Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Reduce bad ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

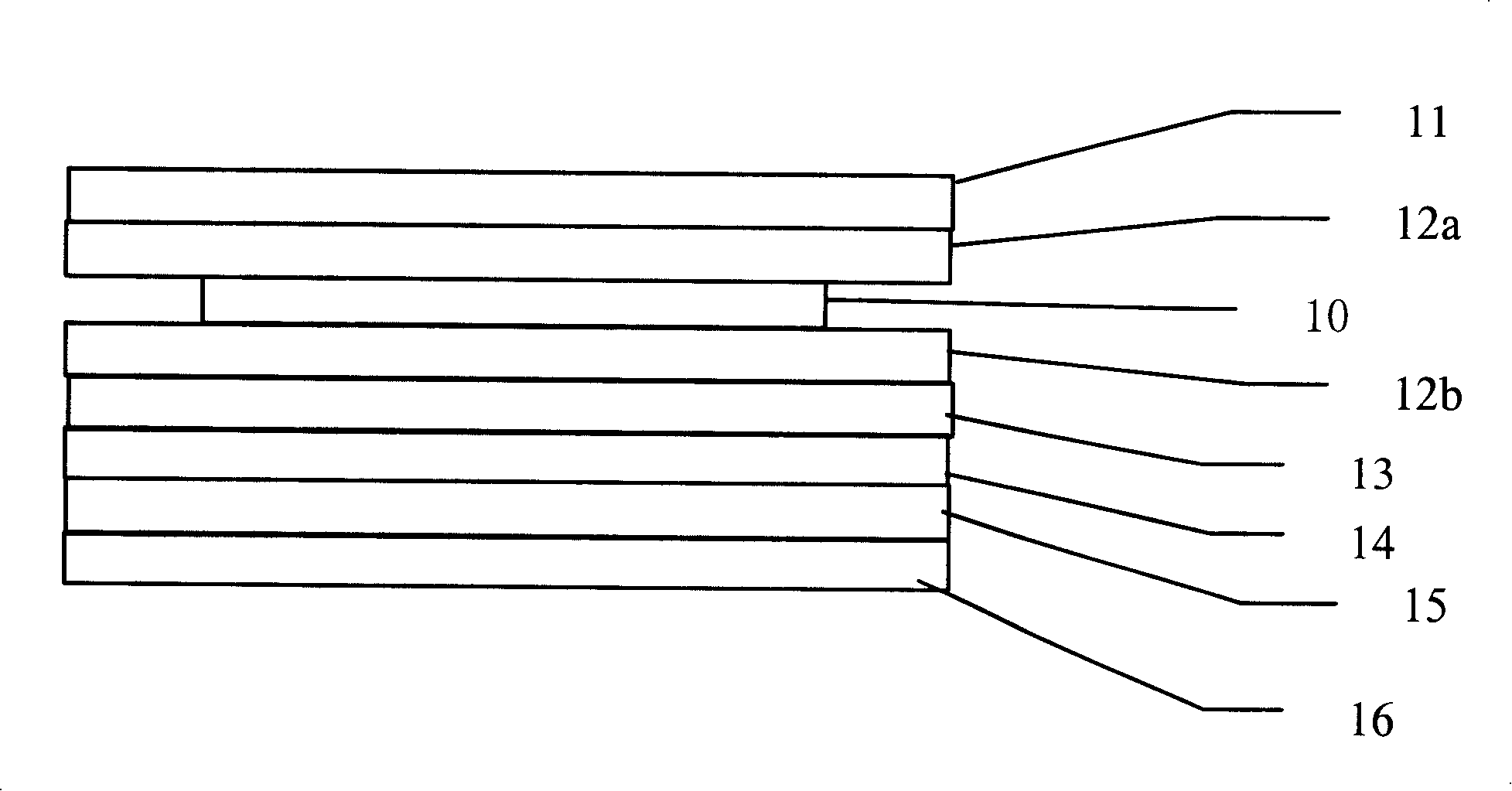

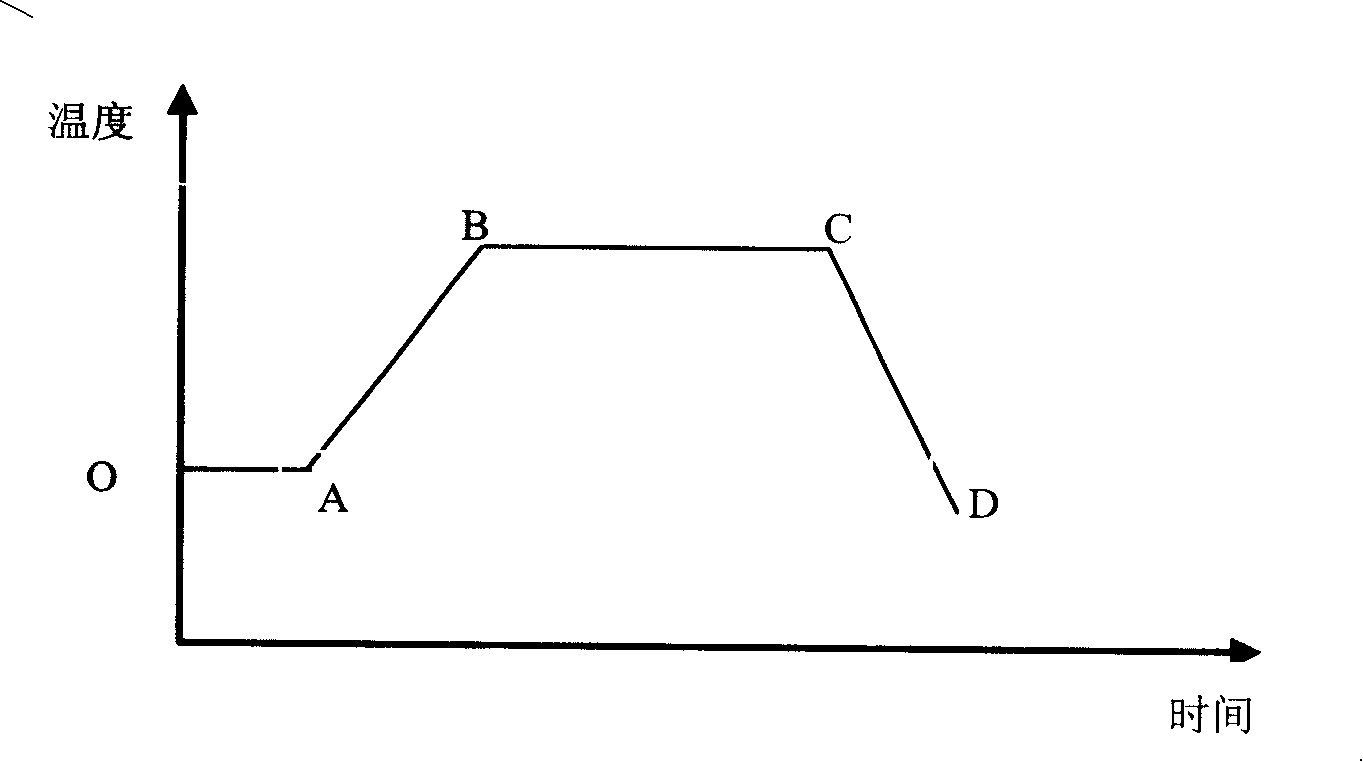

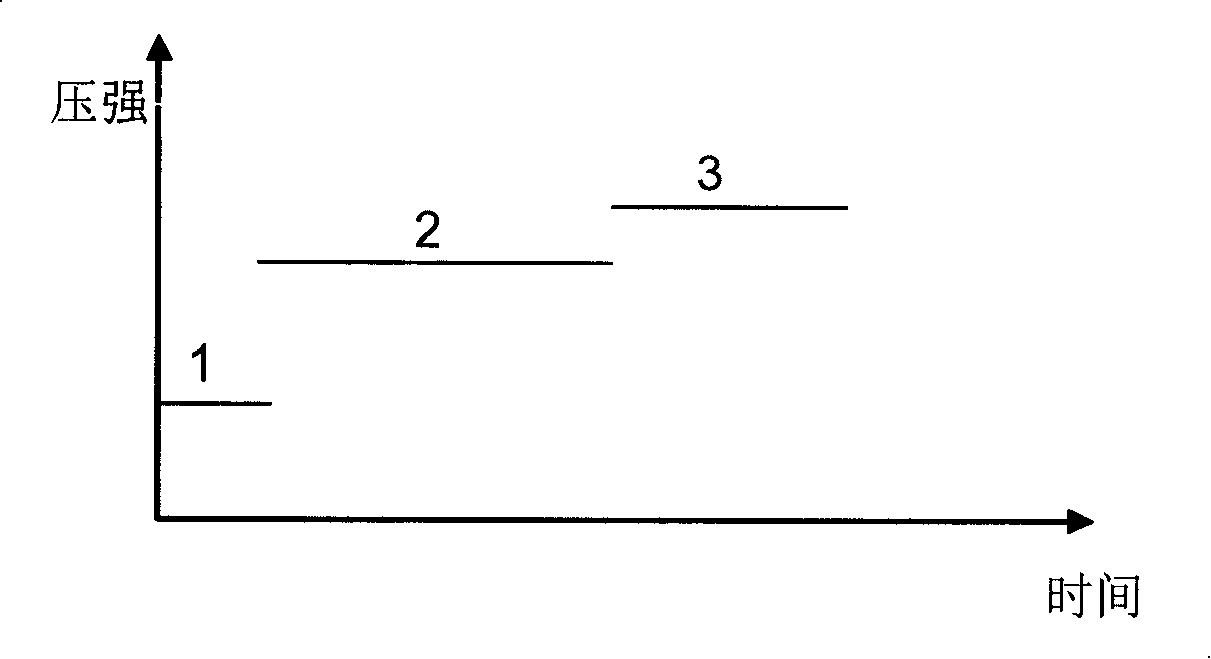

Flexible circuit board press bonding method

ActiveCN101212867APrecise control of glue overflowEliminate bad phenomenaLaminationLamination apparatusFlexible circuitsUltimate tensile strength

The invention discloses a method for pressing a flexible circuit board, which adopts a stacking structure to press the raw material of the flexible circuit board. The pressing method includes a pressing step A and a pressing step B. Using the two step pressing method of the invention can obviously reduce the glue-overflowed amount, lower the ratio of harmful bubbles increase the raising peeling strength and improve the performance of the flexible circuit board.

Owner:靖江市华信科技创业园有限公司

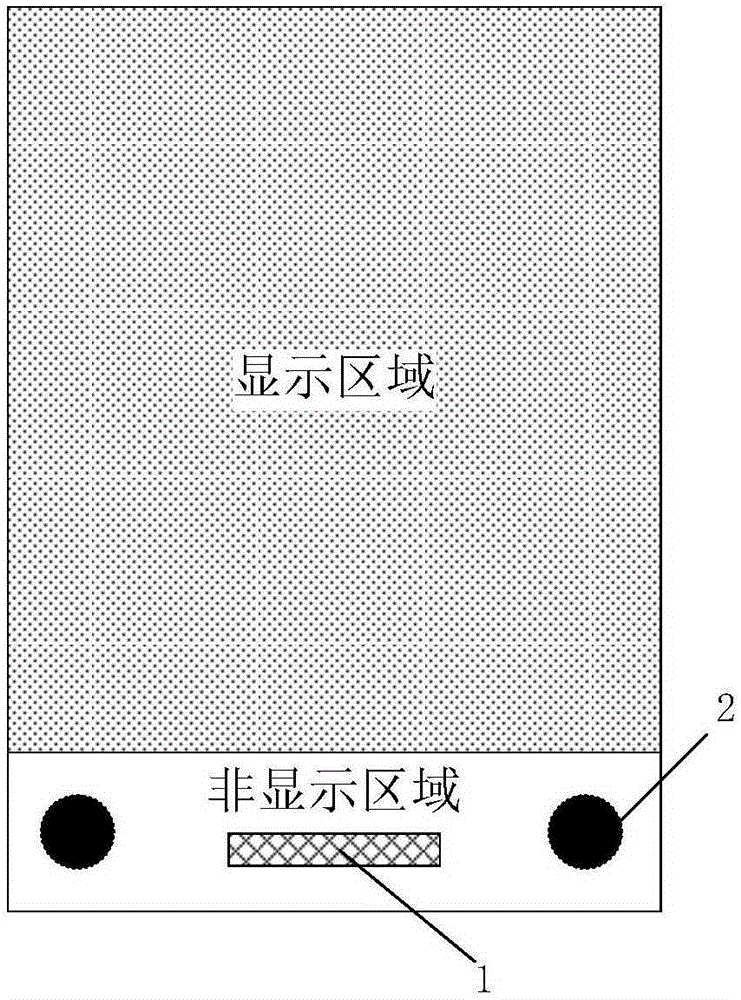

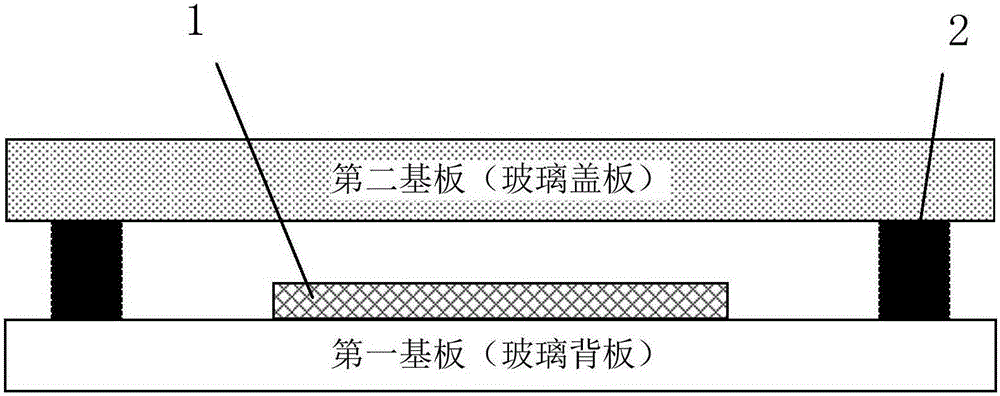

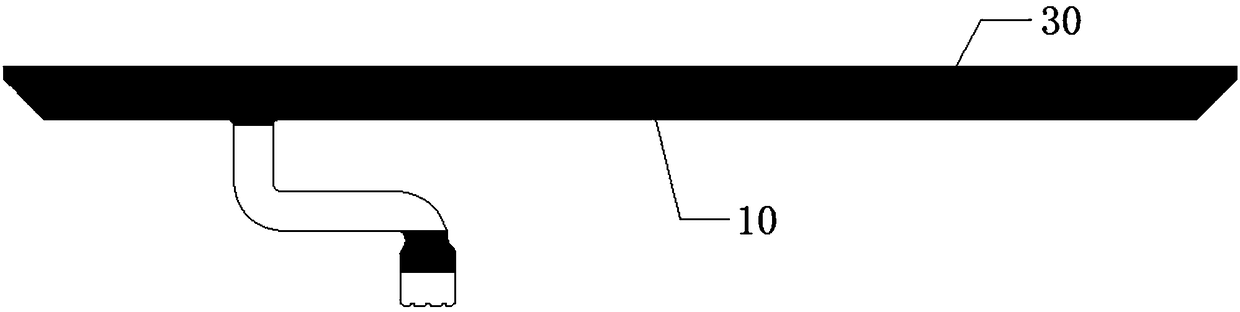

Display panel and manufacturing method thereof

InactiveCN105225608AReduce the probability of scratchesReduce bad ratioSemiconductor/solid-state device detailsNon-linear opticsEngineeringIntegrated circuit

The invention discloses a display panel and a manufacturing method thereof. The display panel comprises a first substrate and a second substrate, and the first substrate and the second substrate are in opposite arrangement. An IC (integrated circuit) is arranged in a non-display region of the first substrate, and supporting parts higher than the IC are arranged in an area, except for the area with the IC, of the non-display region. Therefore, the IC can be protected from being scratched to the maximal extent, and yield of a whole backlight module is increased.

Owner:BOE TECH GRP CO LTD +1

Rinsing fluid used for removing organics on surface of monocrystalline silicon piece and cleaning method

InactiveCN104479913AEfficient removalImprove surface cleanlinessInorganic non-surface-active detergent compositionsCleaning using liquidsMegasonic cleaningPotassium hydroxide

The invention discloses a rinsing fluid used for removing organics on the surface of a monocrystalline silicon piece and a cleaning method. The rinsing liquid comprises the following compositions in parts by volume: 2.30 parts-4.5 parts of hydrogen peroxide, 0.20 parts-1.15 parts of potassium hydroxide, and 94.35 parts-97.5 parts of pure water, wherein the mass fraction of potassium hydroxide is 45% and pure water is 18 M pure water. The cleaning method comprises the following steps: (1) flushing with tap water; (2) immersing in a lactic acid solution; (3) rinsing with tap water; (4) using pure water for ultrasonic pre-cleaning; (5) using a cleaning liquid for ultrasonic cleaning; (6) using pure water for ultrasonic rinsing; (7) using the rinsing fluid for rinsing; (8) using pure water for rinsing; and (9) performing dip coating and baking. The rinsing fluid and the cleaning are capable of effectively removing organics left on the surface of the monocrystalline silicon piece, improving the clean degree of the monocrystalline silicon piece surface, effectively reducing the cleaning unqualified rate of the monocrystalline silicon piece and the adverse ratio of the monocrystalline silicon piece subjected to etching, improving the quality of the monocrystalline silicon piece and enhancing the market competiveness of the product.

Owner:INNER MONGOLIA ZHONGHUAN SOLAR MATERIAL

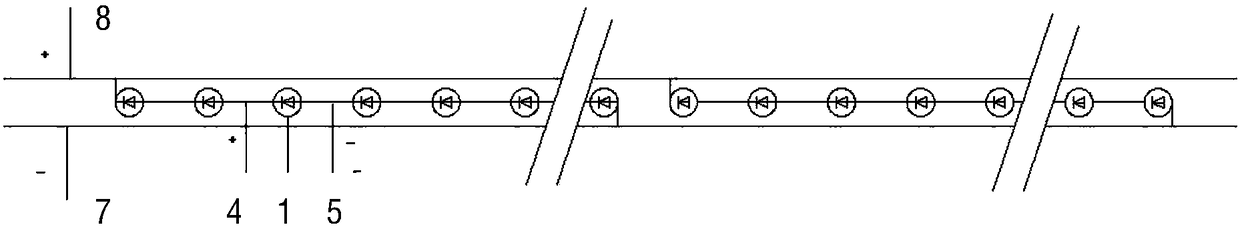

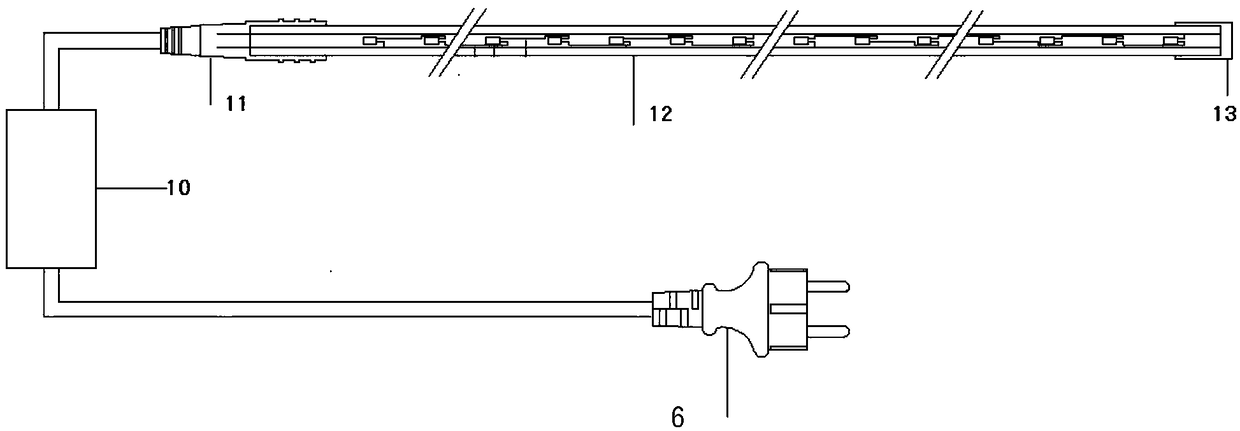

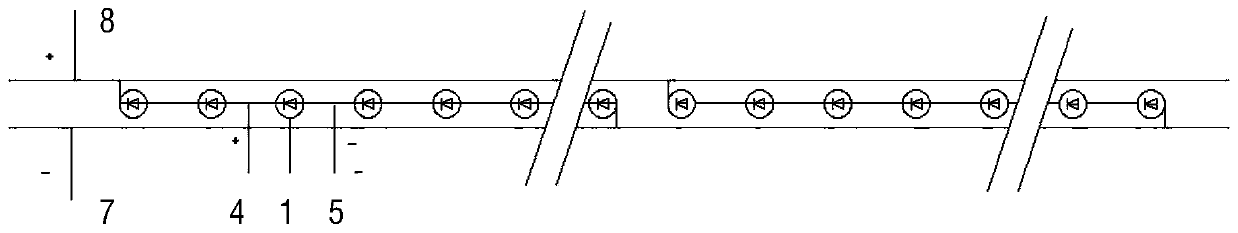

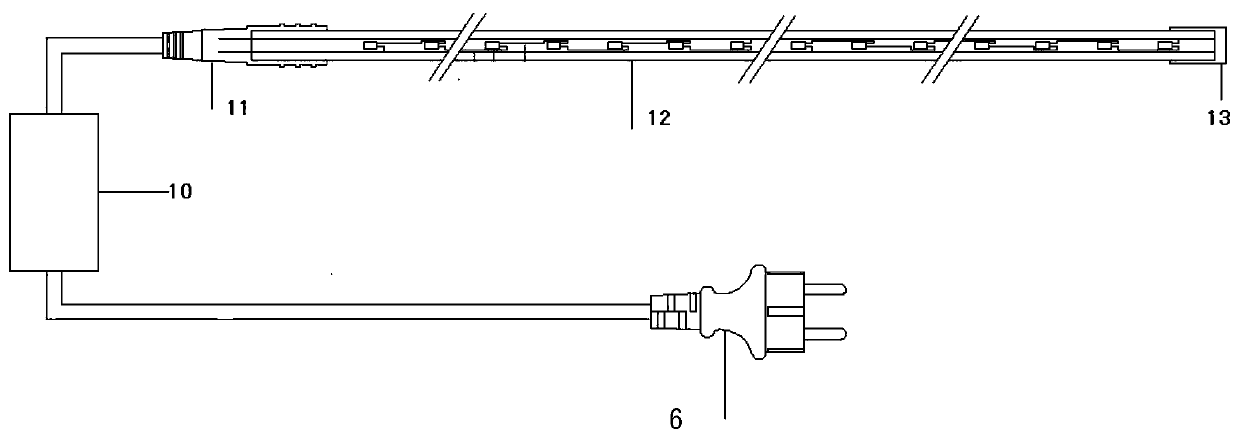

RGB point-control intelligent beauty lamp

ActiveCN108347804AProtection lifeImprove waterproof performanceElectrical apparatusElectroluminescent light sourcesMOSFETTransformer

The invention discloses an RGB point-control intelligent beauty lamp. A beauty lamp string is connected in series with the positive and negative poles of a main line, and is composed of a plurality ofdiodes. The addresses of the diodes are set by an encoder. One end of a plug is connected to a power source, and the other end of the plug is connected with a resistance wire, a voltage dependent resistor, a filter and a filter circuit. The output end of the filter circuit is connected to the input end of a MOSFET and a DCDC transformer. DC power is output to a drive module and a MCU. The MCU isconnected in parallel with a program module, a button, a remote control module, a WiFi module and a Bluetooth module through a circuit board circuit. The output ends of the driver module and the transformer are connected to the input end of the MOSFET. The output end of the MOSFET is connected to the lamp string at the end portion of the main line. The product functions of the point-control intelligent beauty lamp can be arbitrarily programmed and modified by a computer program into monochrome control, two-color control, and multi-color control.

