Gear non-load overall immersion type chemical mechanical coupling surface polishing method

A chemical-mechanical, surface-polishing technology, applied in mechanical equipment, belts/chains/gears, gear teeth, etc., to achieve the effect of convenient and simple operation, reducing scratches, improving efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

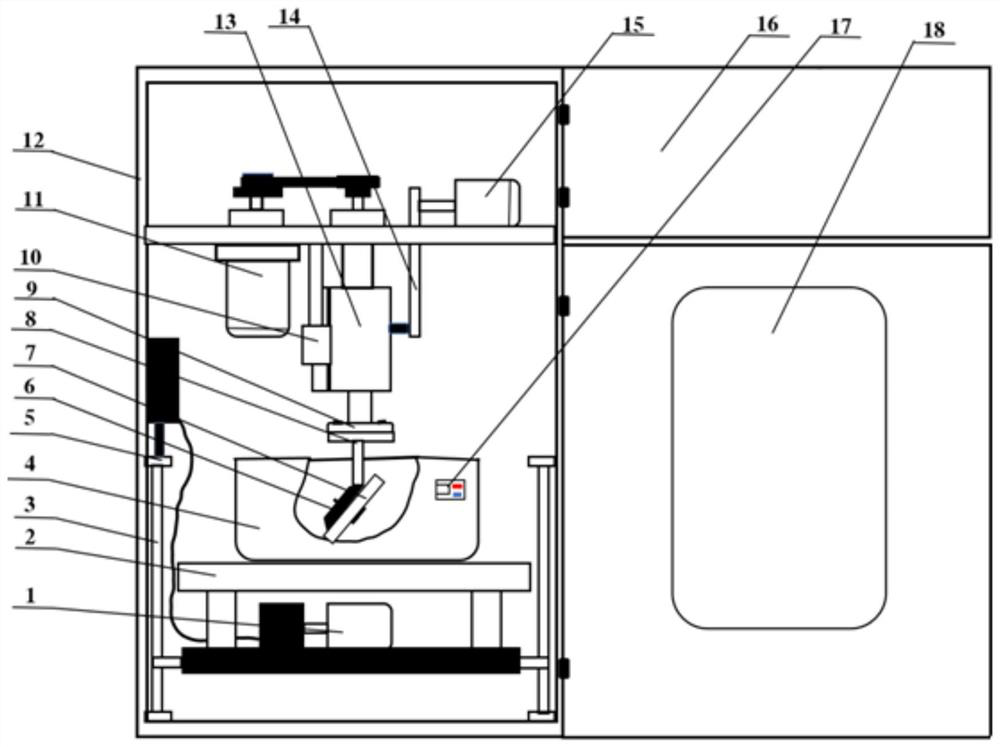

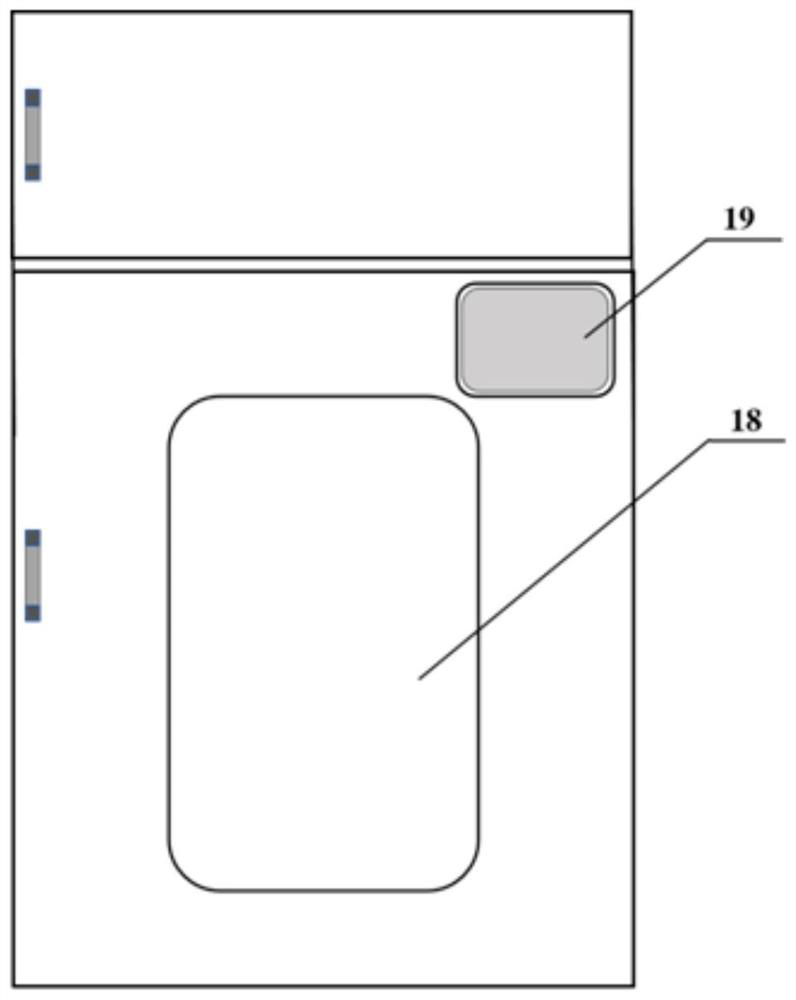

Image

Examples

example

[0036] Example: Using the above method to polish the cycloidal gear of nickel-based alloy material, the surface roughness of the polished gear is significantly reduced, and the surface roughness is reduced from the initial 2-3 μm to 0.8-0.9 μm, and the surface is bright without scratches. Gears undergo the following chemical reactions in the polishing solution:

[0037] Ni+H 2 o 2 →NiO+H 2 o

[0038] Ni+H 2 o 2 →Ni(OH) 2

[0039] 2Cr+3H 2 o 2 →Cr2O 3 +3H 2 o

[0040] Mo+2H 2 o 2 →MoO 2 +2H 2 o

[0041] Mo+3H 2 o 2 →MoO 3 +3H 2 o

[0042] MoO 2 +H 2 o 2 →MoO 3 +H 2 o

[0043] NiO+2H + +5H 2 O→[Ni(H 2 O) 6 ] 2+

[0044] Ni(OH) 2 +2H + +4H 2 O→[Ni(H 2 O) 6 ] 2+

[0045] When the gear is in the polishing solution, the main components of the surface will be NiO, Ni(OH) 2 、Cr 2 o 3 、MoO 2 and MoO 3 Under the mechanical and chemical coupling, the oxide film formed on the surface is preferentially removed, so as to achieve the effect of pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com