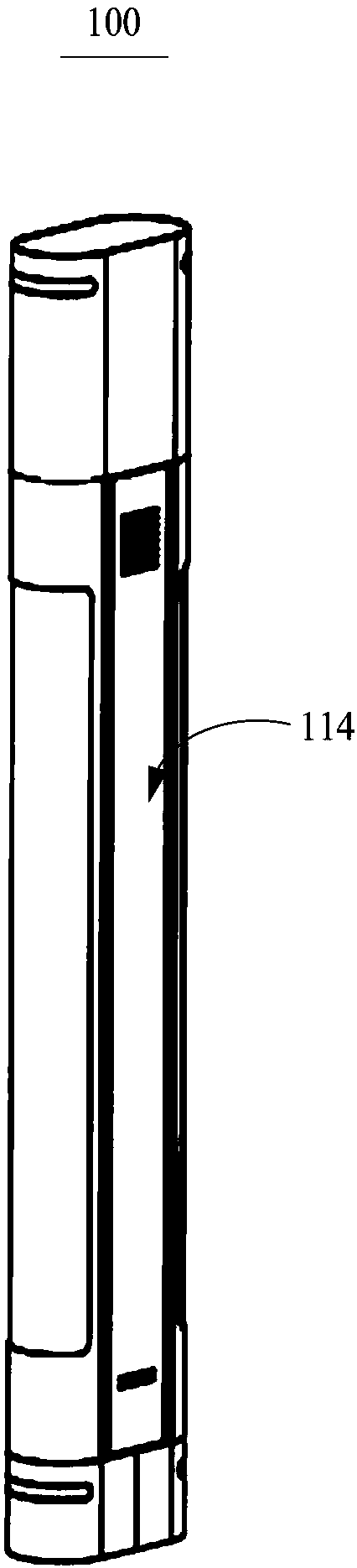

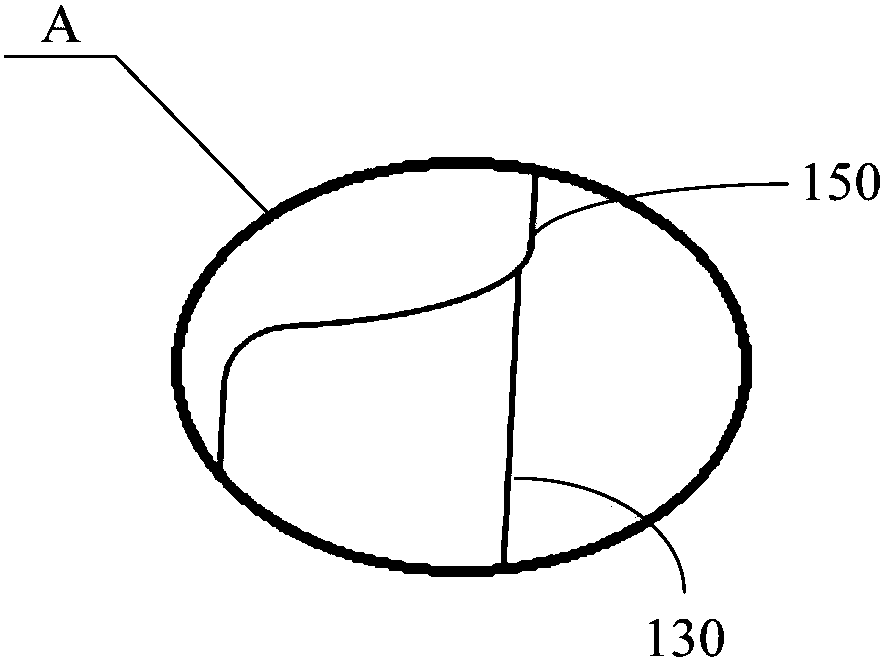

Warning column and warning system

InactiveCN107663834AReduce the probability of scratchesImprove warning effectTraffic signalsRoad signsTraffic signalEngineering

The embodiment of the invention provides a warning column and a warning system. The warning column comprises a columnar shell, wherein the shell comprises a first side surface and a second side surface which are oppositely arranged and are in an arc surface shape; light reflective films are arranged on the first side surface and the second side surface; a main control plate connected with a signalcontrol plate of a traffic signal light is arranged in the shell and is used for acquiring a signal of the signal light of the signal control plate. The warning column also comprises a light emittingdevice connected with the main control plate, and synchronous display of the light emitting device and the traffic signal light is realized according to the signal of the signal light sent by the main control plate. The warning column also comprises an infrared detection device connected with the main control plate and is used for detecting whether pedestrians go through or not under the controlof the main control plate. According to the warning column disclosed by the invention, the light reflective films are arranged on the first side surface and the second side surface which do not belongto a passage and are in the arc surface shape, so that the probability that the light reflective films are scratched can be greatly reduced; moreover, through the arrangement of the infrared detection device, whether the pedestrians go through a road under the premise of the red light can be detected, so that a warning effect can be further improved.

