Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68results about How to "Realize manufacturing——" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

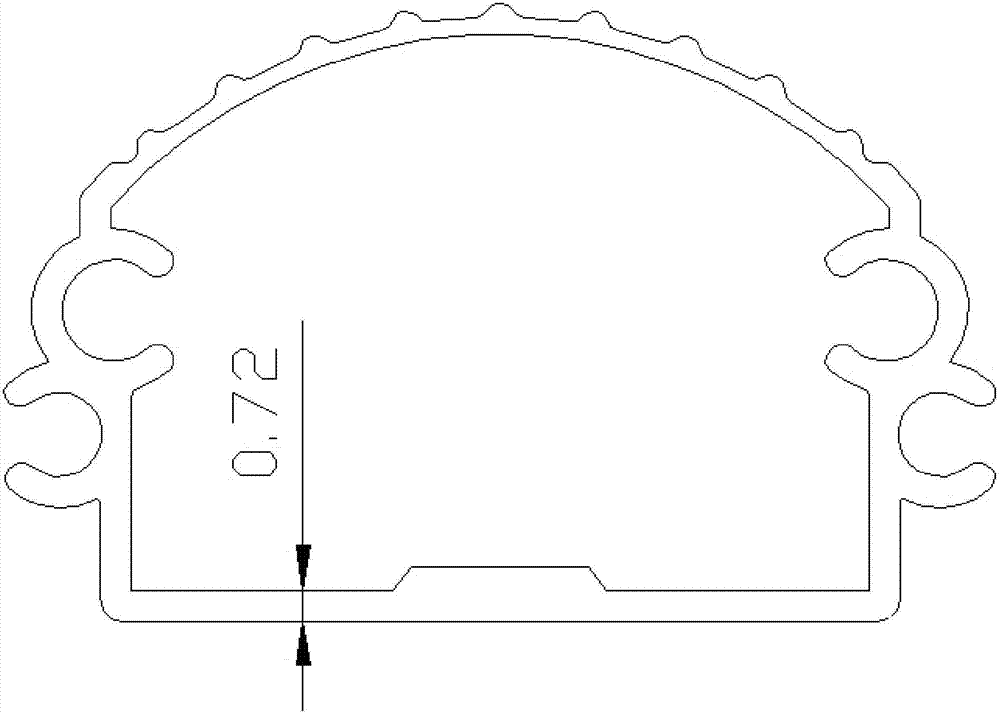

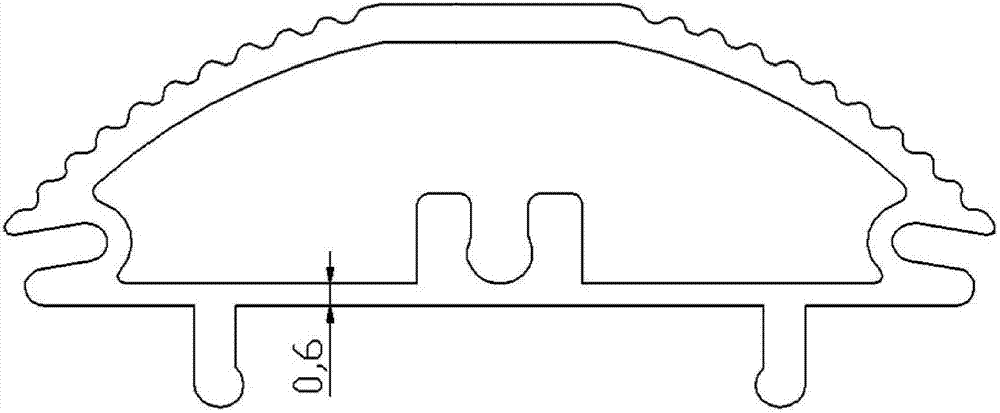

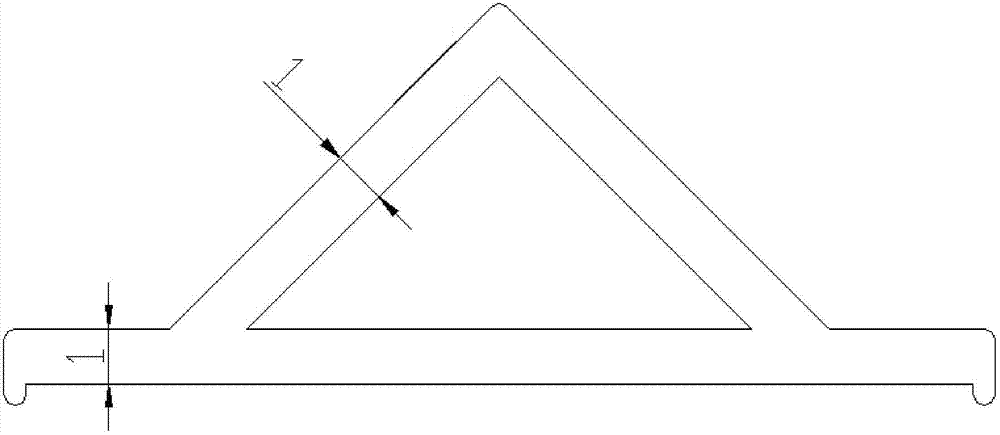

Magnesium alloy LED (Light Emitting Diode) tube profile and extrusion molding process thereof

The invention discloses a magnesium alloy LED (Light Emitting Diode) tube profile and an extrusion molding process thereof. The extrusion molding process comprises the following steps of: (1). according to the component proportioning requirements, smelting a magnesium alloy raw material; (2). preparing a magnesium alloy casting rod with the obtained magnesium alloy raw material; (3). heating the magnesium alloy casting rod to 400 DEG C to carry out heat preservation for 6 hours, and slowly cooling to room temperature along with a furnace after homogenization treatment; (4). heating the magnesium alloy casting rod subjected to homogenization treatment to 350 DEG C to carry out heat preservation for 2 hours, then slowly heating to 410 DEG C to carry out heat preservation for 2 hours, afterwards cooling to 380 DEG C to carry out heat preservation for 1 hour, and simultaneously heating an extrusion mould to 400 DEG C to carry out heat preservation; and (5). finally taking out the extrusion mould, assembling the extrusion mould on an extrusion machine, filling the magnesium alloy casting rod into the extrusion container of the extrusion mould for extrusion molding, so as to obtain the magnesium alloy LED tube profile by extrusion molding. The magnesium alloy LED tube profile and the extrusion molding process thereof have the advantages that the production efficiency and yield are improved and the machining cost is reduced on the premise that the size precision is ensured to meet the design requirements.

Owner:WUXI FUMEI LIGHT ALLOY TECH

Production method of corrosion-resistant bimetal composite pipe

InactiveCN103350320AExcellent metallurgical bonding interfaceQuality improvementWelding apparatusComposite plateHeat treated

The invention relates to a production method of a corrosion-resistant bimetal composite pipe. The production method comprises the following steps: performing explosion composite operation on a corrosion-resistant alloy thin plate and a steel plate, performing heat treatment, leveling, cutting and trimming, and entering a pipe making workshop; forming by a JCO process, pre-welding, externally welding, internally welding, expanding diameter, performing a hydrostatic test, trimming end, performing flaw detection and marking to prepare corrosion-resistant bimetal composite pipe. The production method adopts an explosion composite process to prepare a bimetal composite plate, and obtains an excellent metallurgical bonding interface which is different from the mechanical interface bonding obtained through explosive expansion of the traditional embedded combined pipe, so the quality of the bimetal composite pipe is improved; production and manufacturing of a composite pipe with a large-caliber metallurgical bonding interface can be realized; the production method is particularly suitable for a submerged arc longitudinal welded pipe with the diameter being larger than 400 mm or 16 inches; high-strength metallurgical bonding of various dissimilar metals can be realized, and a brittle compound layer does not exist on the interface or is reduced to the minimal degree; the cladding coating ratio is high, so noble rare metal can be saved and the cost is low.

Owner:EAST CHINA UNIV OF SCI & TECH

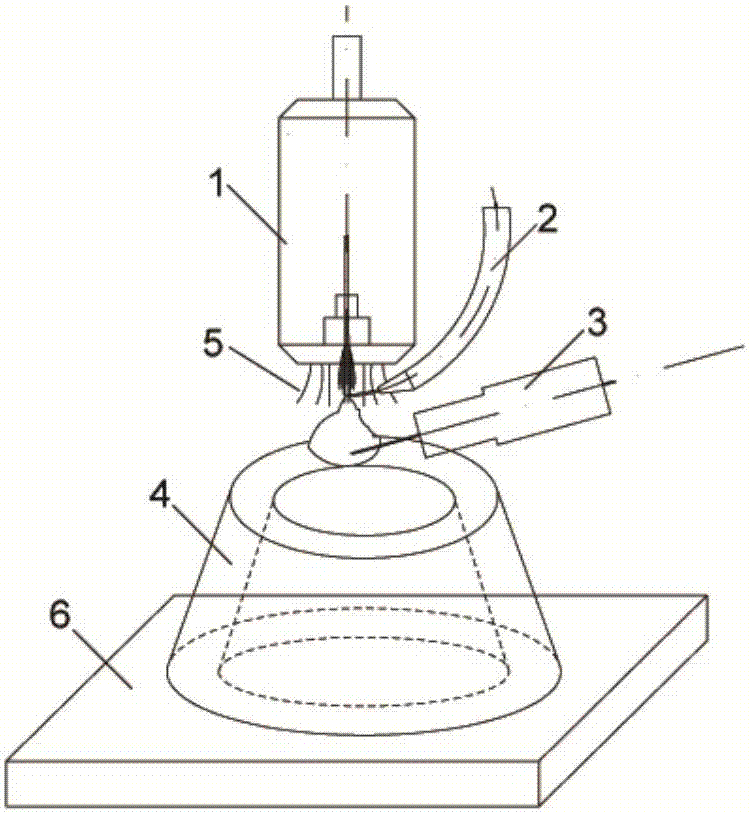

Additive manufacturing method of intermetallic compound part

The invention provides an additive manufacturing method of an intermetallic compound part. The method comprises the following steps: 1) designing a travelling path of a high energy beam heat source reasonably according to the shape of a part; 2) adjusting the wire feed rates of different wire-like materials and the powder feeding amount of a powdery material or powder proportion to met the component proportion of an intermetallic compound; 3) selecting proper process parameters, feeding a filling material into the heat source and melting the filling material, and then carrying out freezing, cooling and forming; 4) changing the heights between the heat source and deposited parts according to each depositing thickness, wherein the height is consistent to a set value, and then carrying out stacking forming continuously; and 5) continuously repeating the steps 3 and 4 to finally obtain the intermetallic compound part. According to the method provided by the invention, two different types of wire-like materials or one wire-like material and one powdery material or the powdery material is adopted fully. The method provided by the invention for preparing the intermetallic compound is short in production period and high in utilization ratio of materials, and the performance of the part is improved compared with that of a casting.

Owner:HUAZHONG UNIV OF SCI & TECH

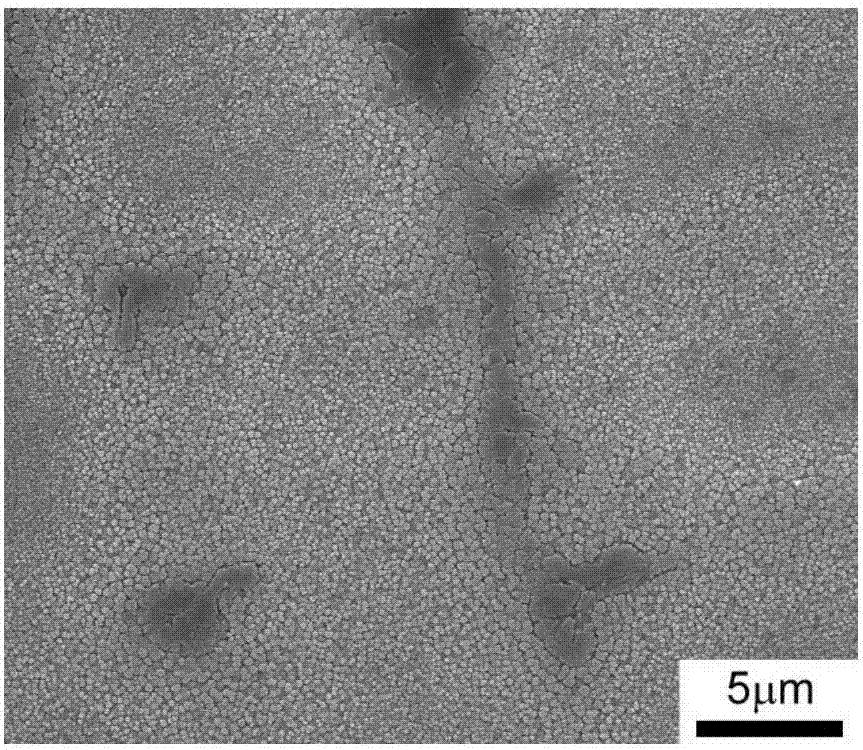

Method for efficiently preparing pore size controllable three-dimensional graphene

The invention provides a method for attaching graphene to foamed metal copper framework through vacuum filtration to control the pore size structure of three-dimensional graphene, which mainly comprises the following processing steps: 1, placing foamed metal copper into a Buchner funnel with spread filter paper, pouring graphene oxide dispersion liquid, and performing vacuum filtration; and 2, coating a polymethyl methacrylate (PMMA) layer on the obtained intermediate compound, reducing with hydriodic acid, immersing in a ammonium persulfate solution to remove the foamed copper framework, then placing in a pipe furnace, introducing argon and hydrogen mixed gas to perform further reduction, and removing the polymethyl methacrylate (PMMA). The process flow is simple and easy to operate, stable in process and low in cost, and can control the pore size and morphological structure of the three-dimensional graphene, thus providing a method for efficiently and stably preparing porous three-dimensional graphene and controlling the pore size thereof; the structural three-dimensional network of the product is continuous and uniform; and the product has favorable adsorbability and electrical conductivity, and has wide application prospects in the aspects of water treatment and electrochemistry.

Owner:SOUTHEAST UNIV

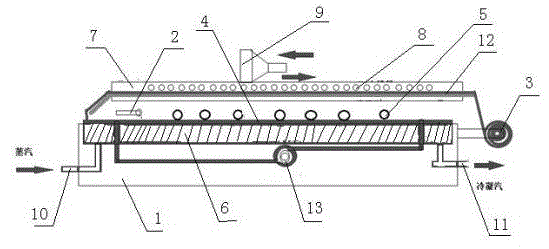

Fully automatic dried beancurd stick and skin machine

InactiveCN105053241ARealize manufacturingEasy to operateCheese manufactureFood scienceMicrocomputerFrequency conversion

The present invention belongs to the technical field of food processing equipments, and particularly relates to a fully automatic dried beancurd stick and skin machine. The fully automatic dried beancurd stick and skin machine includes a body which is provided with a new pulp filling point, and is characterized as follows: the body comprises a heating and cooling device and a conveyer; a drying device is arranged on the top of the heating and cooling device, and one side of the drying device is connected to a collecting device. The fully automatic dried beancurd stick and skin machine is controlled by a microcomputer with frequency conversion, is easy to be operated, can rapidly coagulate beancurd skins, automatically supplement pulp, circulate old pulp with microflow, automatically uncover the beancurd skins, and realize the production of thin beancurd skins, thick beancurd skins, double-layer beancurd skins, small dried beancurd sticks, and large dried beancurd sticks; the machine is designed to have the heat exchange and dehumidification functions, can realize automatic drying during the production process, and ensure the produced products to meet hygienic requirements.

