High-efficiency and low-cost polishing and grinding equipment for green bricks

A low-cost, high-efficiency technology, applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of high cost and complex structure, and achieve the effect of simple structure, cost reduction, and simplified polishing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

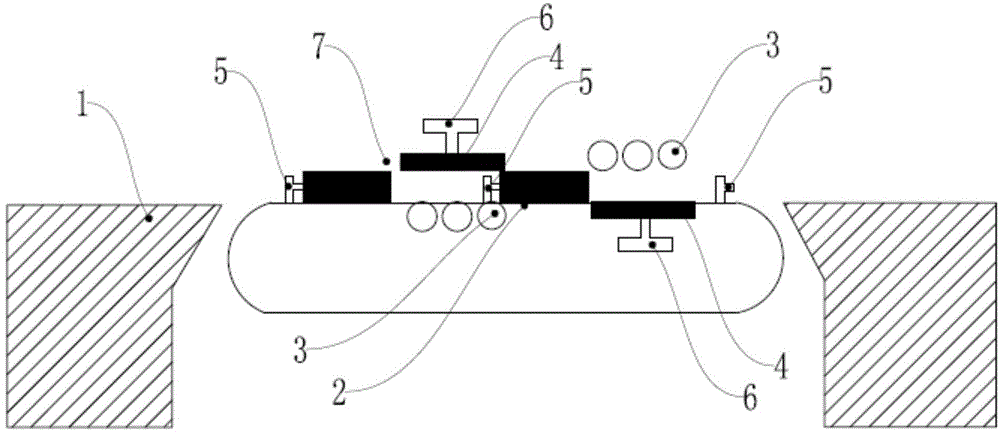

[0015] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0016] Such as figure 1 As shown, it includes a platform 1, a conveying device 2 for conveying adobes is arranged on the platform 1, and at least two sets of polishing devices driven by an external power mechanism are arranged along the transmission direction. The buffing mechanism 3 and the grinding disc 4 arranged opposite to the surface buffing mechanism 3 are constituted, and in the two adjacent sets of buffing devices, the surface buffing mechanism 3 is opposite to the grinding disc 4 .

[0017] With this arrangement, the split brick adobe 7 can be polished and polished on both sides during one conveying and polishing process, which greatly improves the work efficiency. In the above equipment, the power used is preferably electric power. Of course, other power mechanisms can also achieve the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com