Owner:苏州旭安交通科技有限公司

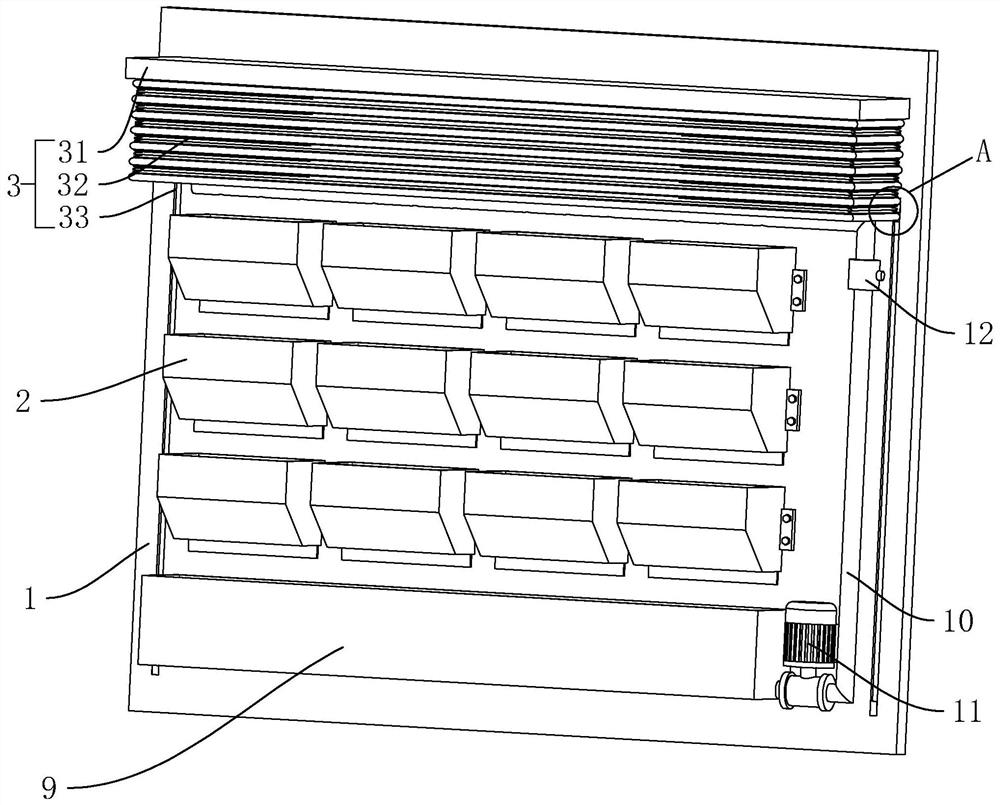

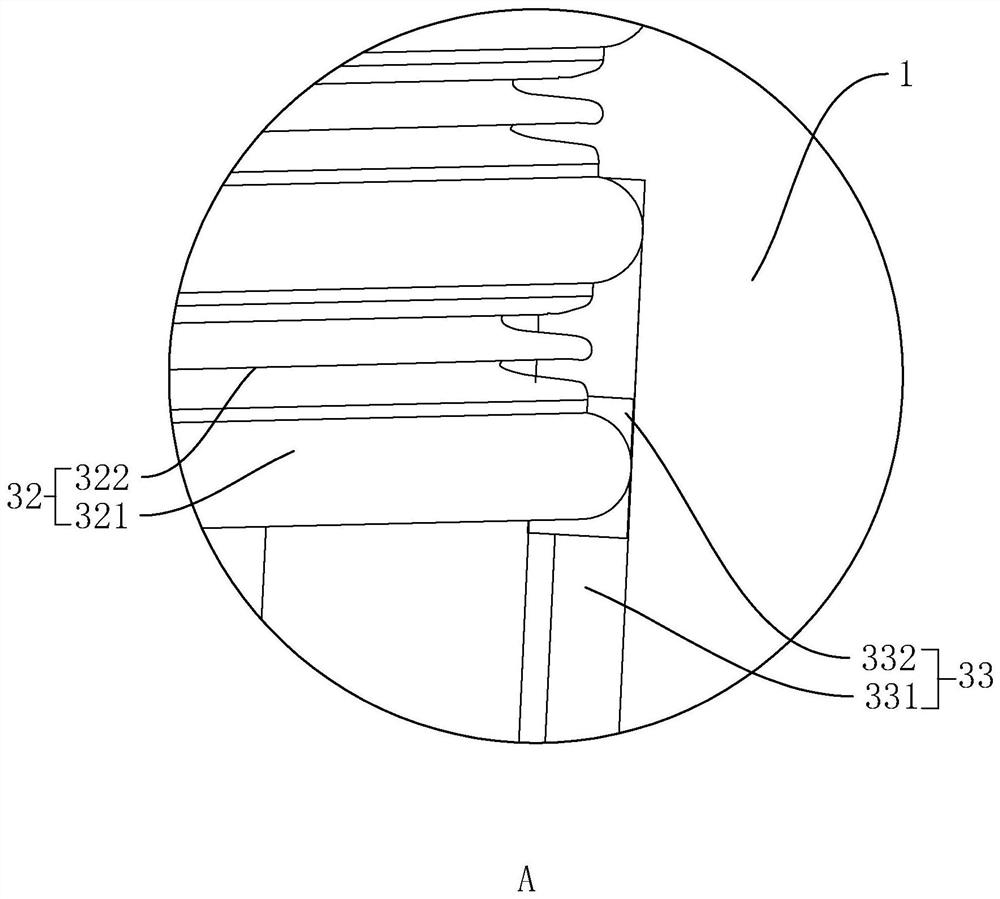

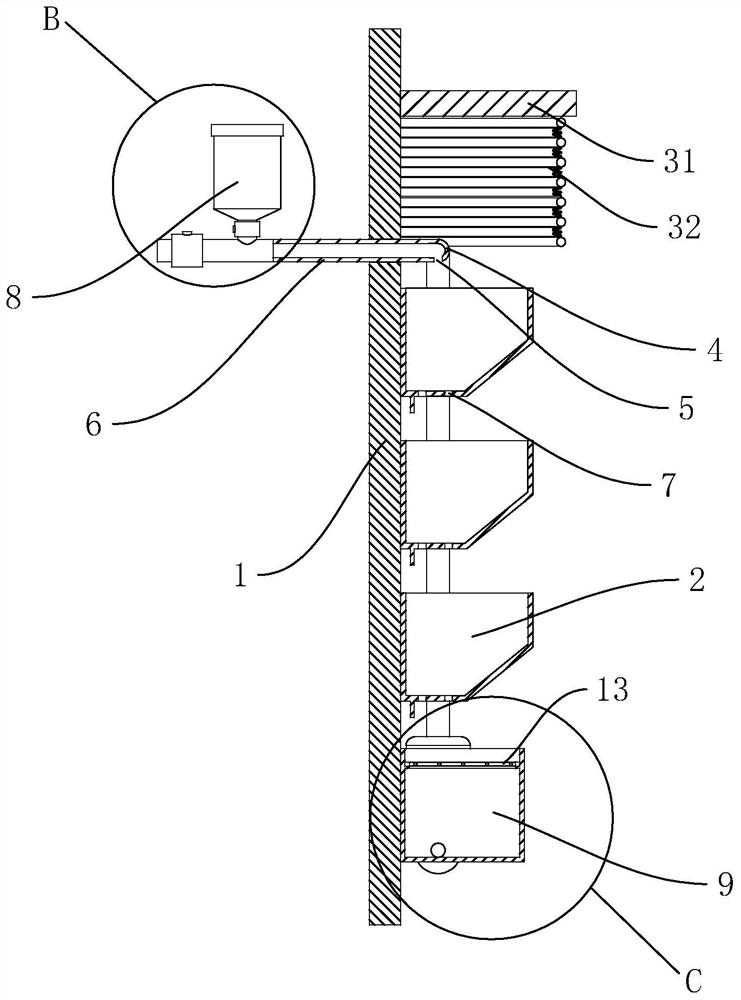

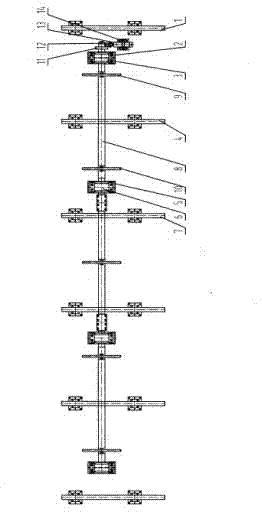

Greening curtain wall system for green buildings

The invention relates to the technical field of green buildings, in particular to a greening curtain wall system for green buildings. The greening curtain wall system for green buildings includes a curtain wall board and a plurality of planting boxes, wherein the curtain wall board is installed on a wall, the planting boxes are installed on the curtain wall board, and a protection mechanism is installed on the curtain wall board; the protection mechanism includes an installation baffle, a folding protection shed and a driving part, the installation baffle is installed above the planting boxes,and the folding protection shed is installed on the side, towards the planting boxes, of the installation baffle in a folded mode; the exteriors of the planting boxes are covered by the folding protection boxes when the folding protection shed is unfolded, the folding protection shed can be placed on the upper ends of the planting boxes when the folding protection shed is folded, and the drivingpart is installed on the curtain wall board; and the driving part is used for driving the folding protection shed to be folded and unfolded. Through the greening curtain wall system, green plants andthe planting boxes can be protected on days with typhoons and other severe weather, and the probability of being blown off of the green plants and the planting boxes is reduced, so that the probability of potential safety hazards is reduced.