Owner:王风宜

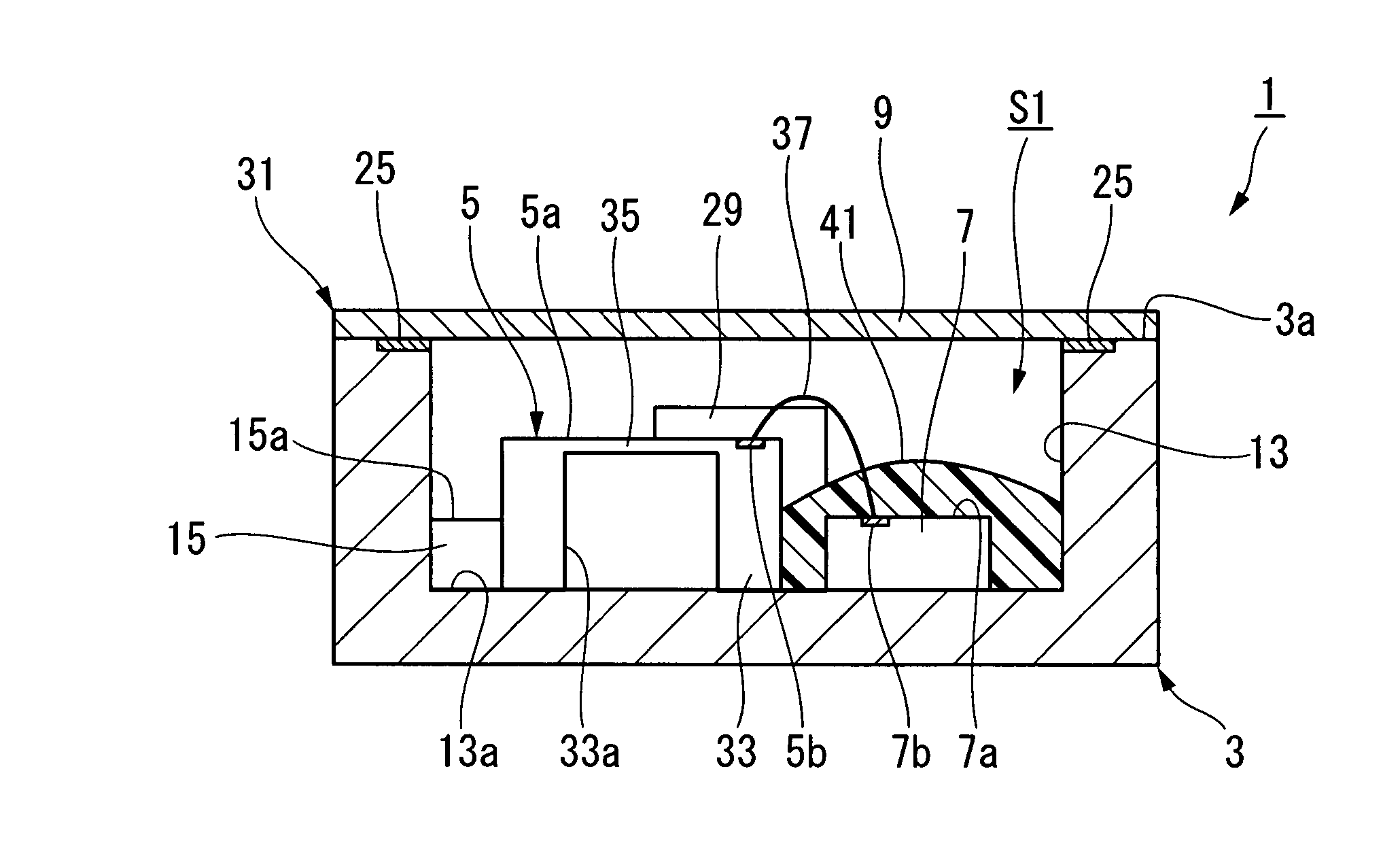

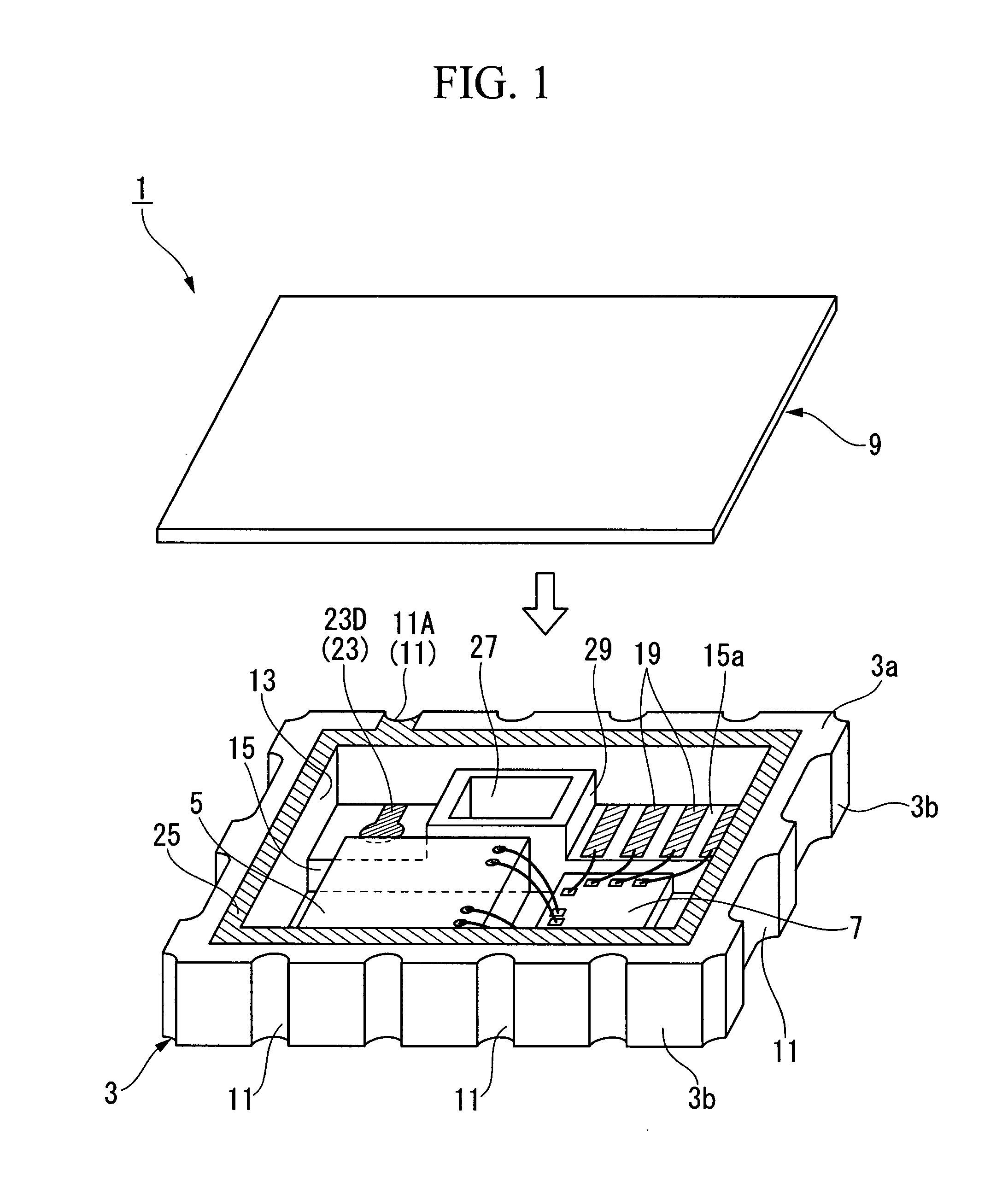

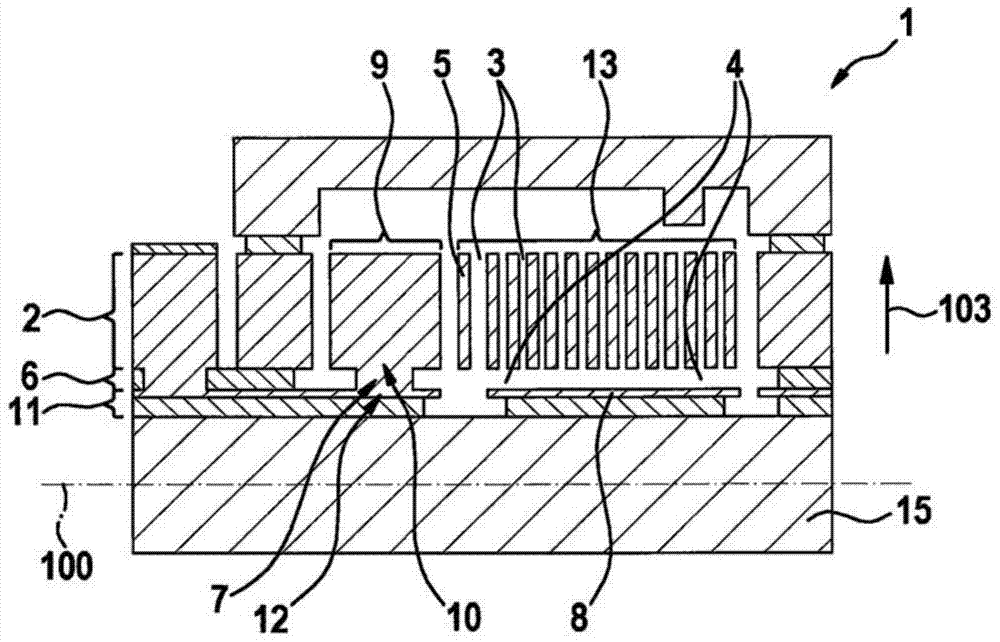

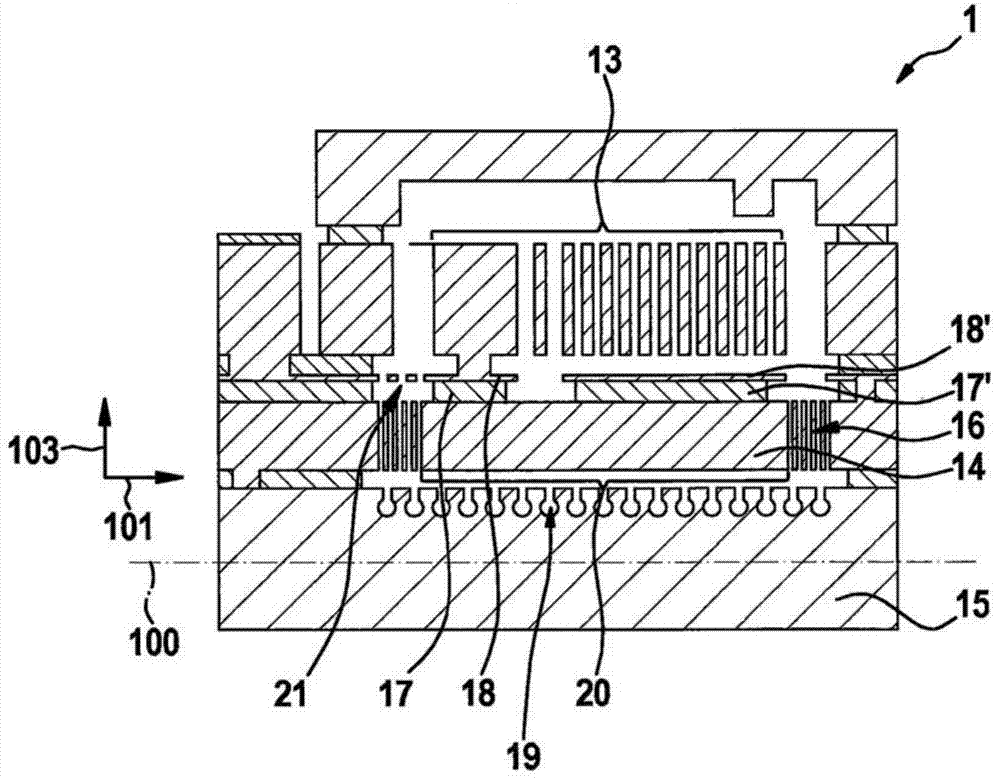

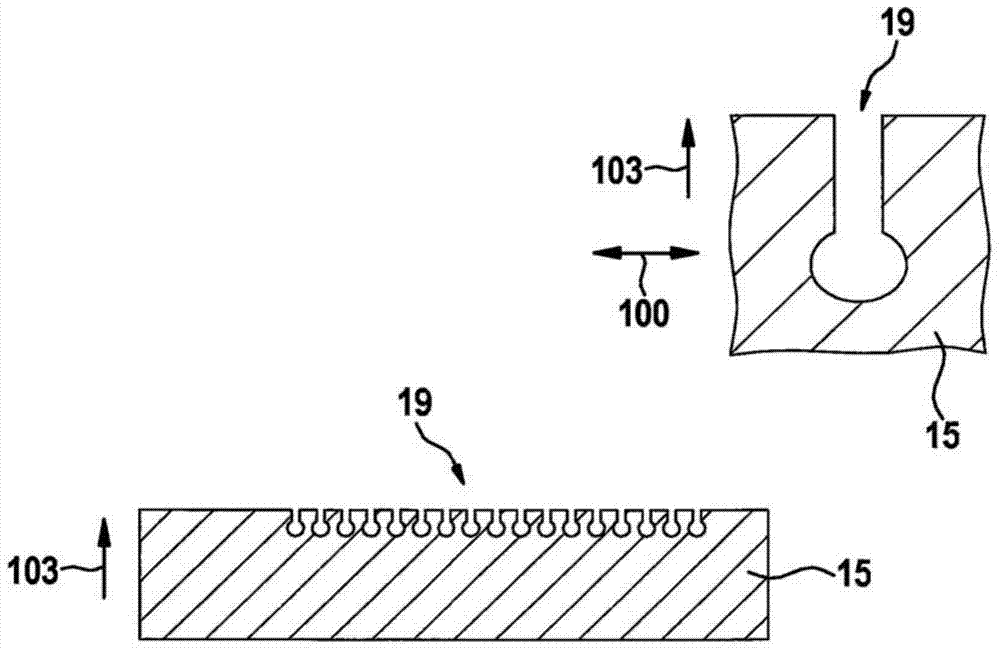

Microphone package

InactiveUS20080056524A1DistanceAvoid flowPiezoelectric/electrostrictive microphonesMicrophone structural associationEngineeringMicrophone

A microphone package includes a housing, which has a cavity and a sound hole for allowing the cavity to communicate with the exterior, and a microphone chip, which is mounted on the mounting surface so as to detect sound within the cavity. The sound hole is opened in connection with the mounting surface and is surrounded by a projection wall projecting upwardly from the mounting surface at a prescribed position in proximity to the microphone chip.