Owner:JIANGSU LEDCO LIGHTING TECH CO. LTD

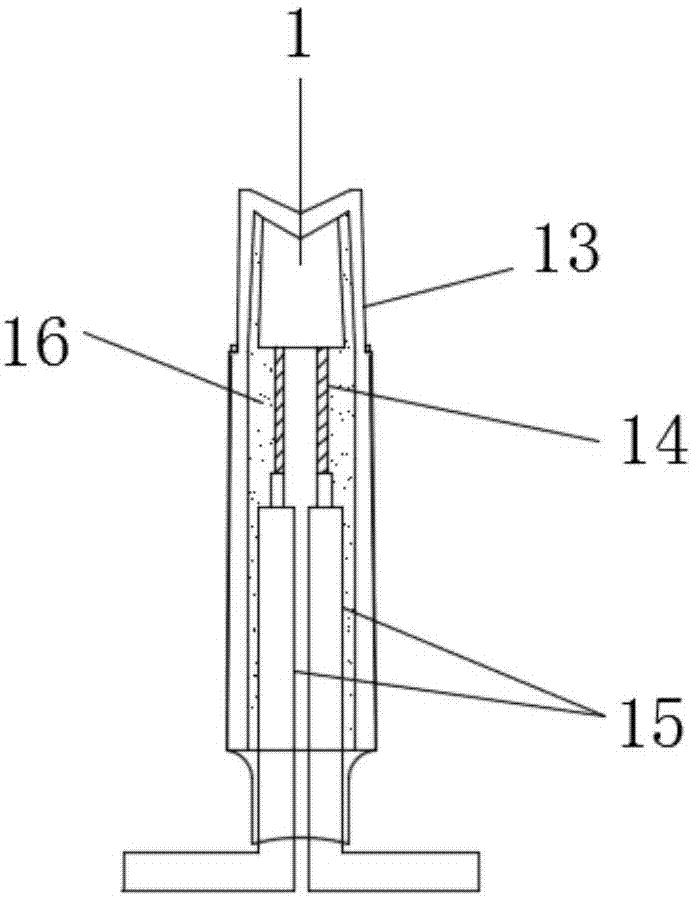

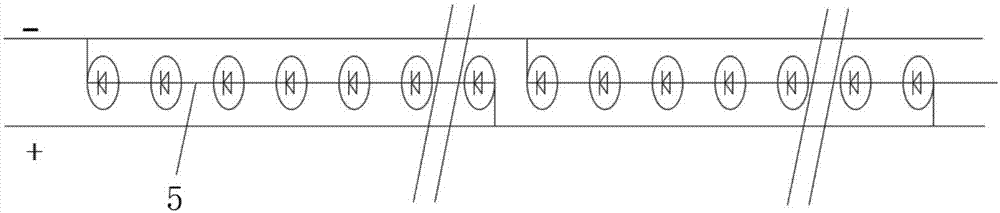

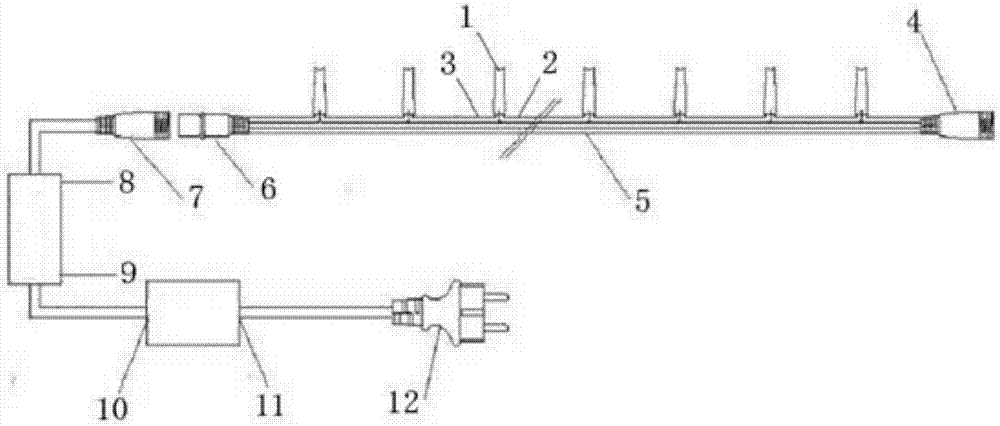

RGB-LED intelligent string light

InactiveCN107366848AImprove waterproof performanceEasy to operateElectrical apparatusElongate light sourcesTransformerEngineering

The invention relates to a RGB-LED intelligent string light particularly, which comprises an intelligent power source and a string light. The intelligent power source comprises a plug, a transformer, and a control box which are electrically connected with a power line mother terminal in order. A loop consists of 30 LED lights. The RGB-LED light bulb is placed in the PC shell, and the bottom end of the RGB-LED light bulb is connected with two brackets, and one bracket is connected with the electric wire; the lower end of the electric wire is located at the inner part of the PC shell, and epoxy resin glue fills at the inner part of the PC shell; the upper end of the electric wire penetrates through the epoxy resin glue and extends to the outside of the PC shell; a positive pole foot and a negative pole foot of adjacent two LED bulbs are electrically connected to each other and combined to be a string light. The RGB-LED intelligent string light has the beneficial effects that single LED, partial LED and the whole string light circuit can be controlled to form single-color control, dual-color control and multi-color control. The injection molding is convenient and simple, service life of the LED is sufficiently protected, and bad proportion is greatly reduced; the greatest characteristic of the RGB-LED is the built-in address of the LED chip. Through the intelligent power control, the single LED control, multi-circuit control and other effects are reached.

