Formula and applications of granite polishing agent

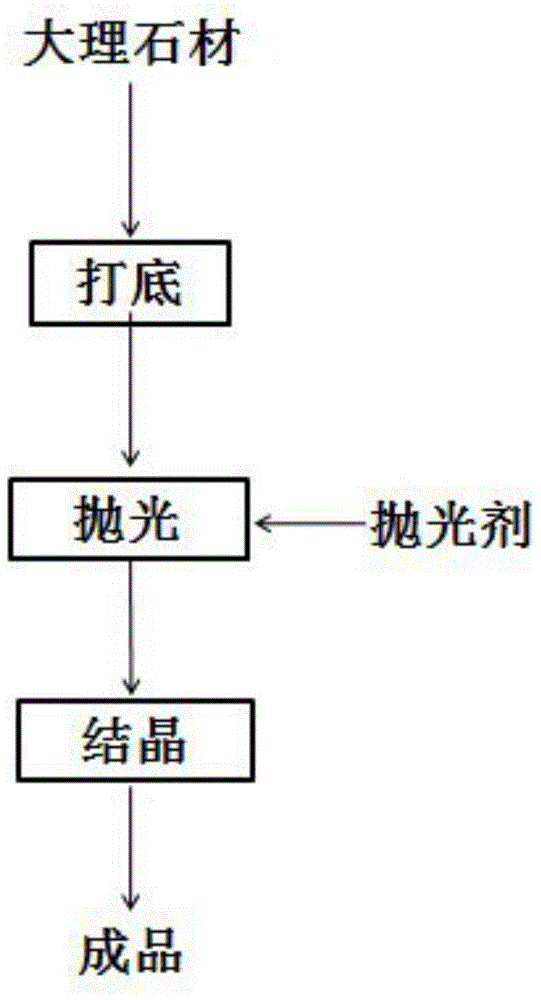

A technology of granite and polishing agent, which is applied in the field of polishing agent, can solve the problems such as yellowing of granite stone, affect the appearance, and yellowing of the surface, and achieve the effects of restoring polishing color, improving gloss, and simplifying the polishing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A formulation of a granite polishing agent is prepared by physically mixing the first solid mixture, the first material liquid, the second material liquid, and the third material liquid in a weight ratio of 23:27:5:5. The first solid mixture is composed of 89% of nano silicon dioxide, 4% of sulfide, and 7% of high molecular polymer. The first feed liquid is composed of 3.7% surfactant, 1.8% silicone oil, and 94.5% deionized water. The second feed solution is composed of 4.6% diethylene glycol monoethyl ether and 5.6% ethoxylated C12-13 alcohol. The third feed solution is composed of 22% acrylic acid copolymer. Sulfides consist of calcium carbonate. The high molecular polymer is composed of phenolic resin. The surfactant is composed of sodium dodecylsulfonate, sodium benzenesulfonate and sodium fatty acid.

Embodiment 2

[0017] A formulation of a granite polishing agent is prepared by physically mixing the first solid mixture, the first material liquid, the second material liquid, and the third material liquid in a weight ratio of 23:27:10:10. The first solid mixture is composed of 89% of nano silicon dioxide, 4% of sulfide, and 7% of high molecular polymer. The first feed liquid is composed of 3.7% surfactant, 1.8% silicone oil, and 94.5% deionized water. The second feed solution is composed of 10% diethylene glycol monoethyl ether and 15% ethoxylated C12-13 alcohol. The third feed solution is composed of 30% acrylic acid copolymer.

[0018] Sulfides consist of calcium carbonate and calcium sulfate. High molecular polymer is composed of phenolic resin and polycarboxylic acid. The surfactant consists of sodium dodecylsulfonate and sodium benzenesulfonate.

Embodiment 3

[0020] A composition of a granite polishing agent is prepared by physically mixing the first solid mixture, the first material liquid, the second material liquid and the third material liquid in a weight ratio of 46:54:35:35. The first solid mixture is composed of 89% of nano silicon dioxide, 4% of sulfide, and 7% of high molecular polymer. The first feed liquid is composed of 3.7% surfactant, 1.8% silicone oil, and 94.5% deionized water. The second feed liquid is composed of 20% of diethylene glycol monoethyl ether and 22% of ethoxylated C12-13 alcohol. The third feed solution is composed of 48% acrylic acid copolymer.

[0021] Sulfides are composed of calcium carbonate, calcium sulfate and calcium silicate. The high molecular polymer is composed of phenolic resin, polycarboxylic acid and hydroxyethyl cellulose. The surfactant consists of sodium dodecylsulfonate, sodium benzenesulfonate and sodium fatty acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com