Owner:YAMAHA CORP

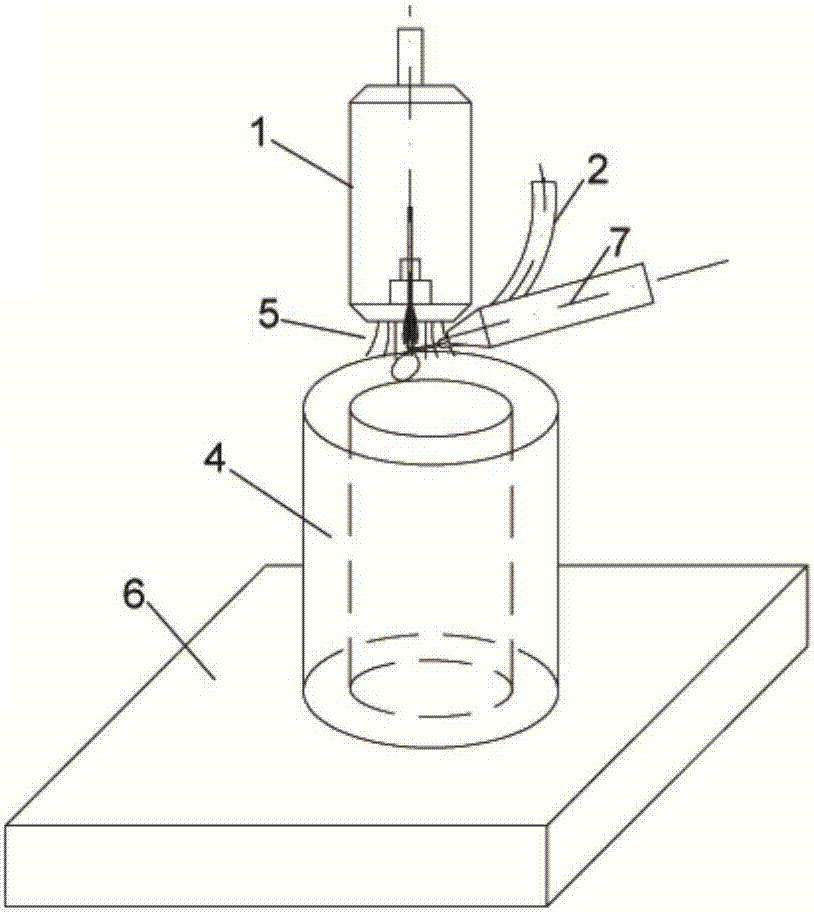

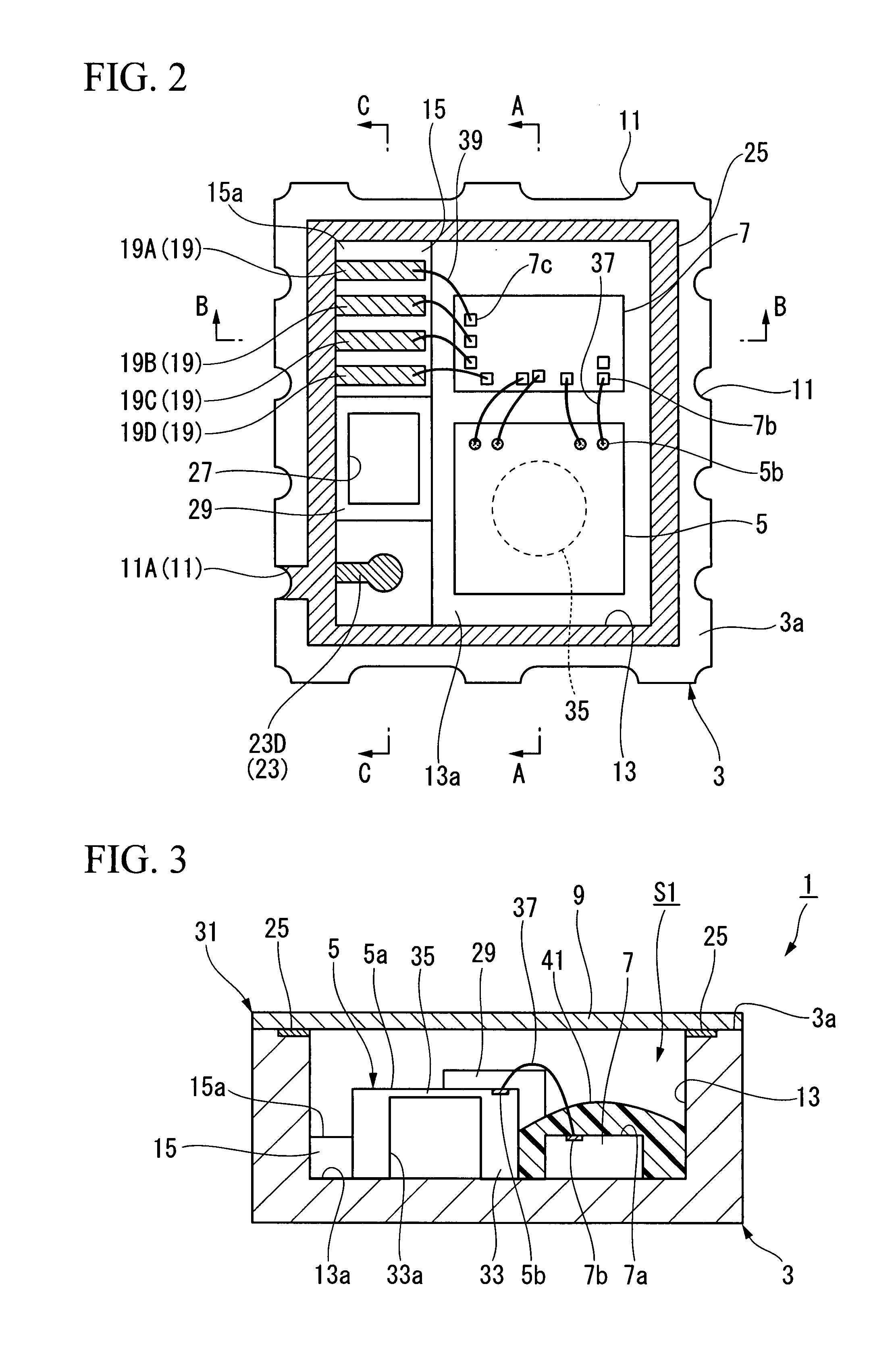

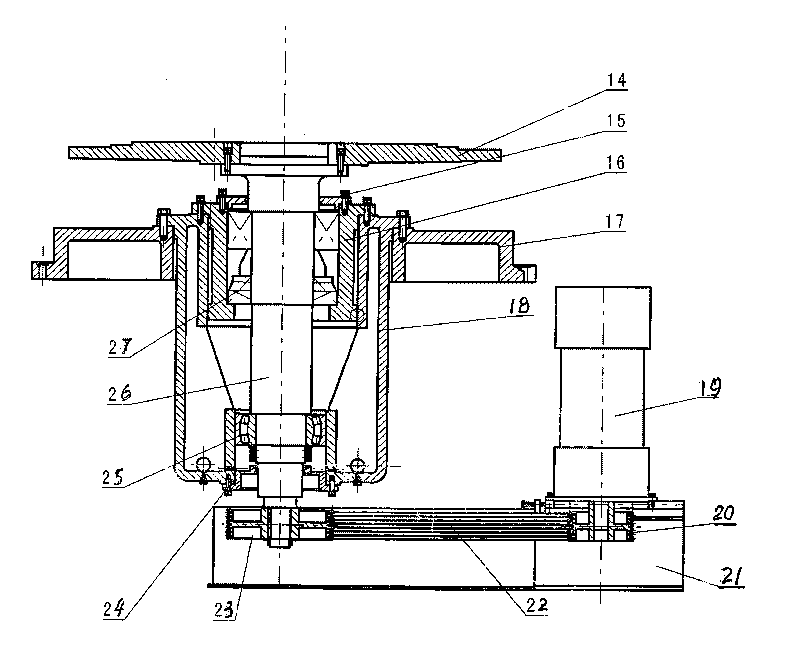

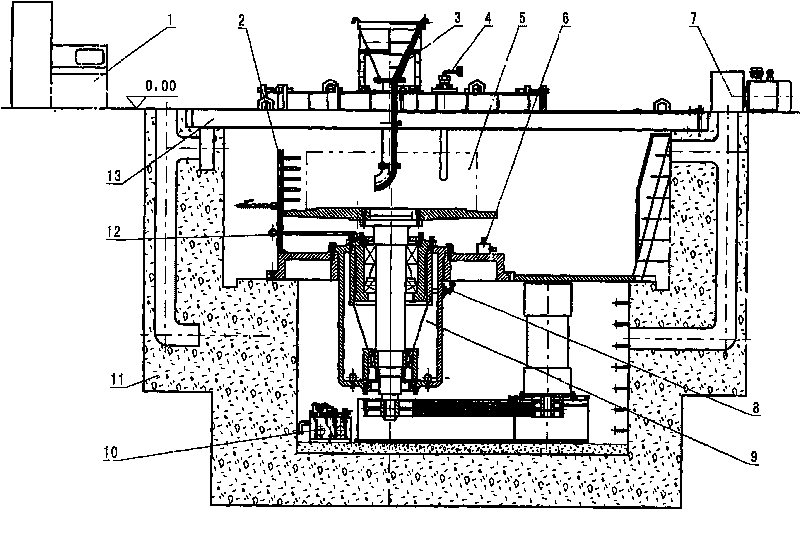

Large vertical centrifugal casting machine

InactiveCN101716664AGuaranteed temperature riseSolve high-risk accidentsAutomatic controlEngineering

The invention discloses a large vertical centrifugal casting machine which is one of centrifugal casting machines. By a reasonable host machine structure and the cooperative working of temperature measuring, vibration measuring, cooling and advanced automatic control systems, the defect of the traditional centrifugal casting machine is overcome, the comprehensive performance of the whole machine is improved, and the safety, the reliability and the carrying capacity are improved, thereby a high-quality casting with a large size can be produced. The machine comprises a host machine, a main motor, a die internal temperature measuring and cooling system, a bearing temperature measuring and cooling system, a pouring system, a vibration measuring mechanism, a lubricating system, an air inducing system, a protecting system and an electrical appliance control system, wherein the host machine is installed on an equipment installation foundation in a pit; the upper end of a main shaft is provided with a die flange, and the lower end is connected with the main motor by a belt wheel and a drive belt. A pouring process curve can be arranged at will and automatically traced, and a host machine die has stepless smooth speed regulation. The machine is used for industries of steel, electricity, petroleum, nuclear engineering, and the like to cast a large roller ring, a nonferrous metal sleeve part and a special shape element.

