Low sodium polishing solution and preparation method and application thereof

The technology of polishing liquid and alcohol polyoxyethylene ether sodium sulfate is applied in the field of polishing liquid, which can solve the problems of high waste water treatment cost, high sodium content and acid radicals, easy crystallization of abrasives, etc., so as to improve the surface quality of wafers and reduce carbon dioxide emissions. Silicon crystallization, the effect of solving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

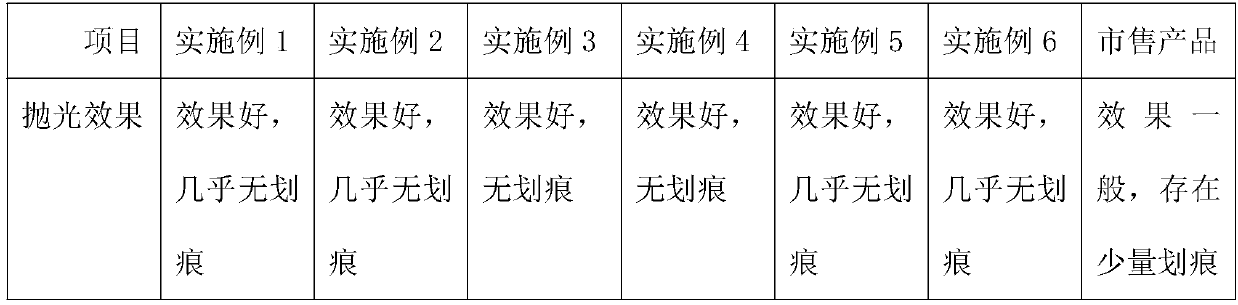

Examples

Embodiment 1

[0018] In the embodiment of the present invention, a low-sodium polishing solution includes the following raw materials in parts by weight: 20 parts of silicon dioxide, 1 part of fatty alcohol polyoxyethylene ether sodium sulfate, 1 part of calcium lactate, 5 parts of aluminum hydroxide, 0.5 parts of diethanolamine parts, 0.5 parts of hydroxyquinoline, 10 parts of hydroxypropyl methylcellulose, and 40 parts of deionized water.

[0019] A kind of preparation method of described low-sodium polishing fluid, comprises the following steps:

[0020] 1) Select an appropriate amount of fatty alcohol polyoxyethylene ether sodium sulfate, diethanolamine, aluminum hydroxide, hydroxyquinoline and deionized water according to the weight ratio, then put the raw materials in a stirring tank and mix them, and stir at 70°C for 10 minutes. The stirring speed of the stirred tank is 200r / min;

[0021] 2) Put silicon dioxide, calcium lactate 1 and hydroxypropyl methylcellulose into the stirring t...

Embodiment 2

[0024] In the embodiment of the present invention, a low-sodium polishing liquid comprises the following raw materials in parts by weight: 25 parts of silicon dioxide, 2 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 2 parts of calcium lactate, 6 parts of aluminum hydroxide, 1 part of diethanolamine 1 part, 1 part of hydroxyquinoline, 13 parts of hydroxypropyl methylcellulose, 45 parts of deionized water.

[0025] A kind of preparation method of described low-sodium polishing fluid, comprises the following steps:

[0026] 1) Select an appropriate amount of fatty alcohol polyoxyethylene ether sodium sulfate, diethanolamine, aluminum hydroxide, hydroxyquinoline and deionized water according to the weight ratio, then put the raw materials in a stirring tank and mix them, and stir at 70°C for 10 minutes. The stirring speed of the stirred tank is 200r / min;

[0027] 2) Put silicon dioxide, calcium lactate 1 and hydroxypropyl methylcellulose into the stirring tank, hea...

Embodiment 3

[0030] In the embodiment of the present invention, a low-sodium polishing solution includes the following raw materials in parts by weight: 30 parts of silicon dioxide, 3 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 4 parts of calcium lactate, 7 parts of aluminum hydroxide, 1.5 parts of diethanolamine 1.5 parts of hydroxyquinoline, 15 parts of hydroxypropyl methylcellulose, and 50 parts of deionized water.

[0031] A kind of preparation method of described low-sodium polishing fluid, comprises the following steps:

[0032] 1) Select an appropriate amount of fatty alcohol polyoxyethylene ether sodium sulfate, diethanolamine, aluminum hydroxide, hydroxyquinoline and deionized water according to the weight ratio, then put the raw materials in a stirring tank and mix them, and stir at 70°C for 10 minutes. The stirring speed of the stirred tank is 200r / min;

[0033] 2) Put silicon dioxide, calcium lactate 1 and hydroxypropyl methylcellulose into the stirring tank, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com