Owner:深圳市东华建设工程有限公司

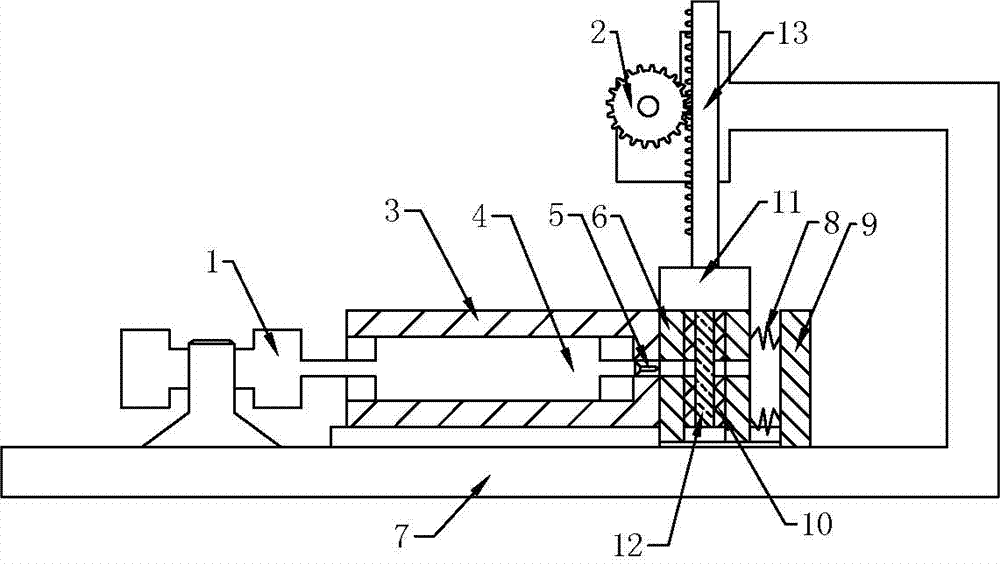

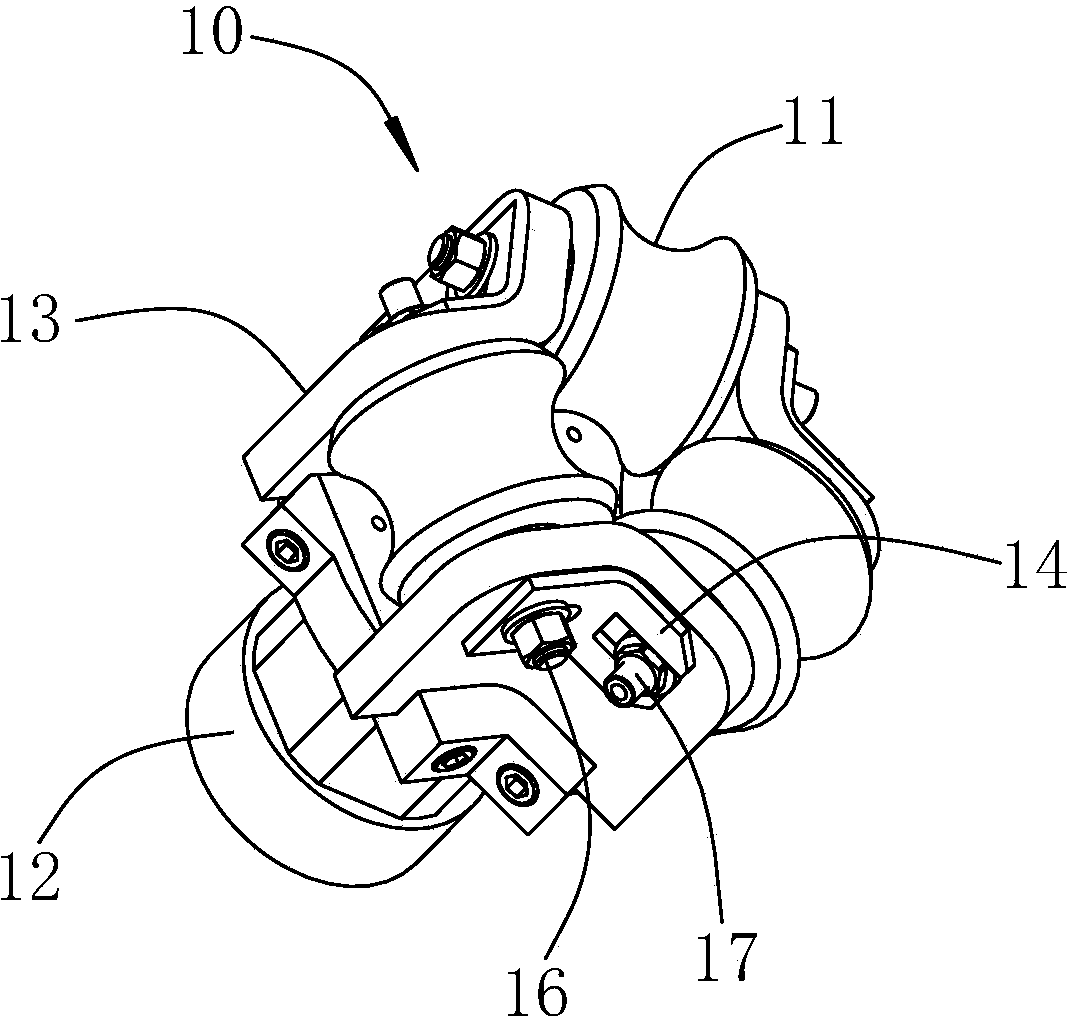

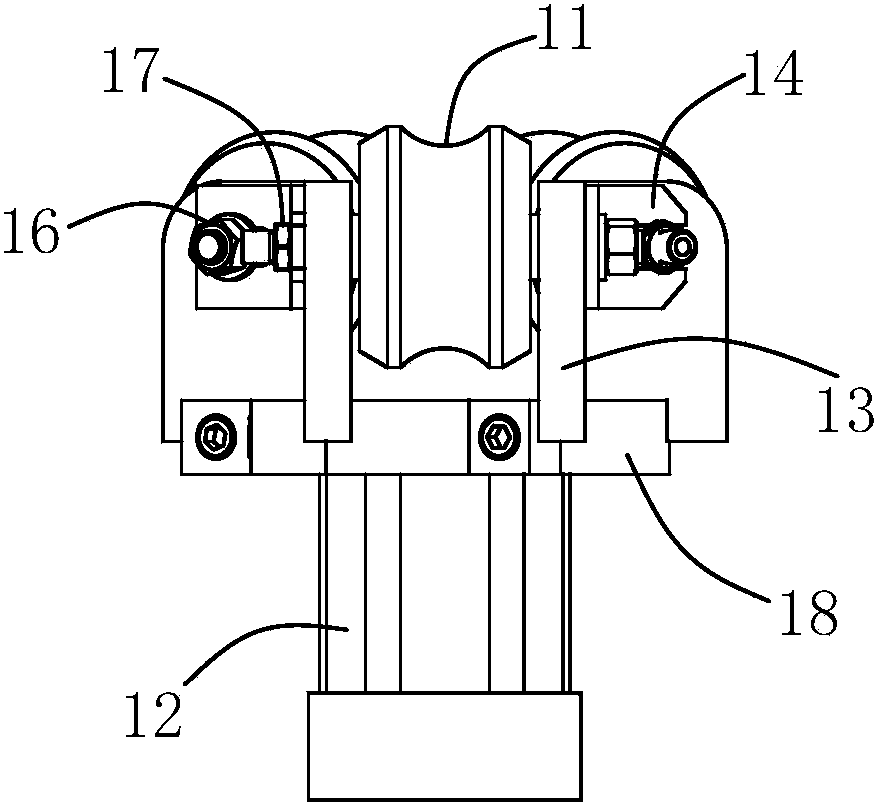

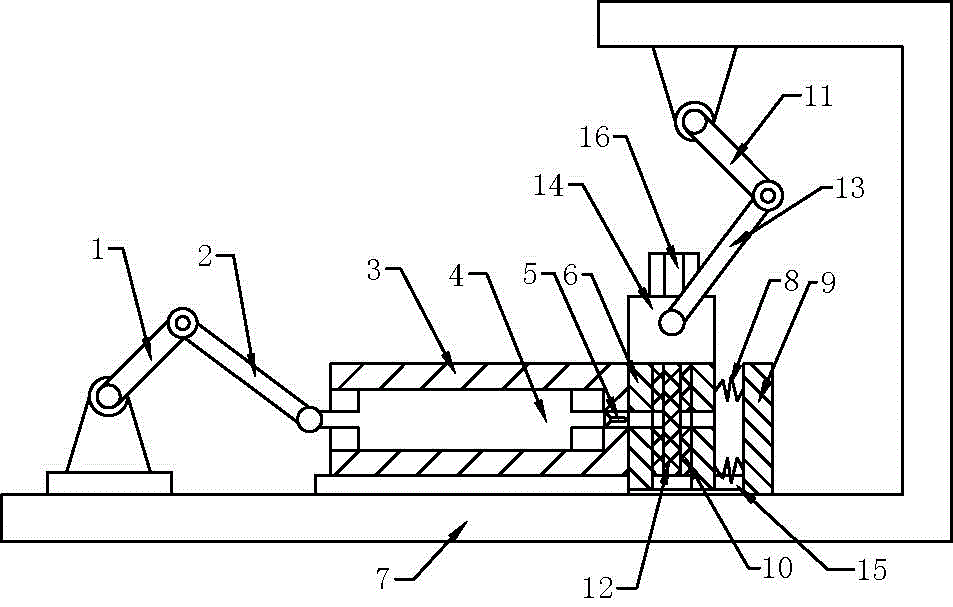

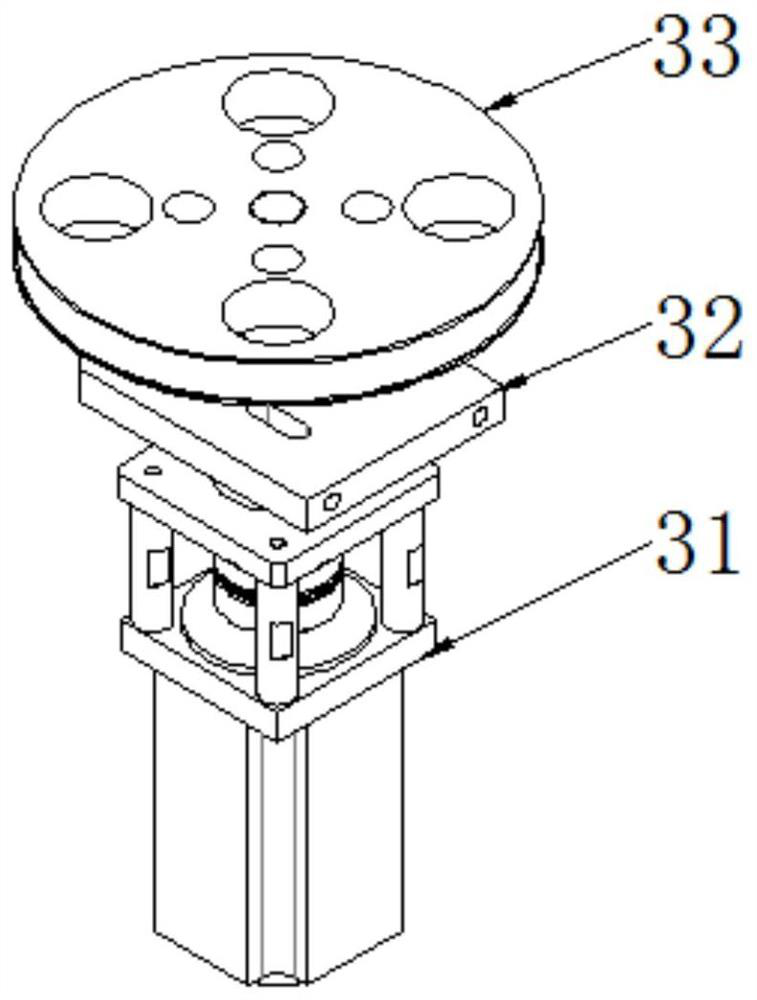

Buffering and dividing device on transition platform of steel pipe production line

The invention discloses a buffering and dividing device on a transition platform of a steel pipe production line. The buffering and dividing device solves the problem that when existing rolled steel pipes pass inclined grates to be buffered and divided into single steel pipes so as to enter a next process, the steel pipes can be easily scratched. The buffering and dividing device comprises inclined grates, a first dividing device base (2) and a second dividing device base (5), the inclined grates are arranged on the transition platform in a mutual parallel manner, a dividing shaft (8) is arranged between the two dividing device bases, two dividing discs are fixed on the dividing shaft (8), a ratchet (11) is penetratingly connected and fixed on a right end shaft of the dividing shaft (8), the end of the right end shaft of the dividing shaft (8) is fixedly connected with one end of a swing arm (12), a shaft end lug on an output shaft of a swing arm drive cylinder (13) is hinged with the other end of the swing arm (12), a pawl pin shaft (15) is arranged on the swing arm (12), and a buffering poking groove (17) is arranged on each dividing disc. By the buffering and dividing device, the steel pipes are divided one by one, and accordingly probability of scratching of the steel pipes is decreased greatly.

Owner:TAIYUAN TONGZE HEAVY IND

Material guide device

ActiveCN103736749AReduce wearPrevent jumpingGuiding/positioning/aligning arrangementsEngineeringMechanical engineering

The invention discloses a material guide device. The material guide device is composed of a plurality of material guide unit sections arranged along an arc trajectory at intervals. The adjacent material guide unit sections are correspondingly arranged end to end. Each material guide unit section is formed by three guide rollers in an enclosing mode, the axes of the three guide rollers are roughly located in the same plane, and every two of the axes of the three guide rollers form an included angle of 60 degrees. A material guide pipe is arranged at the feeding end of each material guide unit section, and material guide areas formed by pipe cavities of the material guide pipes and the three guide rollers in an enclosing mode are arranged in sequence. With the material guide device, a bandaging piece can be conveyed in a guided mode and processed in a pre-deforming mode, and the bandaging piece can be conveyed stably with little jitter.

Owner:HEFEI BAISHENG SCI & TECH

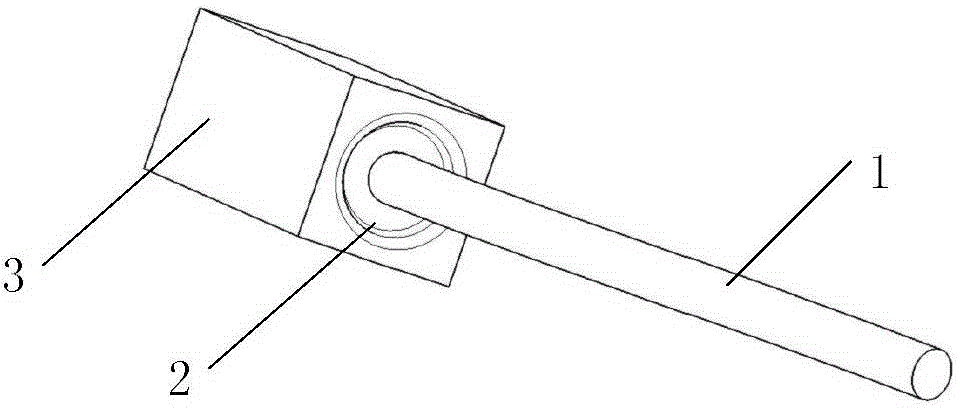

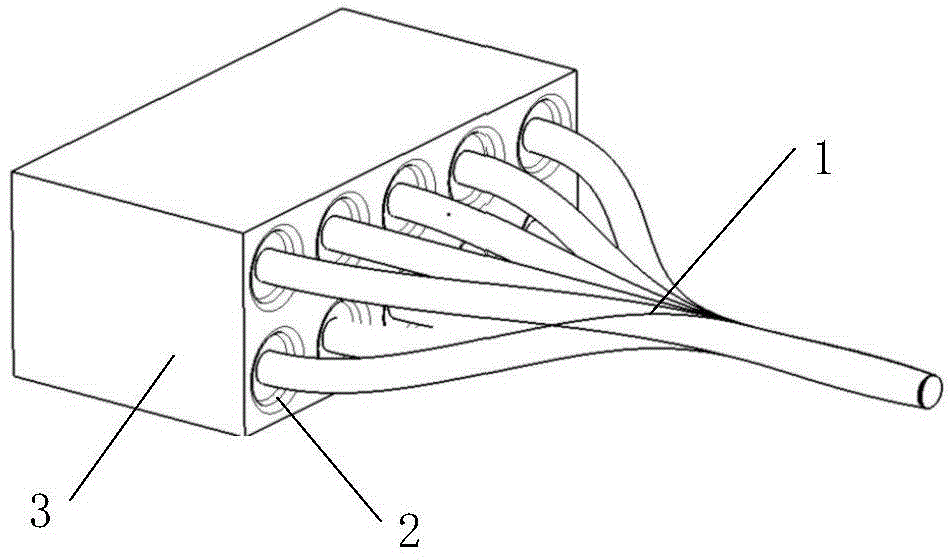

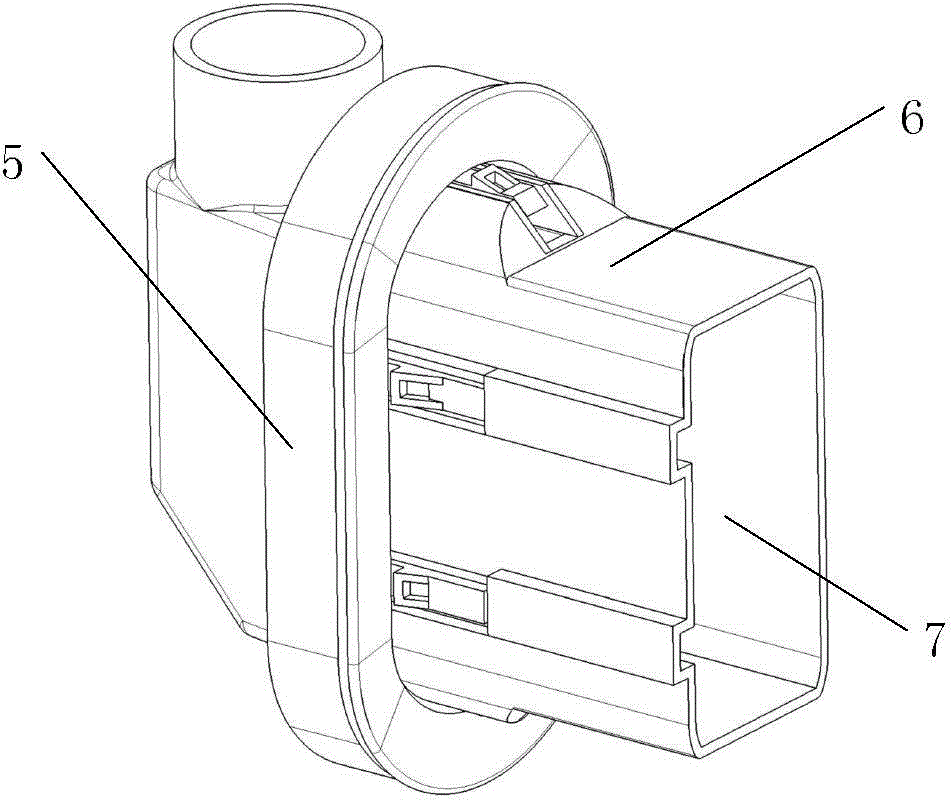

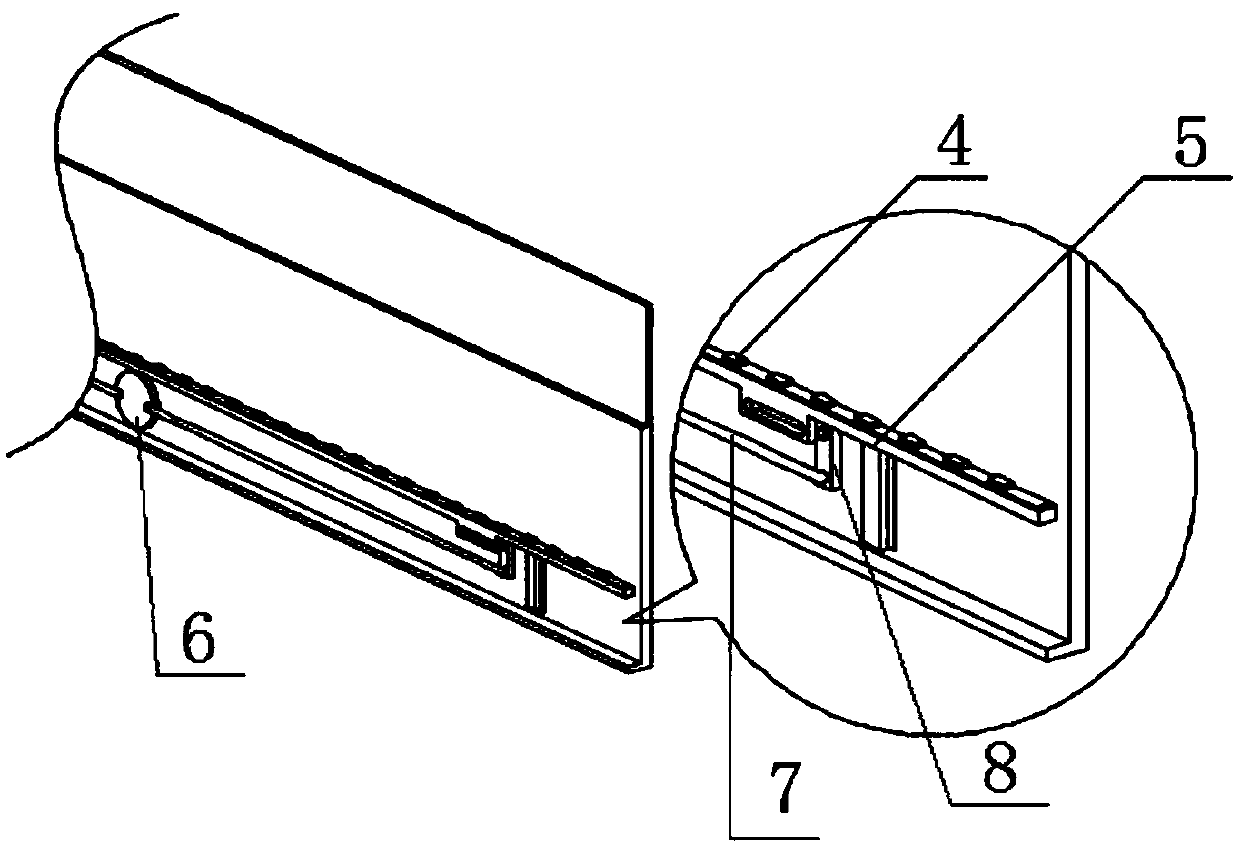

Connector assembly

InactiveCN104393551AReduce the probability of scratchesElectrical apparatusCable harnessElectrical and Electronics engineering