Owner:TIANSHUI HUARONG CASTING MACHINERY

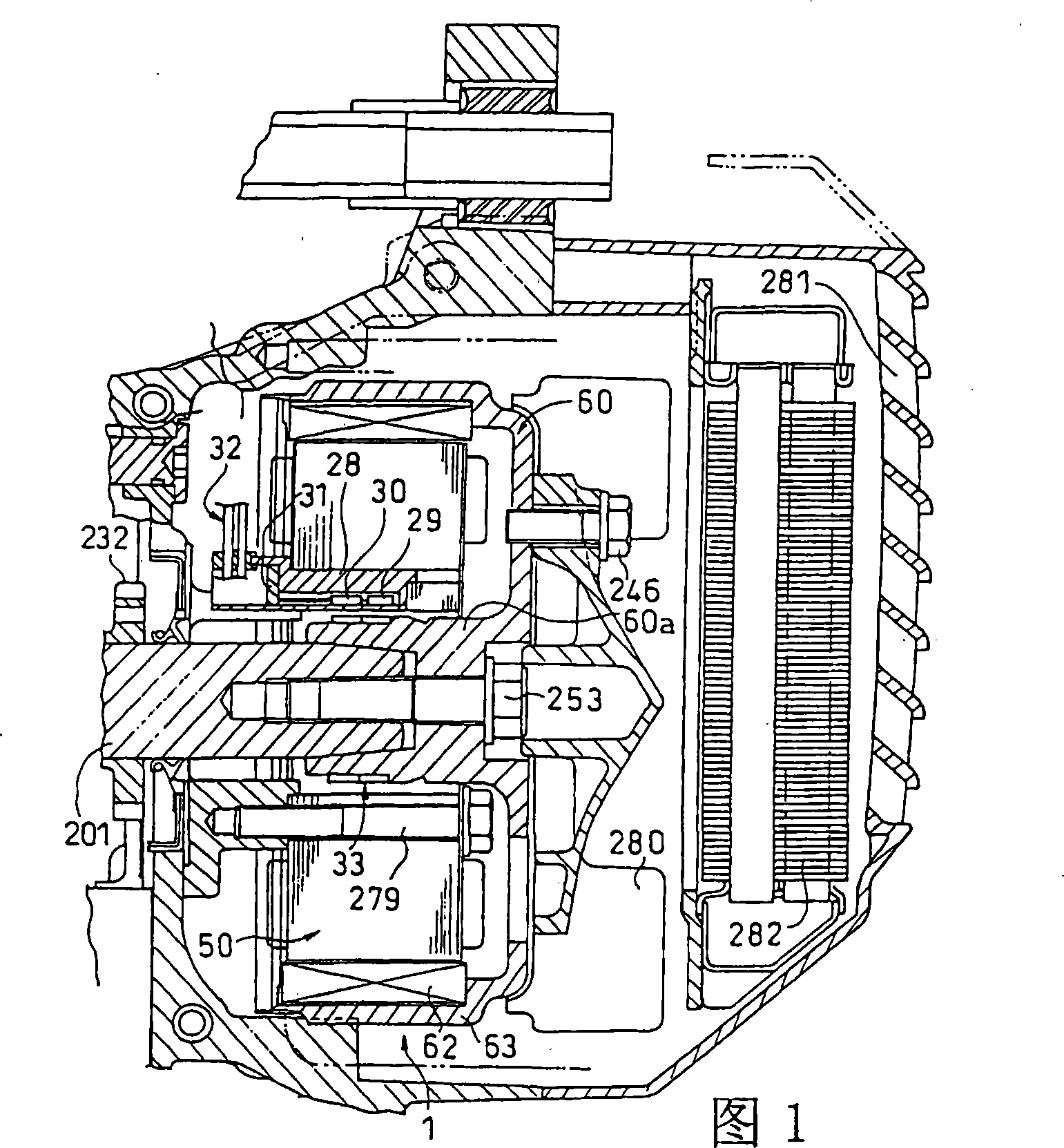

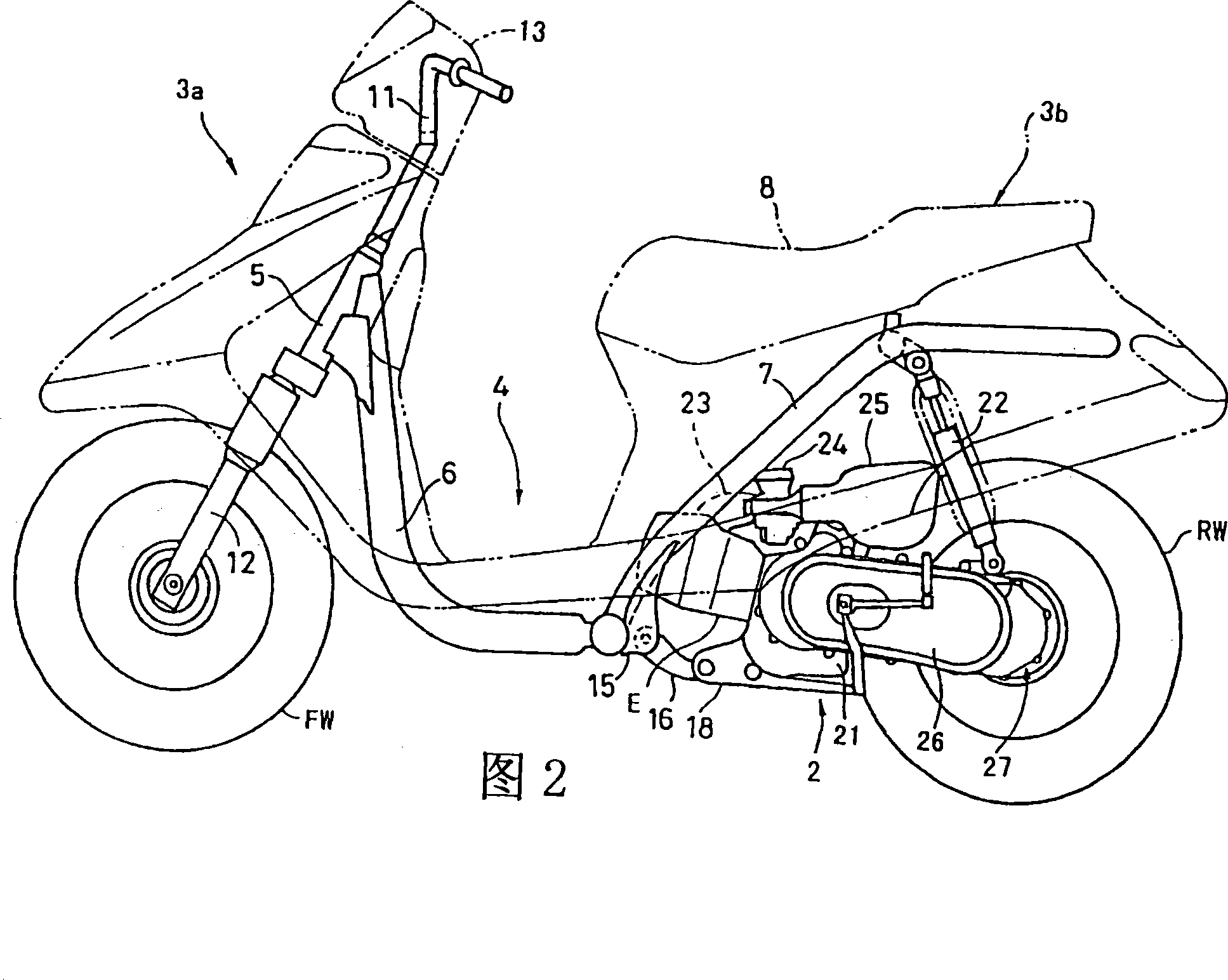

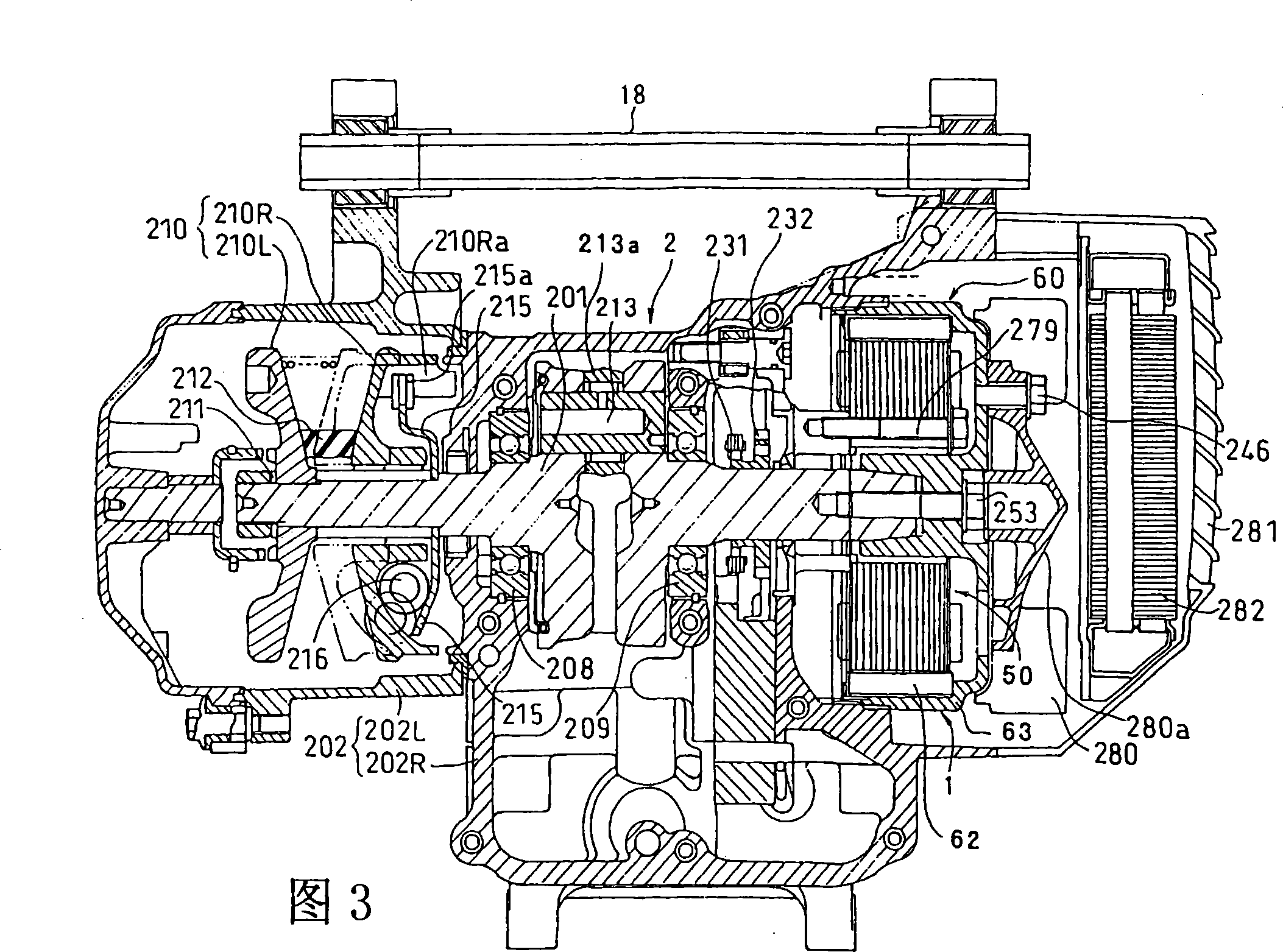

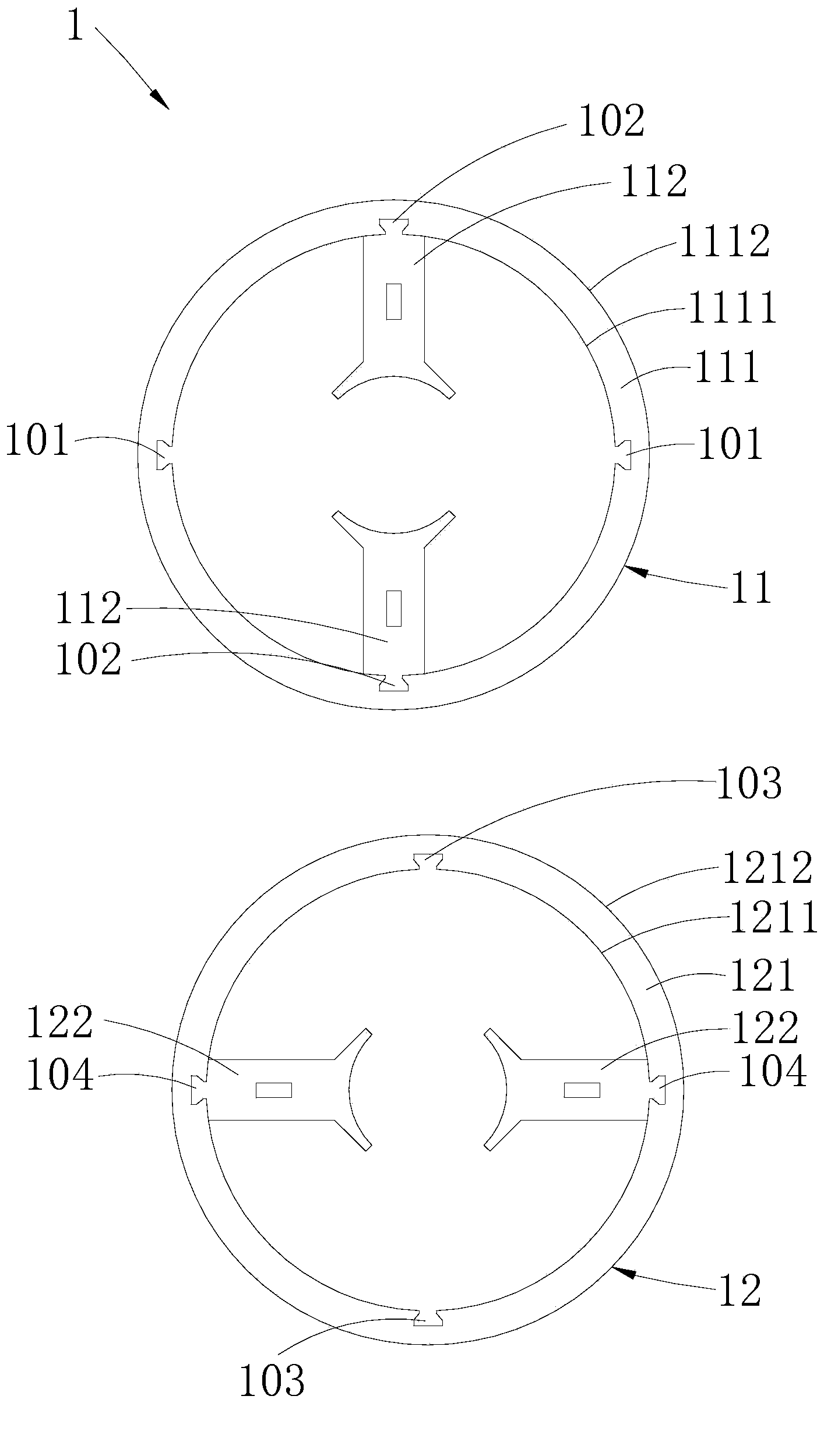

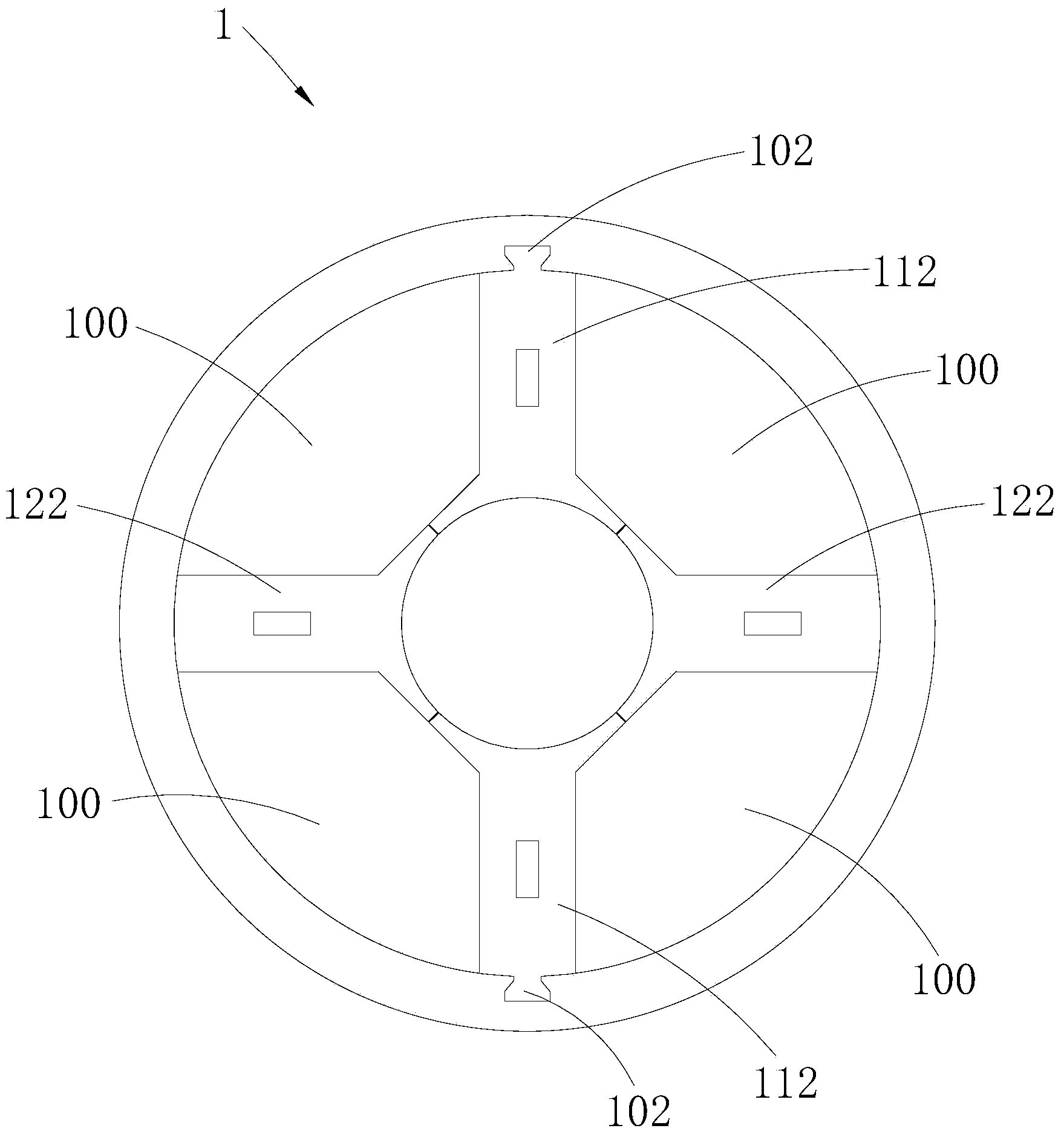

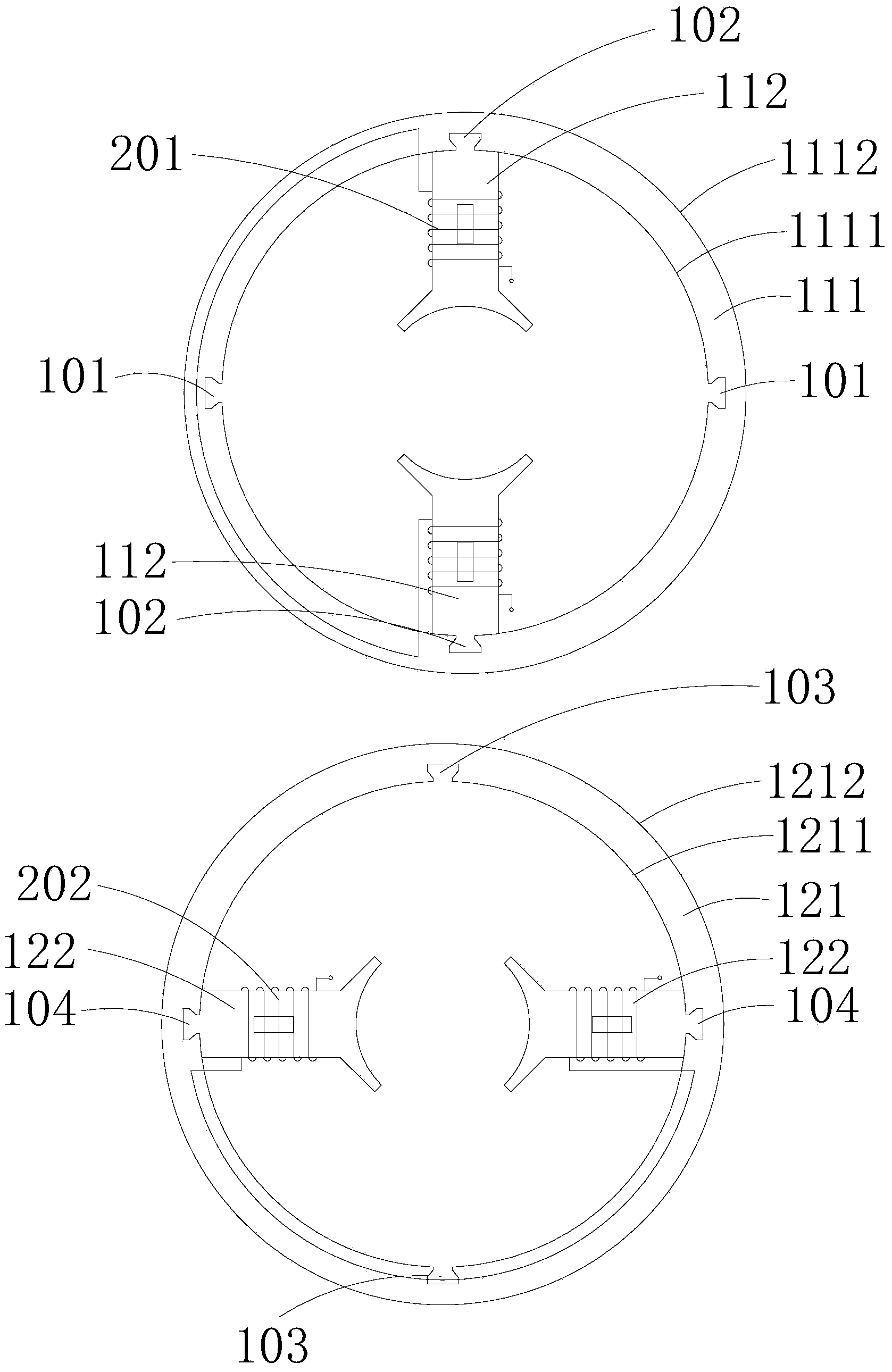

Starter generator

InactiveCN101126364AUse of spaceRealize manufacturingElectric ignition installationMachines/enginesMagnetStator

To mount a rotor angle sensor and a pulser sensor of a brushless type electric rotating machine in a compact apace, and to improve the detection accuracy of an angular position of a rotor. A starter / generator 1 includes a stator 50 disposed around a crankshaft 201, and an outer rotor 60 which is fixed to the crankshaft 201 and which has a magnet member 62 facing to the outer periphery of the stator 50. A rotor angle sensor 29 and a pulser sensor 30 integrally contained in a sensor case 28 are provided on an inner peripheral surface of the stator 50. Magnet rings 33 are inserted in an outer peripheral portion of a hub 60a of the rotor 60. Since the rotor angle sensor 29 and the pulser 30 are integrally disposed, the sensor case 28 containing these sensors 29 and 30 can be miniaturized. Further, since the rotor angle 29 is mounted on the stator 50, it is possible to improve the accuracy of a positional relation ship between the rotor angle sensor 29 and the stator 50 and hence to improve the detection accuracy of an angular position of the rotor 60 with respect to the stator 50.

Owner:HONDA MOTOR CO LTD

Sensor and method for manufacturing a sensor

ActiveCN104843630ARealize manufacturing——No change in manufacturing stepsDecorative surface effectsSolid-state devicesEngineering

