Flexible circuit board press bonding method

A flexible circuit board and pressure technology, applied in chemical instruments and methods, lamination, printed circuits, etc., can solve problems such as difficult equipment and large area, and achieve the effects of improving peel strength, reducing glue overflow, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

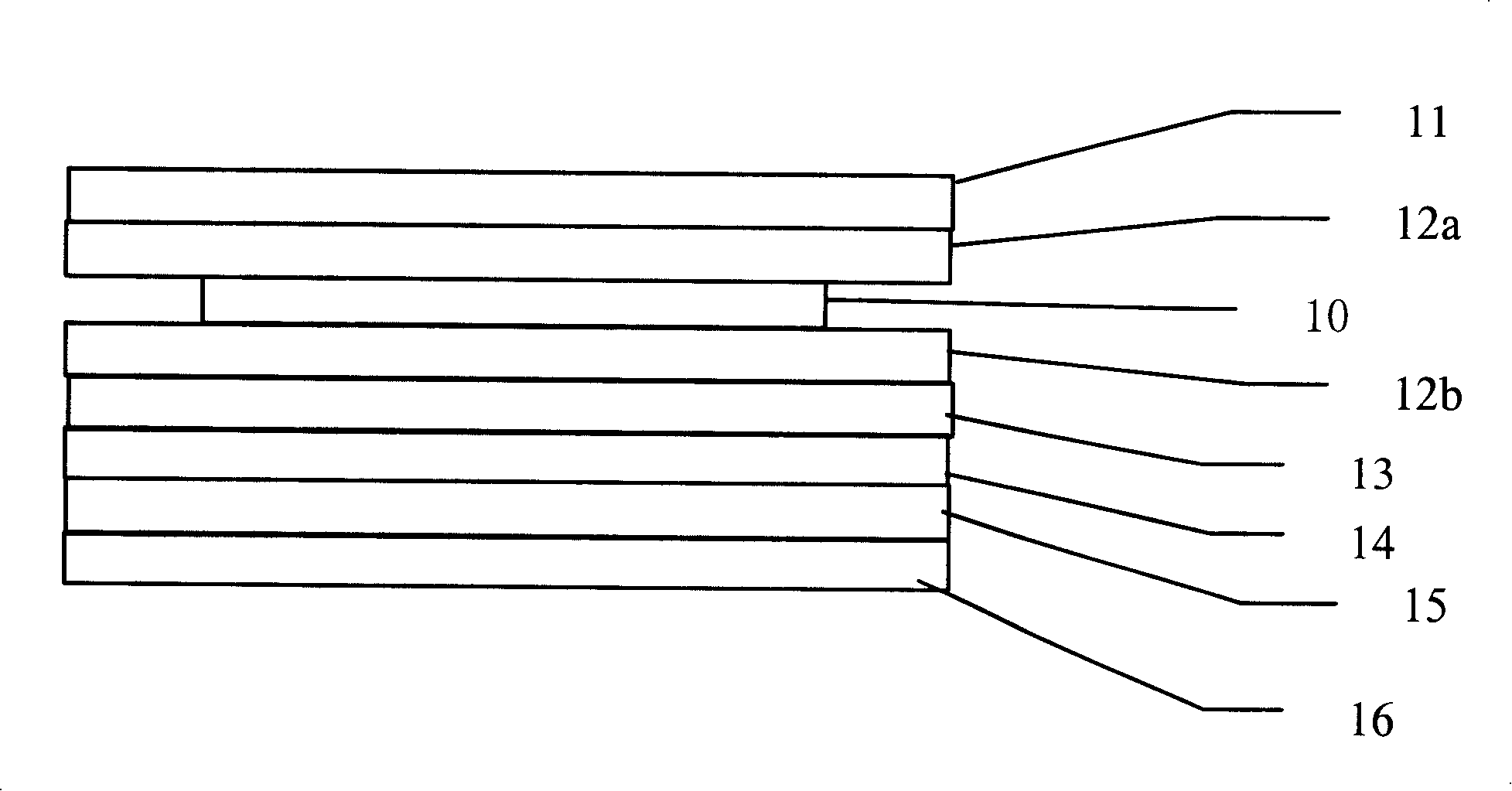

[0067] The first step of lamination is as follows: figure 1 The process conditions of the laminated plate structure shown are as follows:

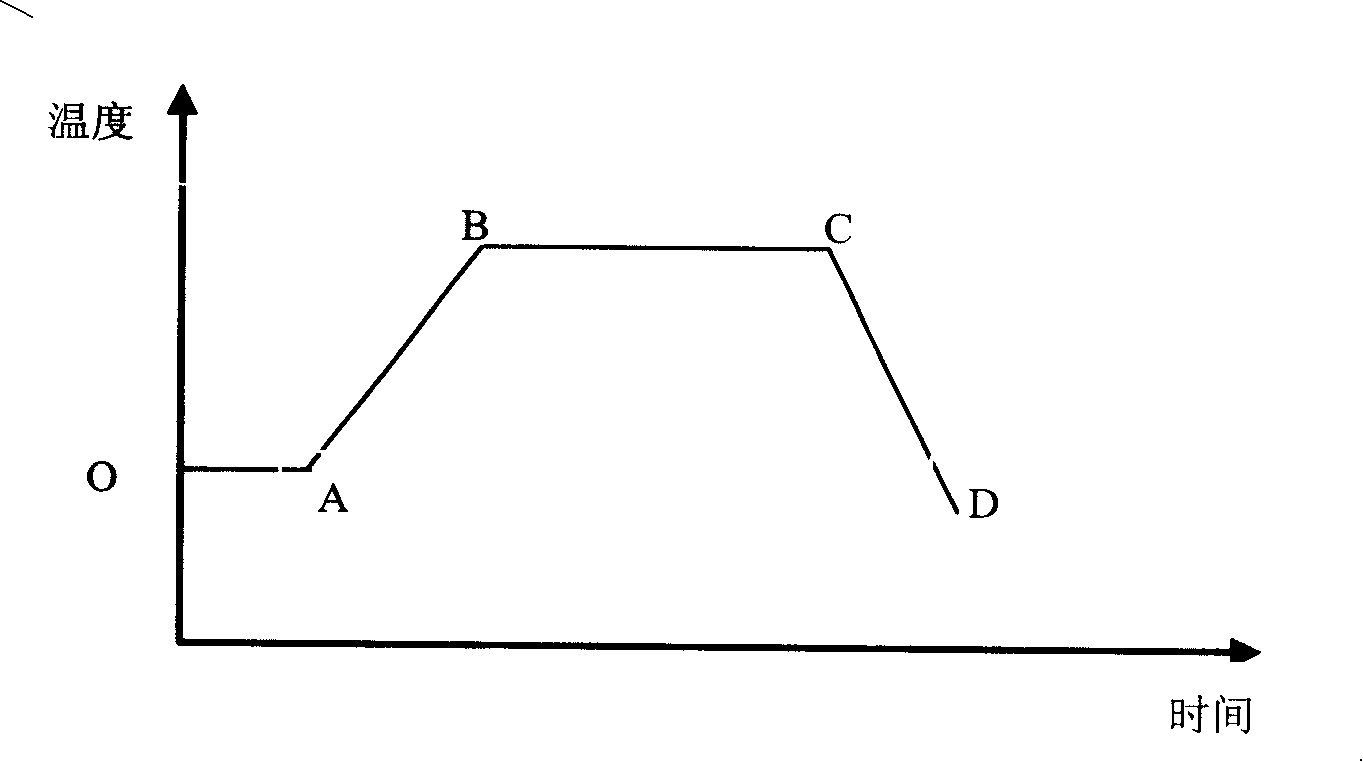

[0068] The pressing temperature process conditions of the first step of pressing are as follows:

[0069] Lamination Process Parameters

O

A

B

C

D

temperature(°C)

40

40

190

190

35

time (min)

