Water-resistant UV-cured resin composition, preparation method and applications thereof

A technology for curing resins and compositions, applied in epoxy resin coatings, coatings, polyester coatings, etc., can solve the problems of increasing production time and difficulty, failing to detect bad defects, increasing energy consumption and management costs, etc. Achieve the effect of reducing the probability of defective products, reducing the probability of scratches, and improving yield and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a preparation method of the water-resistant UV curable resin composition, comprising the following steps:

[0037] (1) Weigh each component according to the formula amount, add the acrylic acid reactive monomer and photoinitiator into a light-proof reaction container, and stir at 10-30°C to pre-dissolve and disperse the photoinitiator;

[0038] (2) Acrylic acid oligomer is joined in the mixture that step (1) obtains, continue to stir;

[0039] (3) Add the auxiliary agent and the hydrophobic agent to the mixture obtained in the step (2) at the same time, and stir until it is transparent and uniform, so as to obtain a water-resistant UV curable resin composition.

[0040] The stirring speed in steps (1) to (3) is a medium-speed stirring of 400-600 rpm / min. Moreover, the stirring time is between 20 and 60 minutes, which can be selected and adjusted according to the actual situation.

[0041] Wherein, the acrylic active monomer includes...

Embodiment 1

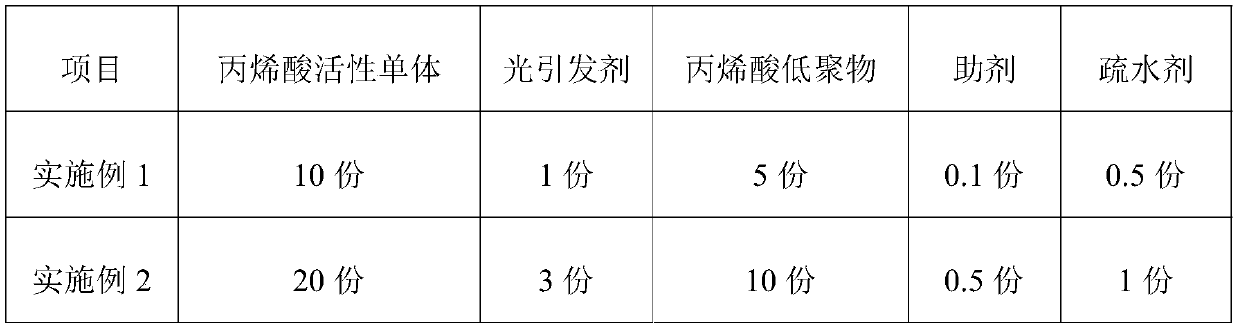

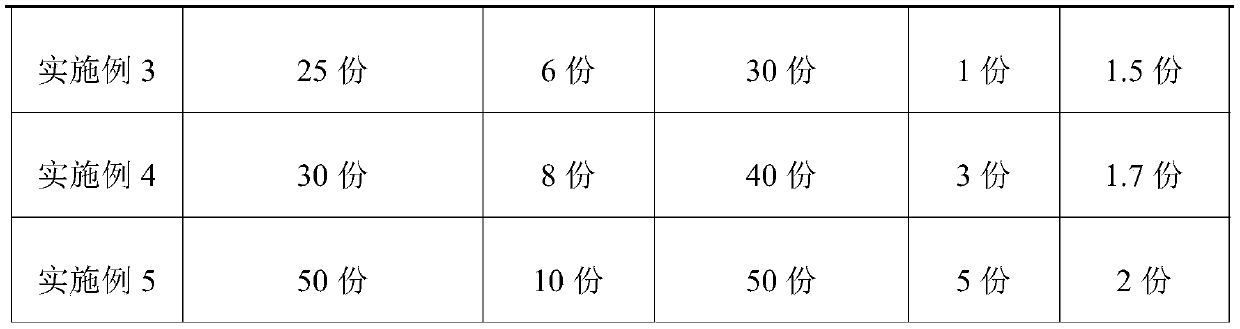

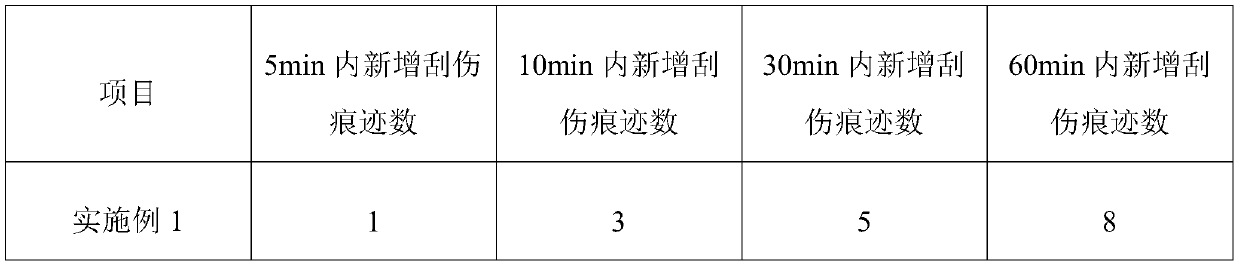

[0049] Weigh each component according to the formula amount in Table 1, first add o-phenylphenoxyethyl acrylate and photoinitiator PI 184 into a light-proof reaction vessel, stir at 10°C and a medium speed of about 400rpm / min for 30min Pre-dissolve and disperse photoinitiator PI 184 to obtain mixed solution A1; then add polyurethane acrylic resin to mixed solution A1 and continue to stir at a medium speed of about 500rpm / min for 30min to obtain mixed solution B1; then add the additive BYK-3530 and hydrophobic agent BYK-333 were added to the mixed solution B1 at the same time, stirred at a medium speed of about 400rpm / min for 20min until the solution was uniformly mixed and transparent, and the water-resistant UV curable resin composition 1 was obtained after the stirring was stopped. This UV curable resin composition 1 is coated on the PET film by the pressure roller method, and the irradiation dose is about 0.2J / cm 2 UV light, which is a metal halide lamp with a main waveleng...

Embodiment 2

[0051] Weigh each component according to the formulation amount in Table 1, first add (ethoxy) phenol acrylate and photoinitiator PI 1173 into a reaction vessel protected from light, stir at 15°C and a medium speed of about 400rpm / min for 40min The photoinitiator PI 1173 was pre-dissolved and dispersed to obtain the mixed solution A2; then the polyurethane acrylic resin was added to the mixed solution A2 and then stirred at a medium speed of about 550rpm / min for 40min to obtain the mixed solution B2; then the auxiliary agent BYK -3535 and hydrophobic agent BYK-3500 were added to the mixed solution B2 at the same time, stirred at a medium speed of about 450rpm / min for 20min until the solution was uniformly mixed and transparent, and the water-resistant UV curable resin composition 2 was obtained after the stirring was stopped. This UV curable resin composition 2 is coated on the PET film by the pressure roller method, and the irradiation dose is about 0.25J / cm 2 UV light, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com