Owner:ROBERT BOSCH GMBH

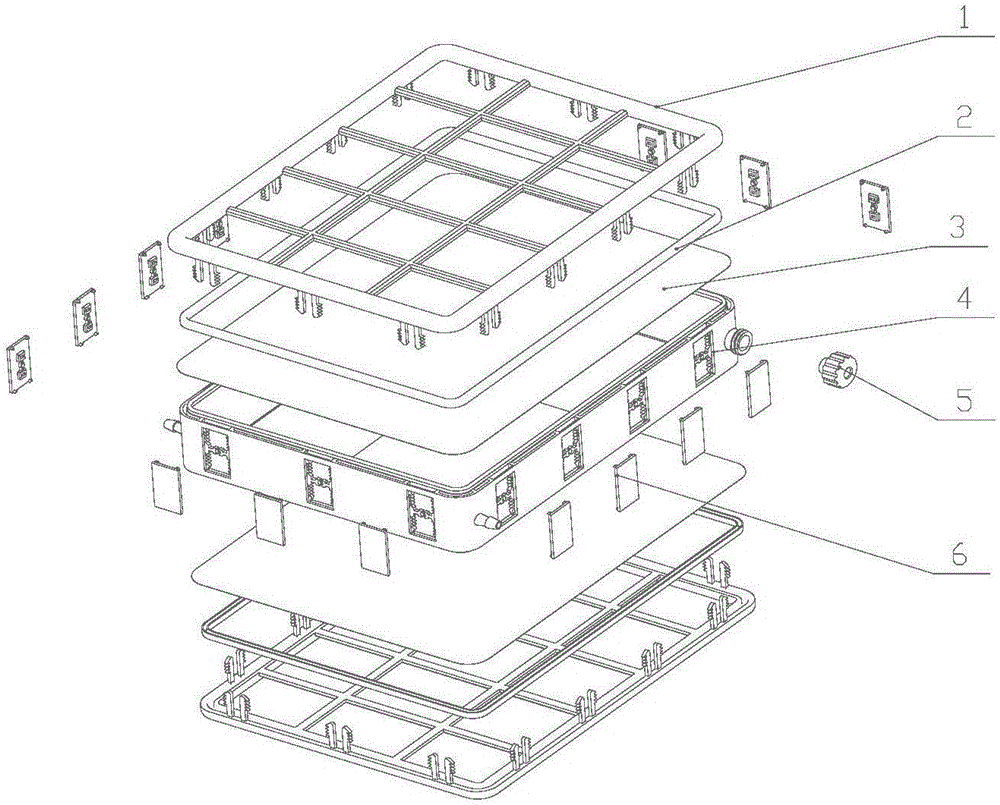

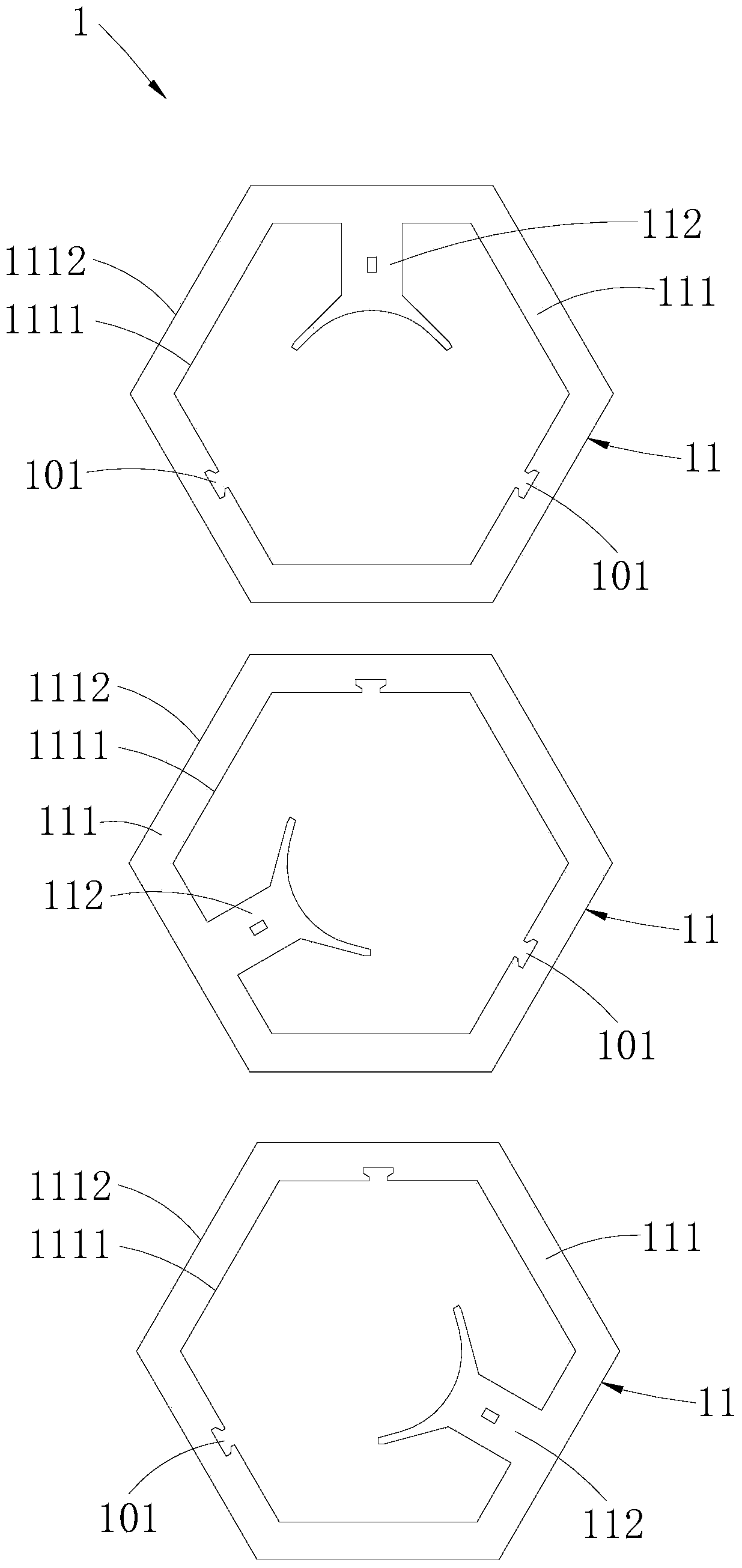

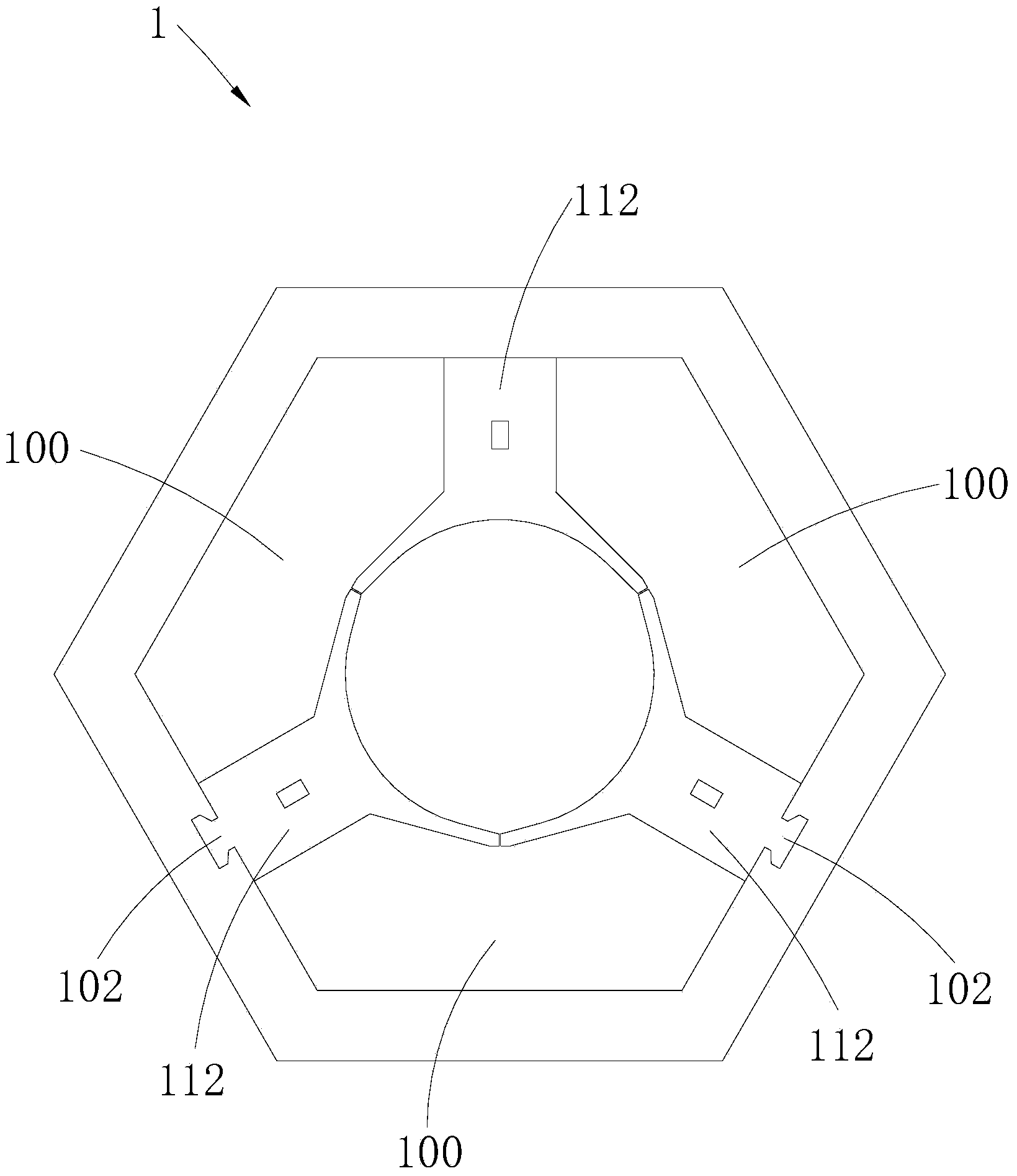

Culture vessel for cell culture and cell sorting

PendingCN106676005AImprove efficiencyHigh scaleApparatus sterilizationTissue/virus culture apparatusTectorial membrane3D cell culture

The invention belongs to the technical field of medical treatment and laboratory equipment, and relates to a novel cell culture vessel related to cell culture. The cell culture vessel mainly consists of a vessel frame, protecting films, end covers, press frames and other components, wherein a plurality of ports can be arranged on the two side surfaces of the vessel frame, the protecting films are pressed on the upper and lower two end surfaces of the vessel frame through the press frames, and then the end covers are screwed on the ports of the vessel frame to form a closed cavity in the whole frame body; also, the ports can be connected with external instruments and equipment to realize continuous perfusion of a culture solution and cell gathering during cell culture. The cell culture vessel is characterized in that cell proliferation and cell differentiation can be realized without the need of filling gaseous substances such as O2, CO2 and N2 required by cell culture, and cell sorting and culture can be carried out in the same culture vessel. The cell culture vessel has a simple structure and convenient use, and the inner space of the culture vessel can realize proliferation and co-culture of various types of cells.

Owner:NANJING XINNUODAN BIOTECH

Method for preparing curcumin from vanillin and related analogues

PendingCN109182398ASynthesis fastSynthetic safetyOrganic compound preparationCarboxylic acid esters preparationBiotechnologyChemical synthesis

The invention relates to a method for preparing curcumin by using vanillin and related analogues, belonging to the technical field of combining chemical industry and bioengineering. The method comprises the following steps: preparing biological fermentation substrate by chemical synthesis of vanillin and its analogues, and carrying out biological fermentation on the biological fermentation substrate to prepare curcumin. The invention combines the chemical synthesis and the biological conversion path and utilizes the cheap raw materials to prepare curcumin, which not only realizes the rapid andsafe synthesis of curcumin, but also has very important engineering significance.

Owner:NORTHEAST DIANLI UNIVERSITY

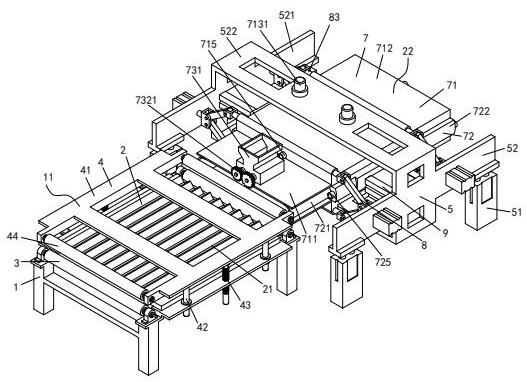

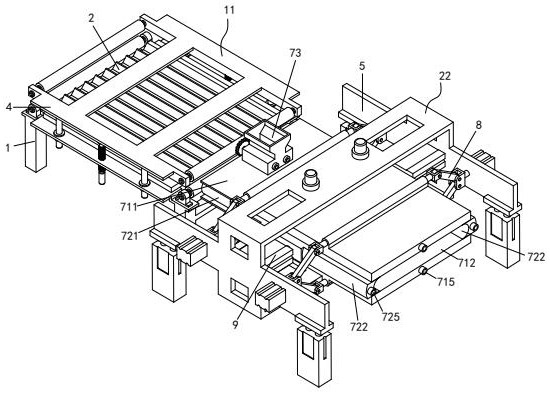

Equipment for automatically producing packaging products

PendingCN113651168ARealize manufacturingGuaranteed to proceed normallyFlexible coversWrappersEngineeringWaste treatment

The invention discloses equipment for automatically producing packaging products. The equipment comprises supporting frames located on the two sides, unit sets are arranged on the supporting frames, each unit set is sequentially provided with a primary feeding unit, a stamping machining unit, a waste treatment unit, a secondary feeding unit, an attaching machining unit, a conveying detection unit and a cutting unit from right to left, the units in the unit group are in transmission through a transmission roller, and the transmission roller is driven by a servo motor. The multiple units are arranged to achieve stamping machining of an upper pearl wool plate in sequence, a lower pearl wool plate and the upper pearl wool plate are heated and integrated through the attaching unit to achieve machining of pearl wool products, positioning control is achieved through a photoelectric sensing device in the conveying process, the servo motor controls the transmission roller to transmit the pearl wool products, normal automatic production is guaranteed, and production and manufacturing of the pearl wool products are achieved.

