Environment-friendly self-lubricating rubber tube mandrel rubber material and preparation method thereof

A rubber material and self-lubricating technology, which is applied in the field of rubber composite materials, can solve problems such as scratches on the inner layer of rubber hoses, environmental protection failures of rubber hoses, residues of benzene-containing substances, etc., and achieve low scratch rate, high core-pulling efficiency, and DEHP The effect of low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

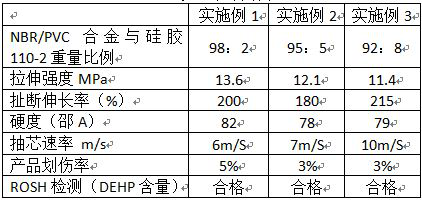

Embodiment 1

[0026] An environment-friendly self-lubricating hose mandrel rubber material, comprising the following raw materials in parts by weight:

[0027] 100 parts of composite material of NBR / PVC alloy and silica gel 110-2, 15 parts of reinforcing agent, 70 parts of semi-reinforcing carbon black, 1 part of coupling agent, 15 parts of environmental plasticizer, 3 parts of antioxidant, processing aid 2 parts of curing agent, 5 parts of heat-resistant auxiliary agent, 0.5 parts of vulcanizing agent, 2 parts of cross-linking auxiliary agent;

[0028] Wherein, the composite material of the NBR / PVC alloy and silica gel 110-2 is a mixture of NBR / PVC alloy and silica gel 110-2 with a mass ratio of 98:2;

[0029] The reinforcing agent is nano white carbon black;

[0030] The coupling agent is a silane coupling agent KH550;

[0031] Described environment-friendly plasticizer is environment-friendly oil;

[0032] Described antioxidant is the mixture of antioxidant NBC and antioxidant 445, an...

Embodiment 2

[0041] The composite material of NBR / PVC alloy and silica gel 110-2 is a mixture of NBR / PVC alloy and silica gel 110-2 with a mass ratio of 95:5, and the others are the same as in Example 1.

Embodiment 3

[0043] The composite material of NBR / PVC alloy and silica gel 110-2 is a mixture of NBR / PVC alloy and silica gel 110-2 with a mass ratio of 92:8, and the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com