Owner:JIANGSU FEITIAN LIGHTING CO LTD

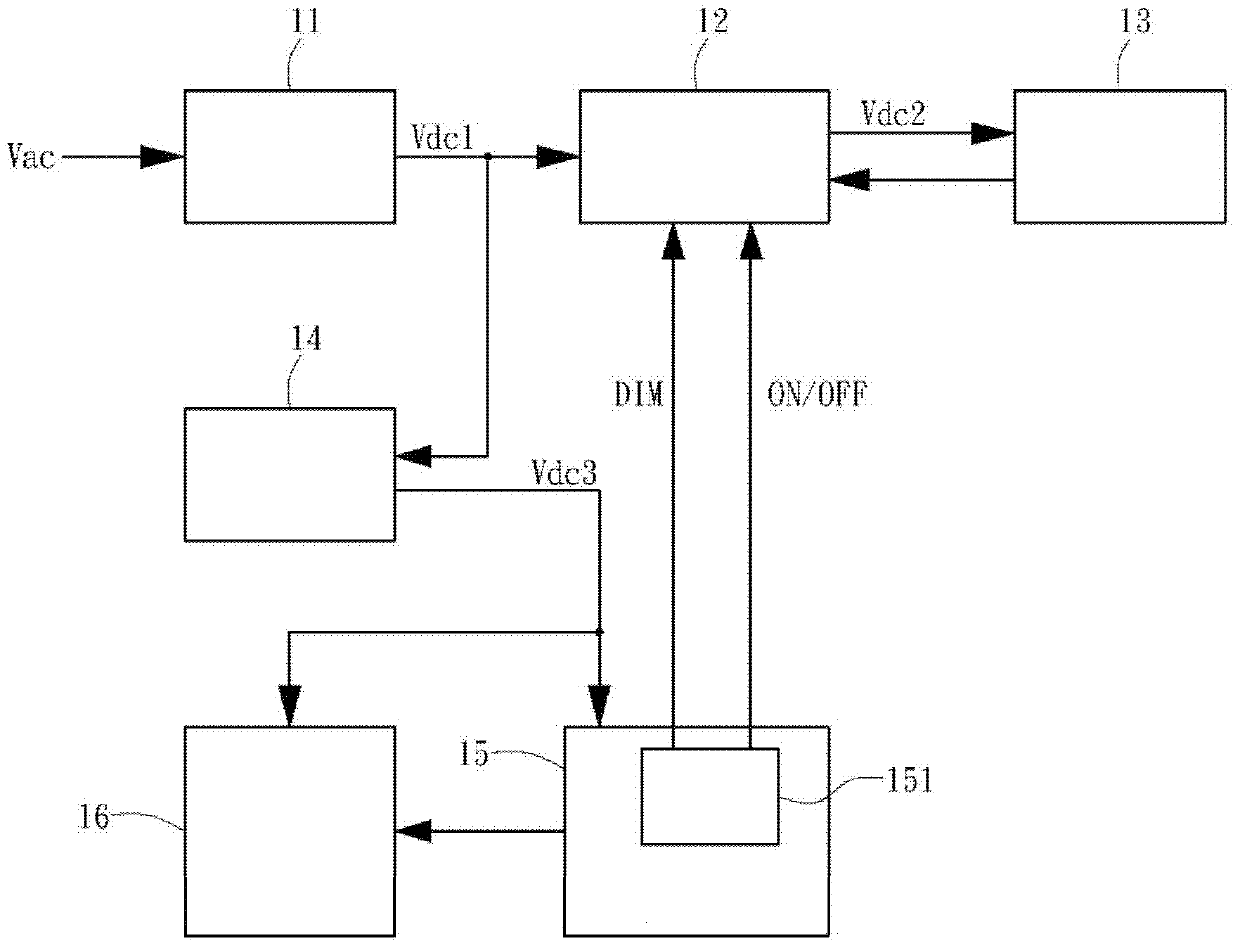

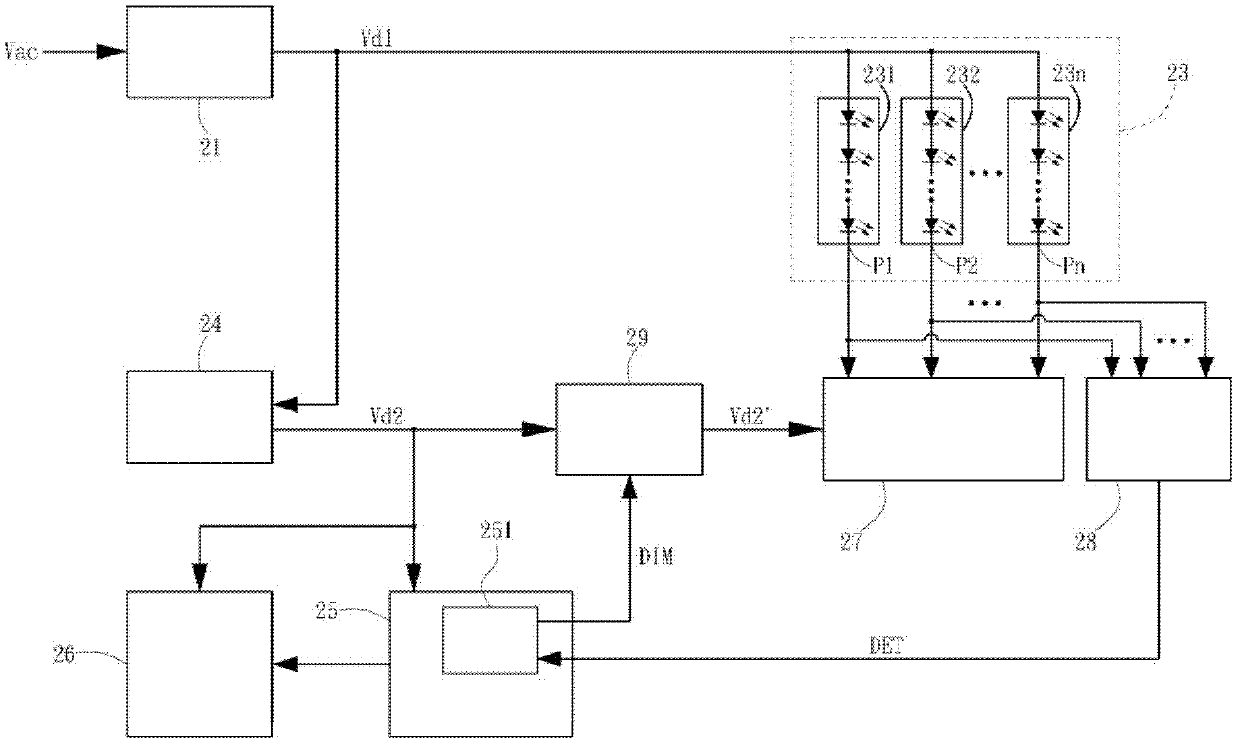

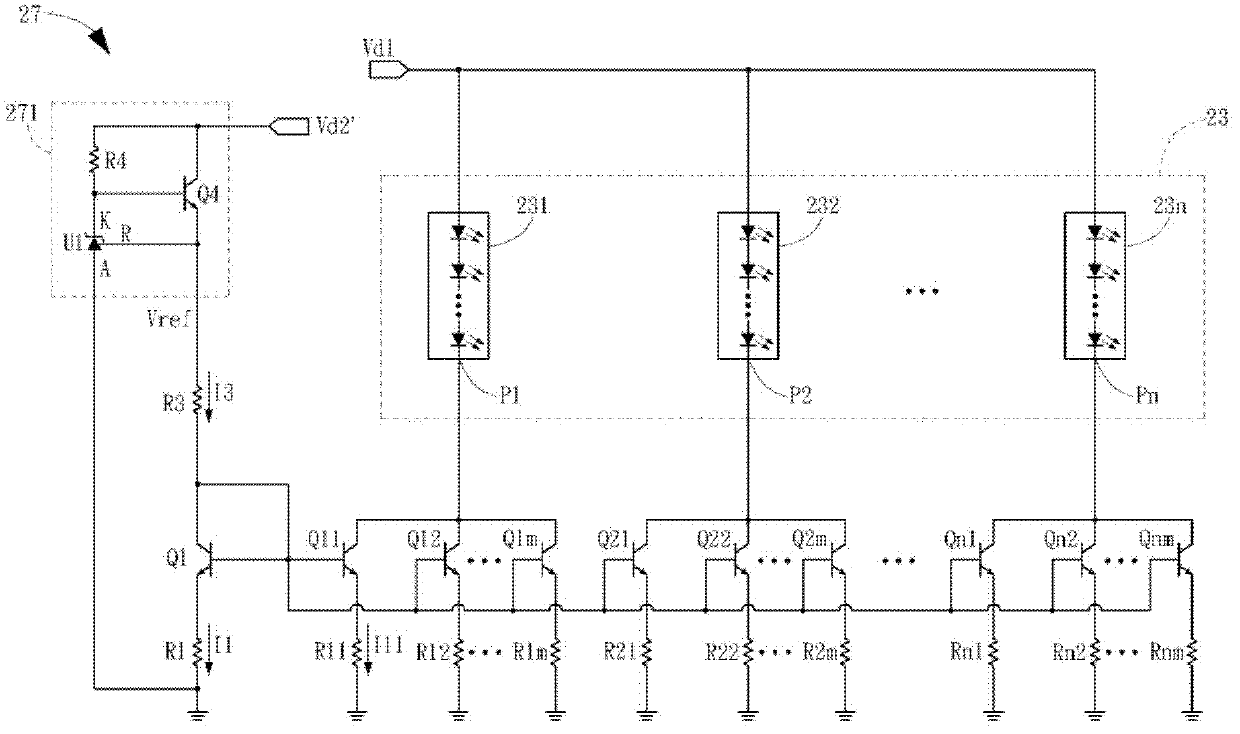

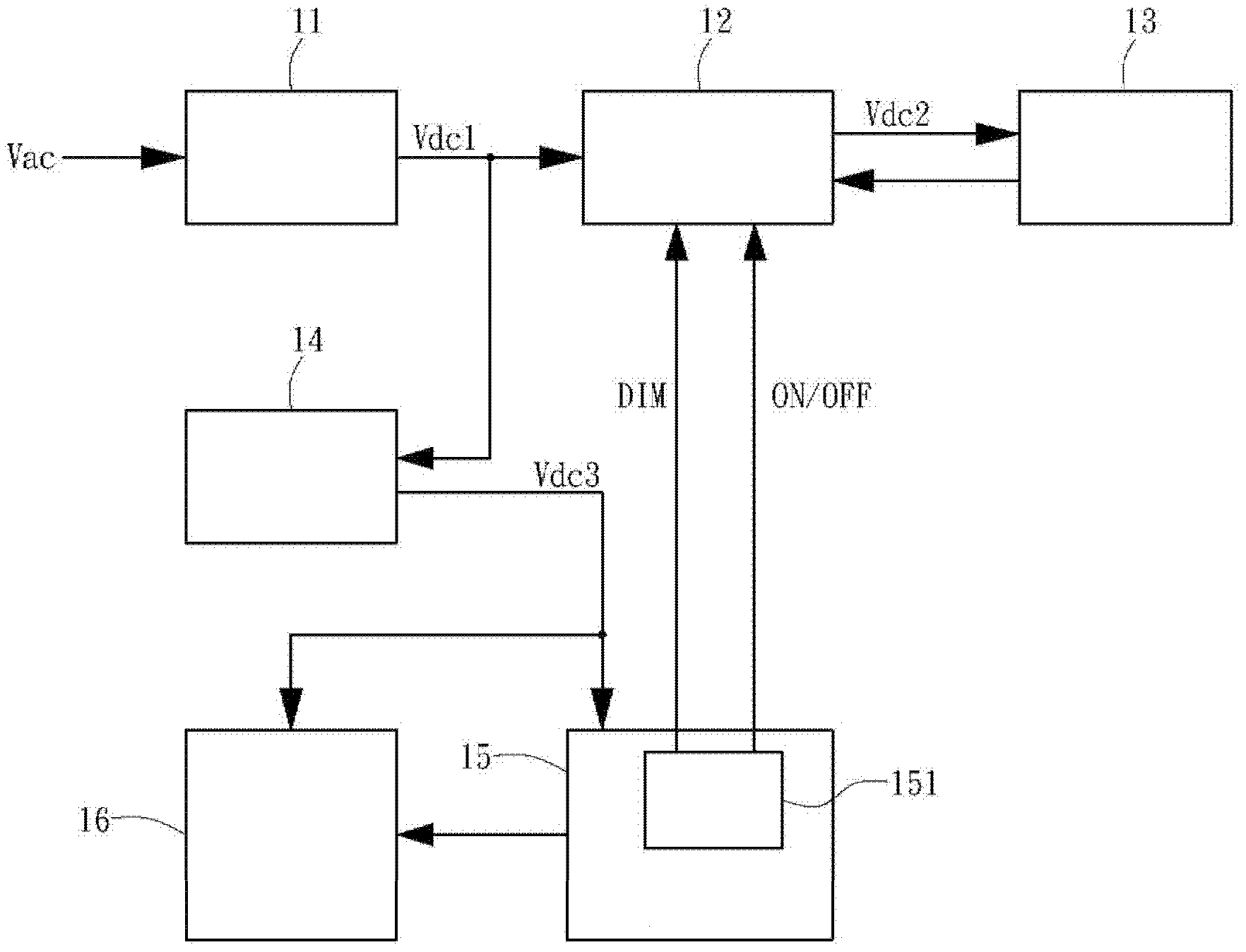

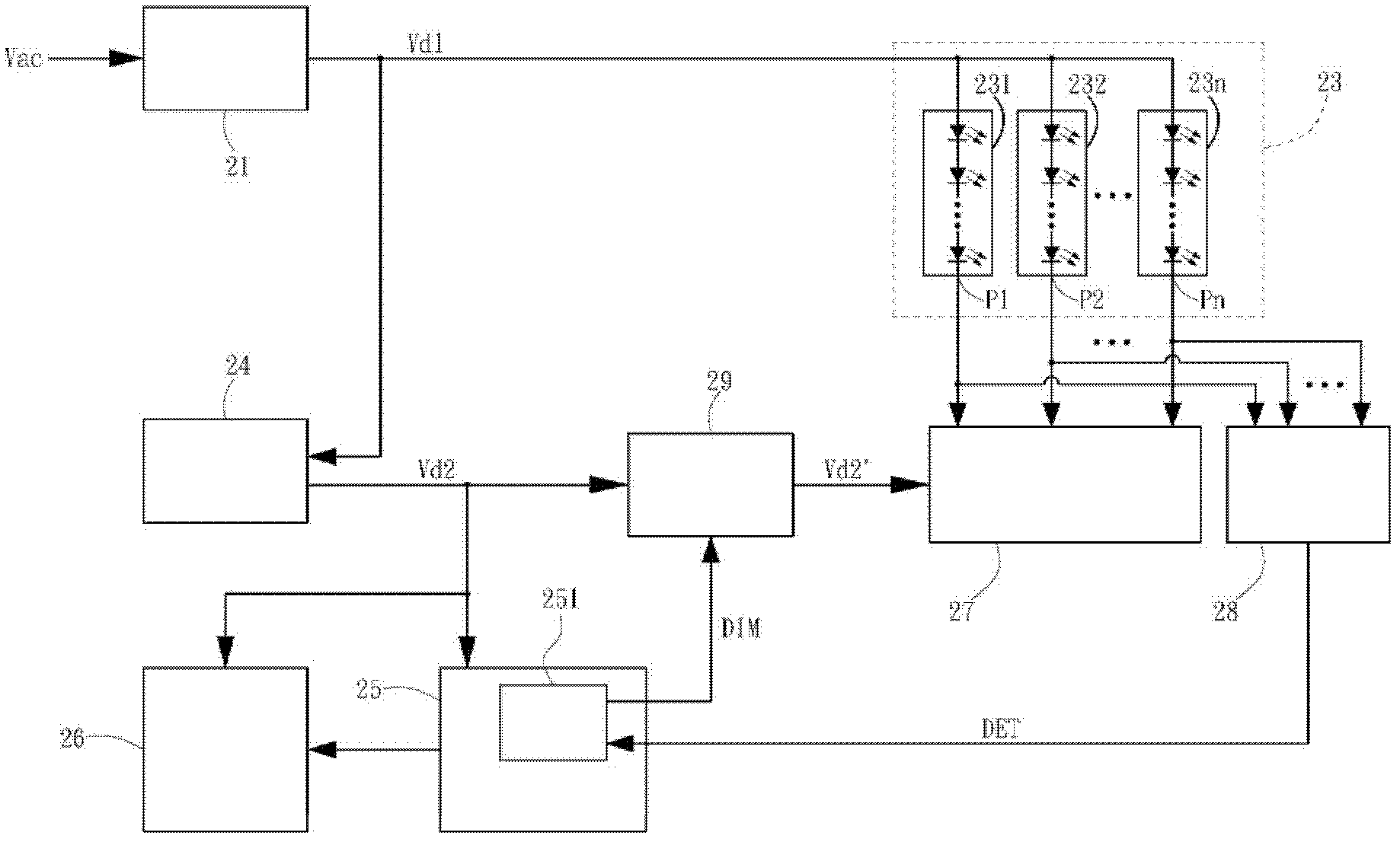

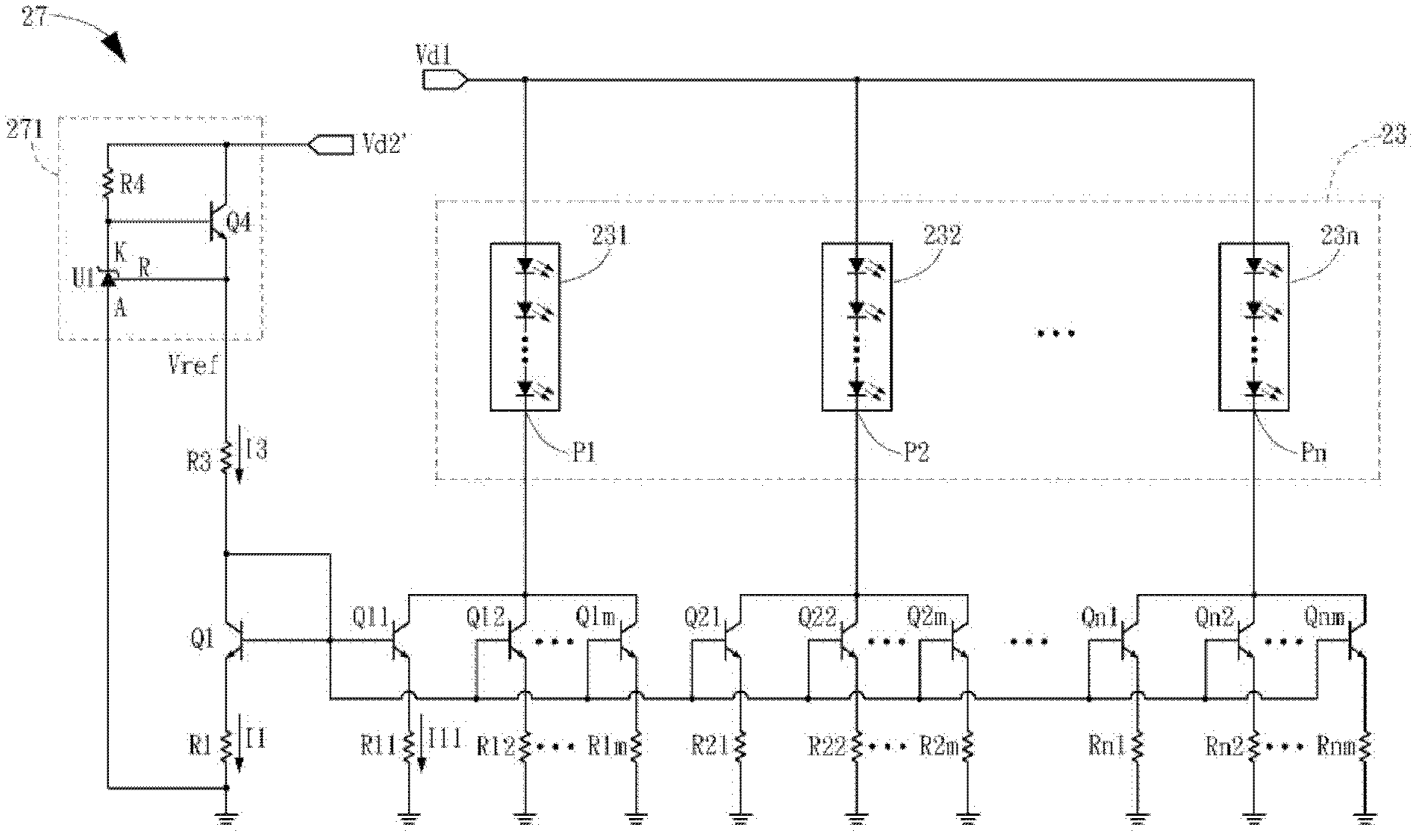

Driving device of LED tube

ActiveCN103379705AReduce design difficultyReduce design costElectric light circuit arrangementEnergy saving control techniquesLiquid-crystal displayElectromagnetic interference

The invention discloses a driving device of an LED tube. The method that a first direct-current voltage which can provide the working voltage of each LED light string of the LED tube is directly output by an AC-DC converter is applied to the driving device of the LED tube. The defects that after an existing AC-DC converter outputs a low direct-current voltage, a DC-DC boost converter is further needed so as to generate a high direct-current voltage which can be provided for the LED light string to enable the LED light string to work in the prior art are overcome. The driving device of the LED tube can reduce generated electromagnetic noise so as to reduce the design difficulty and the design cost of a needed electromagnetic noise interference suppression circuit. The driving device of the LED tube can further reduce the defect ratio of liquid crystal display products which are provided with the driving devices of the LED tubes in a factory and on the market so as to reduce the design cost of power sources of the liquid crystal display products. In addition, due to the fact that the existing DC-DC boost converter is not applied, a constant-current control circuit is adopted to ensure that each LED light string is in the constant-current state in the process of working. Besides, control over opening and closing of the constant-current circuit is used for controlling the average brightness provided by the LED tube. When the LED tube works and the detected voltage of the output end of the LED tube is larger than a protection point set valve, a dimming output port of the control circuit outputs a continuous low level signal to stop normal work of the constant-direct control circuit, the LED tube is finally switched off, and the purpose of protection is achieved.

Owner:TPV ELECTRONICS (FUJIAN) CO LTD

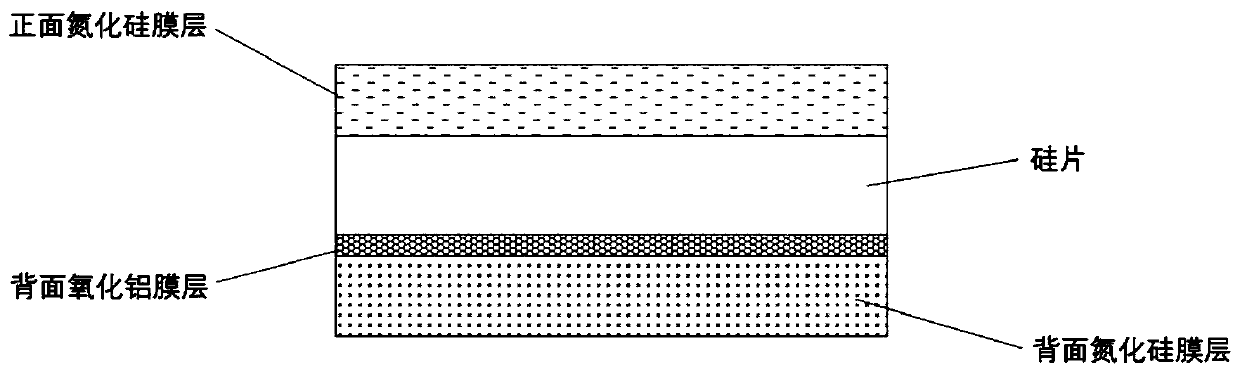

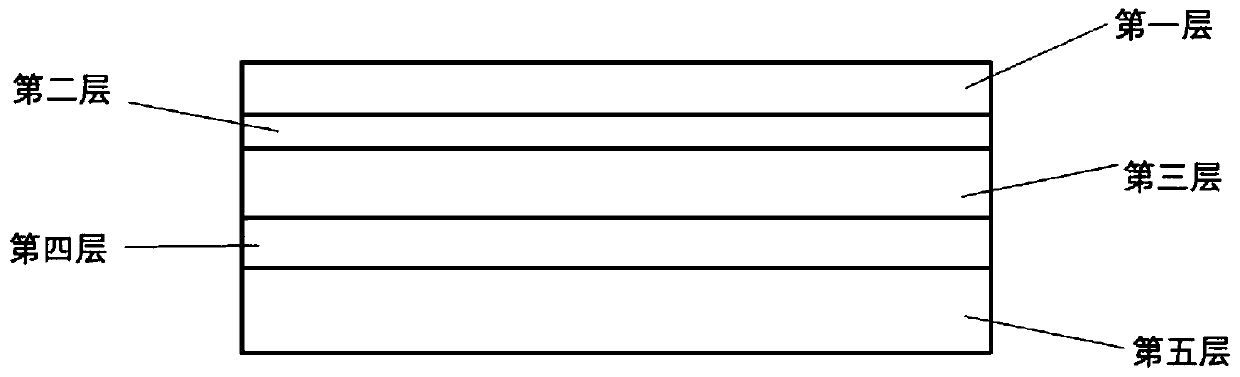

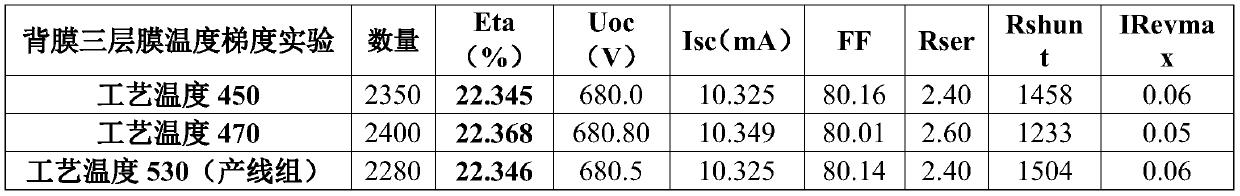

Battery back silicon nitride film layer, PERC battery and preparation method

PendingCN111416002AThe wavelength is matched accordinglyExcellent performance efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingCell fabricationPhysical chemistry

The invention discloses a battery back silicon nitride film layer, a PERC battery and a preparation method and belongs to the field of single crystal PERC battery manufacturing. In the prior art, a battery back film is low in reflectivity, and the conversion efficiency of a battery is slow meanwhile, the temperature requirement of a back film manufacturing process is high, and energy consumption and cost are high. The invention provides a PERC battery. The battery comprises a front silicon nitride film layer, a back aluminum oxide film layer and a back silicon nitride film layer; the back silicon nitride film layer is of a five-layer structure; when the battery is manufactured, a back aluminum oxide film layer, a front silicon nitride film layer and a back silicon nitride film layer are sequentially deposited; a low-temperature manufacturing process is used, so that the photoelectric conversion efficiency of a battery piece is improved, the performance of a single crystal PERC batteryproduct is improved, energy consumption in the manufacturing process is reduced, manufacturing time is shortened, and production efficiency is improved. The manufacturing method is suitable for wide application.