Owner:姚益林

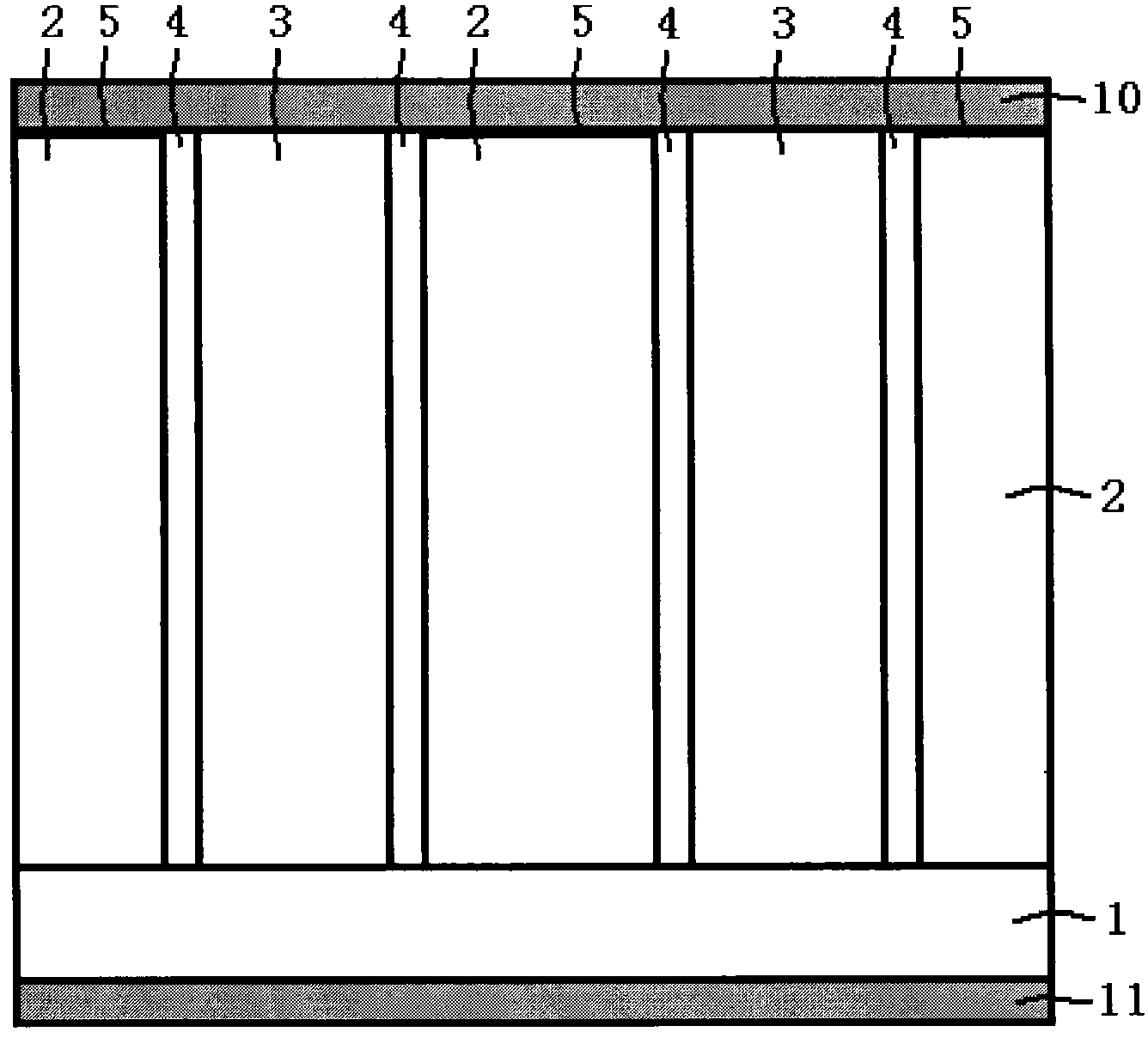

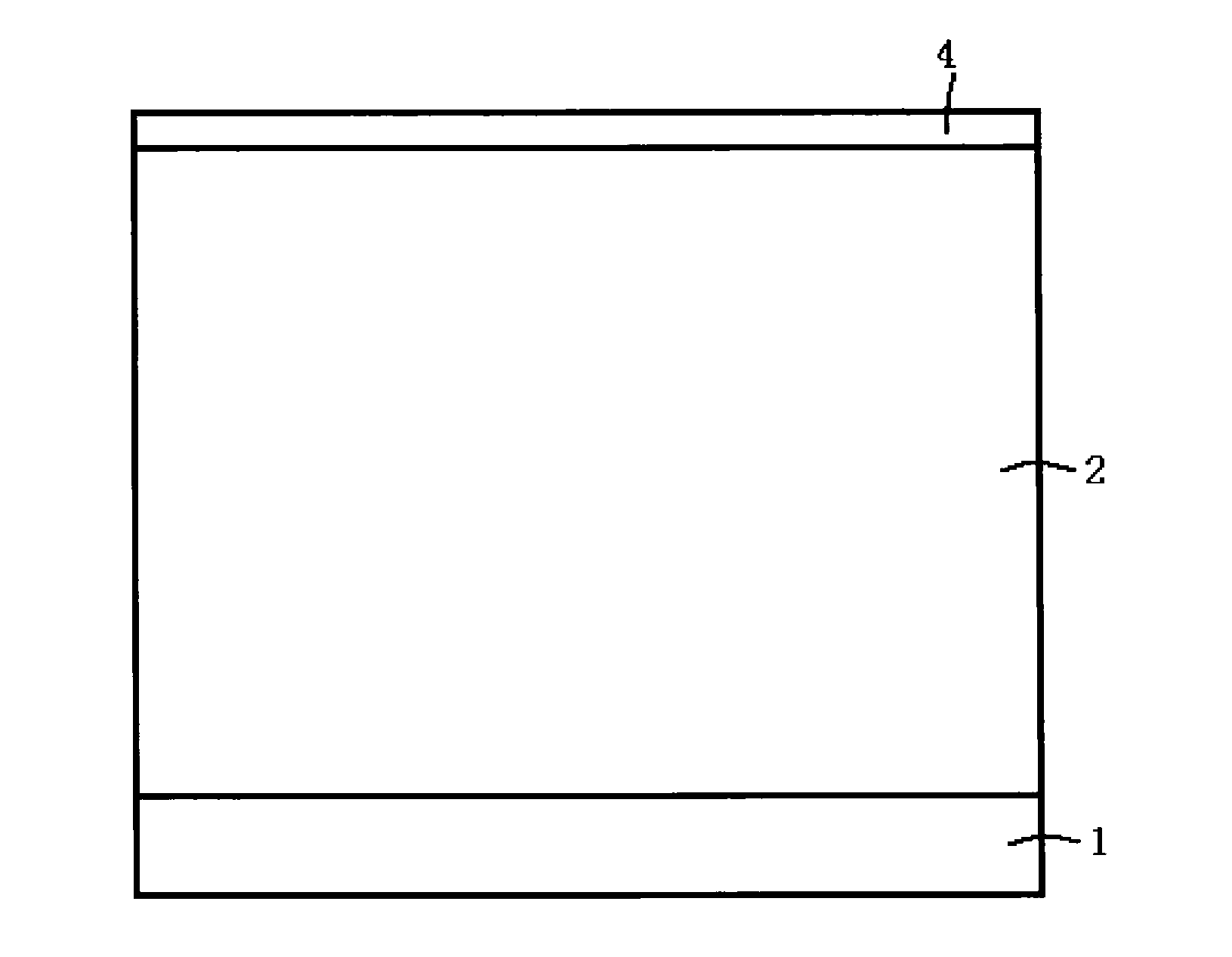

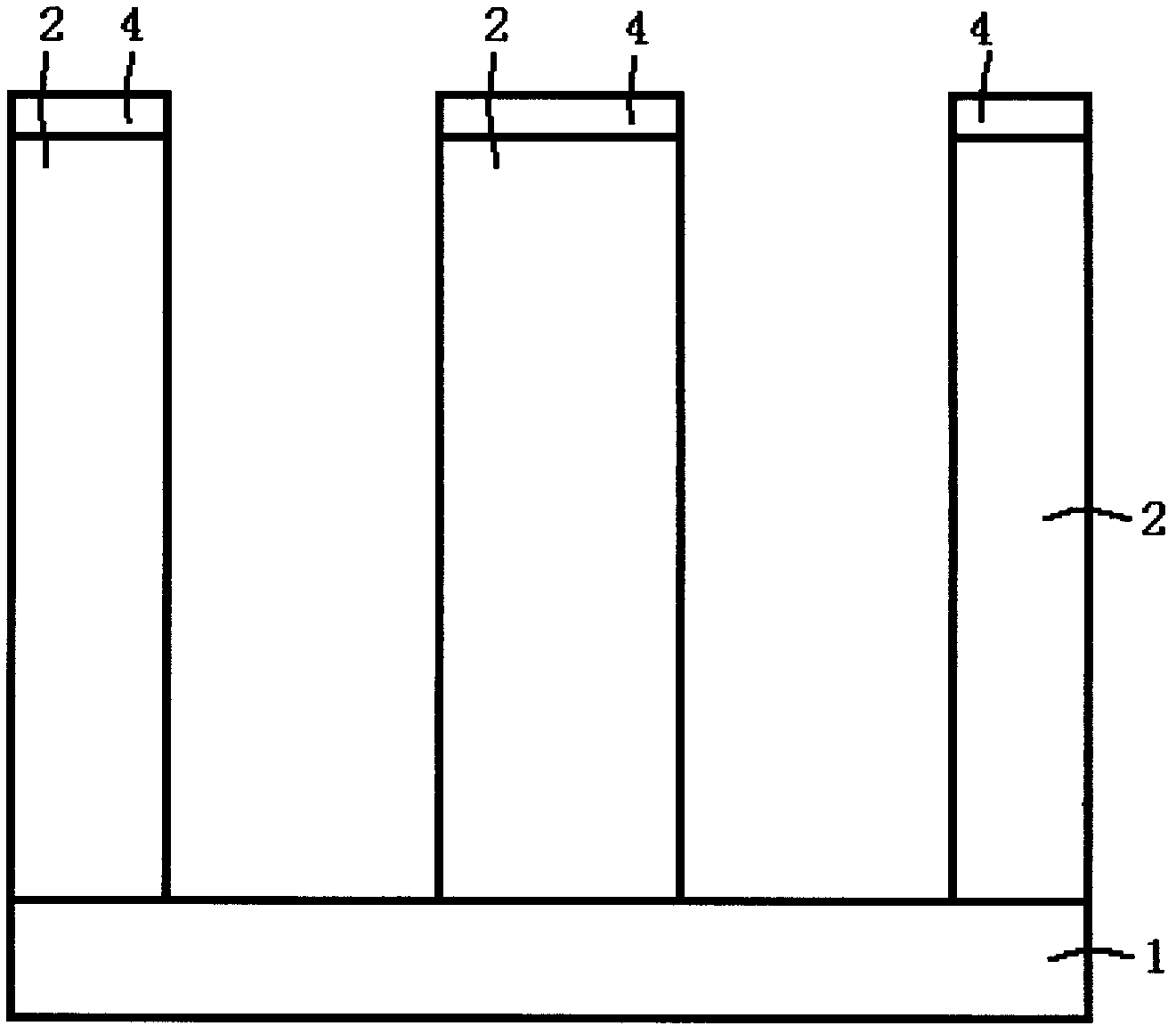

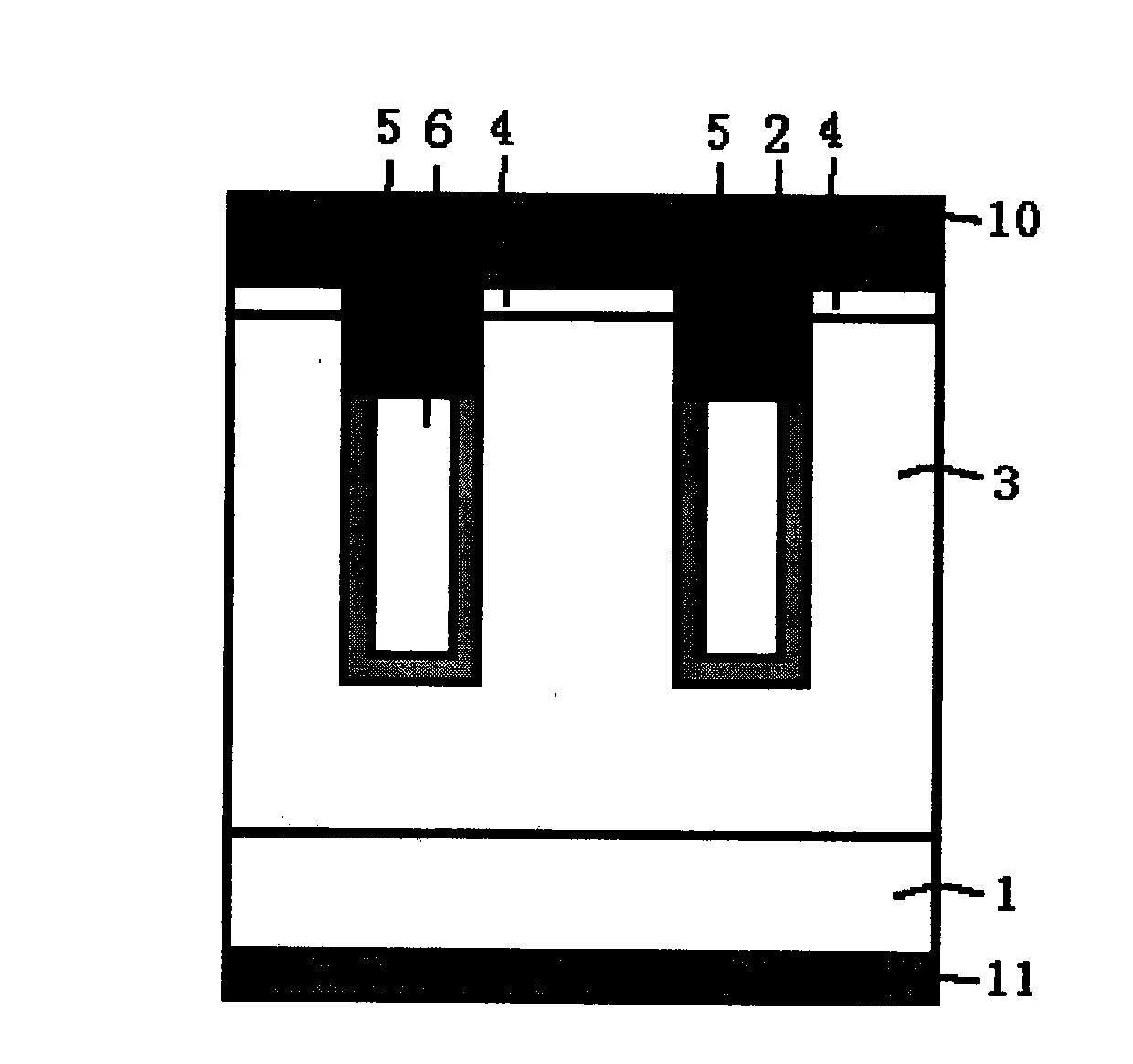

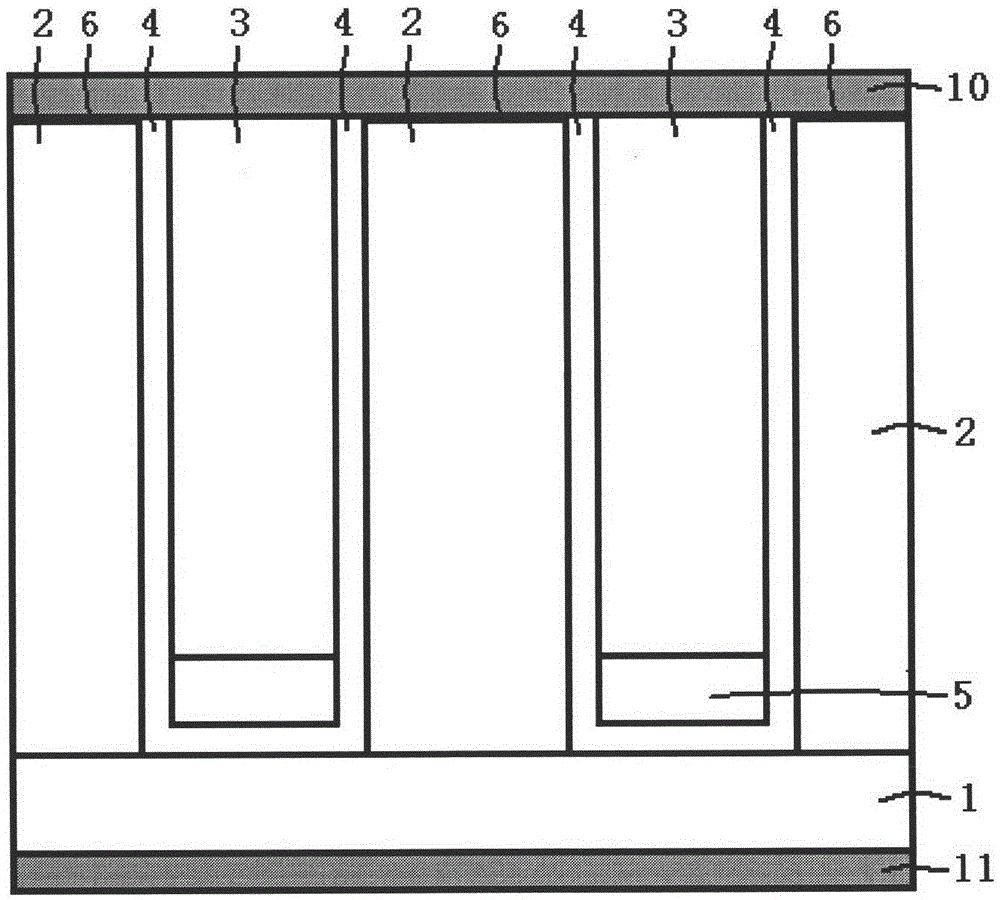

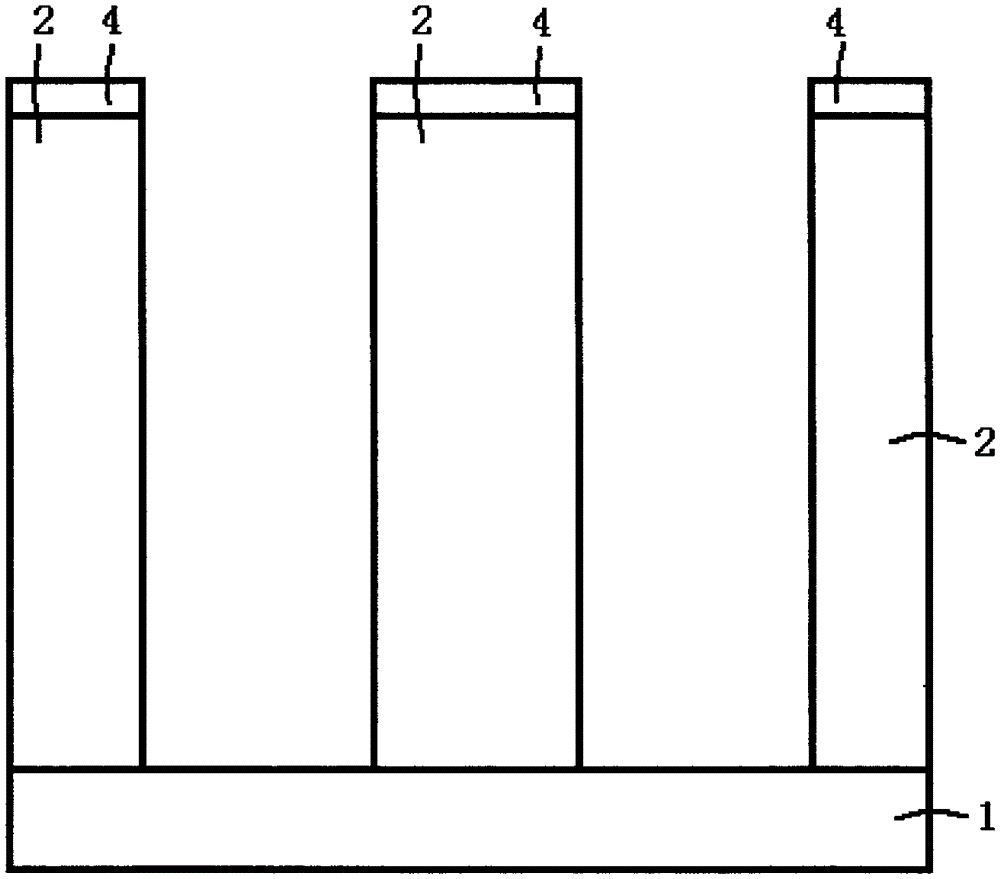

Schottky semiconductor device with insulating layer isolation structure and preparation method thereof

InactiveCN103137711AImprove reverse breakdown voltageLower forward conduction resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesPower semiconductor deviceSemiconductor materials

The invention discloses a Schottky semiconductor device with an insulating layer isolation structure. Through a trench structure, deep strip P-type semiconductor silicon materials 3 can be achieved, and ideal vertical strip semiconductor materials can be achieved through insulating layer isolation. When an apparatus is connected with a reverse bias voltage, the strip P-type semiconductor silicon materials 3 and strip N-type semiconductor silicon materials 2 form charge complementation to form a super-junction structure, and accordingly, the electric field intensity distribution of drift regions is changed, and flat field intensity distribution curves are formed. The invention further provides a preparation method of the Schottky semiconductor device with the insulating layer isolation structure.

Owner:朱江 +1

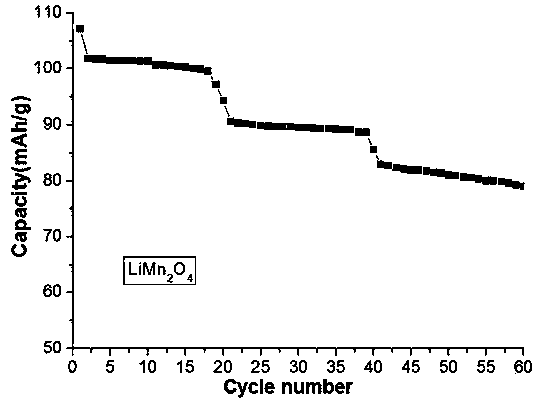

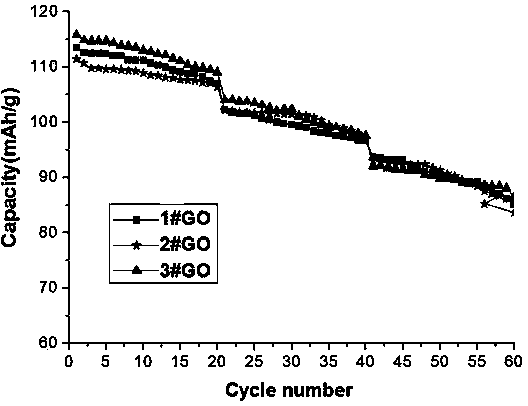

Preparation method of graphene oxide coated lithium salt

ActiveCN103715404ARealize manufacturingIncrease surface areaCell electrodesSecondary cellsAlcoholPhysical chemistry

The invention relates to a preparation method of graphene oxide coated lithium salt. The preparation method comprises the following operation steps: A. adding 3-20 percent by mass of polyethylene glycol to an N-methyl pyrrolidone solution, and stirring so as to dissolve the polyethylene glycol, thus obtaining a solution A; B. adding lithium salt to the solution A, and stirring so as to disperse the lithium salt, thus obtaining a solution B; C. mixing absolute ethyl alcohol suspension liquid with uniformly dispersed graphene oxide ( the mass percent of soluble solids is 0.5%-5%) and the solution B, wherein the usage amount ratio of the suspension liquid to the solution is 1: (1-2.5), uniformly stirring, heating to 70-100 DEG C, keeping the temperature, evaporating the solution so as to obtain humid solid, and drying the humid solid at a normal temperature, thus obtaining the graphene oxide coated lithium salt. Compared with other coating means, the preparation method has the advantages that the method is energy-saving and environmentally friendly, the special process is not needed, the material lost is avoided, and the industrial production of the graphene oxide coated lithium salt is easy.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

