PCB (printed circuit board) resistance welding pretreatment process

A pretreatment and process technology, applied in the field of PCB solder mask pretreatment process, can solve the problems of insufficient copper surface layer and hole roughness, affecting PCB assembly, and high labor costs, reducing the probability of scratches on the board surface, improving The effect of processing efficiency and labor cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

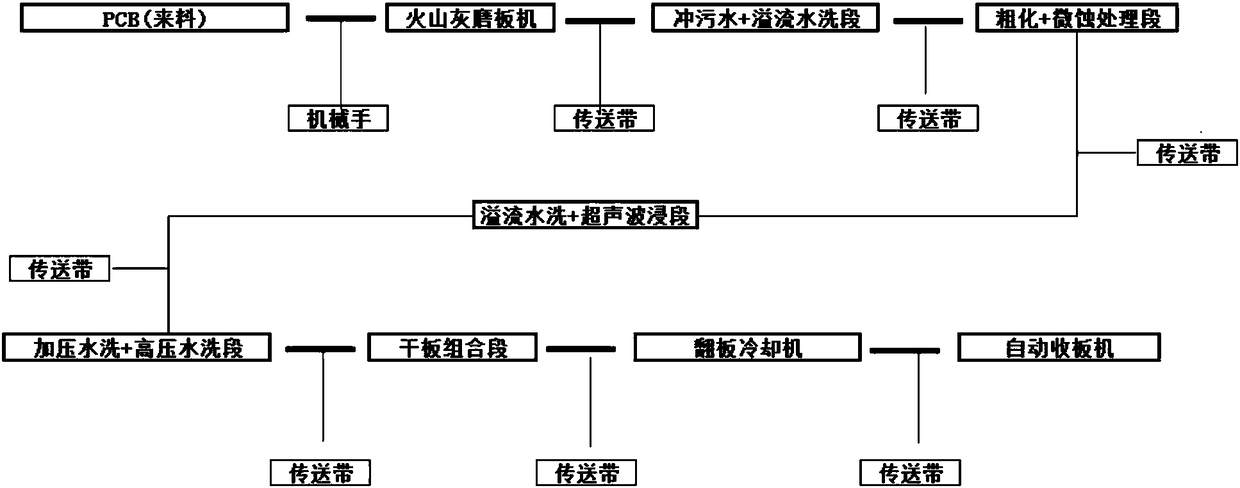

[0029] This embodiment provides a pre-treatment process for PCB solder mask, such as figure 1 As shown, it includes the following steps:

[0030] S1. Automatic feeding. The PCB boards to be processed are stored in a temporary feeding storage rack, and the manipulator is controlled to grab and transport the PCB boards to be processed stored in the temporary feeding storage rack to the feeding end of the volcanic ash grinding machine.

[0031] S2, volcanic ash grinding plate treatment, the volcanic ash grinding machine has a nylon grinding wheel, and the nylon grinding wheel rotates at a high speed to spray the mixture of volcanic ash and water onto the surface of the PCB board. The volcanic ash can be selected from No. 325-400 volcanic ash, this embodiment The volume percentage of medium volcanic ash in the volcanic ash-water mixture is 12% (V / V), and the width of the wear marks on the board surface controlled by the volcanic ash is 8mm. Spray the volcanic ash-water mixture on ...

Embodiment 2

[0037] This embodiment provides a pre-treatment process for PCB solder mask, such as figure 1 As shown, it includes the following steps:

[0038] S1. Automatic feeding. The PCB boards to be processed are stored in a temporary feeding storage rack, and the manipulator is controlled to grab and transport the PCB boards to be processed stored in the temporary feeding storage rack to the feeding end of the volcanic ash grinding machine.

[0039] S2, volcanic ash grinding plate treatment, the volcanic ash grinding machine has a nylon grinding wheel, and the nylon grinding wheel rotates at a high speed to spray the mixture of volcanic ash and water onto the surface of the PCB board. The volcanic ash can be selected from No. 325-400 volcanic ash, this embodiment The volume percentage of medium volcanic ash in the volcanic ash-water mixture is 16% (V / V), and the width of the wear marks on the board surface controlled by the volcanic ash is 10mm. Spray the volcanic ash-water mixture on...

Embodiment 3

[0045] This embodiment provides a pre-treatment process for PCB solder mask, such as figure 1 As shown, it includes the following steps:

[0046] S1. Automatic feeding. The PCB boards to be processed are stored in a temporary feeding storage rack, and the manipulator is controlled to grab and transport the PCB boards to be processed stored in the temporary feeding storage rack to the feeding end of the volcanic ash grinding machine.

[0047] S2, volcanic ash grinding plate treatment, the volcanic ash grinding machine has a nylon grinding wheel, and the nylon grinding wheel rotates at a high speed to spray the mixture of volcanic ash and water onto the surface of the PCB board. The volcanic ash can be selected from No. 325-400 volcanic ash, this embodiment The volume percentage of medium volcanic ash in the volcanic ash-water mixture is 20% (V / V), and the width of the wear marks on the surface of the volcanic ash is controlled to be 12mm. The volcanic ash-water mixture is spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com