Owner:TONGWEI SOLAR (ANHUI) CO LTD

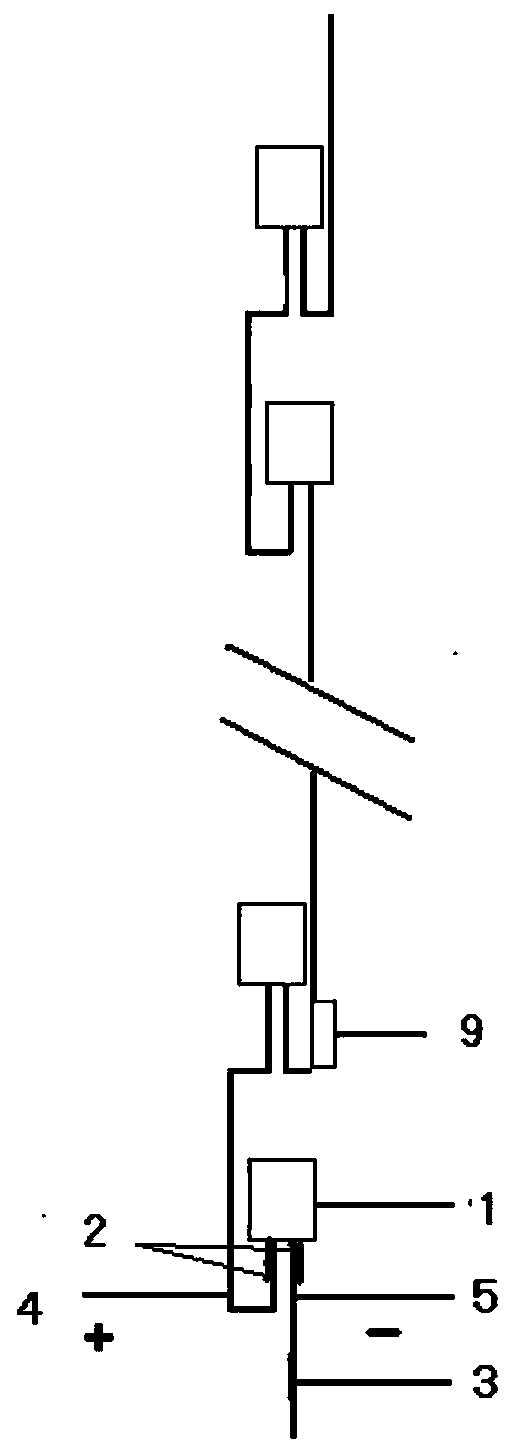

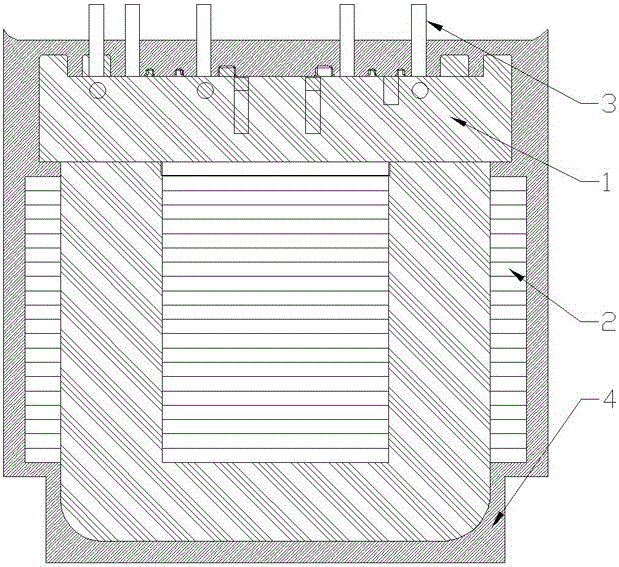

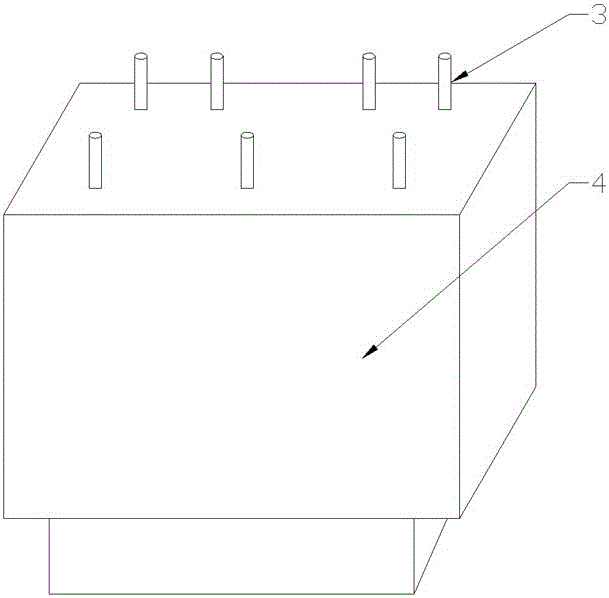

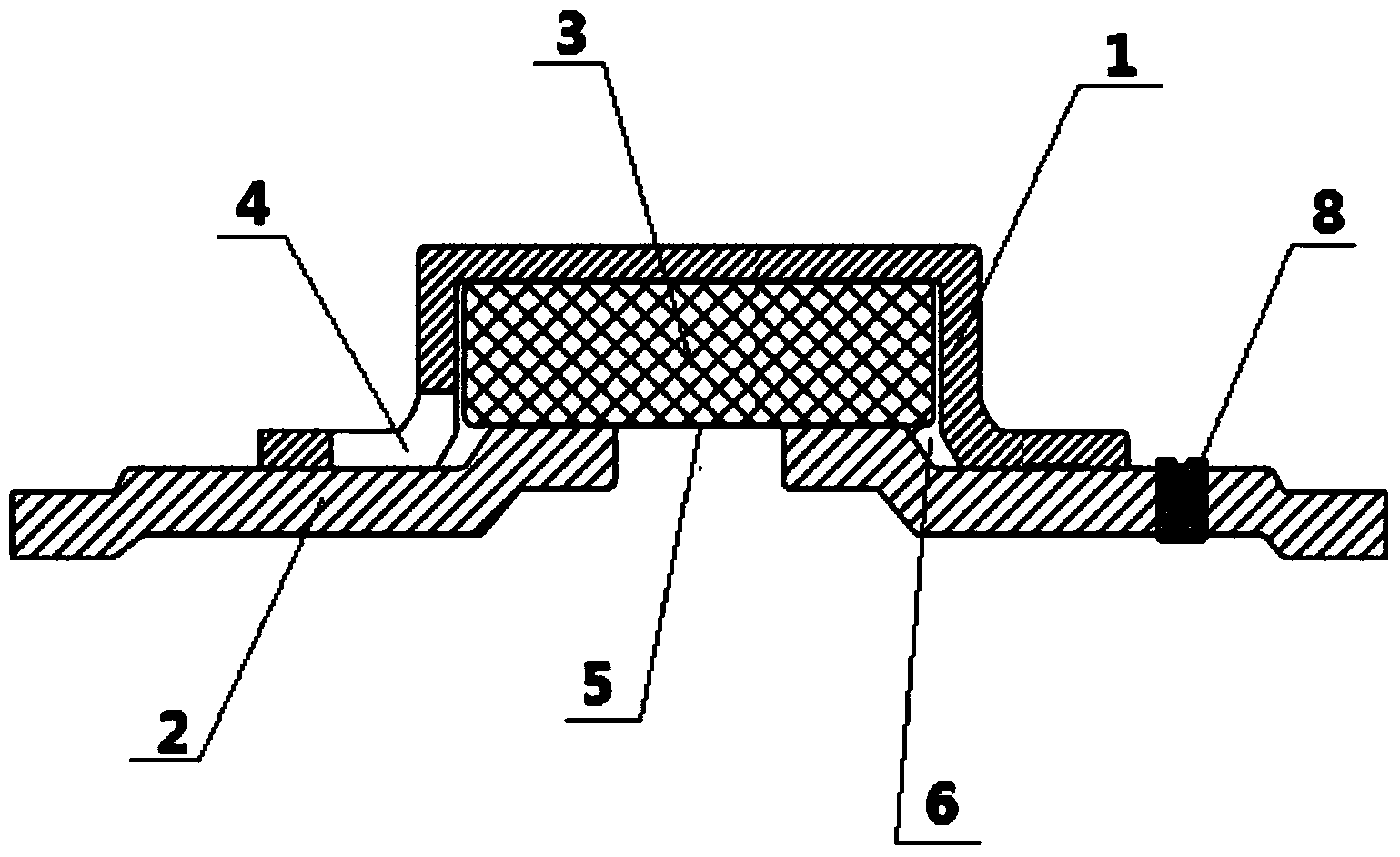

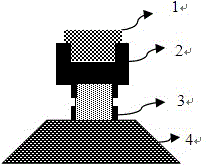

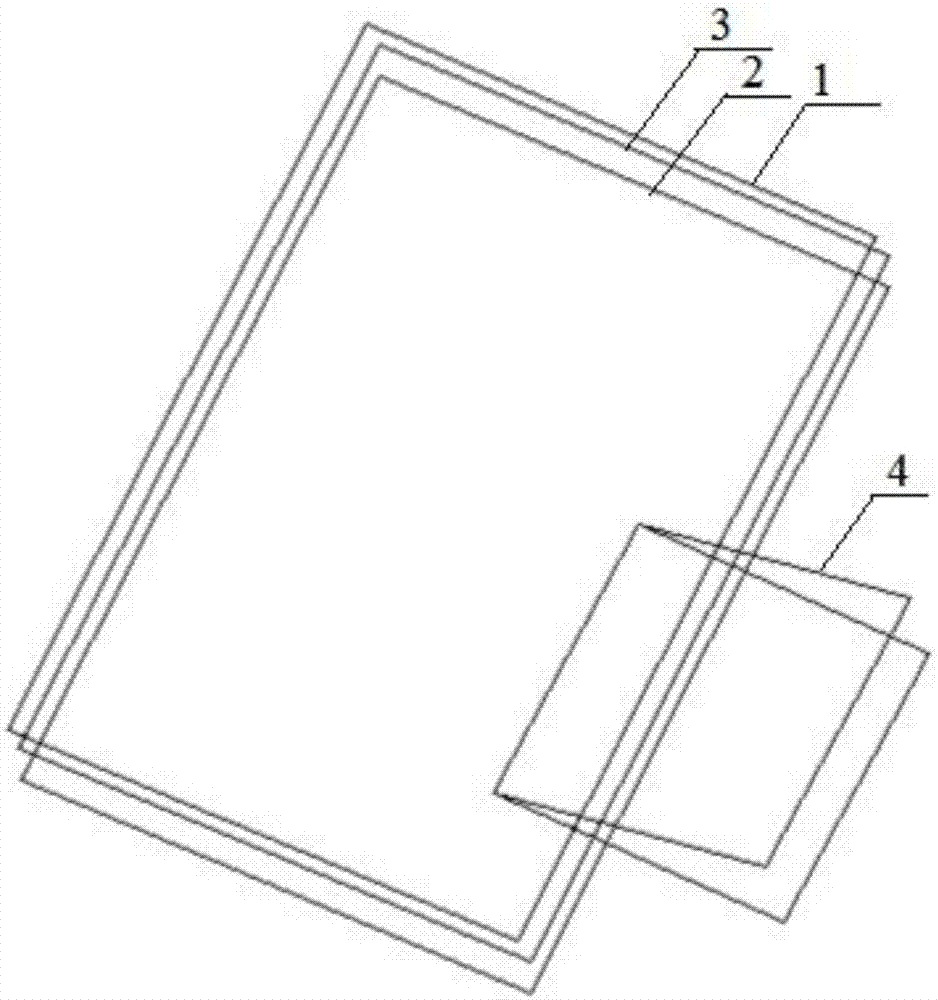

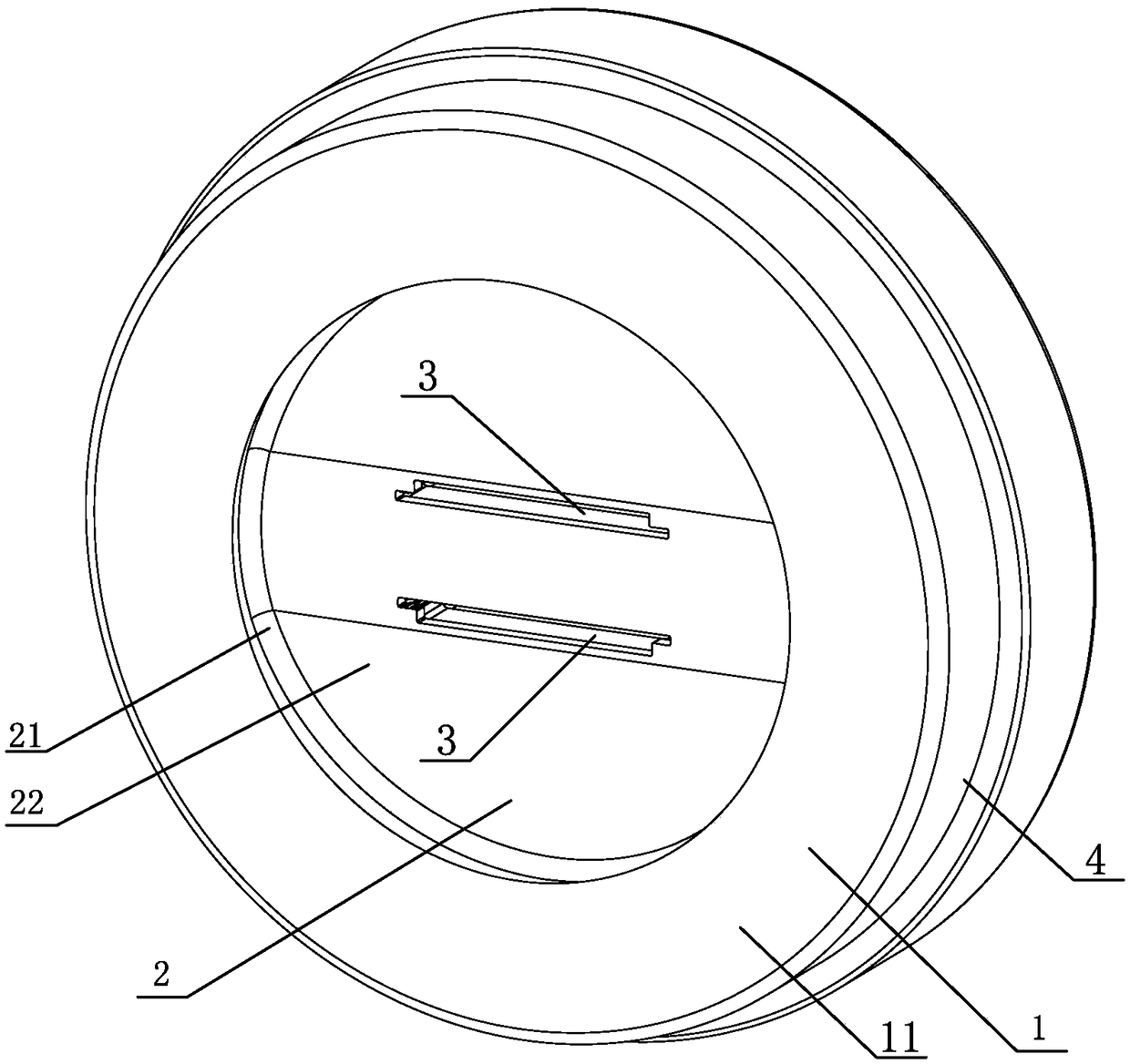

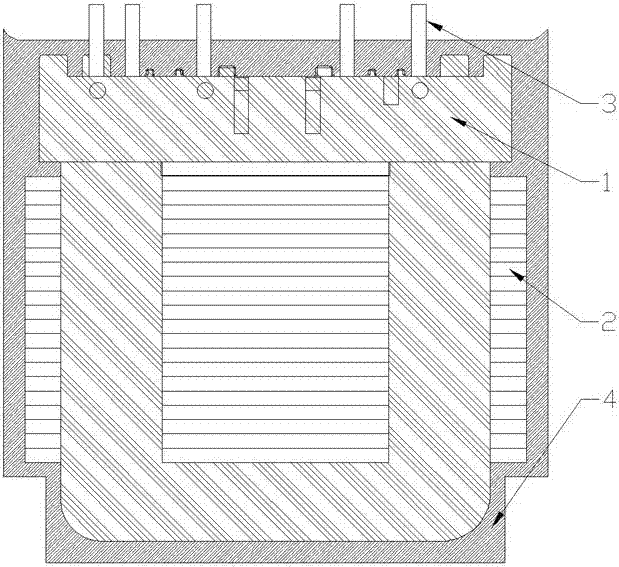

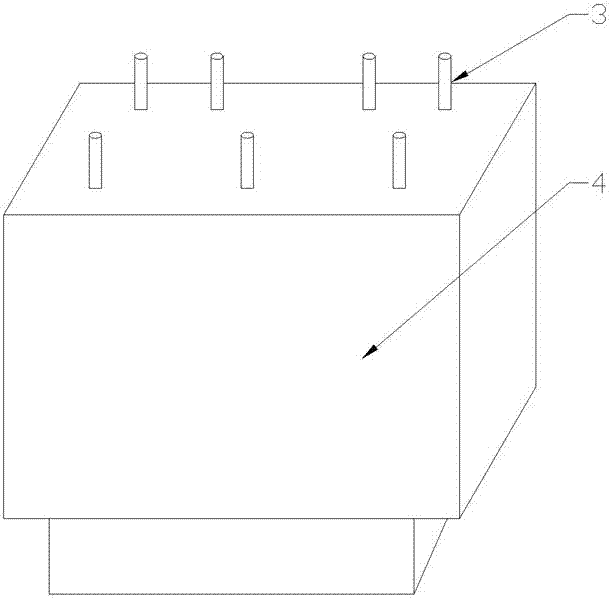

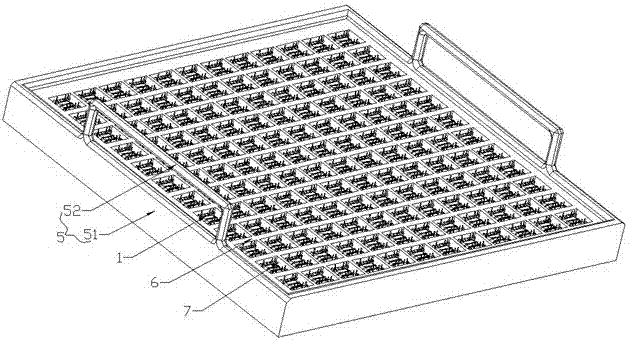

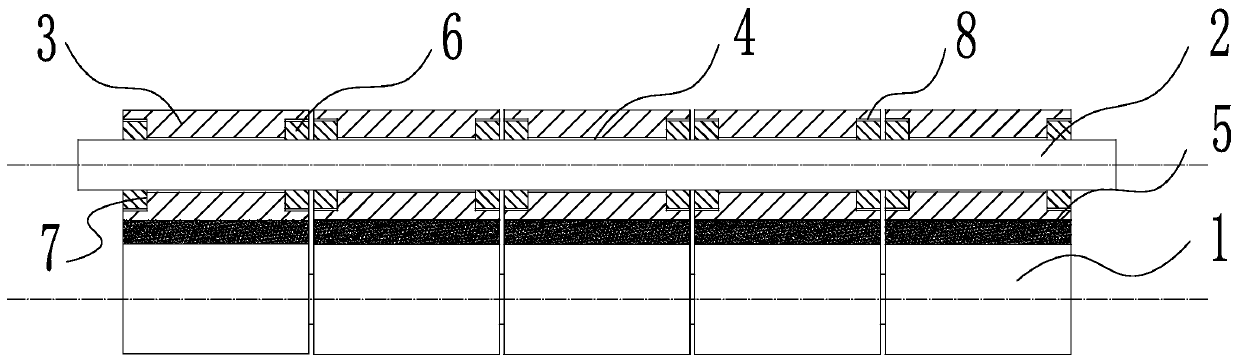

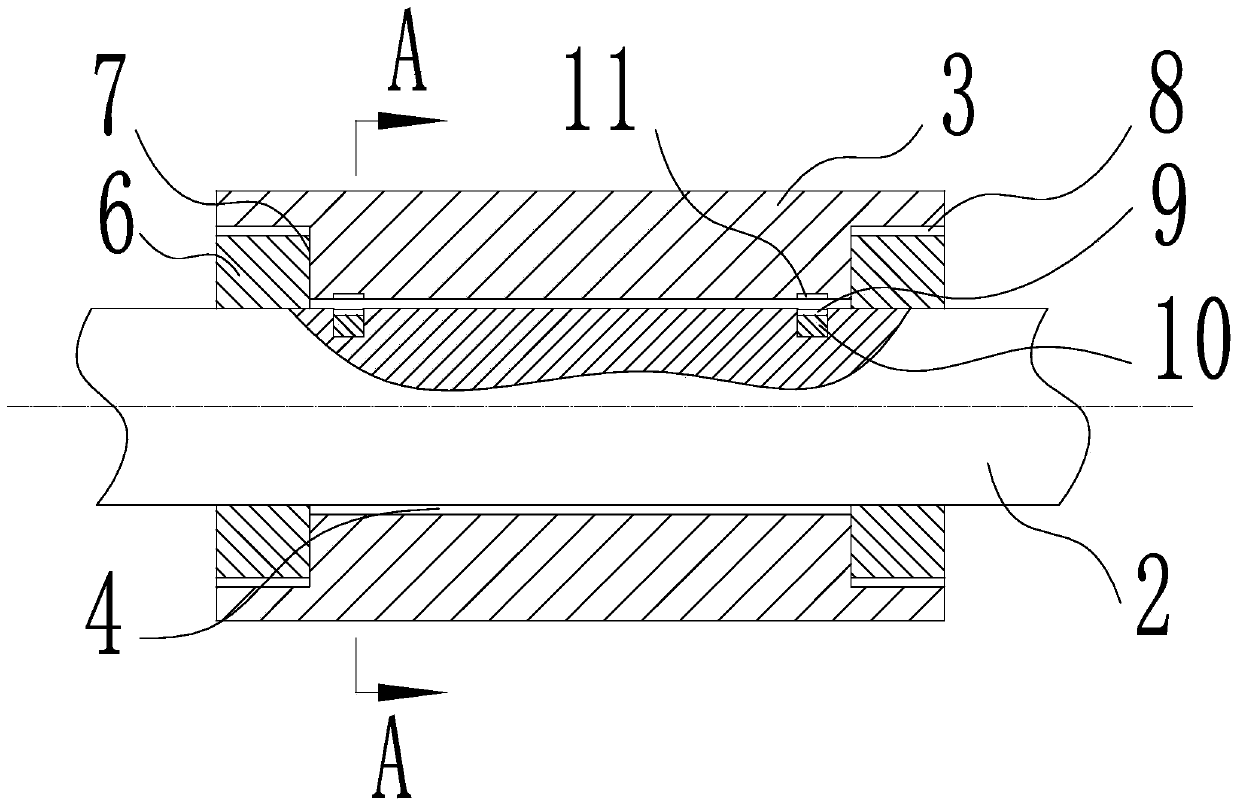

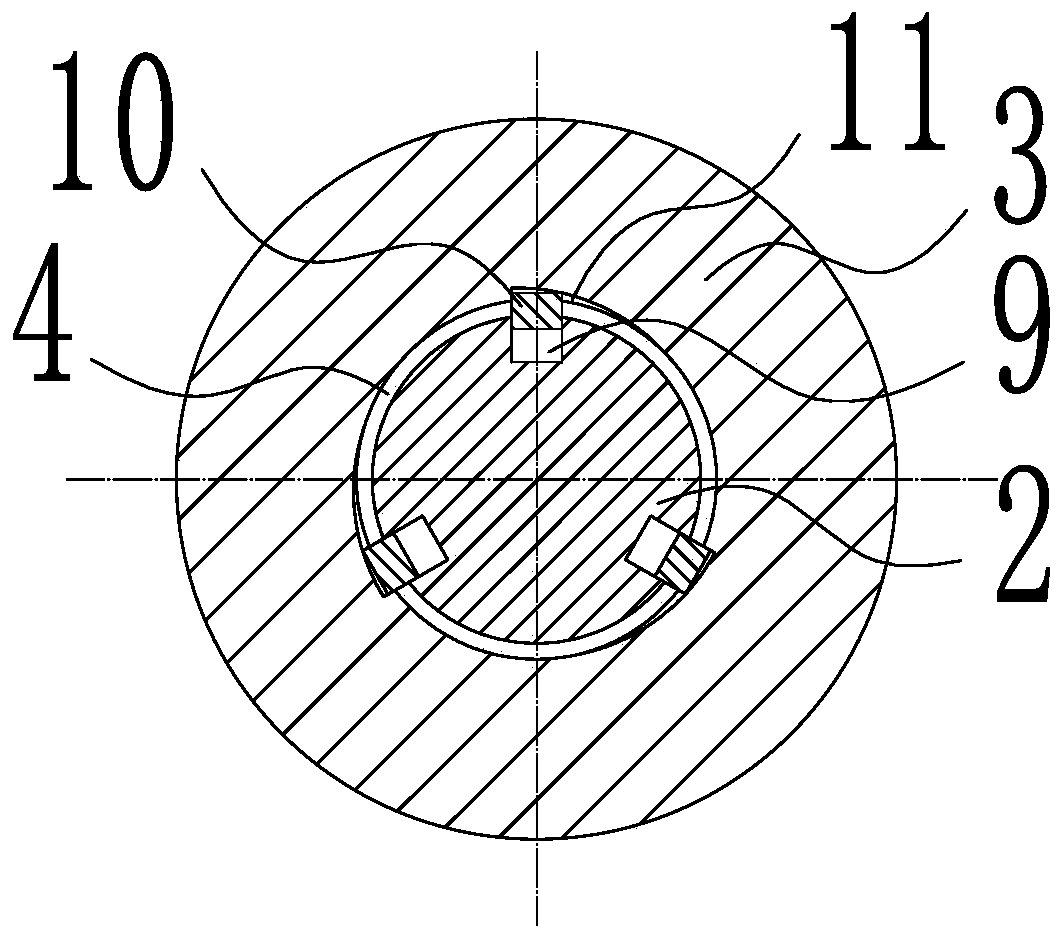

Environment-friendly transformer for potting epoxy resin employing lost-wax process and preparation method of environment-friendly transformer

ActiveCN106449020ASimple structureImprove sealingTransformers/inductances casingsEncapsulation/impregnationEpoxyWax

The invention discloses an environment-friendly transformer with a housing for potting epoxy resin employing a lost-wax process and a method for preparing the environment-friendly transformer; and the environment-friendly transformer is simple in structure, good in sealing effect and high in insulating protection capability and does not pollute the environment. The environment-friendly transformer comprises a transformer body, wherein the transformer body comprises a skeleton (1), a finished coil wound on the skeleton (1) and a silicon steel sheet (2) sleeving the skeleton (1); a plurality of connection pins (3) are arranged on the upper end surface of the skeleton (1); an integrally molded epoxy resin layer (4) coats the periphery of the overall transformer body; and the connection pins (3) are exposed on the epoxy resin layer (4) at the upper part of the skeleton (1). The preparation method comprises the following steps of (a) prefabricating a wax mold; (b) potting the epoxy resin; (c) putting the wax mold into the transformer body; and (d) removing wax and forming the transformer a demolding manner. The environment-friendly transformer can be used for the field of electronic devices.