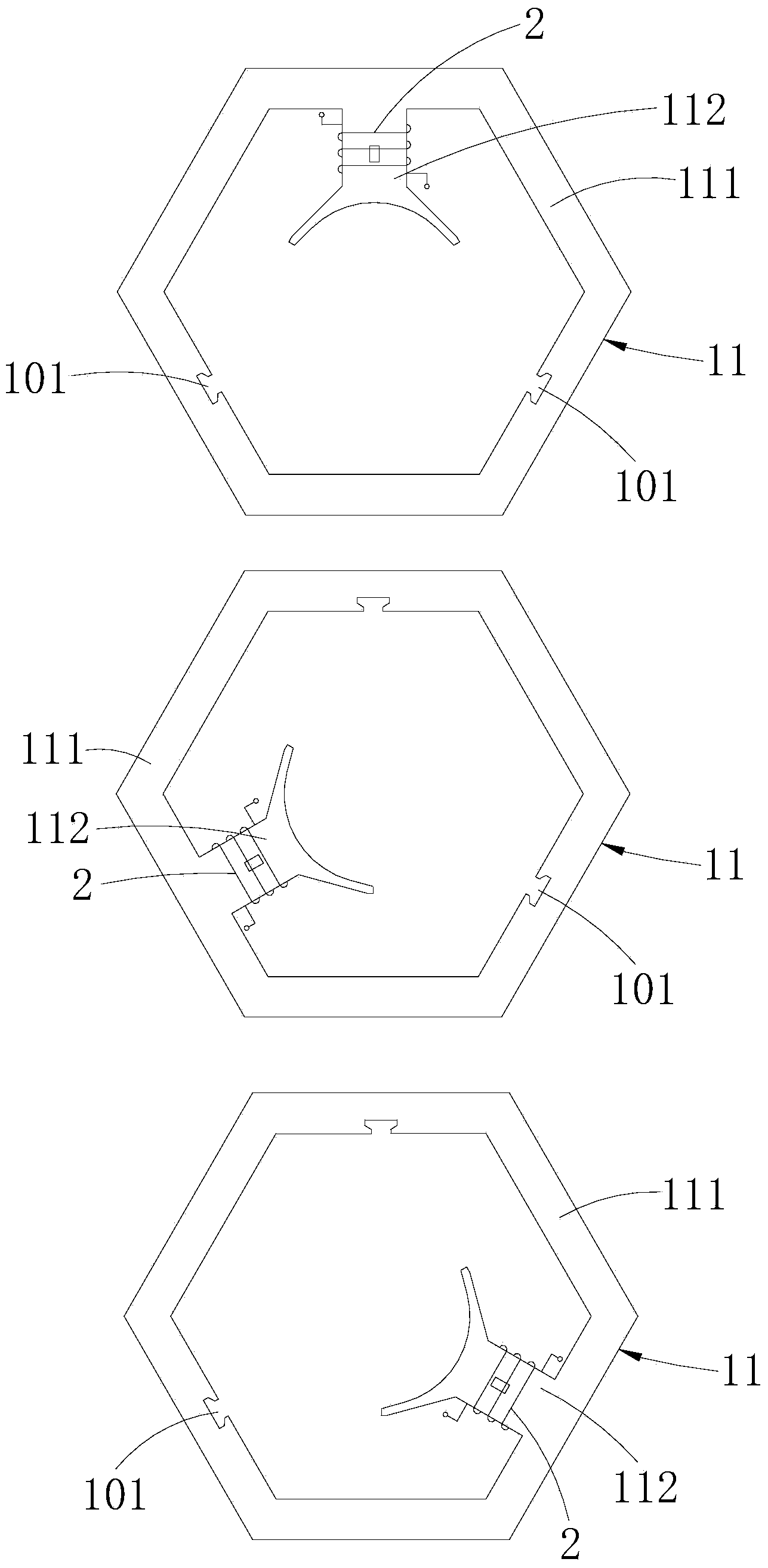

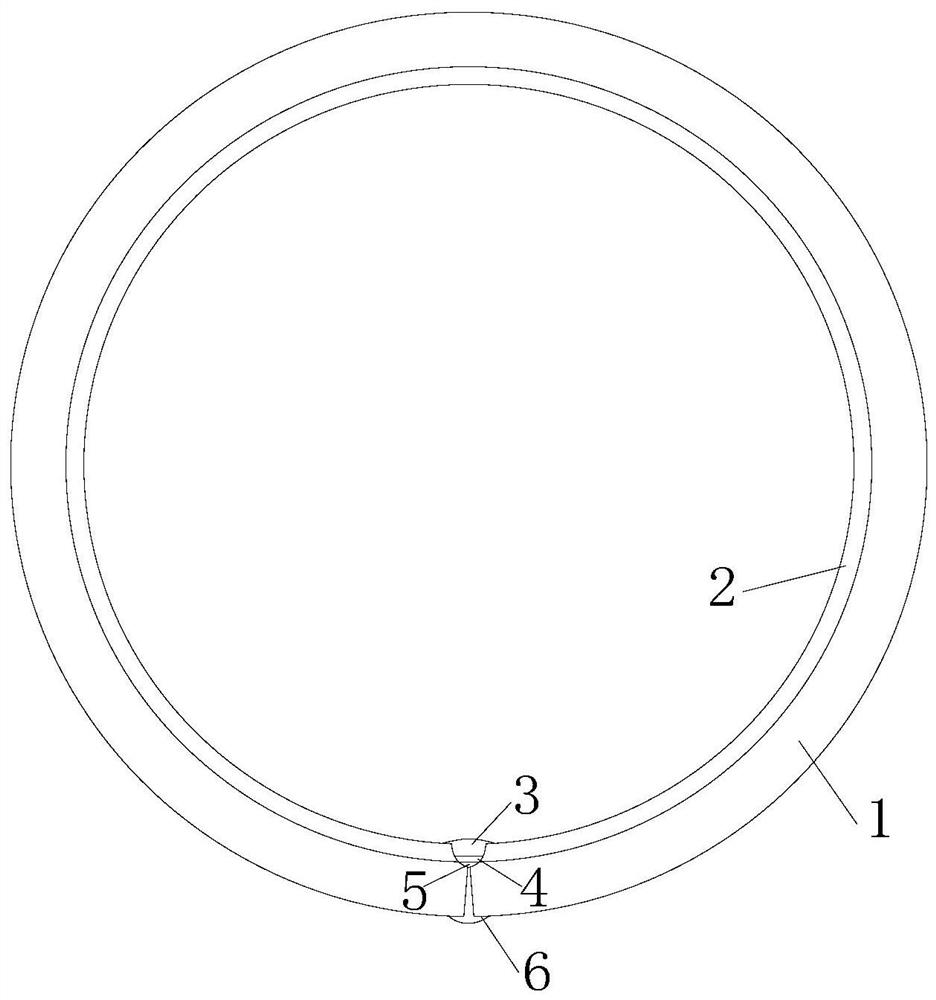

Grating device capable of achieving 2D/3D conversion and displayer containing same

ActiveCN103345067ARealize manufacturingWith the function of three-dimensional stereoscopic displayDiffraction gratingsIdentification meansEngineeringThree dimensional display

The invention relates to a grating device capable of achieving 2D / 3D conversion. The grating device comprises a frame-shaped machine frame, two grating recycling guide rails, a flexible slit grating, an upper locator, a lower locator, a grating tensioning and weighing unit and a plurality of grating recycling units. The grating device enables an LED display screen to directly have the three-dimensional display function, can achieve switch display between a 2D display mode and a 3D display mode according display contents, is simple in manufacturing process and can easily achieve production and manufacturing of large LED three-dimensional displayers.

Owner:FUZHOU UNIV

Manufacturing method for stator

ActiveCN104377903ARealize manufacturingIncrease slot fill rateManufacturing stator/rotor bodiesStatorEngineering

The invention belongs to the field of motors, and discloses a manufacturing method for a stator. The manufacturing method includes the following steps that according to the split manufacturing step of an iron core, a first split body and a second split body which can be axially stacked to form the iron core of the stator are manufactured; according to the winding step, stator windings are wound around the first split body and the second split body respectively, and a first winding coil and a second winding coil are formed on the first split body and the second split body respectively; according to the assembling step, the first split body where the first winding coil is wound and the second split body where the second winding coil is wound are axially stacked to form the stator. Large spaces are provided for winding performed on the first split body and the second split body, the winding efficiency of the iron core of the stator is improved, the slot fullness rate of the stator is increased, the material cost of the stator is lowered, and the performance of a motor is improved; meanwhile, the roundness precision of the stator is guaranteed, the first split body and the second split body do not need to be welded, and therefore the assembling process is simplified.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

Wire and cable production forming processing equipment

ActiveCN114670412ALow costTo meet preparation needsDomestic articlesCoatingsProtection layerElectric cables

The invention relates to the technical field of cable manufacturing, and particularly provides electric wire and cable production forming processing equipment which comprises a guide conveying device used for guiding and conveying a plurality of electric wires and a glue layer forming device arranged at the conveying end of one side of the guide conveying device and used for forming a flat cable insulation protection layer. In the adhesive layer forming device, an adhesive layer forming mold cavity in a forming mold frame assembly is defined by horizontal mold plates which are symmetrically distributed up and down and arc-shaped mold plates which are symmetrically distributed left and right, and the size of the mold cavity can be randomly matched and adjusted according to the number of battery cells of the actually processed flat cable, so that the structure of the mold cavity is variable; the manufacturing requirements for flat cables with different battery cell numbers in the actual production and manufacturing process are met, the production adaptability is greatly improved, the utilization rate of production resources is increased, and the cost of the forming mold is reduced.

Owner:徐州盛丰电子科技有限公司

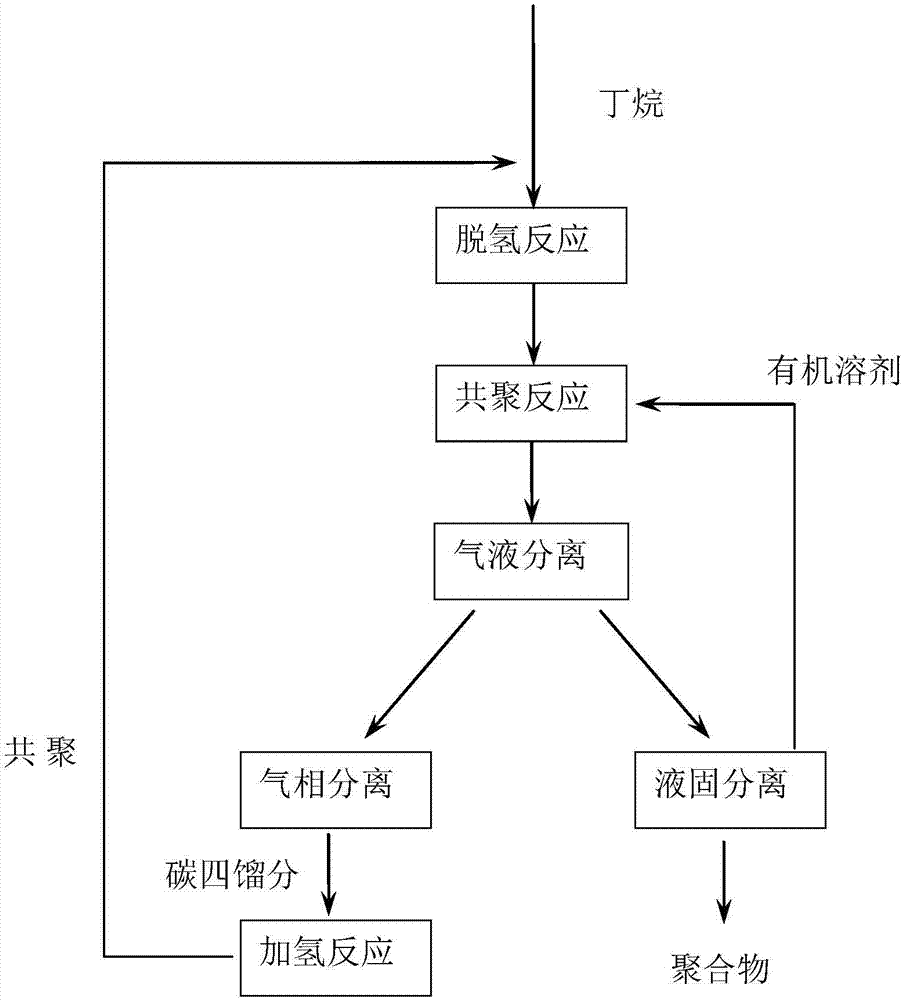

Device and method for processing butane

ActiveCN107880217ARealize manufacturingCatalystsHydrocarbon preparation catalystsHydrogenation reactionGas phase

The invention relates to the processing field of butane and discloses a device and a method for processing butane. The method comprises the following steps: (1) carrying out dehydrogenation reaction on butane, so as to obtain a dehydrogenation product; (2) enabling the dehydrogenation product to be in contact with maleic anhydride, wherein C4 terminal olefin in the dehydrogenation product generates copolymerization with maleic anhydride; (3) carrying out gas-liquid separation on a product obtained in the step (2), so as to obtain a gas-phase product and a liquid-solid mixture; (4) carrying outgas-phase separation on the gas-phase product obtained in the step (3), so as to obtain a C4 fraction, and adding butane obtained through hydrogenation reaction as a circulating material into dehydrogenation reaction in the step (1); and (5) separating the liquid-solid mixture obtained in the step (3), so as to obtain a solid product, namely a polymer containing maleic anhydride functional groups. According to the method, the processing and utilization of butane and the coproduction of the polymer containing the maleic anhydride functional groups can be realized, and butane can be taken as araw material of functional materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

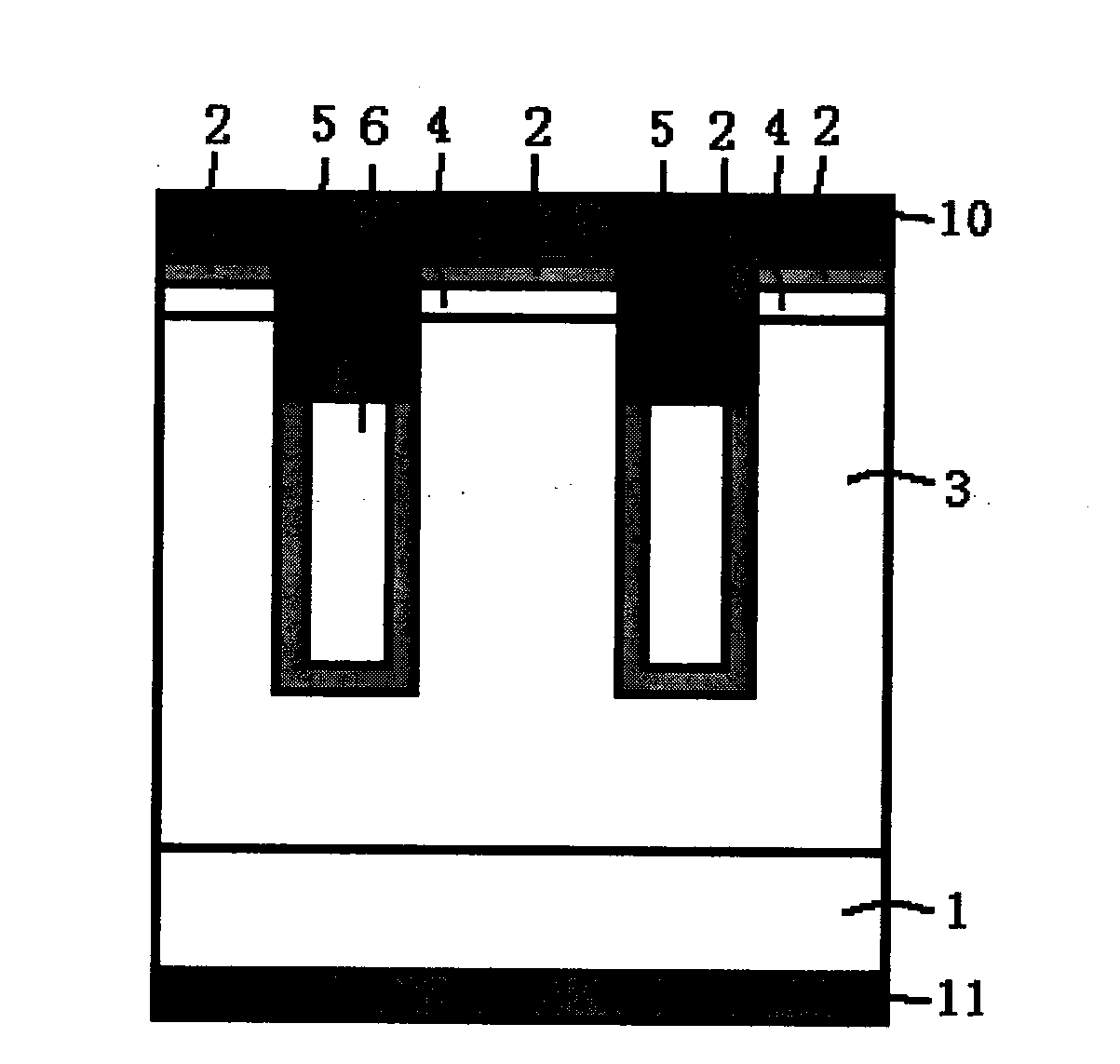

Schottky semiconductor device with grooves and preparation method thereof

ActiveCN103378177AImprove forward conduction characteristicsImprove affordabilitySemiconductor/solid-state device manufacturingSemiconductor devicesSchottky barrierEngineering

The invention discloses a Schottky semiconductor device with grooves. The Schottky semiconductor device with the grooves comprises an MOS structure, a PN junction and a Schottky barrier junction. The electric field distribution of reverse bias voltage is changed through the MOS structure, and therefore the forward-direction conductive character of a component is improved. The bearing capacity of transient high voltage of the component is improved through the PN junction. When the semiconductor device is under the forward-direction small electric current density state, the PN junction is not opened, and therefore minority carrier injection of the component is reduced, and the reverse recovery character of the component is improved. The invention provides a preparation method of the Schottky semiconductor device with the grooves.

