Tab bending method for multi-tab battery cell

A multi-pole and tab technology, applied in circuits, electrical components, secondary batteries, etc., can solve problems such as the large influence of the position of the tabs, the difficulty of inserting the bare cell into the shell, and the loose structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

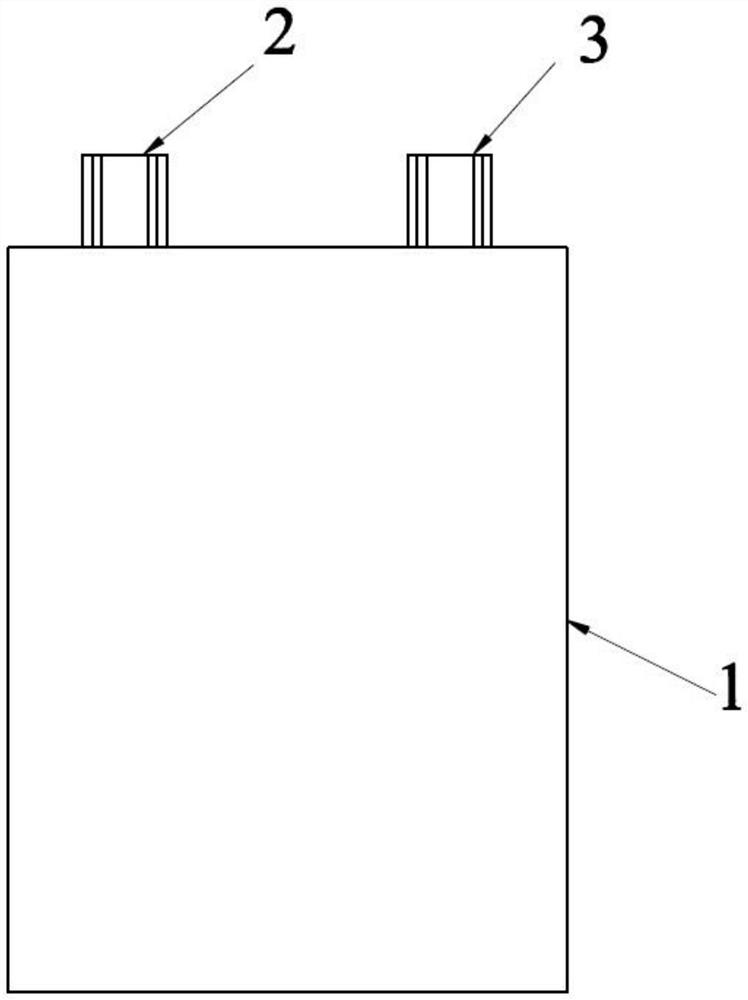

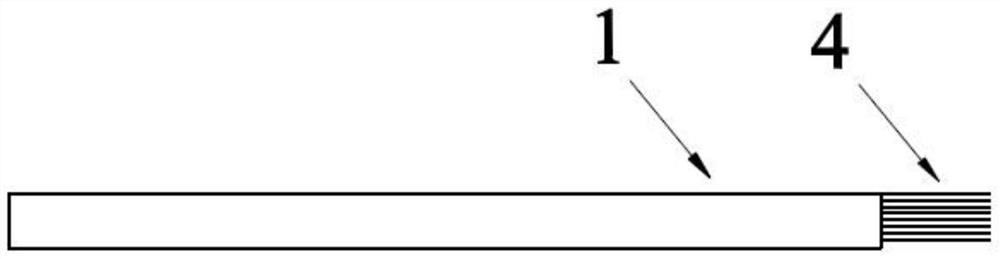

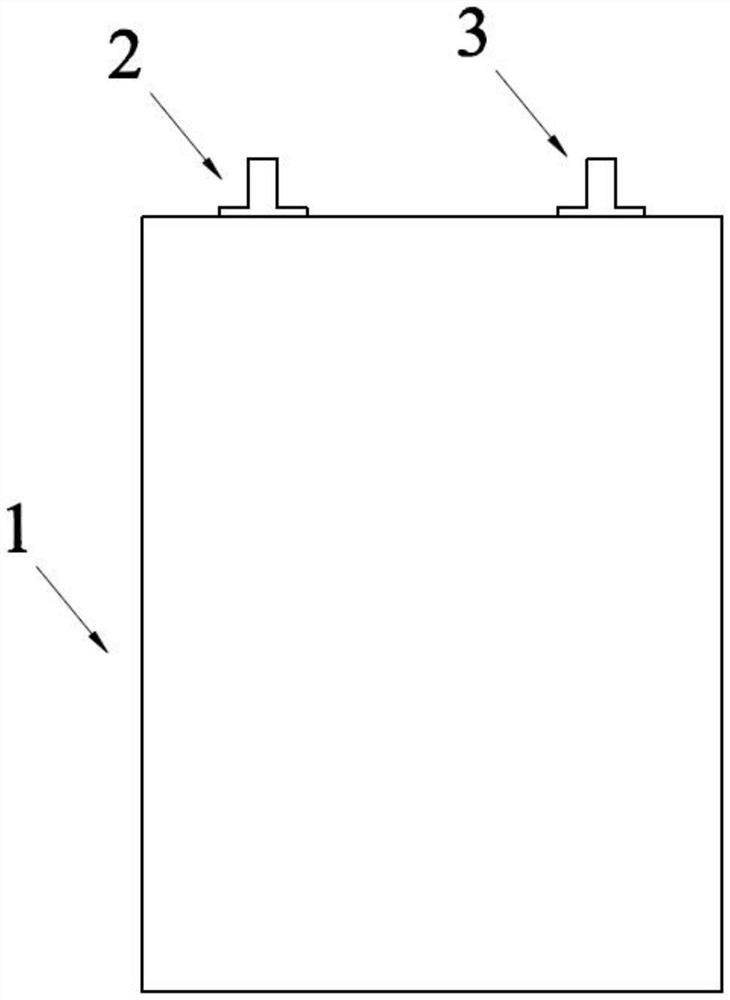

[0043] The method for folding the tabs of the multi-tab battery includes step 1, cutting the tabs on the two pole pieces respectively, and then winding the two pole pieces and the diaphragm in order to prepare a bare battery cell 1 with a multi-tab structure; Step 2: Overlap several tabs with the same polarity, then cut and heat-press to form a foil tab group 4 with a preset shape, and at the same time, bend the metal strip tab 5 with a through hole 51 Preset angle, wherein, the surface of the metal strip tab 5 is pasted with tab glue 52; step 3, the foil tab group 4 is passed through the through hole 51, and the root 54 of the metal strip tab 5 is wrapped, and then The foil tab group 4 and the metal strip tab 5 are fixedly connected; step 4, stick the protective tape on the foil tab group 4 and the metal strip tab 5 .

[0044]In the current industry, the double-folding scheme is commonly used for the head-folding tab structure of the multi-tab structure battery. It is diffic...

Embodiment 2

[0051] The difference from the first embodiment is that the shape of the foil tab group 4 in this embodiment is convex, the shape of the head 53 of the metal strip tab 5 is square, and the shape of the root 54 of the metal strip tab 5 is trapezoidal. , the temperature of the hot