The invention discloses a connector assembly. The connector assembly comprises a connector assembly main body and further comprises a rubber protective sleeve, wherein one end of the connector assembly sleeves one end of the rubber protective sleeve; a wiring harness channel is formed inside the rubber protective sleeve and the connector assembly main body; a boss is formed in the connector assembly main body; a groove is formed in the rubber protective sleeve; the boss is spliced in the groove; an elastic bulge structure is further arranged on the outer surface of the connector assembly main body; and a blocking space is formed between the elastic bulge structure and the rubber protective sleeve. When the connector assembly provided by the invention is used, the large part of the connector assembly main body is positioned at one side of a shielding structure, the rubber protective sleeve is positioned at the other side of the shielding structure, and the connector assembly is blocked on the shielding structure by virtue of the blocking space between the connector assembly main body and the rubber protective sleeve, so that wiring harnesses are protected by the rubber protective sleeve after passing through the wiring harness channel inside the connector assembly, and therefore, the probability that the wiring harnesses are scratched is lowered.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

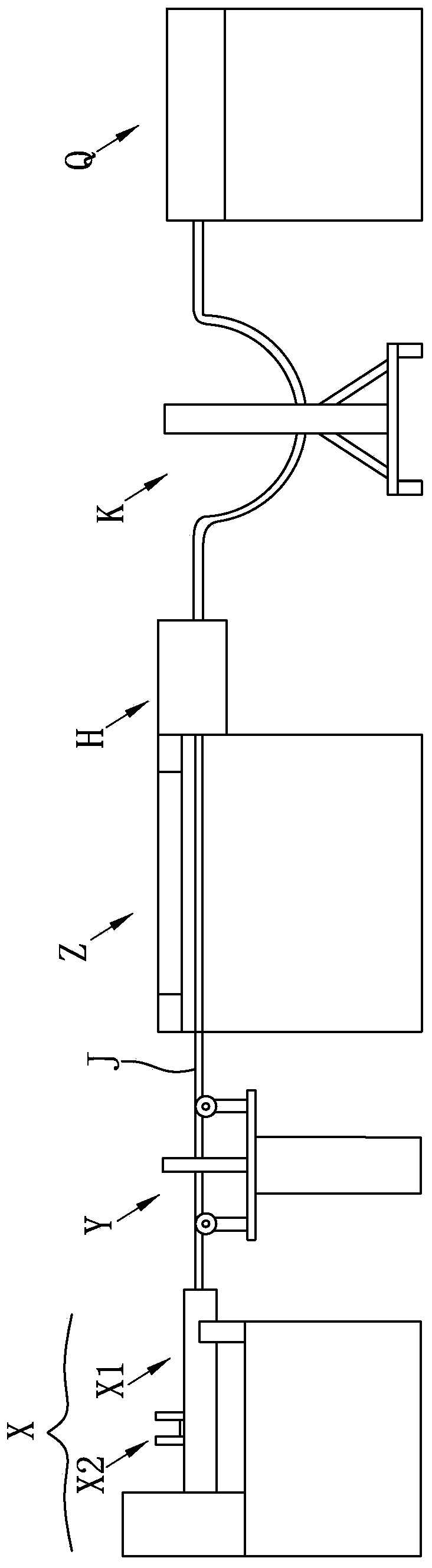

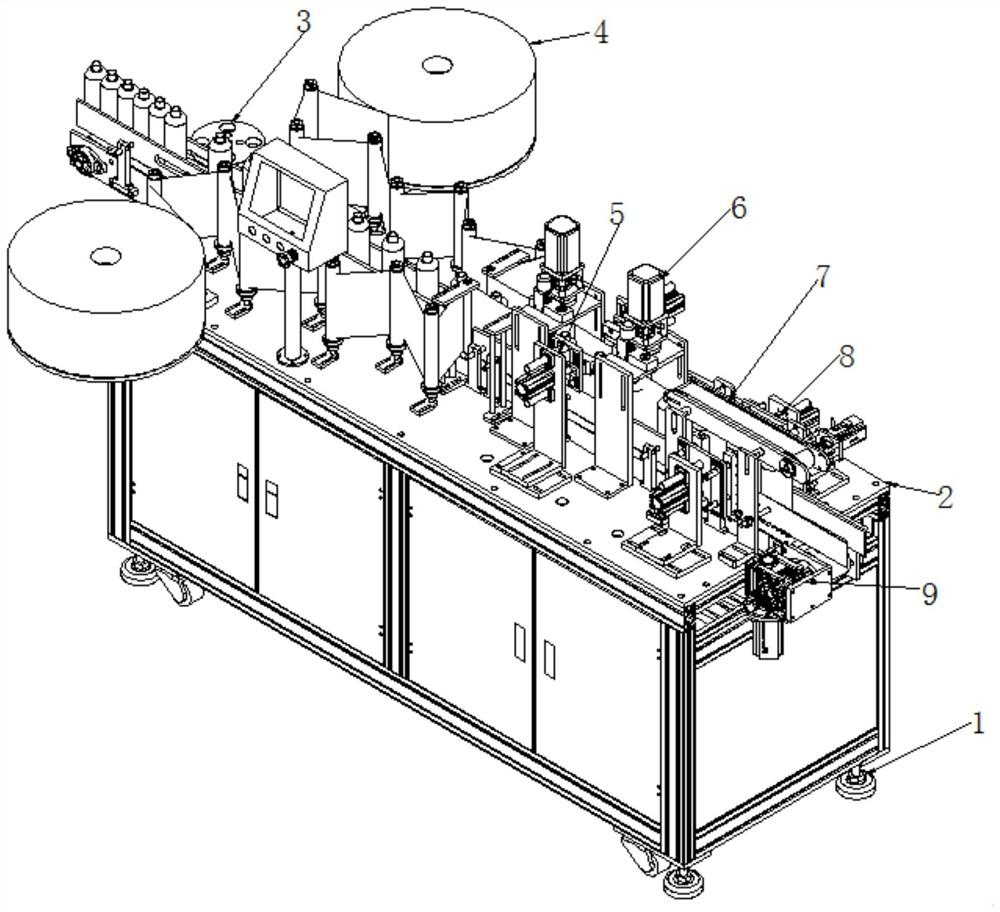

Washing machine rubber tube production line

PendingCN111037878AFast feedingReduce the probability of scratchesTubular articlesChemistryComposite material

The invention relates to a washing machine rubber tube production line which comprises a rubber tube plastic extruding machine, a rubber tube cooling unit, a rubber tube surface anti-sticking treatment unit and a rubber tube online cutting unit. Adhesive tape materials are ensured to be rapidly fed into a washing machine rubber tube production line and the scratching probability of the adhesive tape materials and the material frame is reduced under the guiding of the guide roller, and then whether the adhesive tape materials are in a continuous conveying mode or not is judged by monitoring themovement state of the wheel disc; and water sprayed upwards and splashed downwards scours the surface of the rubber tube in an omnibearing manner so that comprehensive cooling of the rubber tube is realized and the quality of the rubber tube can be ensured; meanwhile, powder brought out by the rubber tube is moved out through the leakage receiving box to be collected, redundant anti-sticking powder on the surface of the rubber tube is brushed and swept to fall into the leakage receiving box through bristles of the annular bristle piece, waste of the anti-sticking powder is reduced, dust diffusion is also reduced and the probability of environmental pollution caused in anti-sticking treatment of the surface of the rubber tube is further reduced.

Owner:SUZHOU HUADONG RUBBER

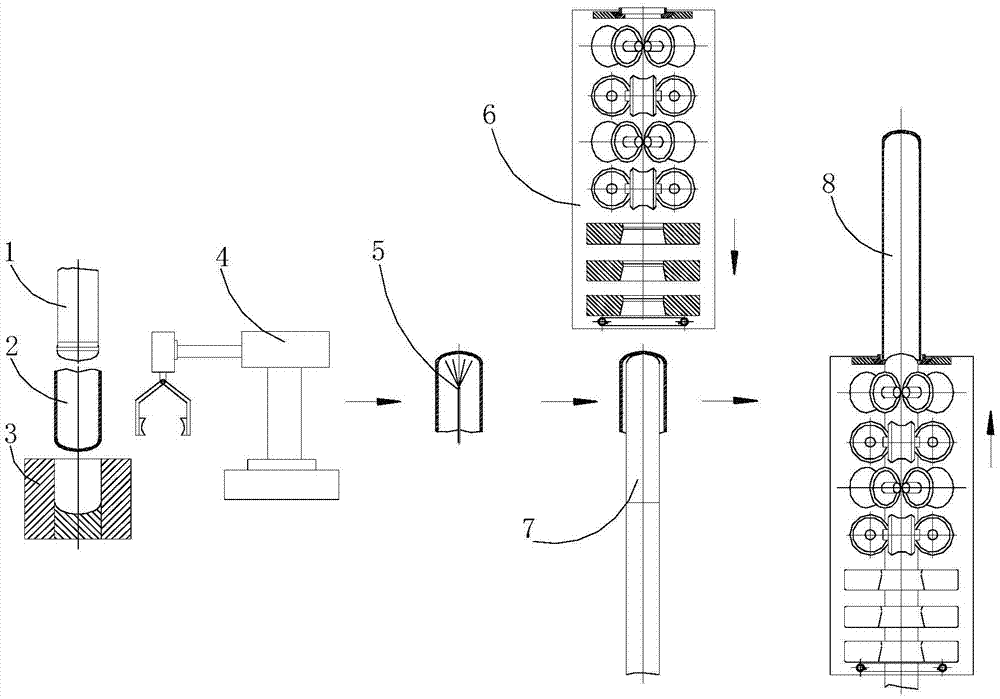

Vertical hot drawing technology for seamless cylinder

InactiveCN106975709ASmall wall thickness deviationReduce eccentricityHollow articlesGas cylinderEngineering

The invention relates to a vertical hot drawing technology for a seamless cylinder. The vertical hot drawing technology for the seamless cylinder is a process that a drawing mold and a vertical drawing press are adopted for draw forming of a cylinder blank after vertical hot piercing. The vertical hot drawing technology has the following technological steps of heating a blank after vertical blanking of a blind hole, placing the hot cylinder blank reversely for blowing impurities, placing the hot cylinder blank in place for preparation for drawing, hot drawing, returning and discharging. The vertical hot drawing technology for the seamless cylinder can reduce the deviation of the wall thickness of a seamless cylinder body, improve the quality of the seamless cylinder, prolong the service life of a mold, and reduce cost.

Owner:NANJING BANQIAO FIRE FIGHTING EQUIP

Perforating machine for plastic

InactiveCN105459204AImprove stabilityReduce the probability of driftMetal working apparatusEngineeringMechanical engineering

The invention relates to a perforating machine for plastic. The perforating machine comprises a perforating rod, a sliding groove and two clamping plates. The perforating rod is connected into the sliding groove in a sliding mode, a first connecting rod is hinged to the left end of the perforating rod, and a first crank is hinged to the first connecting rod. A first slide rail is arranged at the right side of the perforating rod, the two clamping plates are sequentially connected to the first slide rail in a sliding mode from left to right, a fixing block is arranged at the right end of the first slide rail, and springs are connected between the clamping plate located on the side away from the sliding groove and the fixing block. The two clamping plates abut against each other, and an opening for the perforating rod to pass through is formed in the clamping plate located on the side close to the sliding groove. A second slide rail is arranged above the two clamping plates and connected with a pressing block in a sliding mode, a second connecting rod is hinged to the pressing block, and a second crank is hinged to the second connecting rod. Compared with the prior art, the pressing block and the two clamping plates are matched to enable a wood board to be fixed more stably, and therefore the stability of the wood board is enhanced, and the probability that the pointed end of the perforating rod makes scratches on the surface of the wood board is lowered.

