Chemical mechanical polishing solution and polishing method for propeller

A technology of chemical machinery and polishing fluid, which is applied in the direction of polishing compositions containing abrasives, etc., can solve problems such as poor precision consistency, difficulty in paddle processing, manual grinding and polishing efficiency, etc., to achieve good flexibility, good polishing effect, and strong versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] specific implementation plan

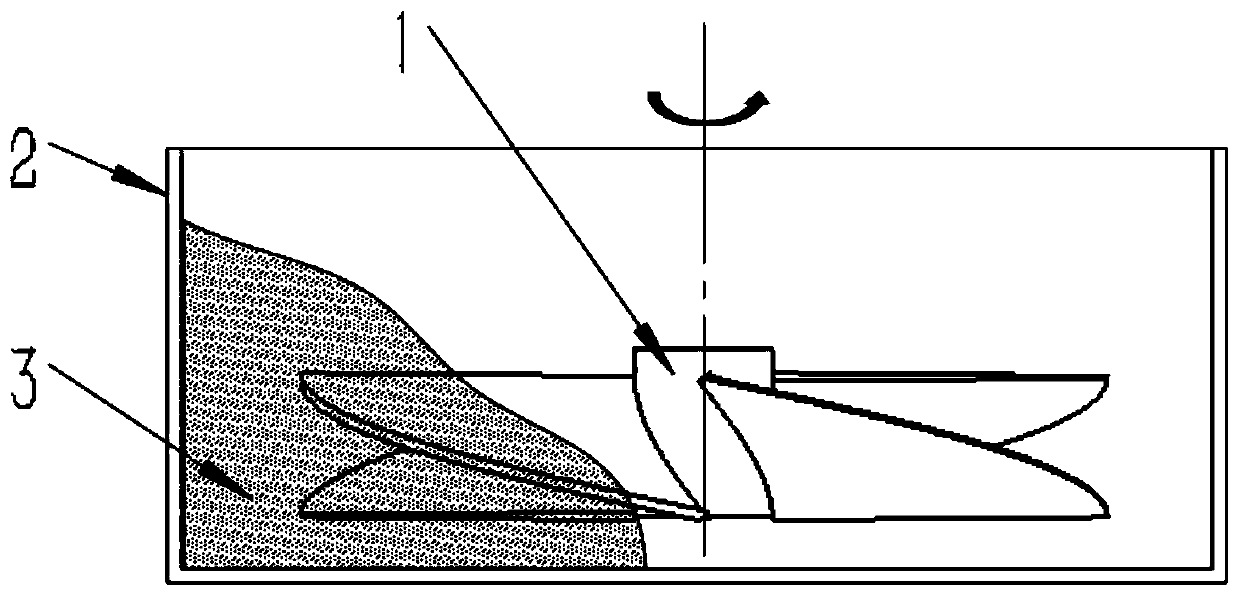

[0028] Attached below Figure 1~2 , the outer diameter is Φ400mm, and the height is the propeller of 60mm as an example, the present invention will be further described.

[0029] A kind of chemical mechanical polishing method of propeller and the preparation concrete operation of polishing liquid are as follows:

[0030] 1. According to the size of the propeller, choose a circular plastic container 2 with an outer diameter of Φ500mm and a height of 400mm. When the propeller 1 is installed, it is close to the bottom of the container 2, so the required height of the polishing liquid 3 only needs to be greater than the height of the propeller 2 by 60mm. Submerge it completely. In this example, the height of the added polishing liquid is 80mm, so it can be calculated that the total volume of the required polishing liquid is 15.7L. For the convenience of calculation, 16L is selected.

[0031] 2. According to the total volume of the polishing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com