Owner:珠海市康定电子股份有限公司

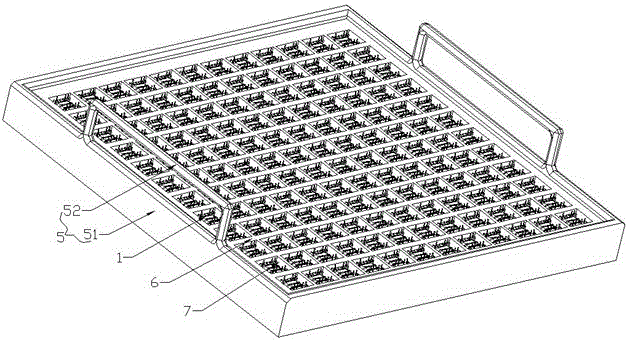

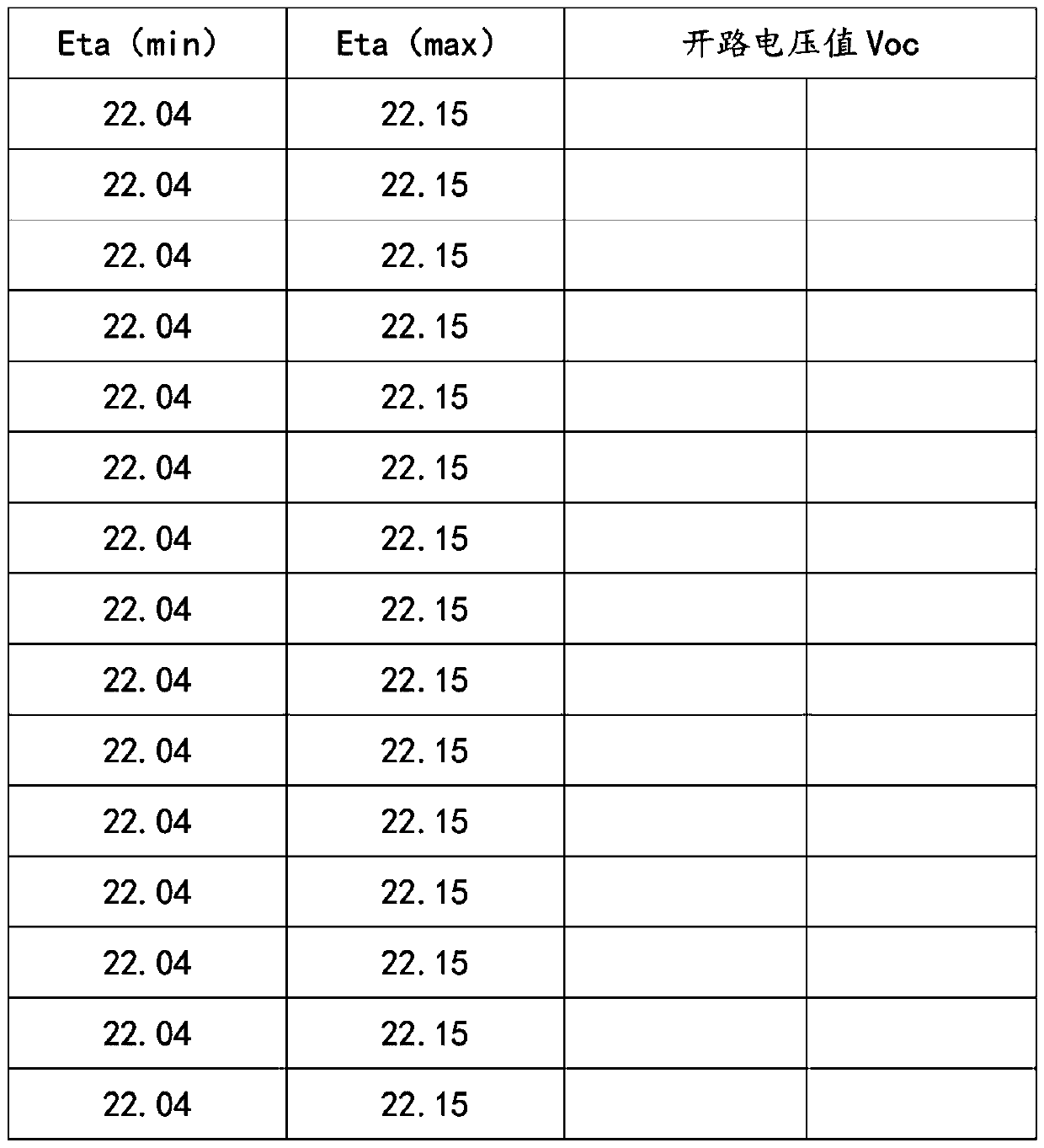

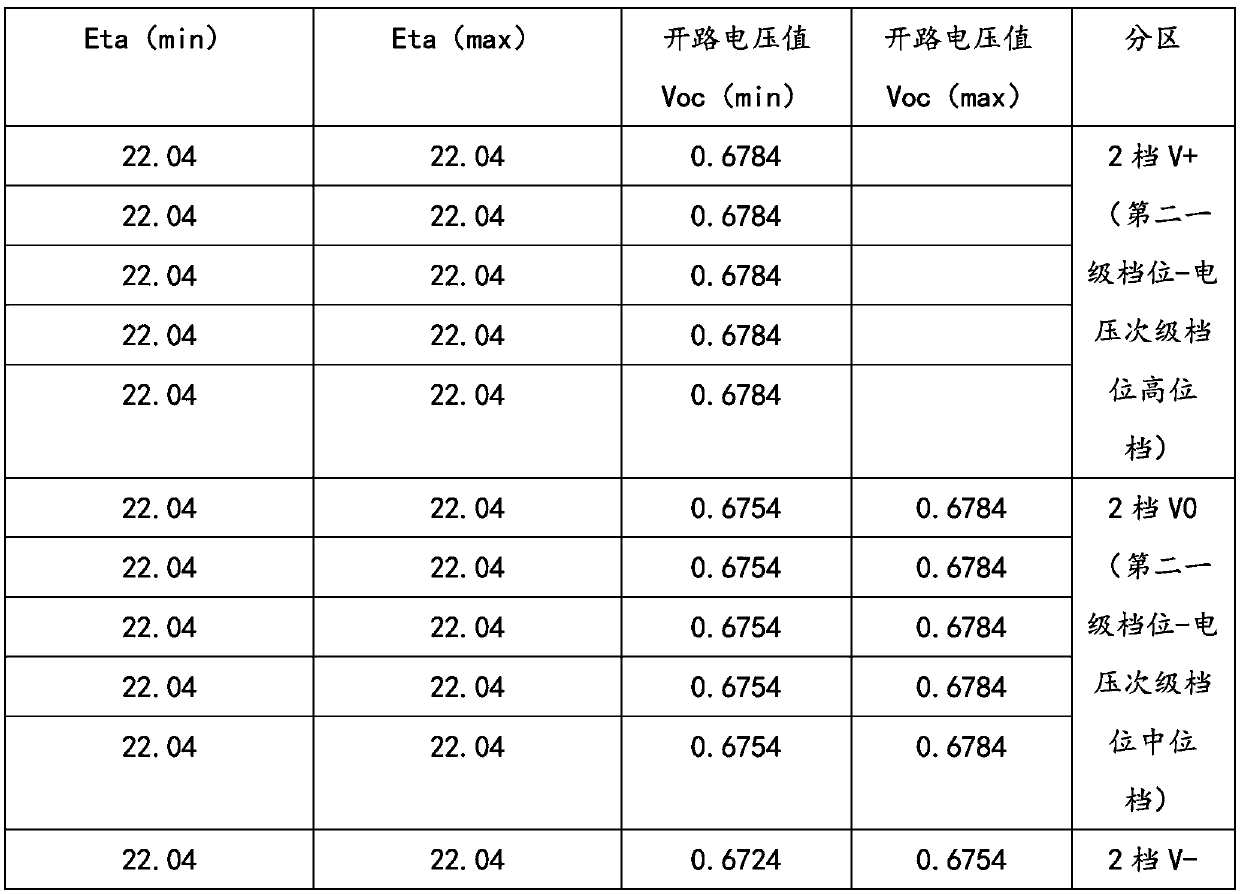

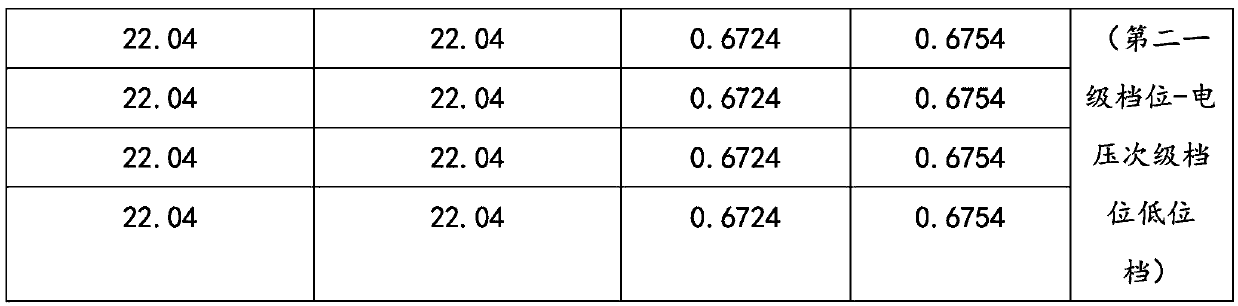

Sorting method for reducing defective proportion of luminance inconsistence of solar cell module

The invention discloses a sorting method for reducing the defective proportion of luminance inconsistence of a solar cell module. According to the method, after coarse grading is conducted based on battery conversion efficiency value in the prior art, then battery pieces in the same battery conversion efficiency value grade are subjected to open-circuit voltage fine grading, or open-circuit voltage fine grading is conducted on battery pieces of the same short-circuit current grade after short-circuit current fine grading is conducted, so that the sorting purposes that the open-circuit voltageof the battery pieces in the same grade is concentrated and high in consistence are achieved, therefore battery pieces with luminance inconsistence and grade mixing under EL can be effectively avoidedat the battery end, so that the defective proportion of the luminance inconsistence under the module EL after module manufacture is reduced, the manufacturing yield of the module is improved, and theoutput power of the module is improved.

Owner:TONGWEI SOLAR ENERGY CHENGDU CO LID

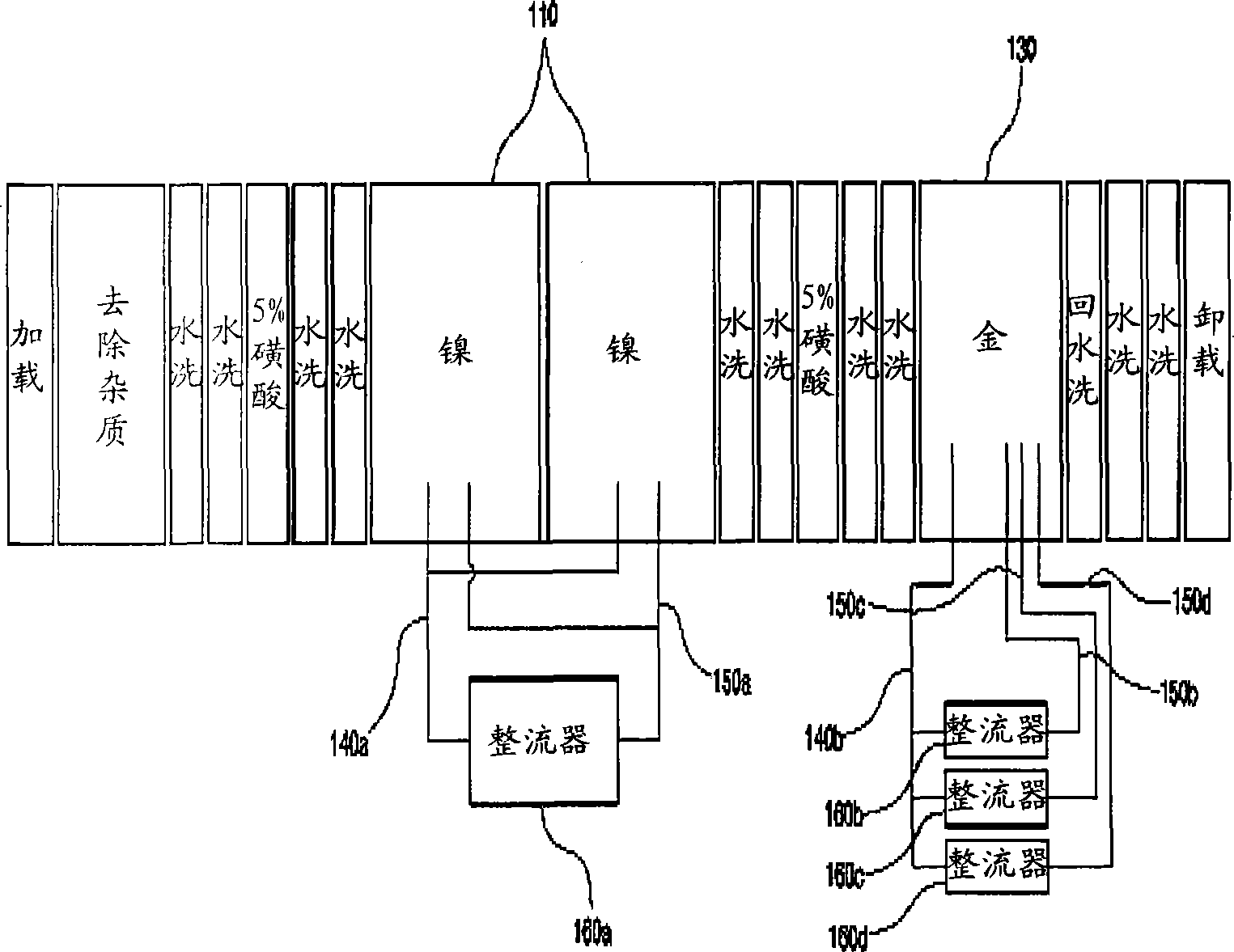

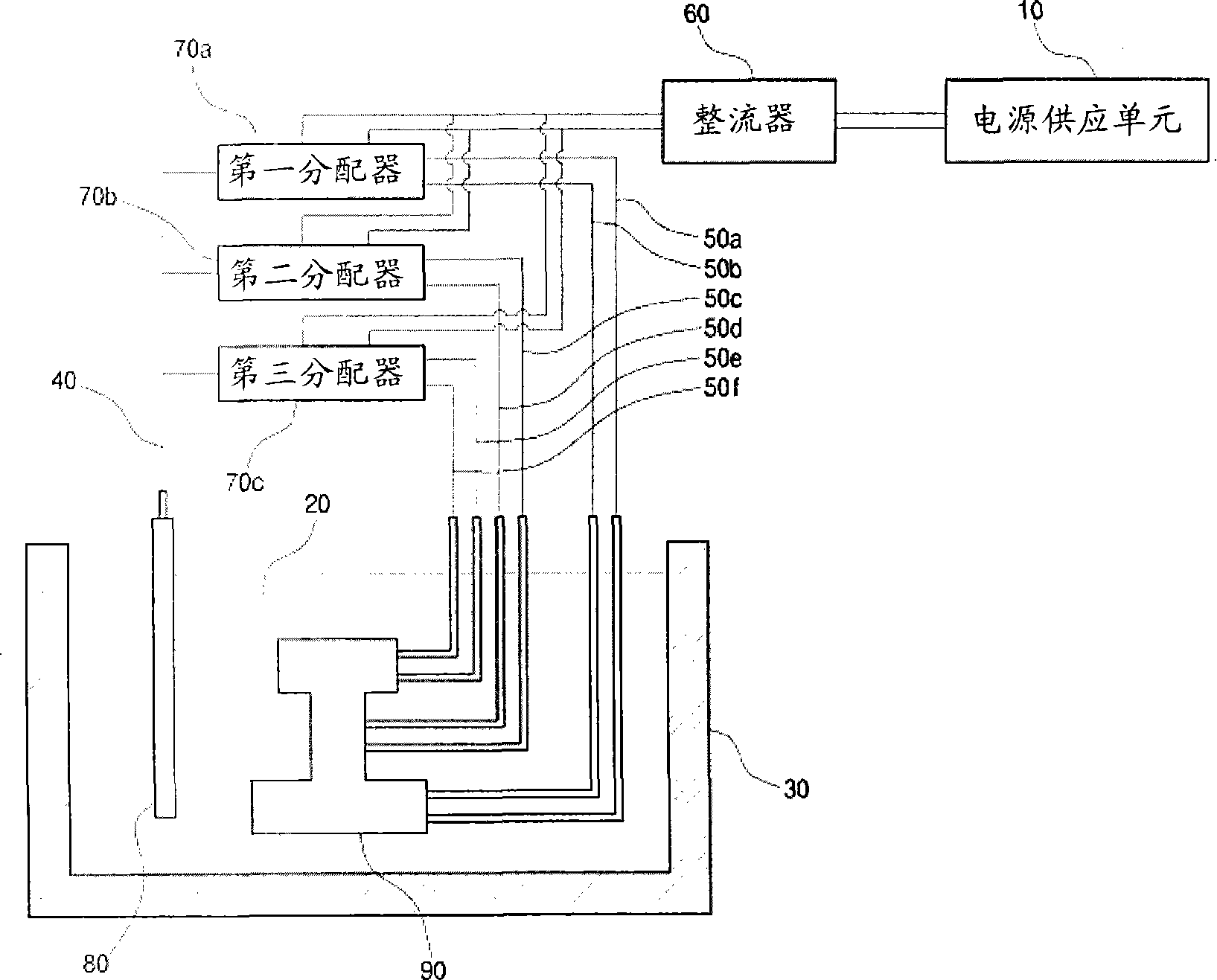

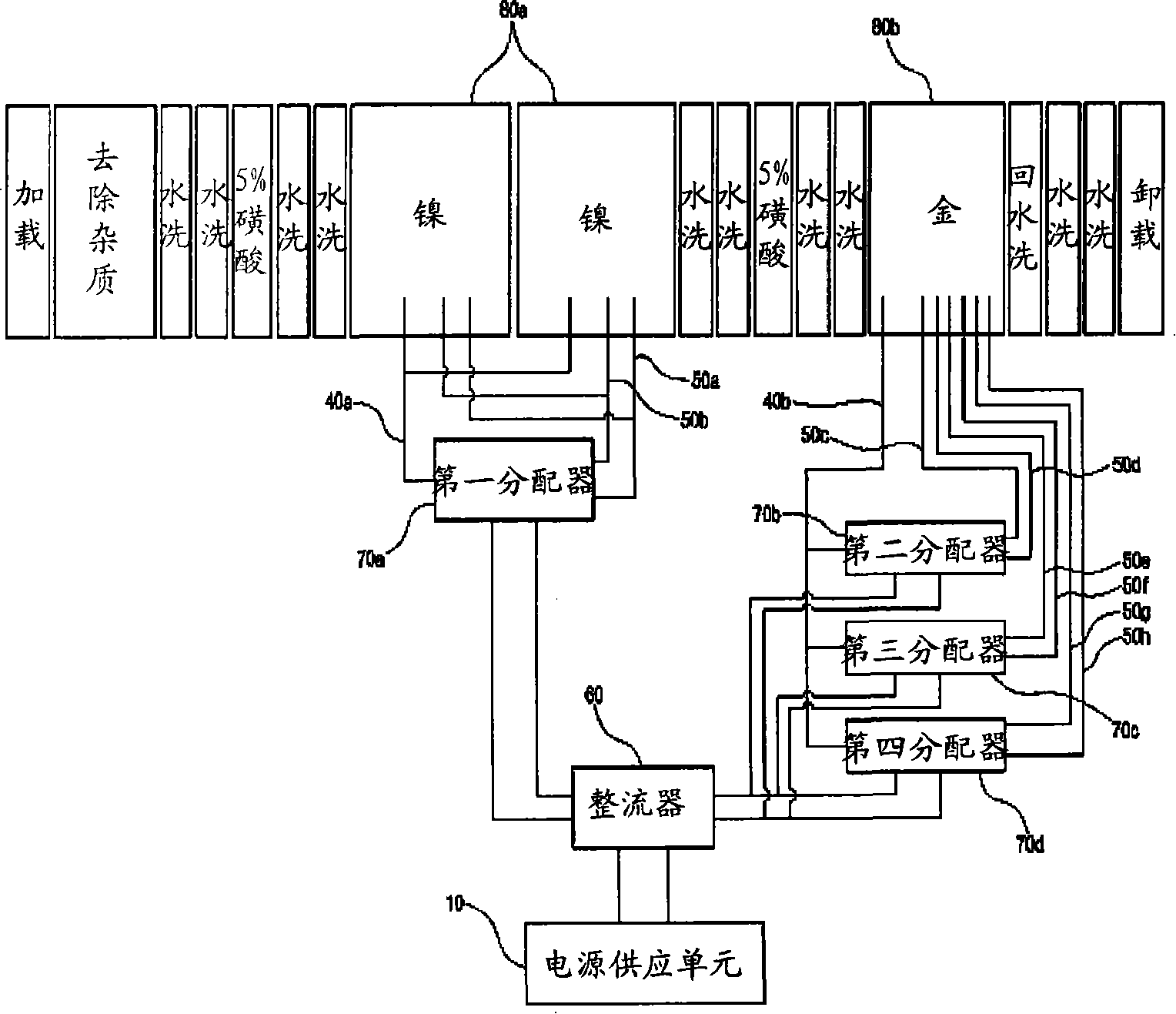

Plating device

The invention relates to a plating device, comprising a power supply unit, an electrolyte for plating, a plating bath including the electrolyte, a positive electrode connected with a plating metal, a negative electrode connected with an electrolyzed object, a rectifier for converting the AC current supplied by the power supplying unit into DC current, and a distributor connected with the rectifier and used for supplying the DC current converted by the rectifier to the positive electrode and the negative electrode. Therefore, the invention has the advantages that the electrolyzed object can be supplied with even current, thereby ensuring the uniformity of the plating film of the electrolyzed object so as to reduce the rate of poor plating; and a plurality of distributors are adopted to reduce the quantity of the rectifier, thereby reducing the overall expense of the plating process.

Owner:辛永议 +3

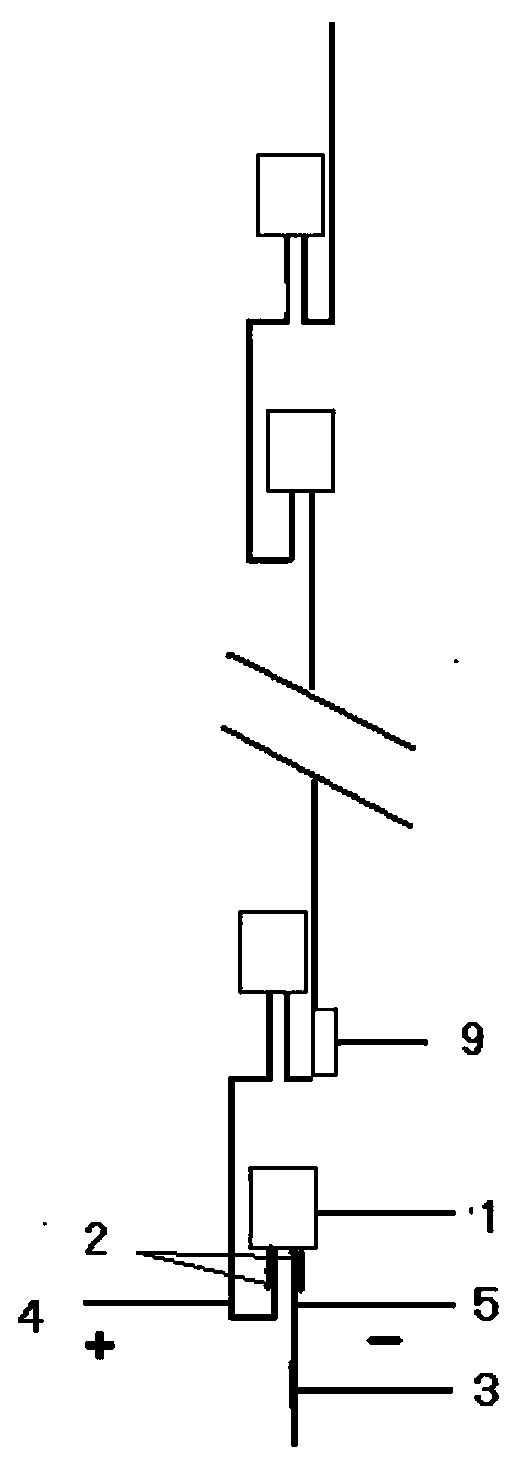

Cover-cap for cylindrical battery and cylindrical battery

The invention provides a cover-cap for a cylindrical battery, which comprises an upper cap, a lower cover and an anti-explosion ball, wherein the upper cap and the lower cover are tightly combined together, at least one exhaust vent is formed in a side edge of the upper cap, an anti-explosion hole is formed in the center of the lower cover, an accommodating space is formed between the upper cap and the lower cover, the anti-explosion ball is arranged in the accommodating space, at least one electrolyte injection hole is formed in a side edge of the lower cover, and the electrolyte injection hole is tightly matched with an electrolyte injection valve to be sealed. The invention further provides the cylindrical battery using the cover-cap. The cover-cap provided by the invention has the advantages that an electrolyte can be added according to the situation through the electrolyte injection hole in the lower cover of the cover-cap, the battery electrolyte injection defect rate is lowered and the scrappage is reduced; after the battery is used after a period of time, the electrolyte injection valve on the electrolyte injection hole is opened for an electrolyte supplement, the internal voltage of the battery is lowered, and the service life of the battery is prolonged.