Owner:CHONGQING RUITING PLASTIC

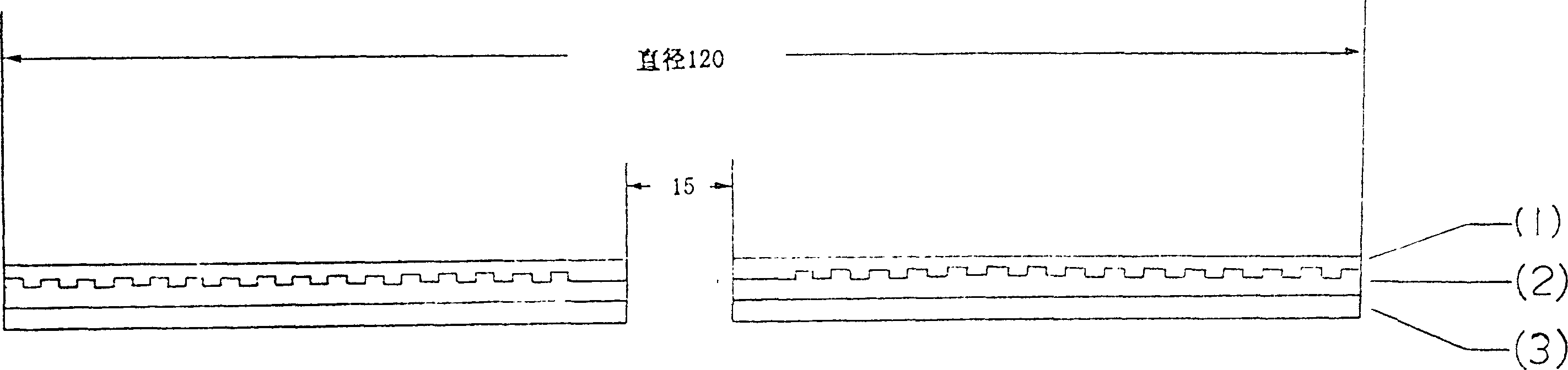

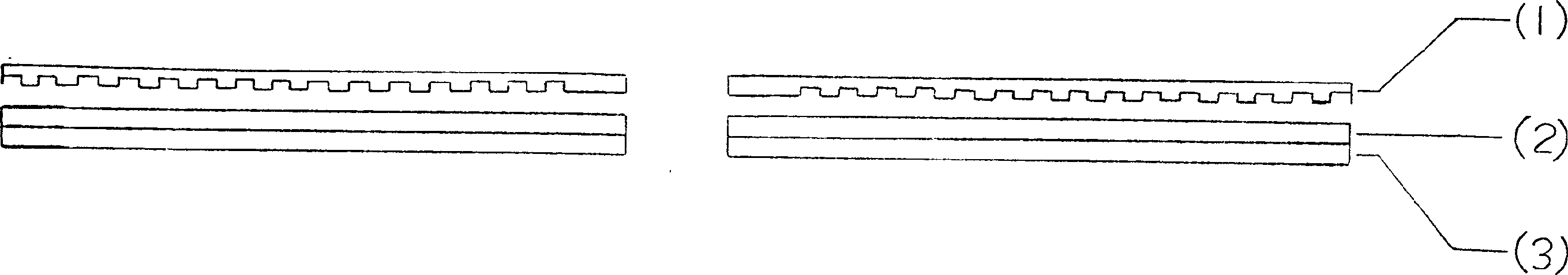

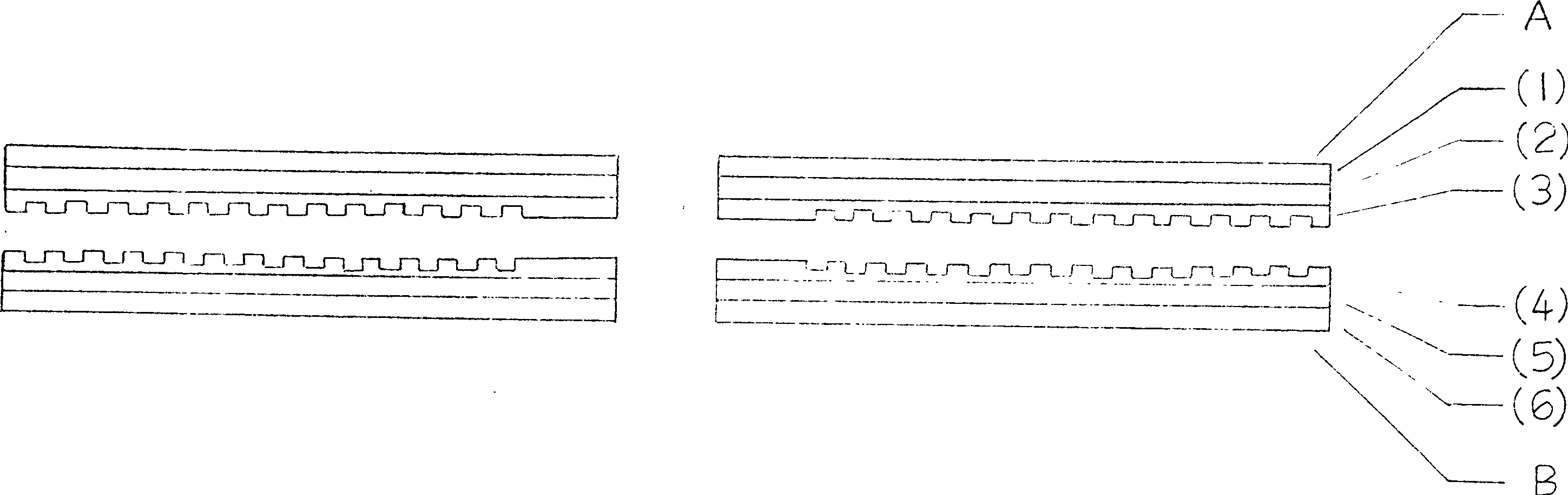

Glass thin layer optic disk structure and process

InactiveCN1783266AIncrease stiffnessNot prone to vibrationRecord information storageOptical recording/reproducingWear resistantThin layer

Owner:崔龙华

Preparation method of sapphire substrate polishing solution

ActiveCN104109481AAvoid enteringEnsure the safety of the production environmentPolishing compositions with abrasivesFiltrationPhysical chemistry

The invention provides a preparation method of a sapphire substrate polishing solution, which comprises the following steps: employing a membrane filtration device to remove metal ions and other impurities in a silica sol raw material; passing the filtered silica sol with concentration of 48-50% under a vacuum negative pressure state through a 100 nano-level folding filter core and then adding in an enclosed reaction pot; adding a stabilizing agent under the vacuum negative pressure state in the enclosed reaction pot; adding a synergist with pH value of 8.0-8.5 under the vacuum negative pressure state in the enclosed reaction pot; fully stirring the liquid in the enclosed reaction pot under a negative pressure tumbling state for 60 minutes, and uniformly mixing and then loading. The preparation method has the following beneficial effects that the alkalescence sapphire substrate polishing solution has no corrosion effect to the polishing device, after the usage of the polishing solution is finished, and then the polishing solution is processed, the processed polishing solution can be used as a building paint additive, so that the problems of easy coagulation and difficult recovery of a traditional acidic polishing solution can be solved.

Owner:HEBEI YUTIAN HAOYUAN NANO MATERIAL

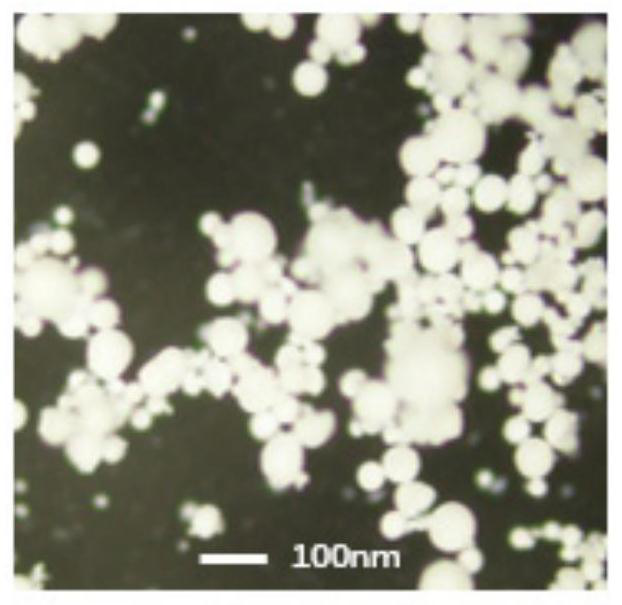

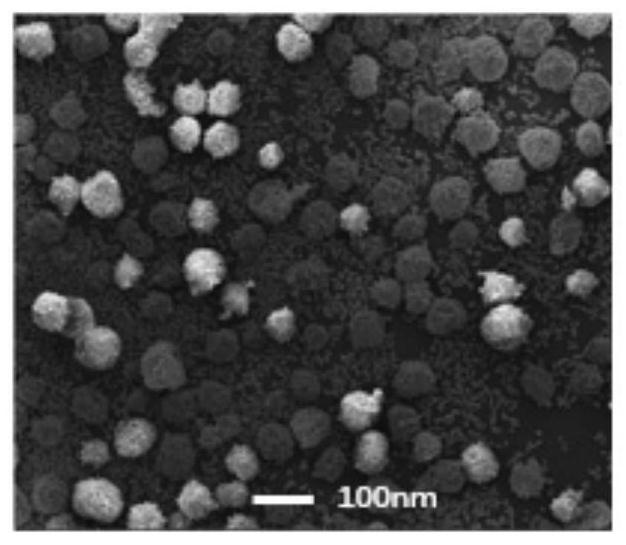

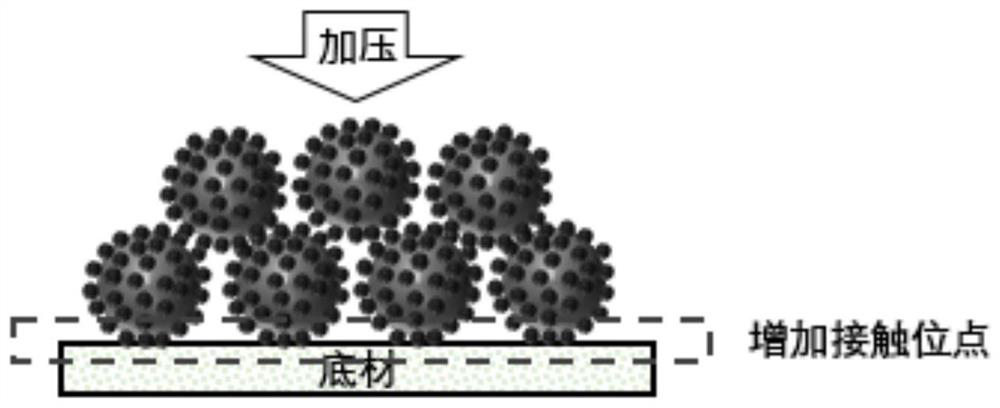

Self-assembled nano silicon dioxide abrasive material, polishing solution containing abrasive material and application thereof

ActiveCN113652200AImprove surface topographyGood for tribochemical reactionsMaterial nanotechnologyOther chemical processesPtru catalystChemical reaction

The invention discloses a preparation method of self-assembled nano silicon dioxide. The preparation method comprises synthesizing a silicon dioxide seed solution and growing of a silicon dioxide seed, and specifically comprises the steps of: mixing a PEO-PPO-PEO triblock copolymer, a solution containing spherical silicon dioxide and a solution containing a catalyst; adding a solution containing a silicon precursor at 40-60 DEG C to obtain a solution A; and stirring and reacting for 20-30 hours to obtain a silicon dioxide seed solution, heating to boil, dropwise adding a silicic acid solution, and reacting for 1-3 hours. The surface appearance of the self-assembled nano silicon dioxide is improved, so that the particles and a wafer form multi-point contact, and the removal rate can be increased through a friction chemical reaction. The multi-point contact can effectively disperse the load, so that the scratch becomes shallow, and the scratch probability can be reduced. The polishing solution is used for ultra-precise polishing of hard and brittle materials. Through the synergistic effect of a dispersing agent and a metal ion capturing agent which are compounded, the adsorption and dispersion effects of abrasive dust ions or particles are well balanced, and cleaning is easy after polishing.

