Scrap collection device of slicer

A collection device and slicer technology, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of different thickness of silicon wafers and can not meet the requirements, and achieve the effect of improving the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

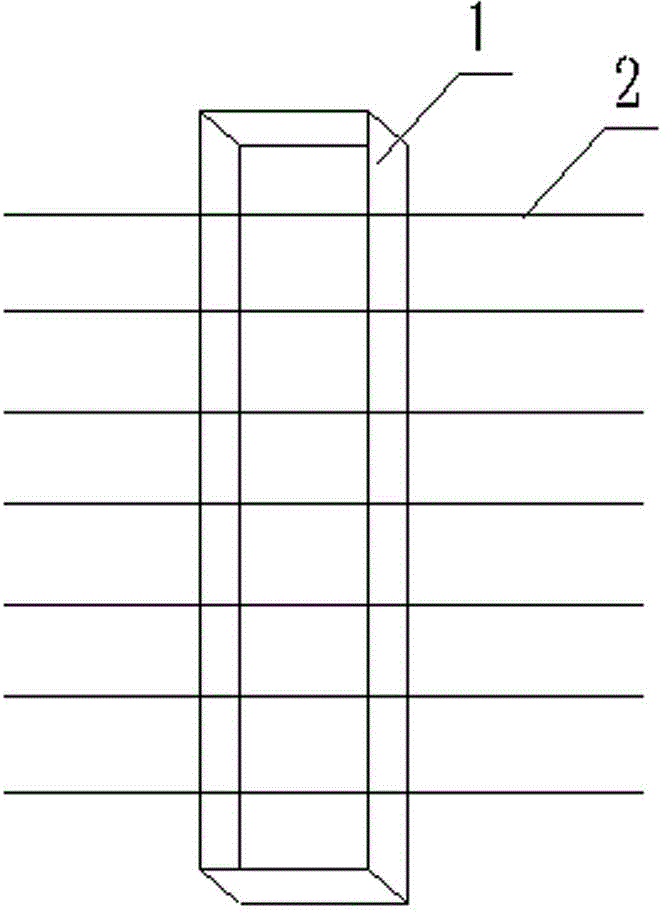

[0011] Such as figure 1 The fragment collection device of a slicer shown includes a fragment box 1 and a wire mesh 2, the wire mesh 2 is arranged directly above the fragment box 1, and the distance between the fragment box 1 and the wire mesh 2 is 10 mm to 25 mm . Preferably, the distance between the debris box 1 and the wire net 2 is 10 mm. At this time, the height of the debris box 1 is 420 mm.

[0012] Since the wire mesh 2 will produce a wire bow during the cutting process (that is, the silicon wafer will be bent downward when it is under pressure during cutting), the height of the fragment box 1 from the steel wire mesh 2 will be smaller than when there is no load, and the fragment box 1 and the wire mesh Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com