Owner:YIYANG CORUN BATTERY

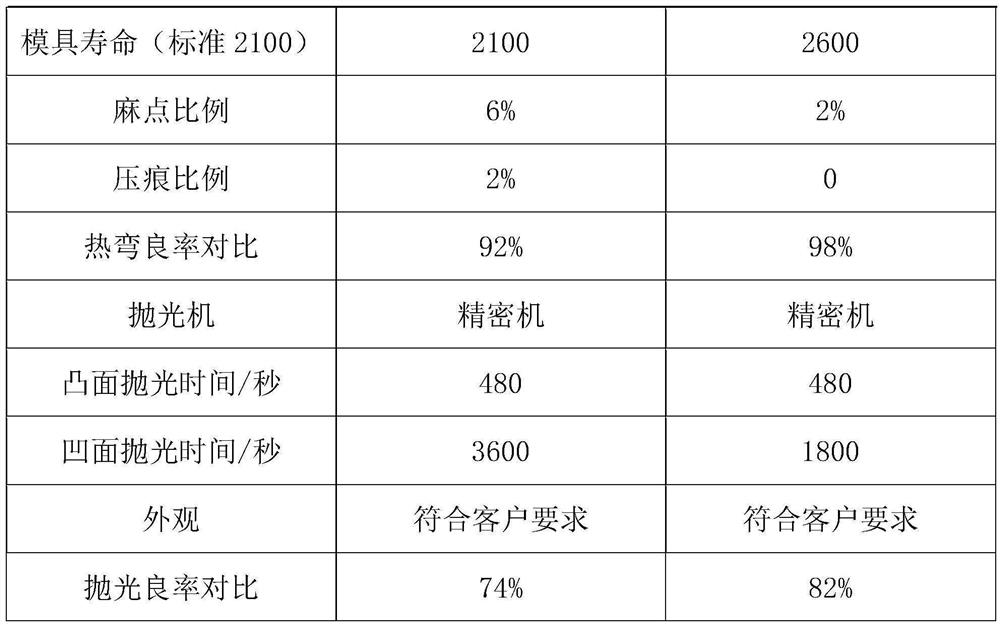

Hot bending protection ink and hot bending polishing process of glass cover plate

InactiveCN113234350AEnsure environmental requirementsProtect cleanlinessInksGlass reforming apparatusGlass coverPrinting ink

The invention relates to hot-bending protective ink and a hot-bending polishing process of a glass cover plate. The protective ink is prepared from the following components in percentage by weight: 45-55% of silicon resin, 5-15% of aluminum oxide, 15-25% of auxiliaries, 5-15% of calcium carbonate and 5-15% of glass powder. According to the hot bending polishing process, hot bending protection printing ink is adopted, so the effect of an interlayer can be effectively achieved, the proportion of concave-convex points is reduced, mold damage is reduced, the service life of a mold is prolonged, the polishing capacity is improved, the proportion of poor polishing is reduced, and cost is saved.

Owner:DONGGUAN RBD TECH

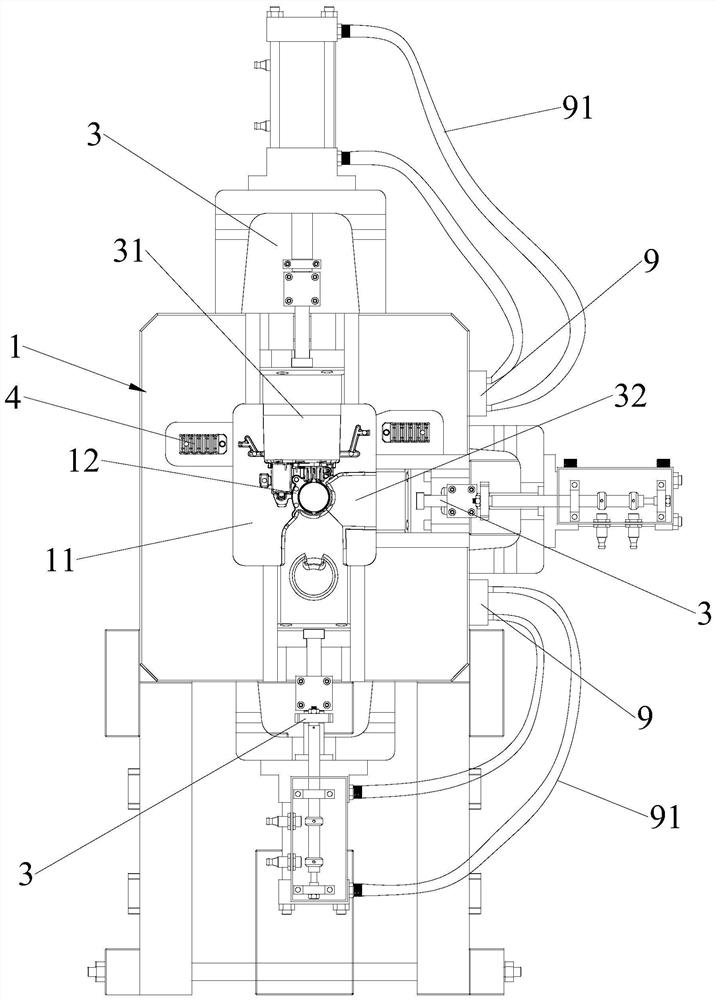

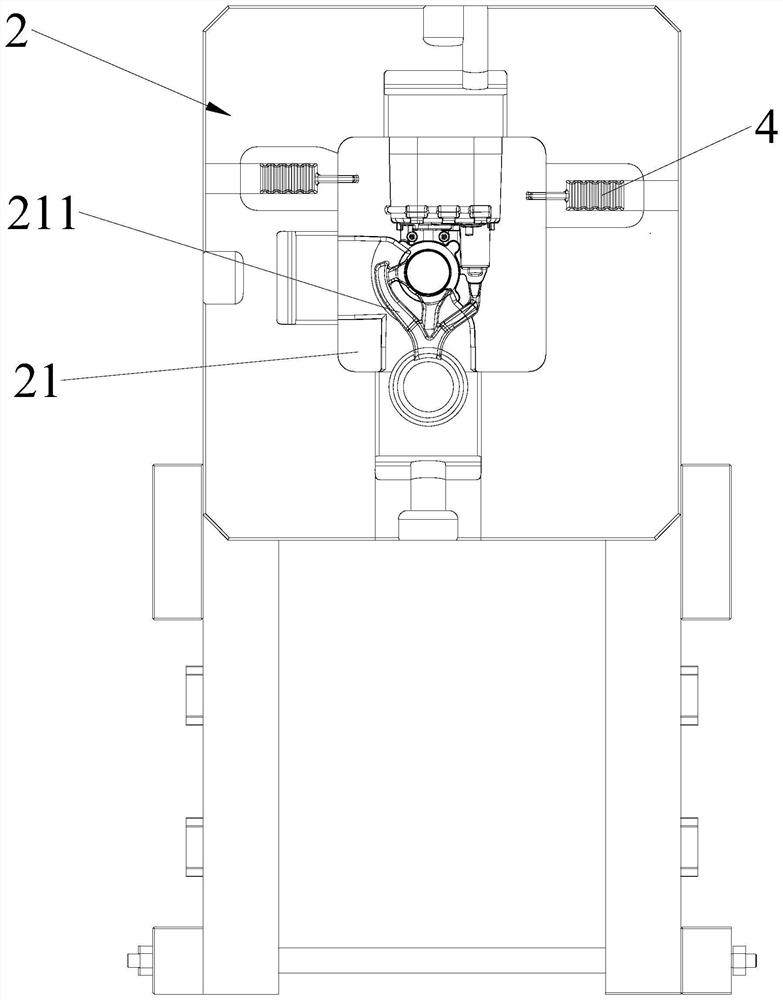

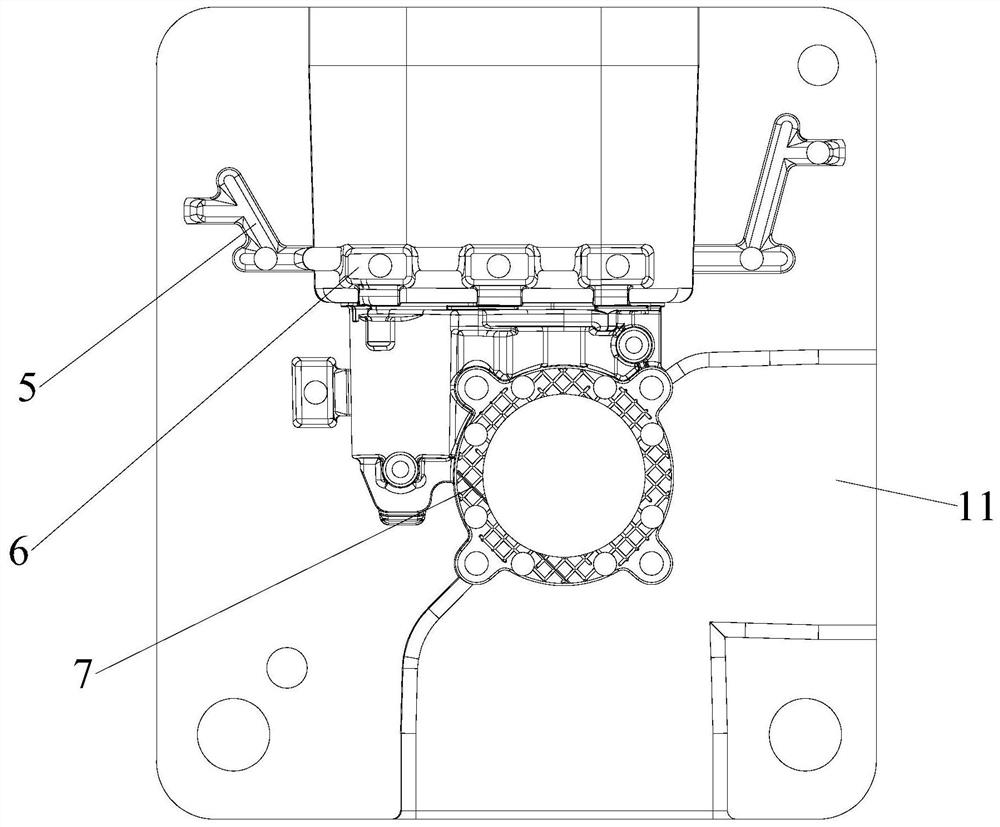

Throttle valve die-casting die and manufacturing method thereof

PendingCN114769557AExhaust function optimizationReduce the proportion of bad poresProcess efficiency improvementEngineeringThrottle

The invention discloses a throttle valve die-casting die which comprises a movable die body, a fixed die body and a plurality of core pulling mechanisms. The plurality of core pulling mechanisms are respectively connected with the fixed mold core and the movable mold core; the fixed mold is provided with a sprue bush located below the fixed lining mold, and the movable mold is provided with a sprue spreader located below the movable lining mold and matched with the sprue bush; the fixed lining die is provided with a plurality of feeding channels connected with the sprue spreader and the forming cavity; the movable mold and the fixed mold are both provided with exhaust blocks connected with the forming cavity, the movable lining mold and the fixed lining mold are provided with a plurality of overflow grooves connected with the forming cavity and the exhaust blocks, the end face, facing the fixed mold, of the movable lining mold is evenly provided with net-shaped gas collecting grooves, and the circumferential face of the fixed mold core is provided with a plurality of vertical gas collecting grooves. According to the injection mold, the net-shaped gas collecting groove is formed in the lining mold, the vertical gas collecting groove is formed in the mold core, and the mode that the slag ladle is connected with the exhaust block is matched, so that the exhaust function of the mold is optimized, and the ratio of poor air holes caused by gas wrapping in the injection process is effectively reduced.

Owner:ZHANJIANG DENI VEHICLE PARTS

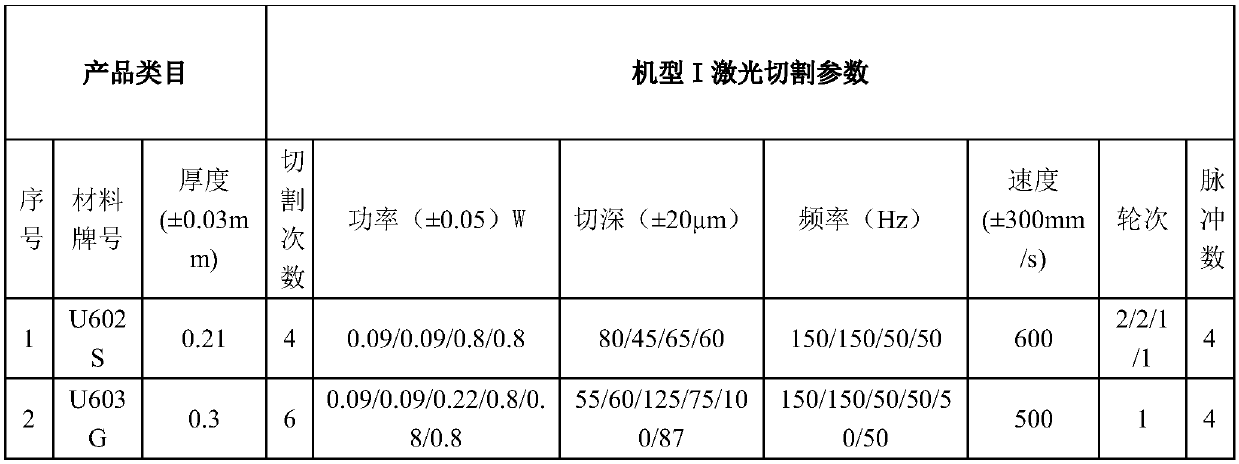

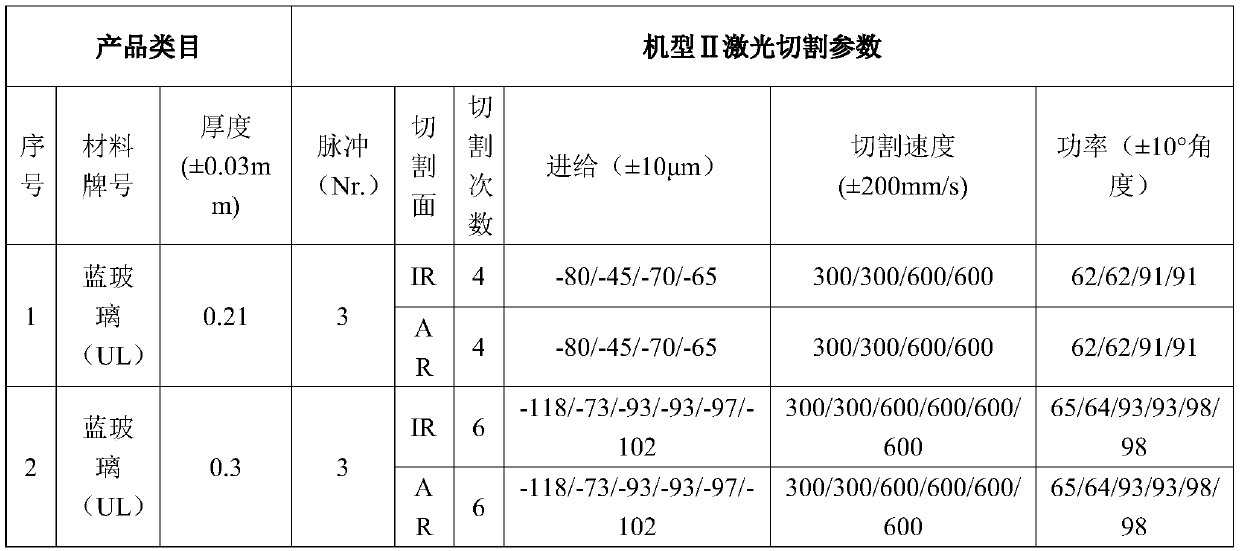

Phosphate glass laser cutting process

ActiveCN109623175ASolve the phenomenon of uneven intensity of different surfacesGuaranteed chemical stabilityLaser beam welding apparatusLaser cuttingPhosphate glass

The invention discloses a phosphate glass laser cutting process. The process comprises the following steps that (1), the position of a cutting section is enabled to be centered by adjusting laser cutting parameters; (2) in the centered cutting layer position, small-power laser is used for dotting; and (3), proper power is used for normal cutting. According to the phosphate glass laser cutting process, the laser cutting parameters are set, so that the product is cut into a good cutting section (the cutting layer is centered, and extension lines are controlled to be within 30 microns) and planeeffect, so that the problem that the strength of different surfaces of a glass sheet is uneven due to the fact that the cutting effect of a traditional cutting section is not centered is solved.

Owner:UNIONLIGHT TECH

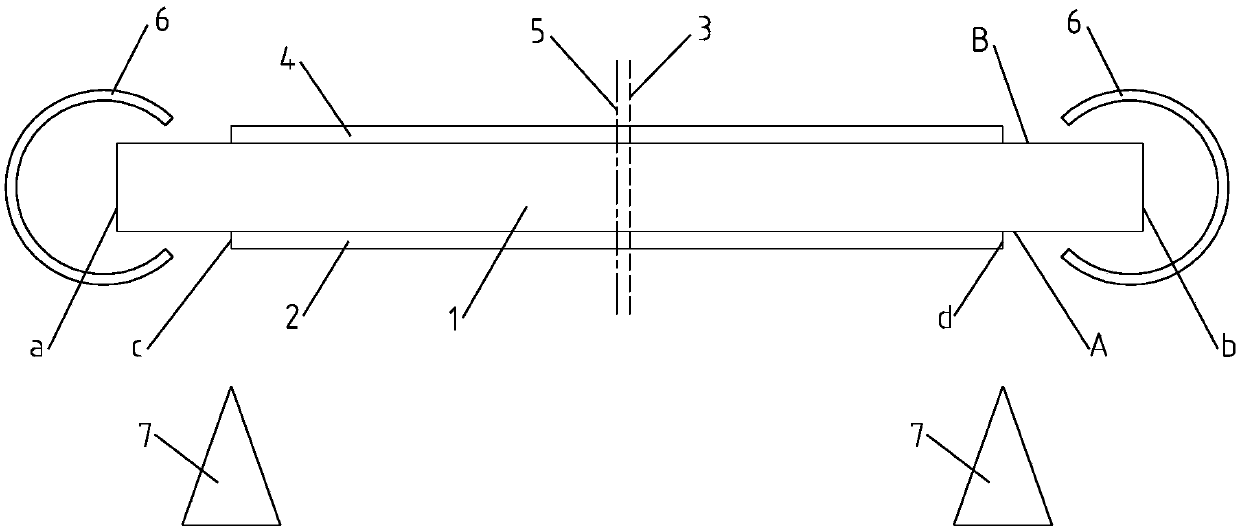

Method for scrubbing silk-screen printing and classification inspection conveyor belt

InactiveCN104475373AReduce bad ratioControl cleaning cycleCleaning using toolsScreen printingEngineering

The invention discloses a method for scrubbing a silk-screen printing and classification inspection conveyor belt. The method involves a device comprising four parts, namely, a base, a screw rod, a sponge block and a sponge clamping groove; the sponge block and the sponge clamping groove are mounted on a stand and under the belt through the screw rod and the base; the belt is automatically transmitted and rubbed against the sponge to be scrubbed, so as to achieve the online cleaning mode. The method has the beneficial effects that reject ratio of the surface of a battery piece caused by dirt on the belt can be reduced, the cleaning cycle of the belt can be effectively controlled, the scrubbing can be performed all the time without shutdown, the operation is convenient and controllable, and therefore, the device maintenance time is reduced, and the output is increased.

Owner:ZHEJIANG FORTUNE ENERGY

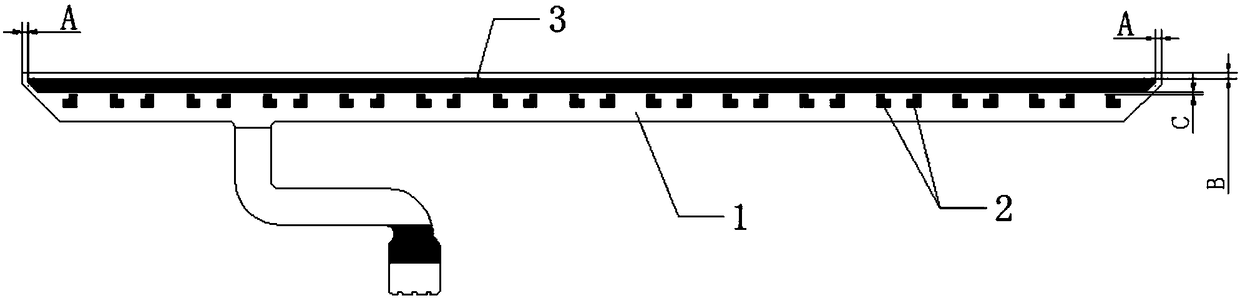

FPC plate of backlight source

The invention discloses an FPC plate of a backlight source. The FPC plate includes an FPC plate body, multiple welding discs are arrayed on the FPC plate body from left to right in sequence, and a strip-shaped white oil layer extending horizontally is formed on the front surface of the FPC plate body through a silk-screen printing process; gaps A are positioned between the left end of the white oil layer and the left border of the FPC plate body and between the right end of the white oil layer and the right border of the FPC plate body, a gap B is positioned between the upper end of the whiteoil layer and the upper border of the FPC plate, and gaps C are positioned between the lower end of the white oil layer and the welding discs. According to the technical scheme, the reject ratio of backlight can be effectively reduced, the consumption of white oil is reduced, the cost of an FPC is reduced, the probability of generation of black and white spots and light spots due to falling of white oil shreds is decreased, and the effects of increasing the product yield and reducing the cost are achieved. Moreover, the falling white oil shreds can also be bonded to the FPC plate body within the coverage range of the FPC plate and are prevented from entering a VA area and then causing generation of the black and white spots and the light spots, and therefore not only is the illumination effect of backlight not damaged, but also the product yield can also be increased.