Owner:ZHEJIANG AUFIRST MATERIAL TECH CO LTD

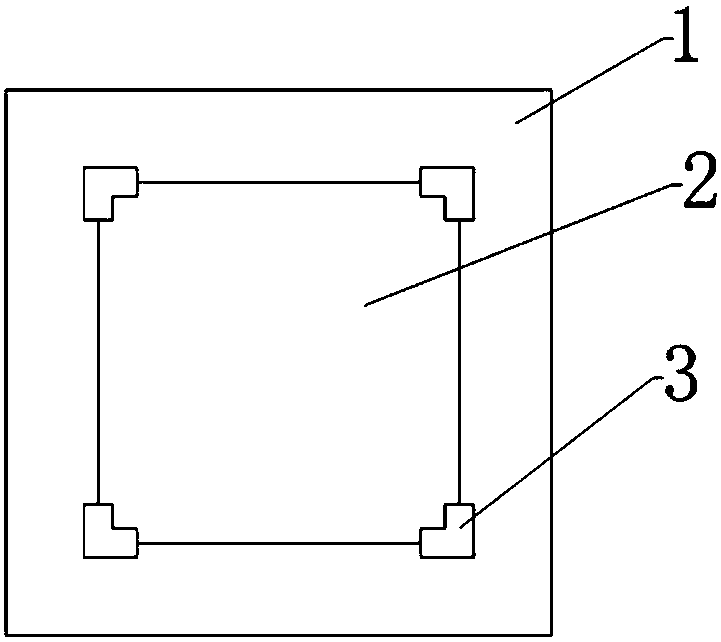

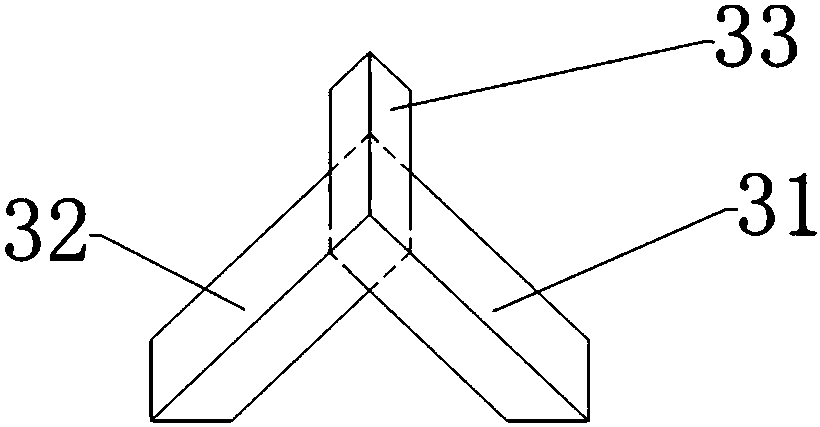

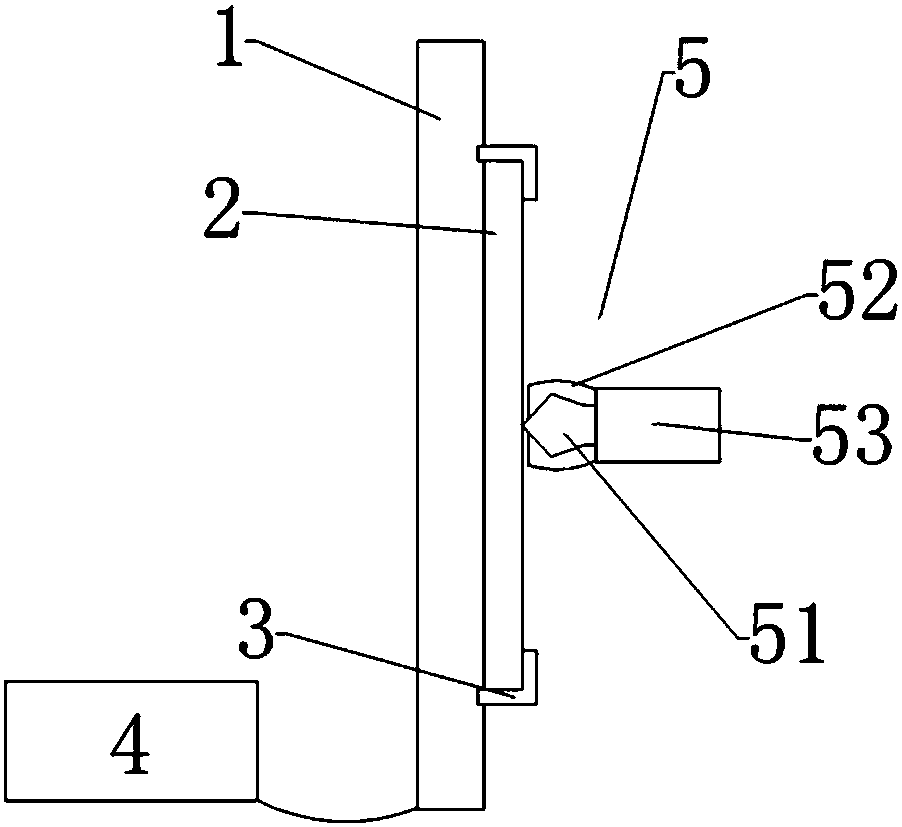

Vertical cutting equipment for glass

InactiveCN109956660APlay a supporting roleReduce the probability of scratchesGlass severing apparatusEngineeringScratching

The invention provides vertical cutting equipment for glass. The equipment comprises a vacuum platform, alignment fixtures and a cutting device; the vacuum platform is perpendicular to a horizontal plane and connected with a vacuuming device, and the interior of the surface of the vacuum platform is provided with a plurality of sets of right-angle grooves; each alignment fixture includes three mutually-perpendicular right-angle arms including a first right-angle arm, a second right-angle arm and a third right-angle arm, and the alignment fixtures fix a glass substrate on the vacuum platform; and the cutting device comprises a cutting head, a protective cover and a rotating body, the top of the rotating body is connected with a support, the bottom of the rotating body is provided with the protective cover with a groove, the cutting head is arranged in the protective cover groove, the cutting head is fixedly connected with the rotating body, and the cutting head is located on the same side of the right-angle grooves and perpendicular to the vacuum platform. According to the vertical cutting equipment for the glass created by the invention, a cutting surface faces an observer, so thatthe observer can take measures when abnormality occurs; and due to the action of gravity and inertia, debris is far away from the glass, so that the probability of surface scratching is low.

Owner:XINCHANG XIANGYUN MACHINERY

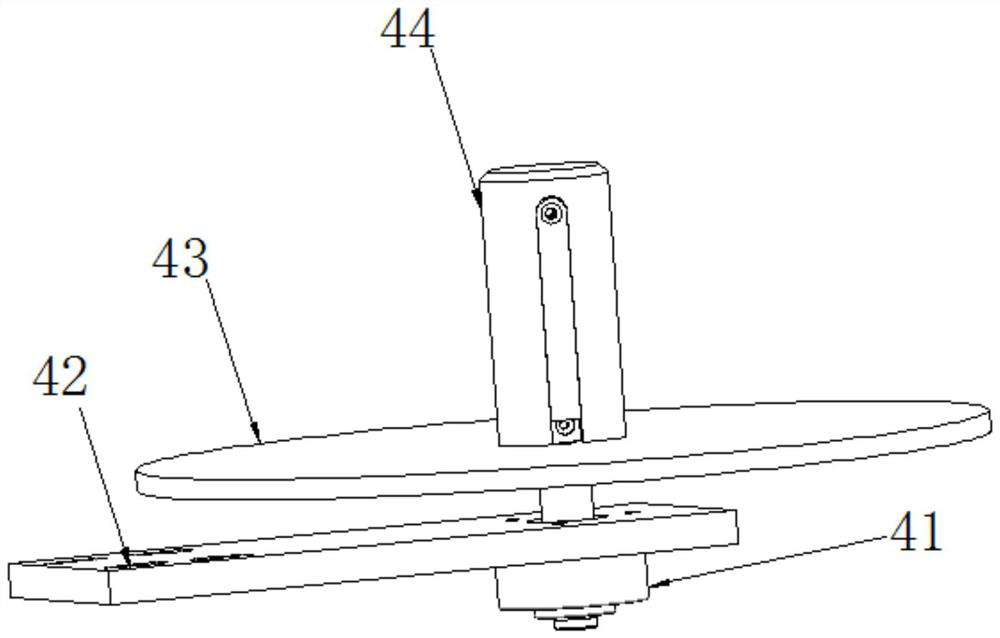

Tricycle part machining device

PendingCN108620969AAchieve fixationAvoid low grinding accuracyGrinding drivesGrinding feedersGear wheelEngineering

The invention belongs to the technical field of machine tools, devices or processes for grinding or polishing, and discloses a tricycle part machining device. The tricycle part machining device comprises a frame and a polishing head; and a movable rod is fixed on the polishing head. The tricycle part machining device further comprises a mounting part, clamping parts and a driving part; the mounting part comprises a mounting frame; a mounting plate is slidingly connected into the mounting frame; two clamping parts are provided; the clamping parts comprise clamping rods, rotating wheels and fixed blocks; upper pull ropes fixed on the movable rod by free ends are wound on the rotating wheels; the ends, positioned in the mounting frame, of the clamping rods are rotationally connected with polishing wheels; the driving part comprises a rotating shaft penetrating through the polishing head and rotationally connected with the polishing head; the frame is provided with a driving piece for driving the rotating shaft to rotate; and a tensioning sleeve is arranged at the bottom end of the rotating shaft. The tricycle part machining device solves the problem of time and power waste caused by polishing of the other end surfaces of gears through manual disassembly, overturning and fixation of the gears after polishing of one end surfaces during polishing of two end surfaces of the gears in the prior art.