pressing is 10°C, the pressure of the hot pressing is 0.1Mpa, and the bending angle of the tab 5 of the metal strip is 70°. In this embodiment, after cutting, the shape of the foil tab group 4 can be designed as a convex shape or other shapes, so that the foil tab group 4 can pass through the through hole 51, and the metal strip tab 5 is divided into two ends. The root 53 and the root 54, the root 54 is the end close to the bare cell 1, the shape of the root 54 of the metal strip tab 5 is trapezoidal, the lower bottom of the trapezoid is connected to the head 53, and the foil tab with a convex shape Group 4, to avoid scratching between the root 54 of the metal strip tab 5 and the foil tab group 4, resu...

Embodiment 3

[0054] The difference from Example 1 is that in step 1 of this example, the active material is also coated on the foil, and then rolled and slit to form pole pieces. The pole pieces include cathode pieces and anode pieces. Cut out several cathode lugs 2 on the sheet, cut out several anode lugs 3 on the anode sheet, the temperature of hot pressing is 100°C, the pressure of hot pressing is 0.6Mpa, and the bending angle of the metal strip tab 5 is 110° . Specifically, the pole piece is divided into a cathode piece and an anode piece, and several cathode lugs 2 are cut out on the cathode piece, and several anode lugs 3 are cut out on the anode piece, and several cathode lugs 2 are stacked into a The foil tab group 4 of the cathode, and several anode tabs 3 are stacked to form the foil tab group 4 of the anode before being hot-pressed and bent. Both foil tab groups 4 can adopt the above-mentioned tab folding process, or One of the foil tabs 4 can adopt the above-mentioned process;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com