Owner:JIANGXI HOLITECH TECH

Secondary defoaming device and secondary defoaming method

InactiveCN107351505AReduce bad ratioAvoid lossLaminationLamination apparatusMechanical engineeringWorking hours

The invention discloses a secondary defoaming device. The secondary defoaming device comprises a first cover plate, a second cover plate and a clamp, wherein the first cover plate is arranged above the front surface of a touch product; the second cover plate is arranged under the back surface of the touch product; the clamp is used for clamping the first cover plate and the second cover plate; the clamp consists of an upper clamping sheet and a lower clamping sheet, one end of the upper clamping sheet is movably connected with one end of the lower clamping sheet, the other end of the upper clamping sheet is clamped onto the upper surface of the first cover plate, and the other end of the lower clamping sheet is clamped onto the lower surface of the second cover plate. The invention also provides the secondary defoaming method. The secondary defoaming device has the beneficial effects that by using the auxiliary device before secondary defoaming, the ratio of poor air bubbles, such as dot-shaped air bubbles and edge air bubbles which are difficult to eliminate, is reduced; the excessive detaching and consumption of materials can be avoided, the working loss is reduced, and the amounts of supplemented materials and work hours are reduced; the number of delivered products is increased, and the lack of delivery number is avoided.

Owner:CHANGSHA YUSHUN DISPLAY TECH +3

Driving device of LED tube

ActiveCN103379705BReduce design difficultyReduce design costElectric light circuit arrangementEnergy saving control techniquesLiquid-crystal displayElectromagnetic interference

The invention discloses a driving device of an LED tube. The method that a first direct-current voltage which can provide the working voltage of each LED light string of the LED tube is directly output by an AC-DC converter is applied to the driving device of the LED tube. The defects that after an existing AC-DC converter outputs a low direct-current voltage, a DC-DC boost converter is further needed so as to generate a high direct-current voltage which can be provided for the LED light string to enable the LED light string to work in the prior art are overcome. The driving device of the LED tube can reduce generated electromagnetic noise so as to reduce the design difficulty and the design cost of a needed electromagnetic noise interference suppression circuit. The driving device of the LED tube can further reduce the defect ratio of liquid crystal display products which are provided with the driving devices of the LED tubes in a factory and on the market so as to reduce the design cost of power sources of the liquid crystal display products. In addition, due to the fact that the existing DC-DC boost converter is not applied, a constant-current control circuit is adopted to ensure that each LED light string is in the constant-current state in the process of working. Besides, control over opening and closing of the constant-current circuit is used for controlling the average brightness provided by the LED tube. When the LED tube works and the detected voltage of the output end of the LED tube is larger than a protection point set valve, a dimming output port of the control circuit outputs a continuous low level signal to stop normal work of the constant-direct control circuit, the LED tube is finally switched off, and the purpose of protection is achieved.

Owner:TPV ELECTRONICS (FUJIAN) CO LTD

A kind of MWT component conductive adhesive rating test method

ActiveCN109827645BAccurately calculate lossReduce manufacturing costWeighing apparatus for materials with special property/formProduction lineTest sample

Owner:JIANGSU SUNPORT POWER CORP LTD

Lithium battery coating method

ActiveCN109659489AImprove end-face alignmentReduce width defect rateElectrode rolling/calenderingLiquid surface applicatorsEngineeringReference line

The invention discloses a lithium battery coating method. The method comprises the steps of: when the A side of a base material layer is coated with a first active material layer, error correction isperformed on transportation of the base band by taking a first error correction reference line as the transportation central line through a first error correction device, wherein the first correctionreference line is the central line of the base material layer; and when the B side of the base material layer is coated with a second material layer, error correction is performed on the transportation of the base band coated with the first active material layer by taking a second error correction reference line as the transportation central line through a second error correction device, wherein the second correction reference line is the central line of the first active material layer. According to the invention, alignment degree of end faces of active materials of the two faces of the base material layer can be improved; coating tolerance is reduced; process capability of negative electrode edge ceramic width is improved; defective ratio is reduced; and safety performance of lithium battery products is improved.

Owner:UNITED AUTO BATTERY CO LTD

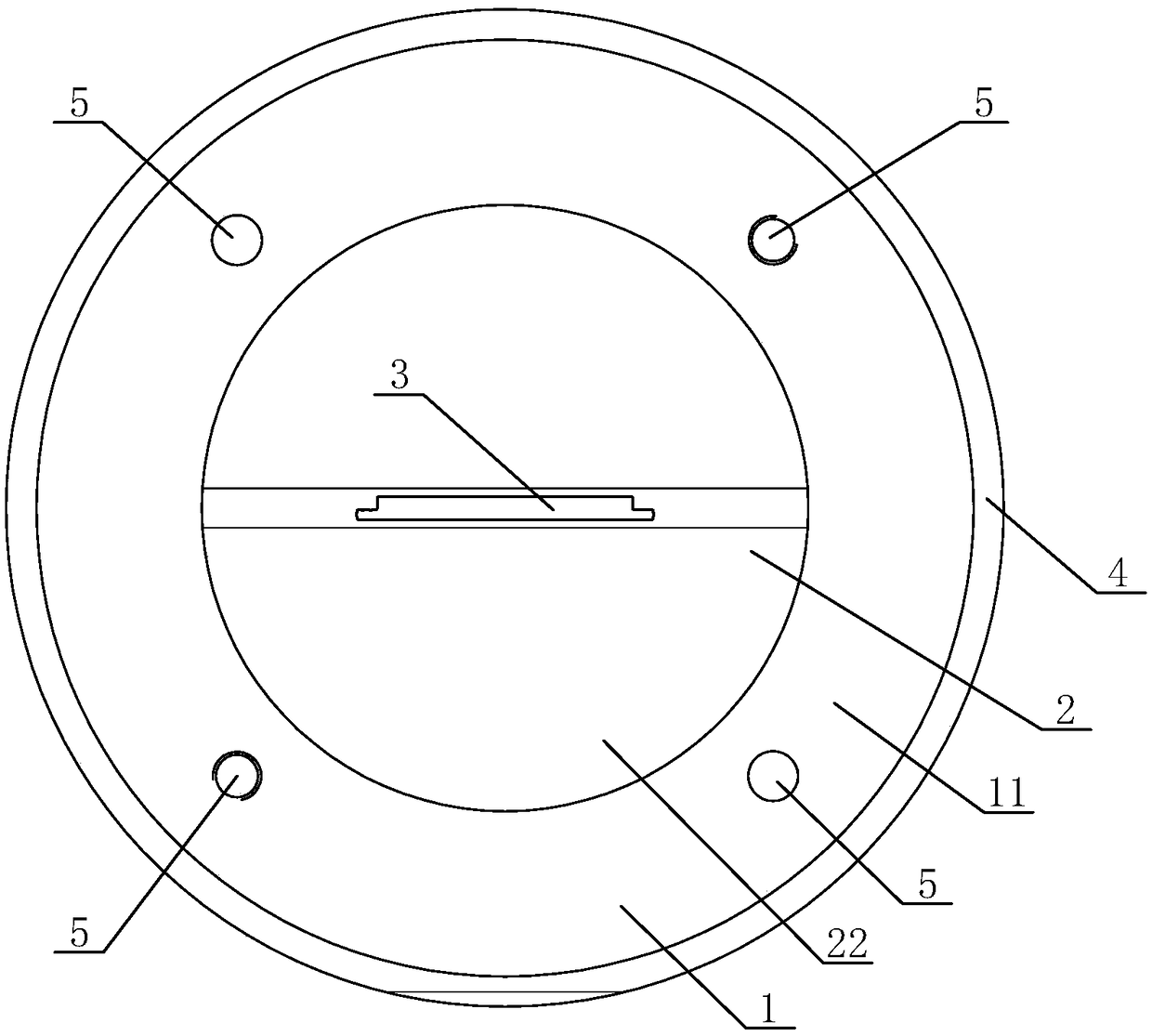

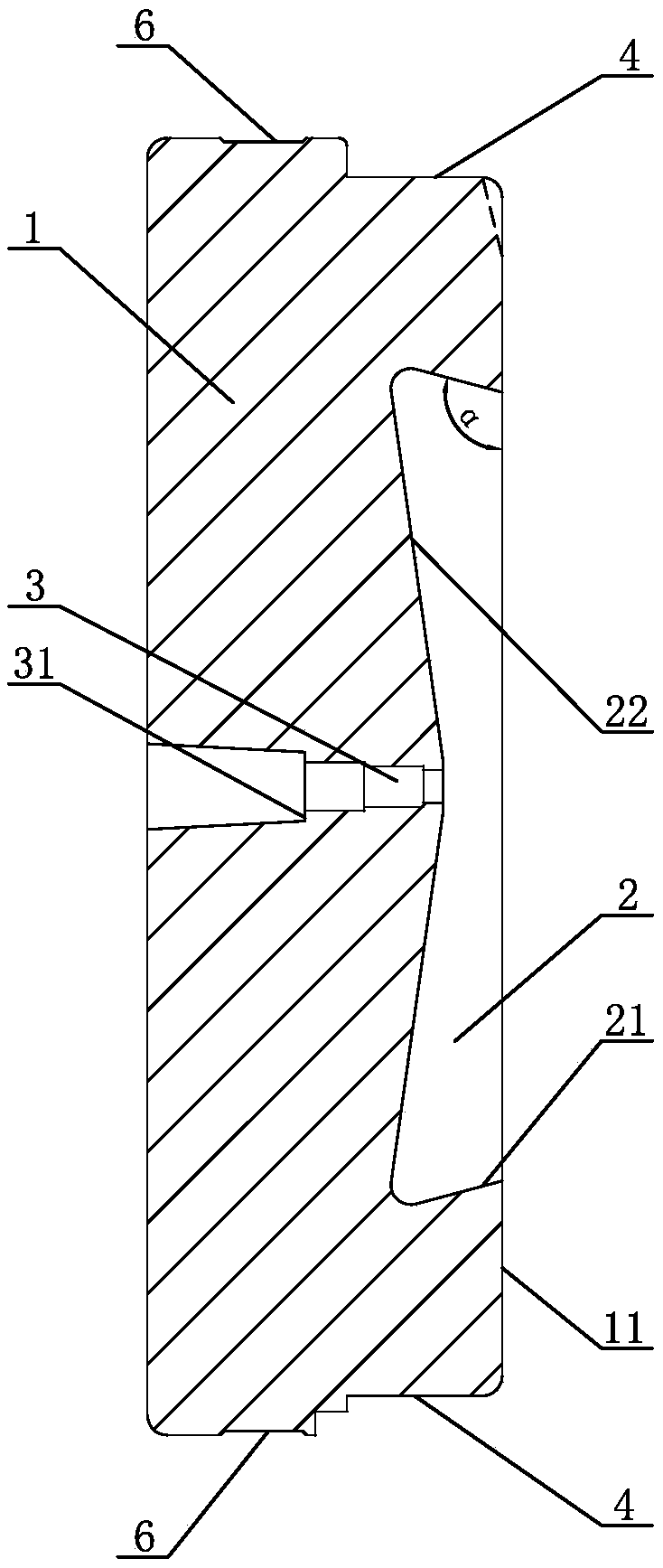

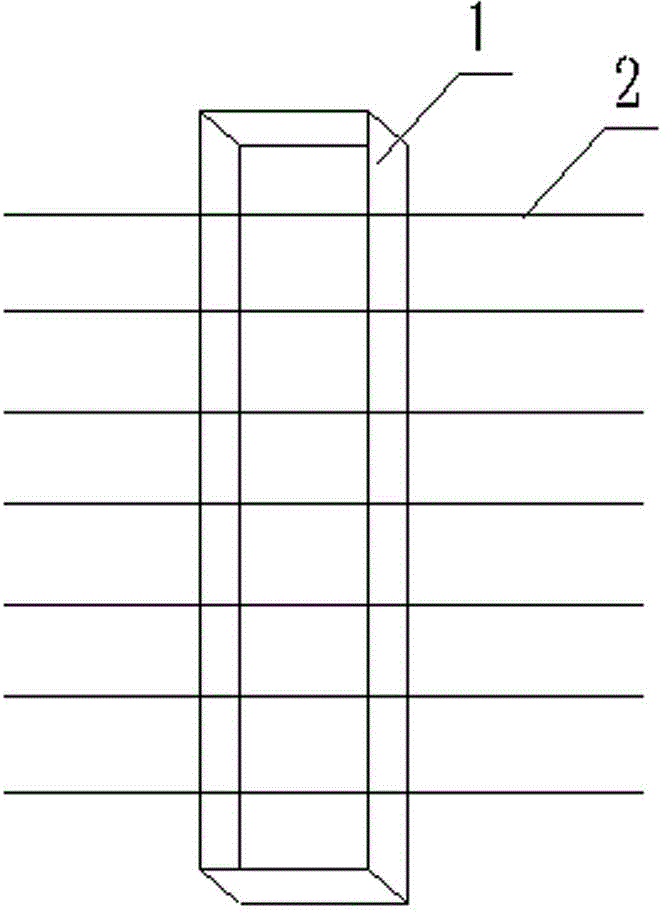

Mold for profiles with high surface requirements and using method thereof

The invention discloses a sectional material mold with high surface requirements. The sectional material mold comprises a mold body and feeding grooves formed in the mold body. The mold body is further provided with at least one molding cavity communicating with the feeding grooves, the included angle alpha between the side face of each feeding groove and the front end face of the mold body is larger than 90 degrees, and the bottom face of each feeding groove is in the shape with the high middle and the low periphery. The invention further discloses a using method of the sectional material mold with the high surface requirements. The method comprises the steps that 1, a spigot of the mold body and an extruder are assembled together; 2, the mold is fixed and accurately positioned through positioning pins; 3, raw materials are placed in the feeding grooves; and 4, the raw materials are continuously extruded and molded from the molding cavities under the extrusion effect of the extruder. Due to the design, the problem that raw material skin defect tissue flows into an extruded product during extrusion is solved, the extruded sectional material surface quality is improved, the ratio of rejection caused after oxidization is lowered, the workpiece yield is improved, and the cost of a single product is reduced.

Owner:GUANGDONG HOSHION IND ALUMINUM CO LTD

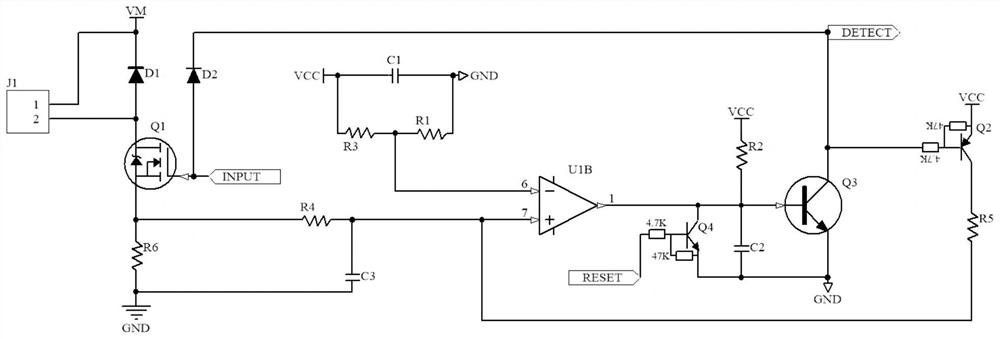

Short-circuit protection circuit for load of massage chair

InactiveCN113381377AAvoid damageReduce security risksArrangements responsive to excess currentPhysical medicine and rehabilitationMassage

The invention discloses a short-circuit protection circuit for a load of a massage chair. The protection circuit comprises R6, R3, R1 and U1B, one end of R6 is connected to a GND end, and the other end of R6 is connected with a source electrode of a Q1; the drain electrode of the Q1 is connected with the positive electrode of a D1, and the grid electrode of the Q1 is connected with the INPUT end; and the negative electrode of the D1 is connected with a VM end. according to the invention, output can be terminated at the moment that the load end is short-circuited, so that open fire generated by instant heating is avoided, damage to a control panel is avoided, the defective ratio in the production process caused by the open fire is reduced, and the potential safety hazard that a terminal user is on fire due to the short circuit of the load is also reduced.

Owner:上海桥翼电子科技有限公司

Scrap collection device of slicer

The invention discloses a scrap collection device of a slicer. The scrap collection device comprises a scrap box and a wire mesh, wherein the distance between the scrap box and the wire mesh is 10-25mm. According to the scrap collection device, the distance between existing scrap boxes and wire meshes is modified and is decreased by 2cm, most of scrap silicon wafers fall into the scrap box, and the ratio of TTV (Total Thickness Variation) greater than 50 is decreased; before replacing deep grooves, the TTV greater than 50 accounts for 3.5%, and after replacing the deep grooves, the TTV greater than 50 accounts for 1.08%, so that the ratio of the TTV greater than 50 is effectively decreased by 2.42%.

Owner:无锡荣能半导体材料有限公司

MWT assembly conductive adhesive rating test method

ActiveCN109827645AReduce manufacturing costReduce wasteWeighing apparatus for materials with special property/formTest sampleEngineering

The invention discloses an MWT assembly conductive adhesive rating test method. The method comprises the following steps: 1, selecting at least two conductive core plates in the same production line batch as test samples; 2, preparing an EVA strip, and marking the EVA strip as a ribbon of a bundle of conductive core plates; 3, calibrating an electronic scale, and recording a weighing result of theconductive core plates as W1; 4, only brushing glue on the conductive core plates without laying other materials; 5, after glue brushing, taking out the conductive core plates under the condition ofavoiding inaccurate weighing caused by the fact that the conductive core plate does not touch the conductive glue, and weighing a result W2 after glue brushing; 6, taking W2-W1 as the usage amount ofthe conductive adhesive. The method aims to solve the problem of large conductive adhesive loss deviation caused by adhesive shoveling and mesh plate hole blocking.

Owner:JIANGSU SUNPORT POWER CORP LTD

rgb point control intelligent melamine lamp

ActiveCN108347804BProtection lifeImprove waterproof performanceElectrical apparatusElectroluminescent light sourcesMOSFETTransformer

The invention discloses an RGB point-controlled intelligent melamine lamp. The melamine lamp string is connected in series on the positive pole and the negative pole of the main line. One end of the plug is connected to the power supply, and the other end of the plug is connected to the resistance wire, varistor, filter and filter circuit. The output terminals of the filter circuit are respectively connected to the input terminal of the MOSFET and the DCDC transformer, and the direct current is output to the drive module and MCU. The MCU passes through The circuit board circuit is connected in parallel with a program module, a button, a remote control module, a WiFi module and a Bluetooth module, the drive module and the transformer output are connected to the MOSFET input, and the MOSFET output is connected to the light string at the end of the main line. The product effect of the point-controlled intelligent melamine lamp of the present invention can be programmed and modified arbitrarily through a computer program to form functions such as single-color control, double-color control, and multi-color control.