Owner:重庆中铃兆虎机车制造有限公司

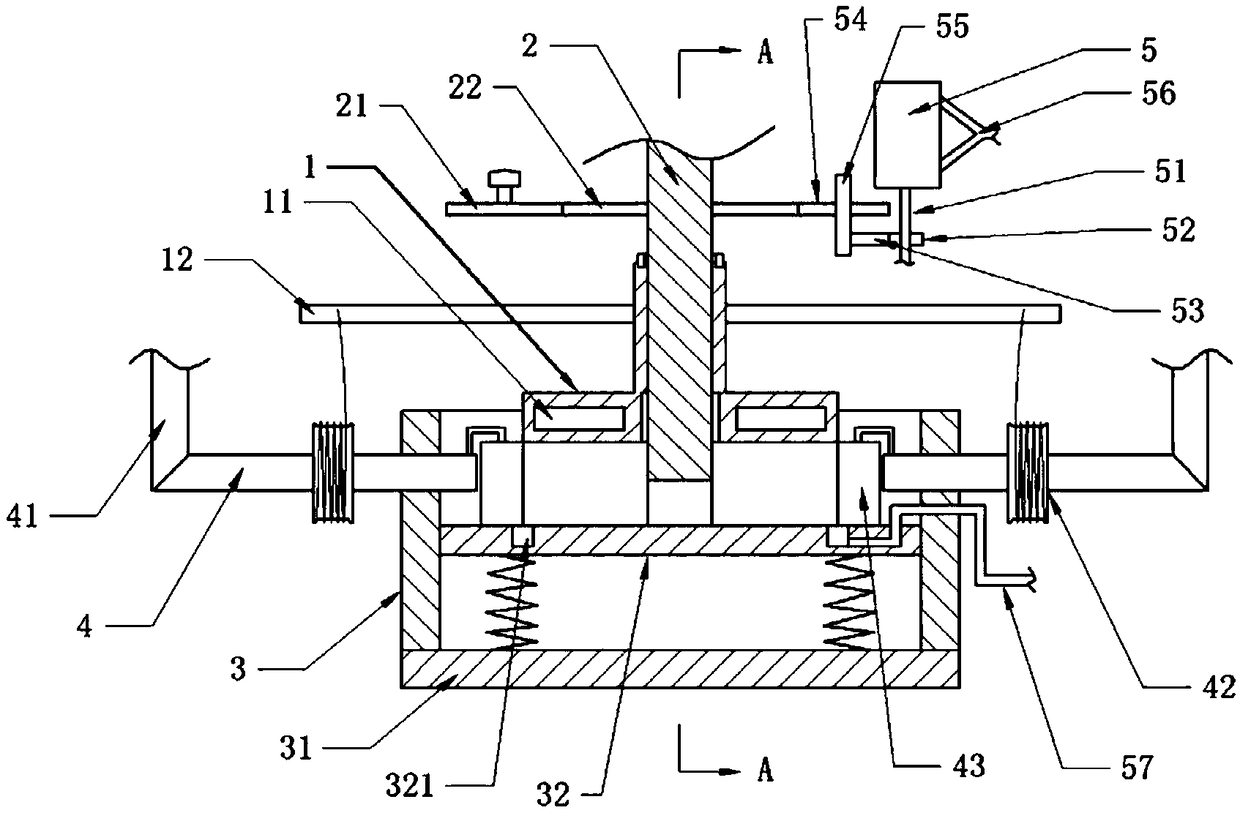

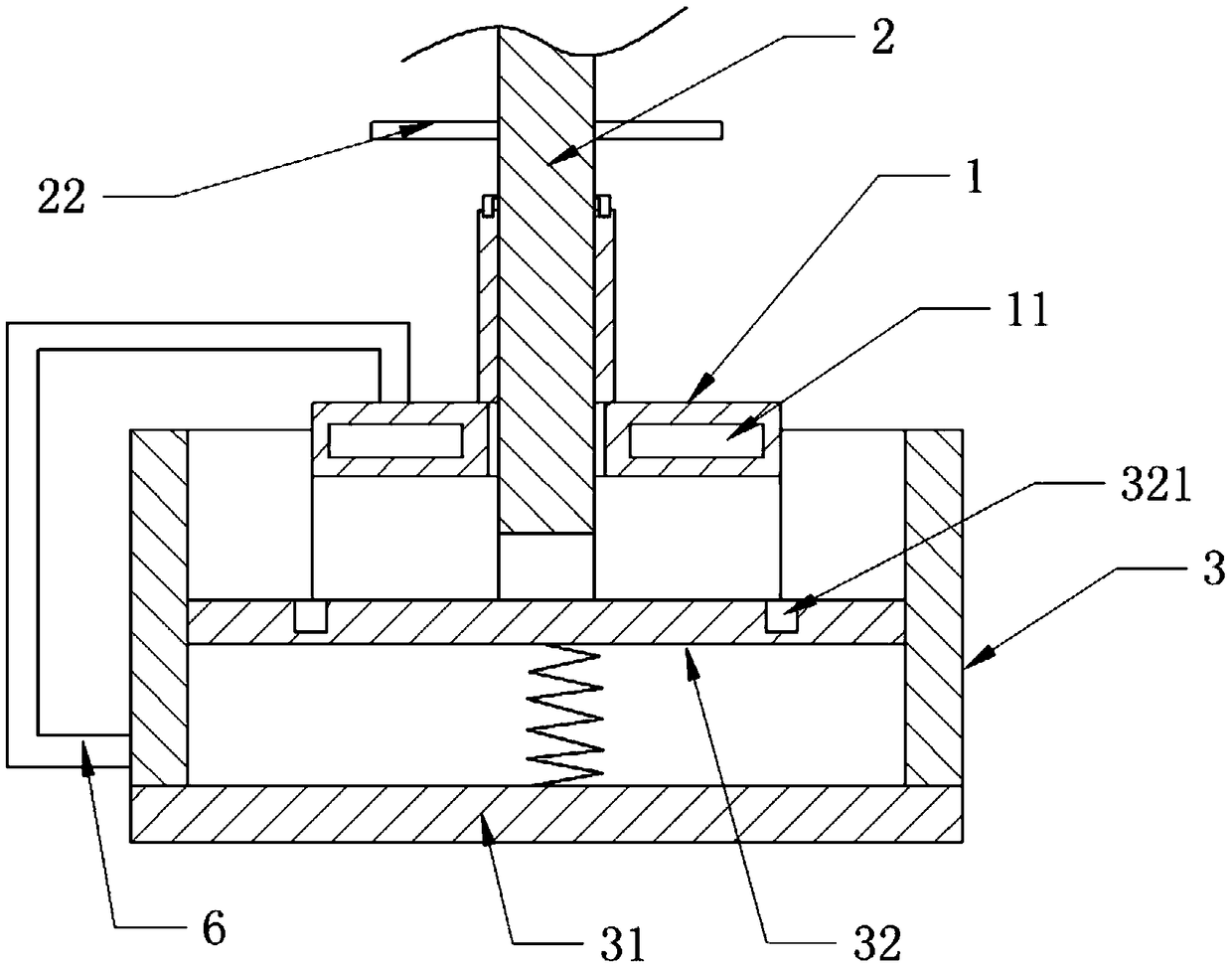

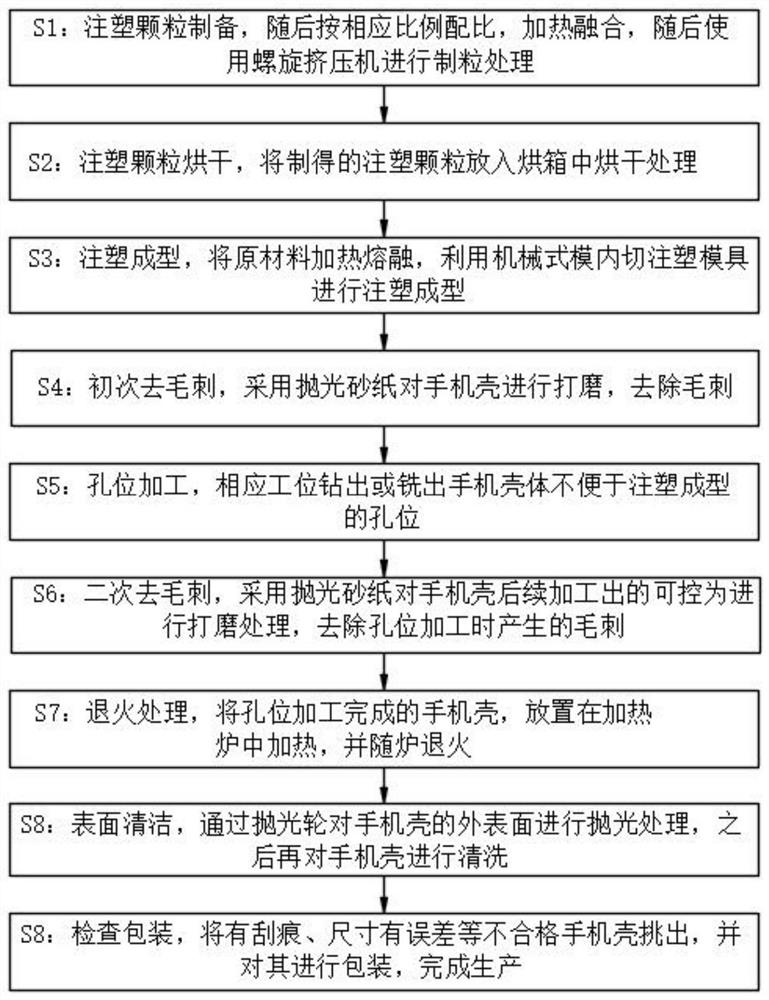

Mobile phone shell spraying-free injection molding method adopting mechanical mold inner cutting

InactiveCN111805831AStrong metal textureHigh hardnessTelephone set constructionsGlass fiberAl powder

The invention discloses mobile phone shell spraying-free injection molding method adopting mechanical mold inner cutting. The method is characterized in that a raw material is formed by preparing following elements comprising, by weight percentage, 1.3%-2.5% of aluminum powder, 0.04% of carbon black, 0.15% of anti-oxygen, 0.15% of dispersing agent, 0.8% of high-light toner, 4%-10% of hardness modifying agent and the balance ABS plastic raw material, the total weight percentage of all the components is 100%, preparing is carried out according to the corresponding proportion, all the materials are heated and fused, a spiral extruding machine is used for carrying out pelleting treatment on the fused materials, and thus injection molding particles are formed for standby use. According to the method, by means of reasonable matching and mixing of the aluminum powder, the carbon black and glass fiber, produced mobile phone shells have good metal texture and good color and luster uniformity, the phenomena of reducing sink marks, flow marks and weld lines can be effectively avoided, and by using the glass fiber reasonably, the produced mobile phone shells have high hardness.

Owner:深圳市博耀科技集团有限公司

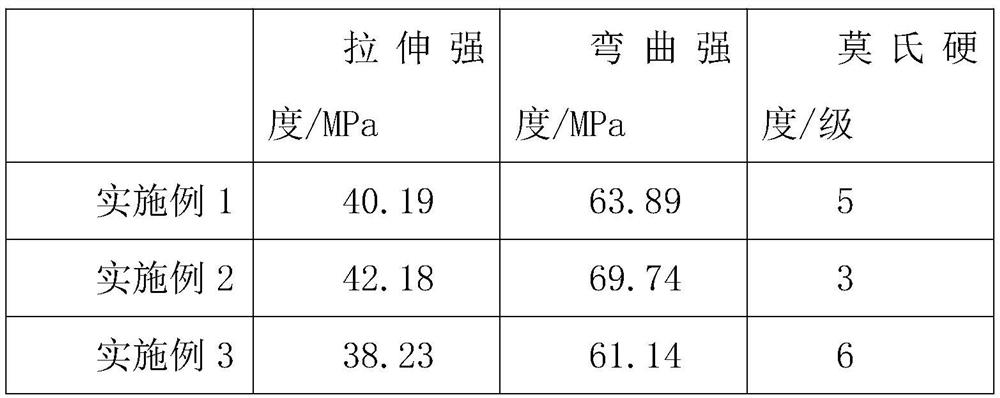

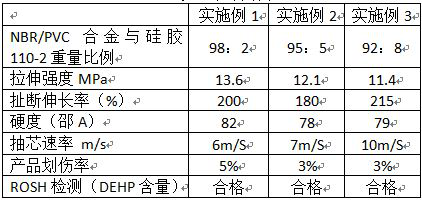

Environment-friendly self-lubricating rubber tube mandrel rubber material and preparation method thereof

The invention discloses an environment-friendly self-lubricating rubber tube mandrel rubber material which comprises the following raw materials in parts by weight: 100 parts of a composite material of NBR / PVC alloy and silica gel 110-2, 15-35 parts of a reinforcing agent, 35-70 parts of semi-reinforced carbon black, 1-3 parts of a coupling agent, 5-15 parts of an environment-friendly plasticizer, 2-3 parts of an antioxidant, 2-3 parts of a processing aid, 5-15 parts of a heat-resistant aid, 0.5-2.5 parts of a vulcanizing agent and 2-5 parts of a crosslinking aid, wherein the composite material of the NBR / PVC alloy and the silica gel 110-2 is a mixture of the NBR / PVC alloy and the silica gel 110-2. Meanwhile, the invention also provides a preparation method of the rubber material. A rubber tube prepared from the mandrel rubber material disclosed by the invention conforms to domestic environment-friendly upgrading and European Union ROSH standards, and the DEHP content is low; in the rubber tube production, the core pulling operation efficiency is high, and the scratch rate of an inner layer of the rubber tube is low.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