0

10

55

85

135

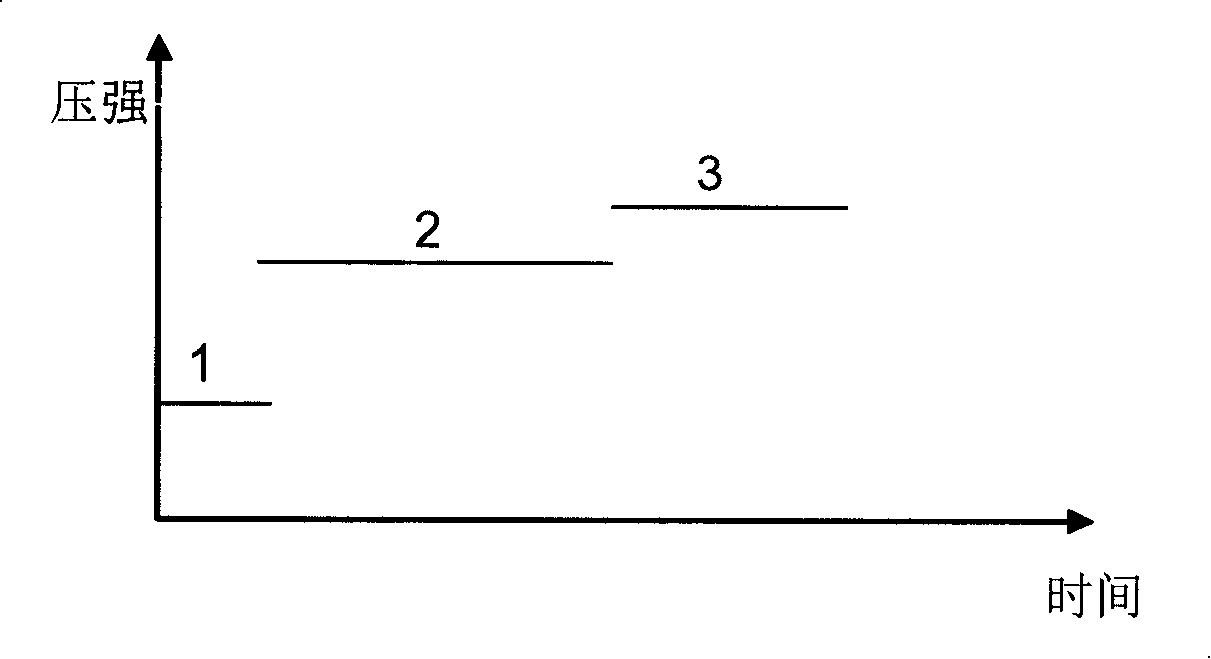

[0070] The pressure process conditions of the first step of lamination are as follows:

[0071] Lamination Process Parameters

starting point

Pressure: Pa(×10 6 )

0.62

0.62

2.4

2.1

time (min)

0

10

70

20

[0072] The second step of lamination adopts such as Figure 4 The process conditions of the laminated plate structure shown are as follows:

[0073] Temperature: 180°C;

[0074] Press...

specific Embodiment approach 2

[0077] The first step of lamination is as follows: figure 1 The process conditions of the laminated plate structure shown are as follows:

[0078] The pressing temperature process conditions of the first step of pressing are as follows:

[0079] Lamination Process Parameters

O

A

B

C

D

temperature(°C)

70

70

170

170

45

time (min)

0

5

80

125

155

[0080] The pressure process conditions of the first step of lamination are as follows:

[0081] Lamination Process Parameters

starting point

Paragraph 1

Paragraph 2

Paragraph 3

Pressure: Pa(×10 6 )

0.80

0.80

1.8

1.8

time (min)

0

15

90

50

[0082] The second step of lamination adopts such as figure 1 The process conditions of the laminated plate structure shown are as follows:

[0083] Temperature: 170°C;

[0084] Pressu...

specific Embodiment approach 3

[0087] The first step of lamination is as follows: figure 1 The process conditions of the laminated plate structure shown are as follows:

[0088] The pressing temperature process conditions of the first step of pressing are as follows:

[0089] Lamination Process Parameters

O

A

B

C

D

temperature(°C)

100

100

155

155

60

time (min)

0

20

110

170

190

[0090] The pressure process conditions of the first step of lamination are as follows:

[0091] Lamination Process Parameters

starting point

Paragraph 1

Paragraph 2

Paragraph 3

Pressure: Pa(×10 6 )

0.40

0.40

0.55

2.4

time (min)

0

20

120

80

[0092] The second step of lamination adopts such as Figure 4 The process conditions of the laminated plate structure shown are as follows:

[0093] Temperature: 190°C;

[0094] P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com