Owner:JIANGSU LEDCO LIGHTING TECH CO. LTD

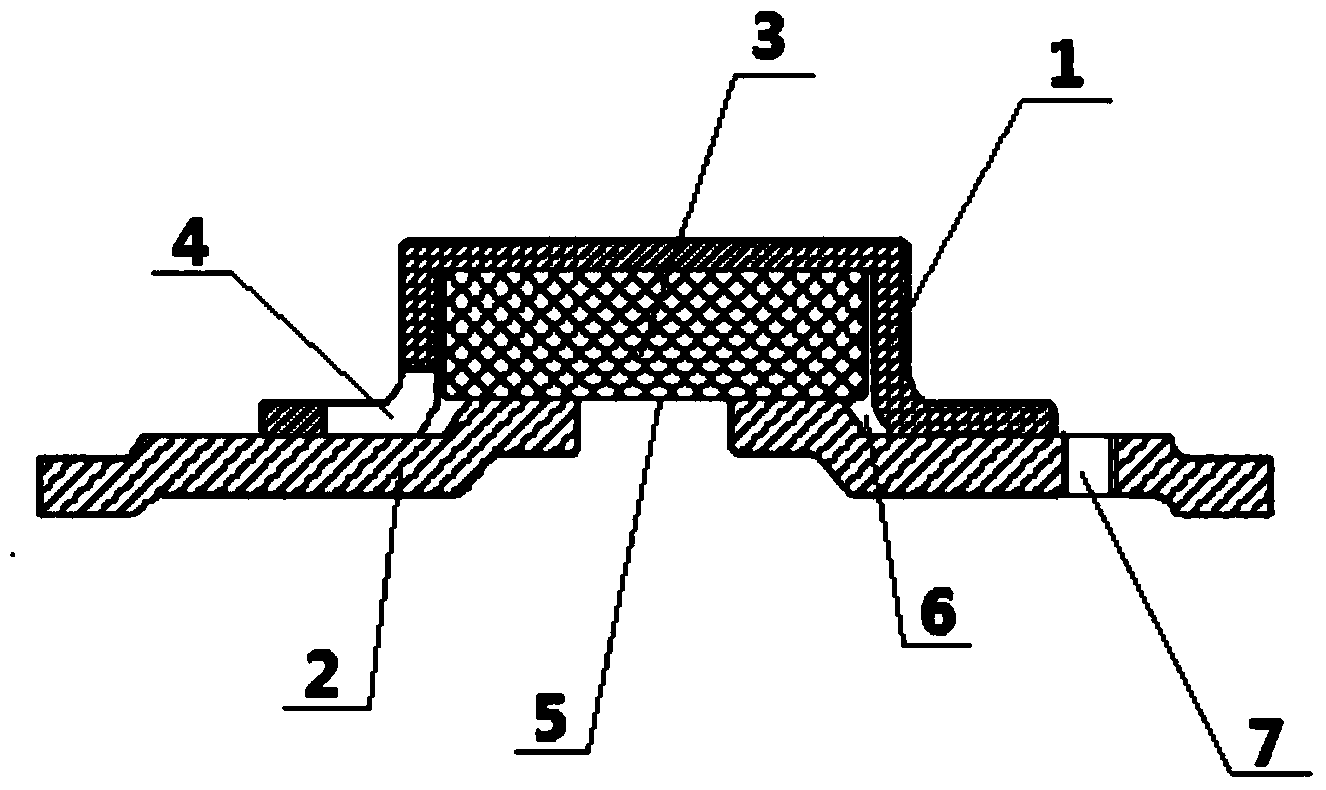

Environmental protection transformer with lost wax method potting epoxy resin and preparation method thereof

ActiveCN106449020BSimple structureImprove sealingTransformers/inductances casingsEncapsulation/impregnationWaxEpoxy

The invention discloses an environment-friendly transformer with a housing for potting epoxy resin employing a lost-wax process and a method for preparing the environment-friendly transformer; and the environment-friendly transformer is simple in structure, good in sealing effect and high in insulating protection capability and does not pollute the environment. The environment-friendly transformer comprises a transformer body, wherein the transformer body comprises a skeleton (1), a finished coil wound on the skeleton (1) and a silicon steel sheet (2) sleeving the skeleton (1); a plurality of connection pins (3) are arranged on the upper end surface of the skeleton (1); an integrally molded epoxy resin layer (4) coats the periphery of the overall transformer body; and the connection pins (3) are exposed on the epoxy resin layer (4) at the upper part of the skeleton (1). The preparation method comprises the following steps of (a) prefabricating a wax mold; (b) potting the epoxy resin; (c) putting the wax mold into the transformer body; and (d) removing wax and forming the transformer a demolding manner. The environment-friendly transformer can be used for the field of electronic devices.

Owner:珠海市康定电子股份有限公司

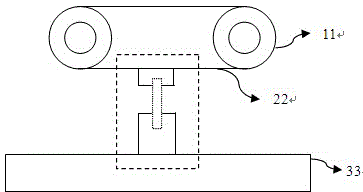

A squeeze roller for wet etching

ActiveCN108574024BReduce roughnessAccelerated corrosionFinal product manufactureSemiconductor devicesEtchingEngineering

The invention relates to and provides a water squeezing roller. By using the water squeezing roller, the structure is simple, a silicon chip surface can be effectively protected during a production process, an EL bad proportion is reduced and production cost is saved. In the prior art, during a production process, the water squeezing roller is easy to wear, production cost is high, the silicon chip surface is easy to pollute, there are a lot of finished-product defective products and so on. By using the roller of the invention, the above technical problems are solved. The roller comprises a transmission wheel group and a support shaft which is transversely arranged above the transmission wheel group. A smooth surface extrusion sleeve sleeves the support shaft. A first gap is arranged between the middle hole of the smooth surface extrusion sleeve and the support shaft. A silicon chip is clamped between the transmission wheel group and the corresponding smooth surface extrusion sleeve. The silicon chip is moved towards an output side under the driving of the transmission wheel group.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

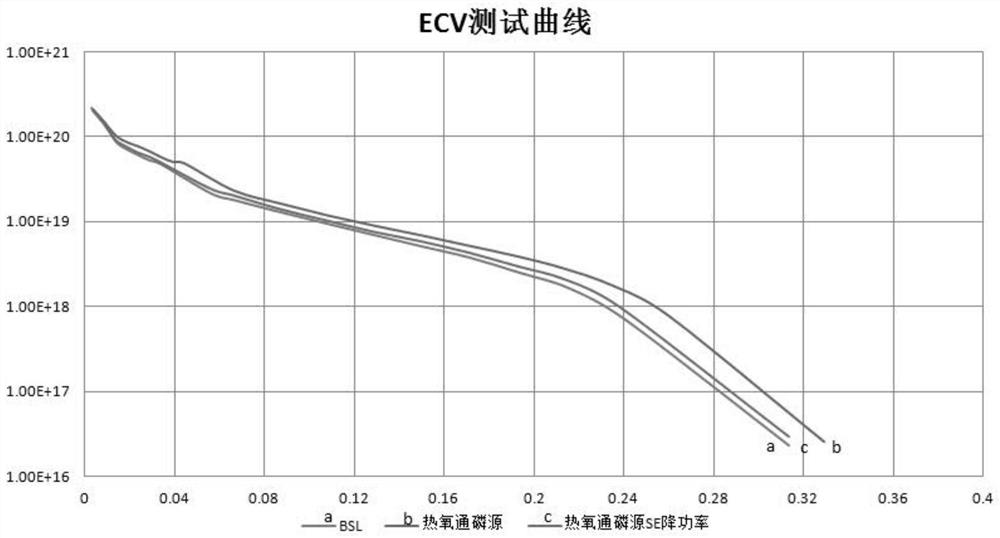

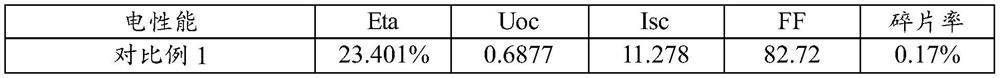

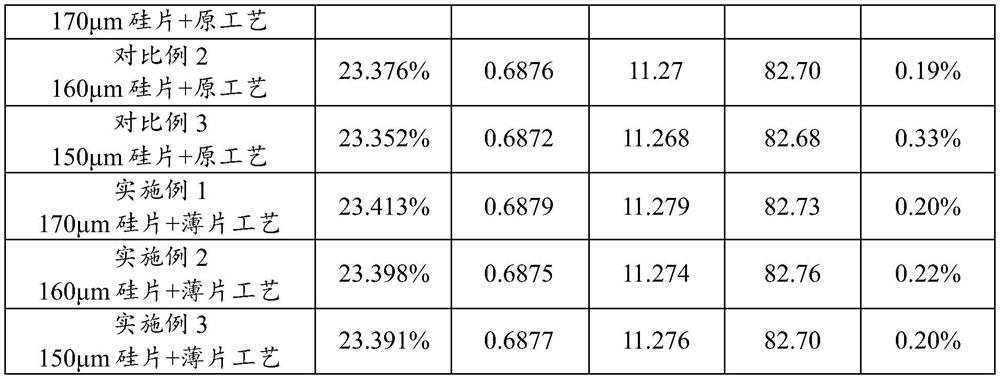

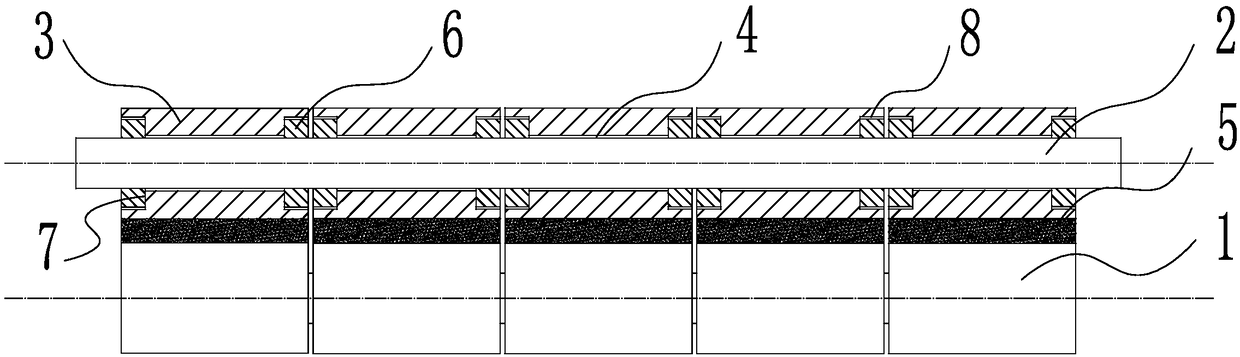

Manufacturing process of PERC battery piece

PendingCN114256383AGuaranteed conversion efficiencyReduce bad ratioFinal product manufacturePhotovoltaic energy generationScreen printingLaser processing

The embodiment of the invention provides a manufacturing process of a PERC battery piece, and relates to the technical field of photovoltaic product preparation. The manufacturing process of the PERC battery piece comprises the steps of texturing, diffusion, SE laser doping, thermal oxidation, polishing, annealing, back surface coating, front surface coating, laser grooving, screen printing and sintering which are sequentially carried out on a P-type silicon wafer, during thermal oxidation, nitrogen and oxygen carrying a phosphorus source are firstly introduced for thermal treatment, and then nitrogen and oxygen are introduced for oxidation; and during SE laser doping and laser grooving, light spots generated by laser processing are controlled to be arranged at intervals, and the distance between every two adjacent light spots ranges from 15 micrometers to 30 micrometers. The manufacturing process of the PERC battery piece is particularly suitable for manufacturing a thin-sheet battery, the conversion efficiency of the thin-sheet battery is guaranteed, and meanwhile the proportion of defective fragments is reduced.

Owner:TONGWEI SOLAR ENERGY CHENGDU CO LID

Water squeezing roller used for wet etching

ActiveCN108574024AReduce roughnessAccelerated corrosionFinal product manufactureSemiconductor devicesState of artEtching

The invention relates to and provides a water squeezing roller. By using the water squeezing roller, the structure is simple, a silicon chip surface can be effectively protected during a production process, an EL bad proportion is reduced and production cost is saved. In the prior art, during a production process, the water squeezing roller is easy to wear, production cost is high, the silicon chip surface is easy to pollute, there are a lot of finished-product defective products and so on. By using the roller of the invention, the above technical problems are solved. The roller comprises a transmission wheel group and a support shaft which is transversely arranged above the transmission wheel group. A smooth surface extrusion sleeve sleeves the support shaft. A first gap is arranged between the middle hole of the smooth surface extrusion sleeve and the support shaft. A silicon chip is clamped between the transmission wheel group and the corresponding smooth surface extrusion sleeve. The silicon chip is moved towards an output side under the driving of the transmission wheel group.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

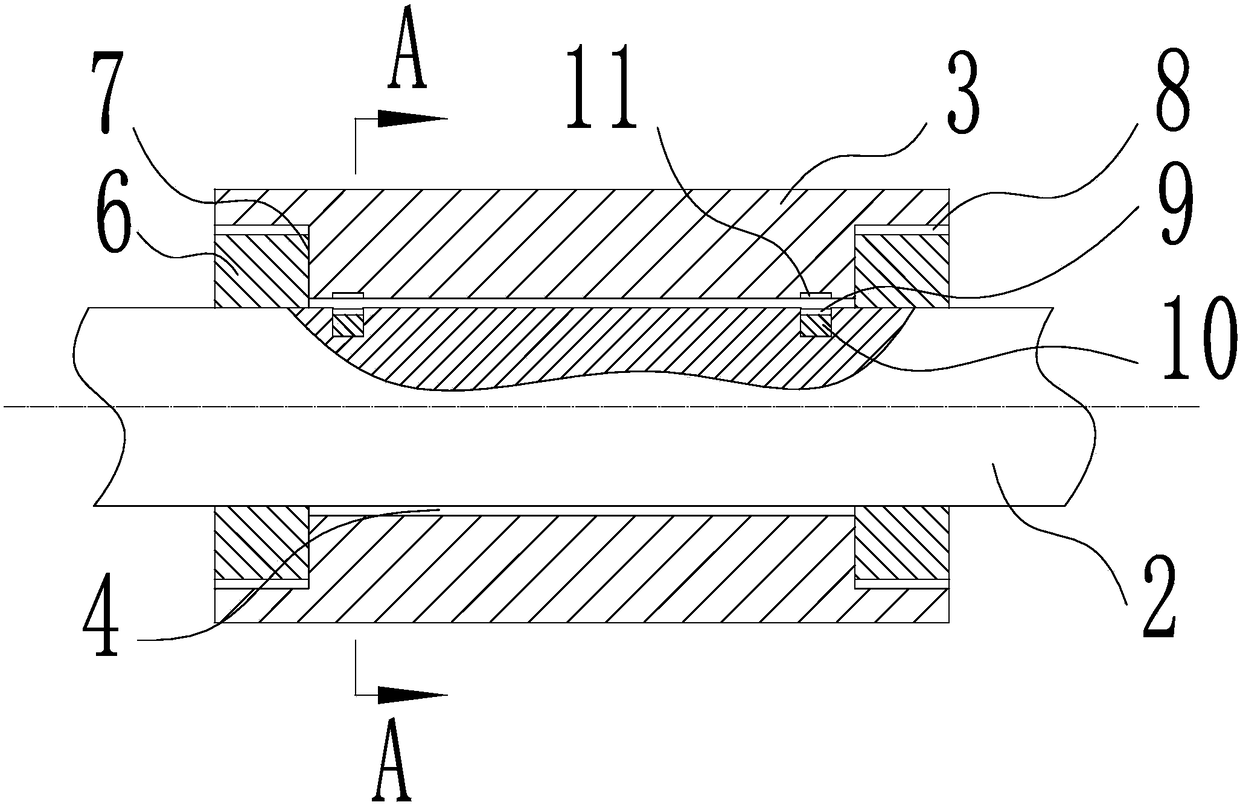

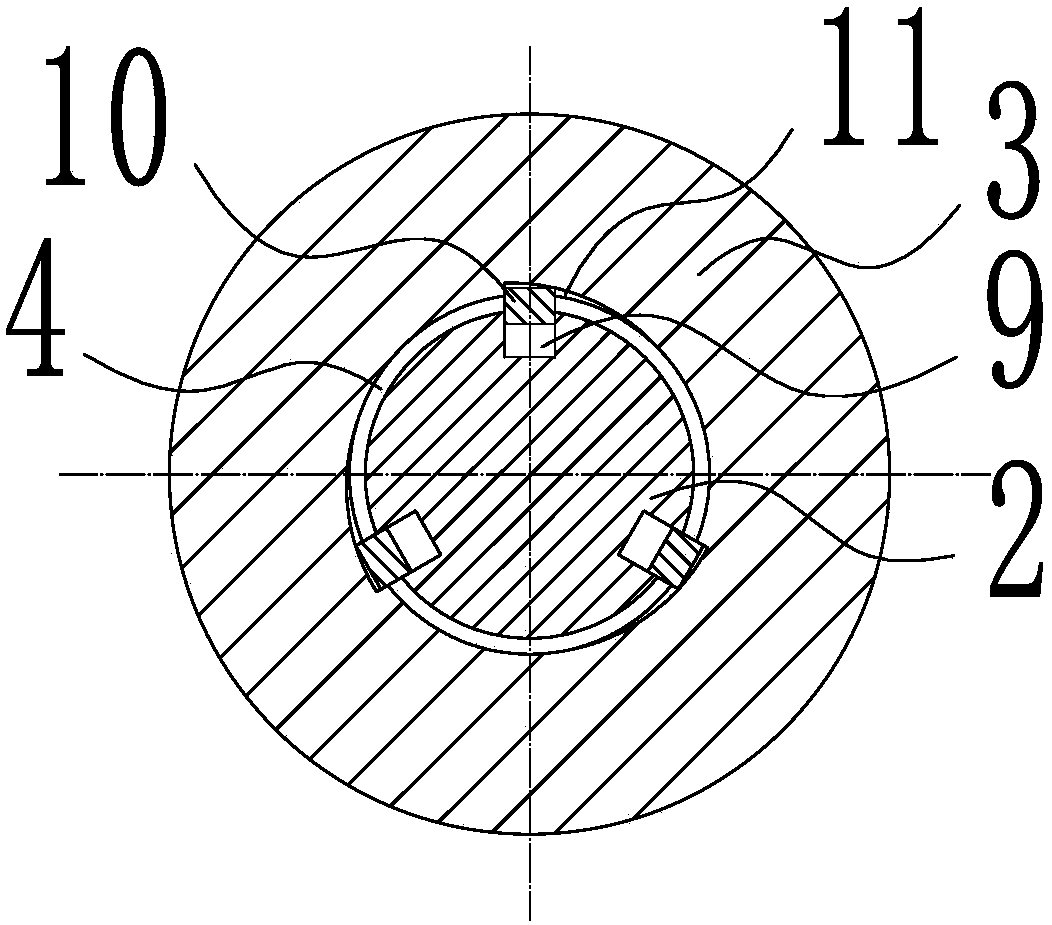

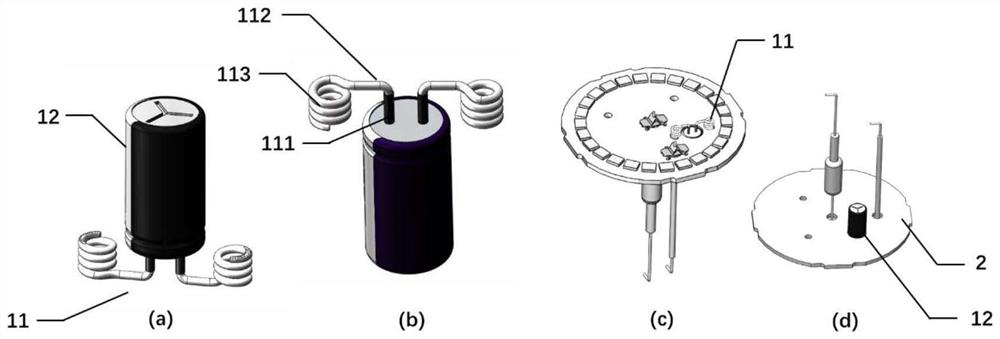

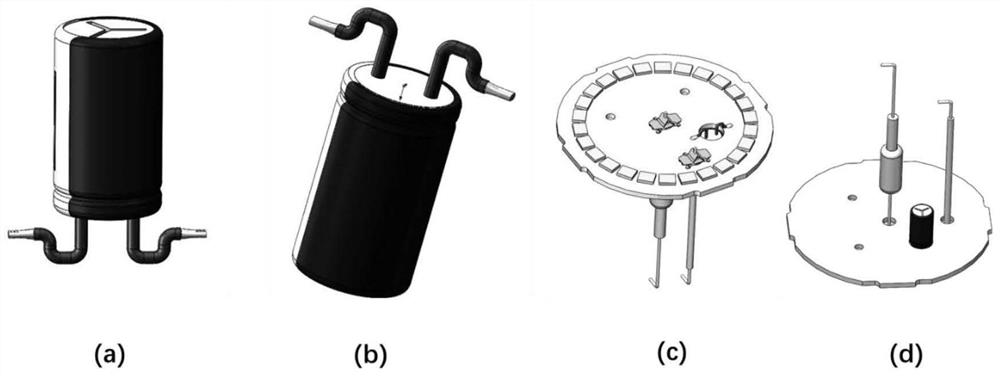

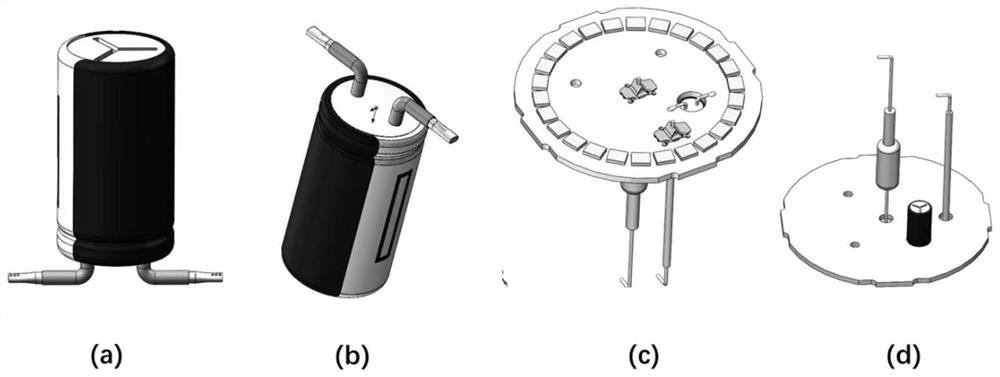

Aluminum electrolytic capacitor, circuit board assembly and preparation method thereof

PendingCN114188158AAchieve electrical connectionAvoid deformationPrinted circuit assemblingCapacitor terminalsLight fluxSurface mounting

The invention discloses an aluminum electrolytic capacitor which comprises a body and a lead, the lead comprises a root part, a tip part and a bending part, the root part is subjected to insulation treatment, the bending part is provided with an arc bending structure, and the tip part comprises a spring-shaped buffer structure; a circuit board assembly comprises a circuit board, the aluminum electrolytic capacitor and other electronic devices, the mounting area of the aluminum electrolytic capacitor is located on the front face of the circuit board, and the body of the aluminum electrolytic capacitor penetrates through the circuit board to be located on the back face, so that the aluminum electrolytic capacitor is inversely arranged on the circuit board. According to the scheme, the aluminum electrolytic capacitor is inversely arranged in the perforated circuit board in a front surface mounting manner, so that the circuit board can be normally conducted to work through the aluminum electrolytic capacitor, the luminous flux is improved, meanwhile, a connector is omitted, and the cost is reduced. And the steps of welding the connector on the circuit board and then installing the aluminum electrolytic capacitor in a plug-in manner in the prior art are omitted, so that the electric connection of the circuit board is realized simply and reliably.

Owner:LEEDARSON IOT TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com