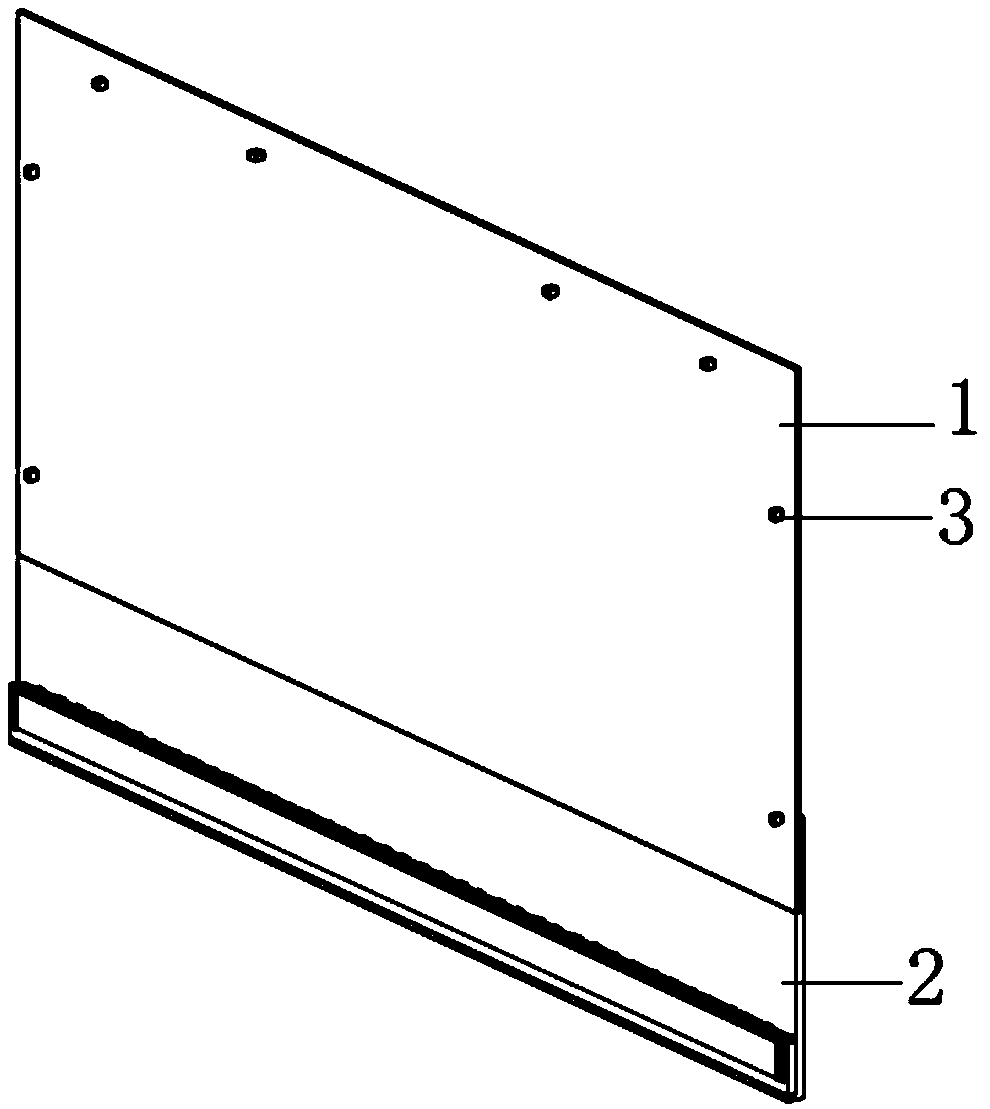

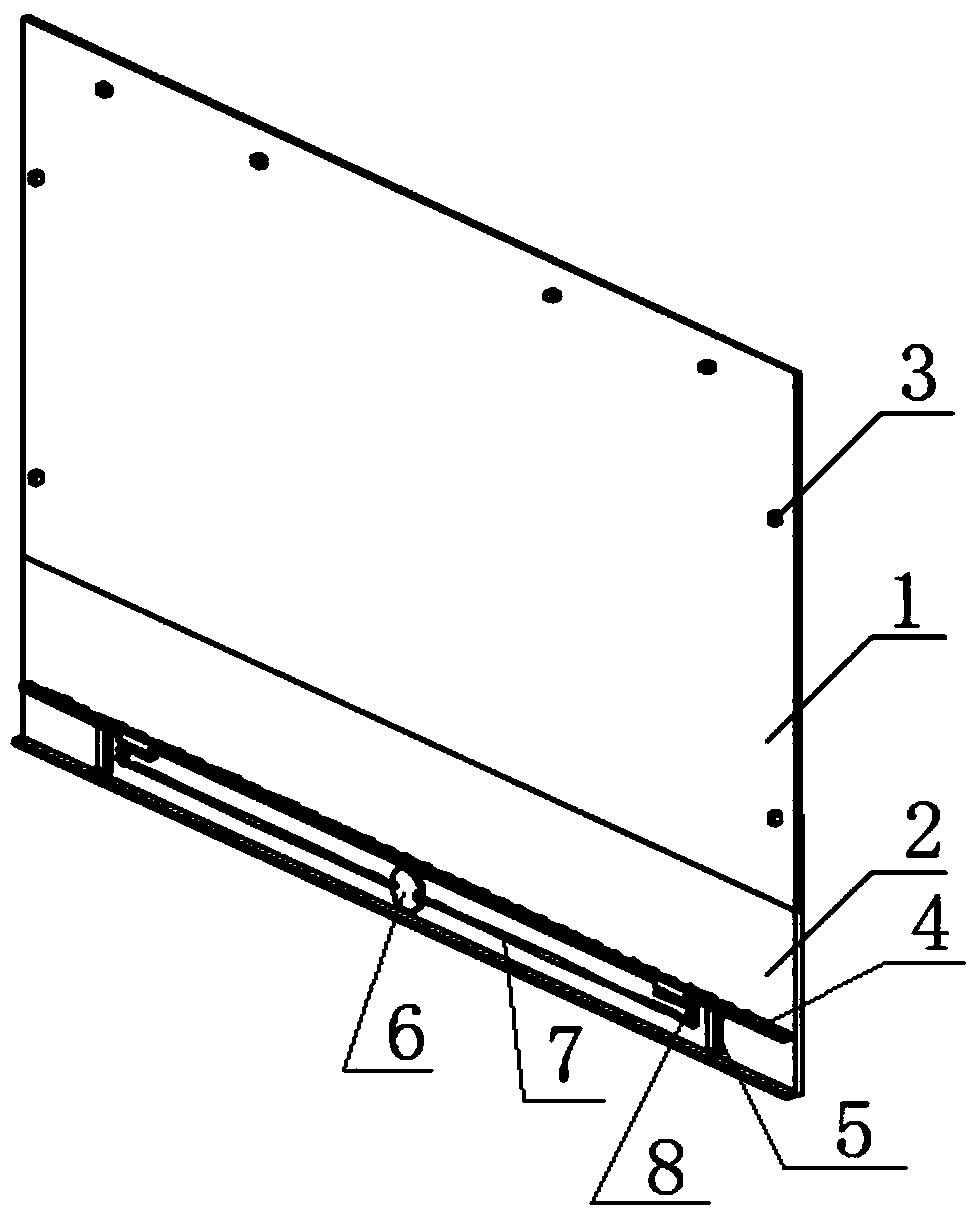

Side-entering type backlight module and liquid crystal display device and backlight plate optical inspection method

InactiveCN109683395AReduce lossesLow costTesting optical propertiesNon-linear opticsLiquid-crystal displayEngineering

The invention discloses a side-entering backlight module and a liquid crystal display device and a backlight plate optical inspection method. The backlight module comprises a backlight plate main body, wherein the backlight plate main body comprises a first substrate used for bearing a light guide plate to be inspected and a second substrate detachably connected with the first substrate, the second substrate is provided with a light source moving module, and the light source moving module is provided with a light source. According to the invention, the light source moving module is adopted todrive the light source to move in the direction perpendicular to the light source moving module, so that the distance between the light source and the light guide plate is adjusted, the phenomenon that the optical index is not qualified due to the distance problem between the incident side of the light guide plate and the light source is avoided, namely, the misjudgment probability of whether thelight guide plate is qualified or not is reduced, in the process, the light guide plate does not need to be touched and moved, the pollution and scratch of the light guide plate cannot be caused, theloss is reduced, the cost is saved, and the backlight plate main body is not an integral structure, so that the transportation is convenient.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Low sodium polishing solution and preparation method and application thereof

InactiveCN109575818AReduces the chance of contaminating the wafer surfaceReduce crystallizationSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesAluminium hydroxideSilicon dioxide

The invention discloses low sodium polishing solution. The low sodium polishing solution comprises the following raw materials in parts by weight: 20-40 parts of silicon dioxide, 1-5 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 1-6 parts of calcium lactate, 1-10 parts of aluminum hydroxide, 0.5-2.5 parts of diethanol amine, 0.5-2.5 parts of hydroxyquinoline, 10-20 parts of hydroxypropyl methyl cellulose, and 40-60 parts of deionized water. A preparation method for the low sodium polishing solution comprises the following steps: selecting a suitable amount of the fatty alcohol polyoxyethylene ether sodium sulfate, the diethanol amine, the aluminum hydroxide, the hydroxyquinoline and the deionized water according to a weight matching ratio, placing the raw materials in a stirring kettle, and stirring for 5-15 min in a condition of 60-80 DEG C, wherein a stirring speed of the stirring kettle is 100-300 r / min; putting the silicon dioxide, the calcium lactate and the hydroxypropyl methyl cellulose into the stirring kettle, stirring in a warming condition, wherein the stirring speed of the stirring kettle is 600-1200 r / min; and 3) adding a pH value regulator, after filtering, to obtain the polishing solution. The low sodium polishing solution is capable of improving washing efficiency of a wafer, reducing scratching probability, and effectively reducing later period waste liquid treatment cost of the polishing solution, thereby improving the cmp polishing effect.

Owner:天津洙诺科技有限公司

Intelligent water quality sampling device and method in complex lake reservoir water environment

InactiveCN110095307AAvoid unrecyclableGuaranteed power supplyWithdrawing sample devicesTesting waterWind drivenWater quality

The invention discloses an intelligent water quality sampling device and method in a complex lake reservoir water environment. The device comprises a conical vertical cylinder supported and installedon a floating pad by an outer ring plate. An inner ring plate is fixed in the conical vertical cylinder; a mounting frame is fixed on the inner ring plate; and a wind driving device for providing power is installed at the top center of the mounting frame. A sampling device for sampling of a water body is arranged at the bottom center of the conical vertical cylinder. A plurality of detecting armsare fixed on the mounting frame; electrically controlled hydraulic telescopic rods are installed at the end portions of the detection arms and pass through the floating pad; and water quality inspection heads are installed at the ends of the electrically controlled hydraulic telescopic rods. The intelligent water quality sampling device has advantages of remote operation, great convenience in usage, and high motion flexibility; and on the basis of the appearance design of the conical cylinder, the device is not easy to wind by the water plants. The device being integrated with sampling and detection functions has advantages of high applicability and high safety.

Owner:CHINA THREE GORGES UNIV

Vertical empty bottle packaging machine

PendingCN112591187ARun fastRun smoothlyWrapper twisting/gatheringPackaging bottlesElectric machineryMagnetic powder

The invention discloses a vertical empty bottle packaging machine. The vertical empty bottle packaging machine comprises a rack trundle cup, and the top of the rack trundle cup is fixedly connected with a fixed table top. The top of the fixed table top is fixedly connected with a material distributing mechanism, a film releasing mechanism, an upper end edge sealing mechanism, a film drawing and conveying mechanism, an upper end belt pressing and conveying mechanism, a side edge sealing and cutter mechanism and a vacuum air suction belt conveying mechanism, and the material distributing mechanism comprises a material distributing servo motor. The top of the material distributing servo motor is fixedly connected with a material distributing fixing base through a connecting rod, the top end of an output shaft of the material distributing servo motor penetrates through the material distributing fixing base and extends to the top of the material distributing fixing base, and the film releasing mechanism comprises a magnetic powder motor. The invention relates to the technical field of packaging machines. According to the vertical empty bottle packaging machine, the operation automationcapacity of the empty bottle packaging machine is improved, and in addition, empty bottles are conveyed in a vertical mode instead of a horizontal mode, the operation radius of the packaging machine is effectively shortened, the empty bottle scratching probability is reduced, and the overall packaging effect is improved.

Owner:GUANGZHOU SANLI MACHINERY EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com