Owner:北海惠科半导体科技有限公司

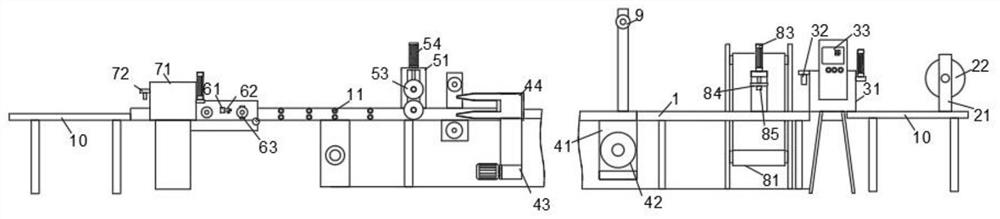

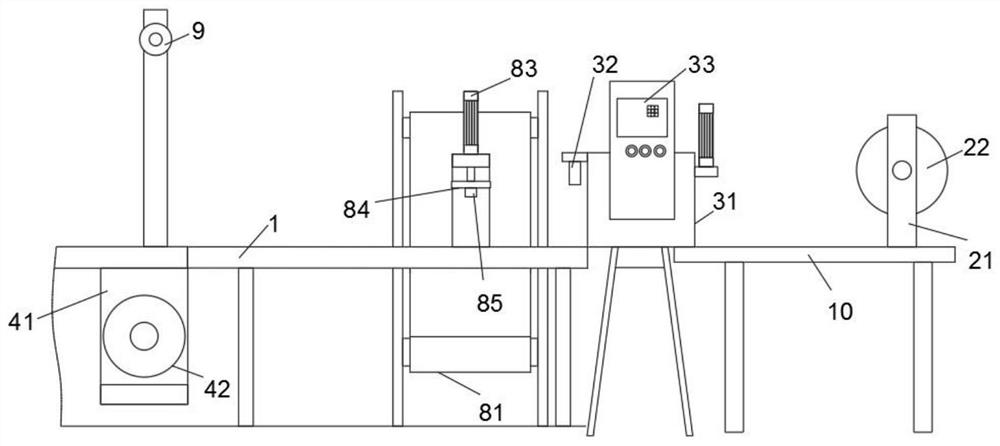

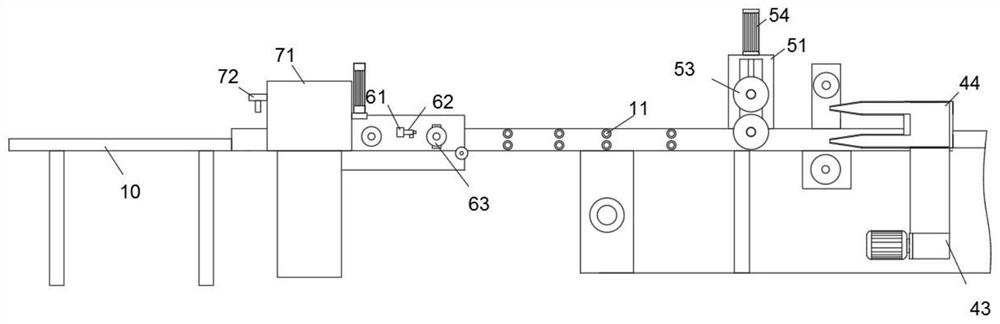

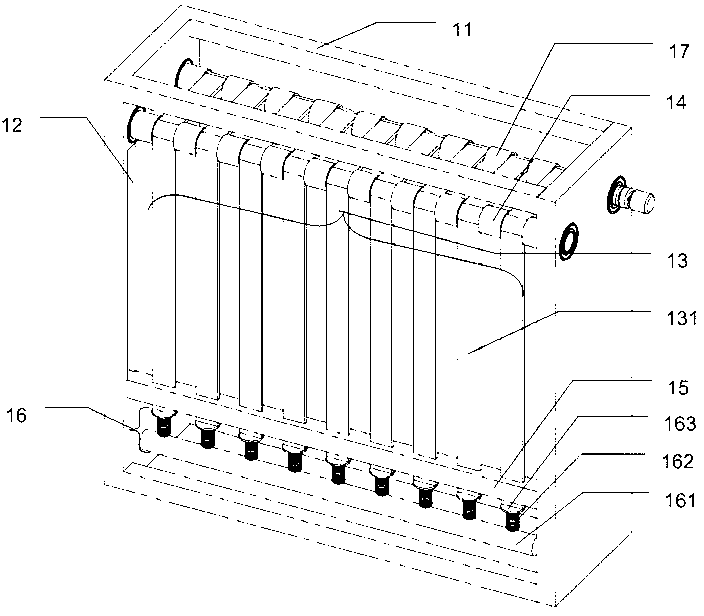

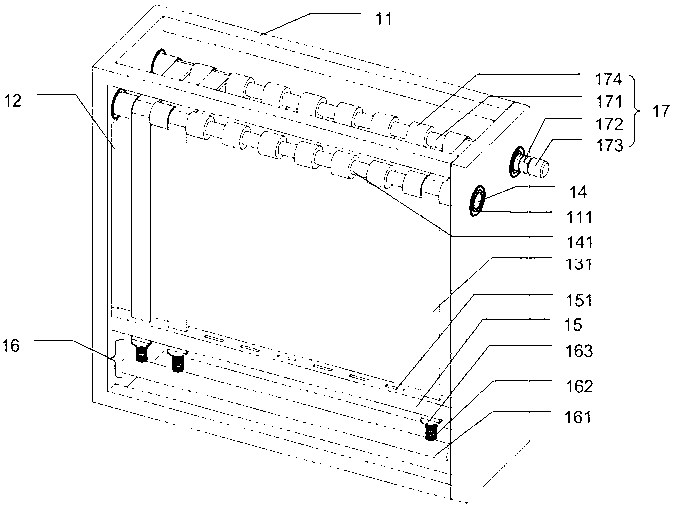

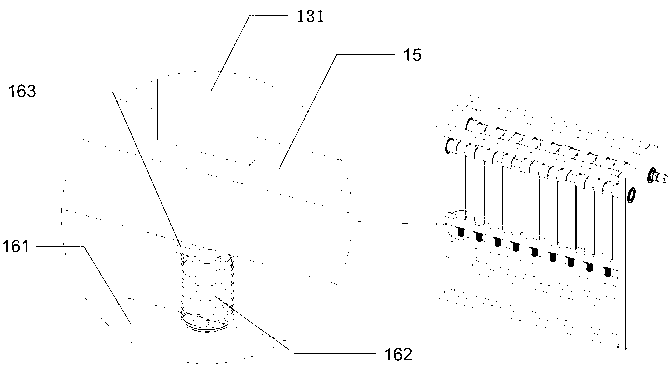

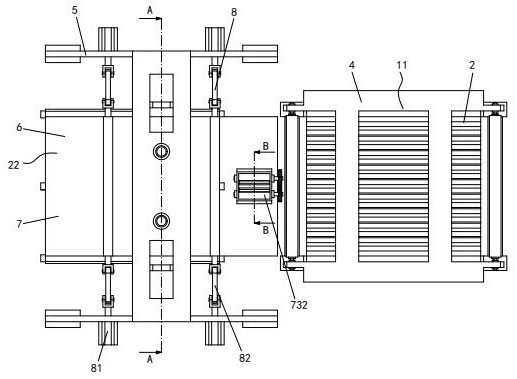

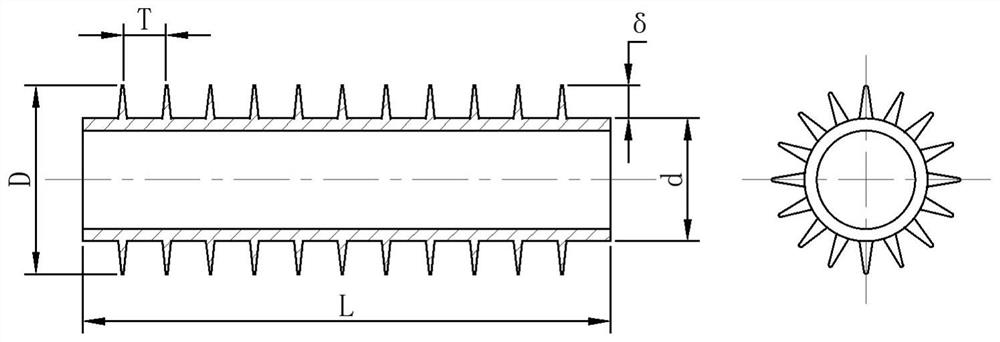

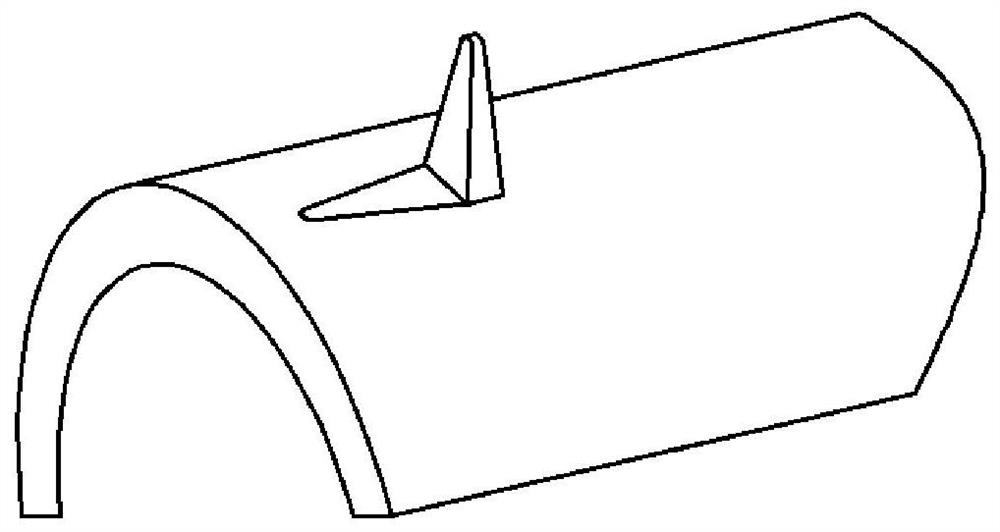

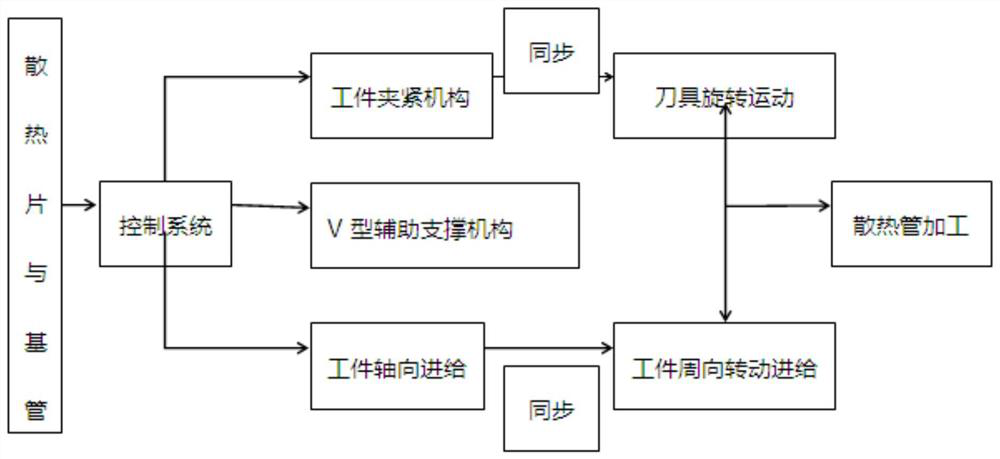

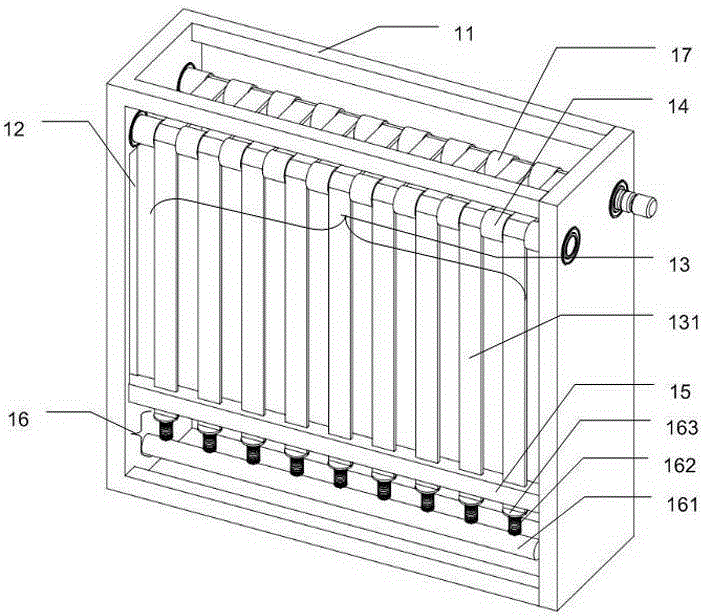

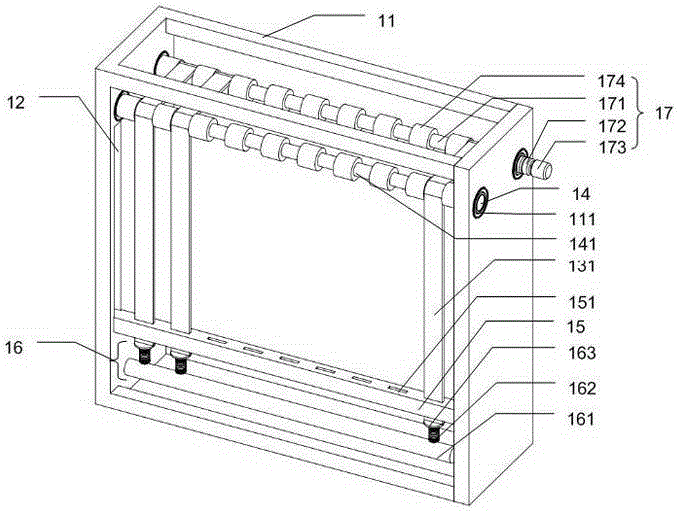

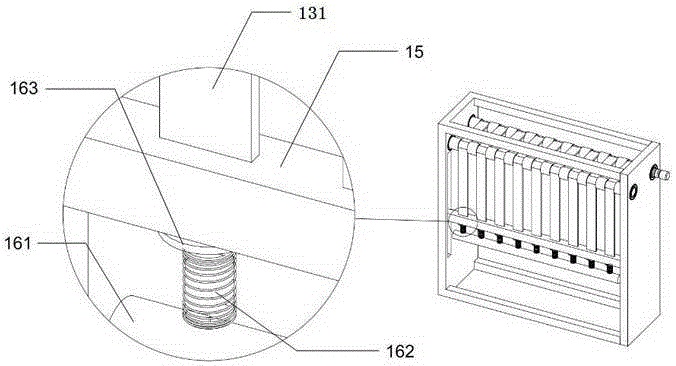

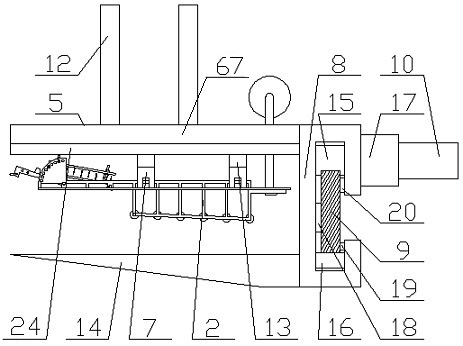

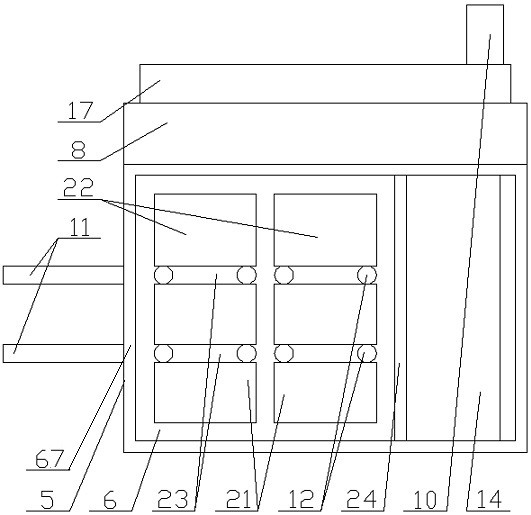

Radiating fin and base tube integrated radiating tube forming machine as well as working method thereof

InactiveCN113814475AReduce thermal resistanceHigh thermal conductivityFeeding apparatusLarge fixed membersHeat transfer efficiencyHeat sink

The invention discloses a radiating fin and base tube integrated radiating tube forming machine as well as a working method thereof. According to radiating fin and base tube integrated radiating tubes processed and produced through the radiating fin and base tube integrated radiating tube forming machine, the heat resistance is reduced and the heat conductivity is greatly improved; through the spiral arrangement of radiating fins, the circulation of a medium (air or a liquid) is facilitated and the resistance is reduced; and furthermore, the medium which flows through the radiating fins is in a turbulent state, the heat exchange between the radiating tubes and the medium is accelerated, the heat transfer efficiency is higher, and the radiating efficiency is higher. The radiating fin and base tube integrated radiating tubes have high shock resistance, durability and pressure resistance. During the processing of the radiating fin and base tube integrated radiating tubes, the volume transfer of a metal material in a plastic state is realized, and the material utilization rate is higher. The manufacturing cost is greatly reduced and the product quality is integrally improved.

Owner:南通品杰模塑科技有限公司

Method for producing environment-friendly cigarette tipping paper with decorative images and texts

InactiveCN108263079ARealize manufacturingProduction methods are environmentally friendlyTransfer printingPunchingTransfer procedure

The invention belongs to the technical field of cigarette packaging, and relates to tipping paper, in particular to a method for producing environment-friendly cigarette tipping paper with decorativeimages and texts. The method includes the following steps that an aluminum coated layer is formed on the surface of cigarette tipping paper body paper through a common aluminum coating transfer procedure; a plurality of color layers are formed on the surface of the aluminum coated layer through a printing procedure, so that a tipping paper semi-finished product is obtained; the tipping paper semi-finished product is placed between a pair of customized steel rods, squeezing is conducted at the pressure of 20-60kg / cm<2>, and accordingly the clear images and texts can appear on the surface of thetipping paper; and slitting, punching and packaging are carried out. According to the method for producing the environment-friendly cigarette tipping paper with the decorative images and texts, the customized steel rods are used for squeezing, and the brand decorative images and texts are manufactured on the surface of the tipping paper. A plurality of stations of traditional gold stamping equipment are modified and applied, and thus the tipping paper can be produced and manufactured. The tipping paper can be subjected to physical squeezing by customizing the two matched customized steel rodswith the corresponding special-edition images and texts based on a traditional tipping paper production technology, no gold stamping or ink printing is required, production is made more environmentally friendly and products are made safer.

Owner:JIANGSU DAYA NEW PACKAGING MATERIALS

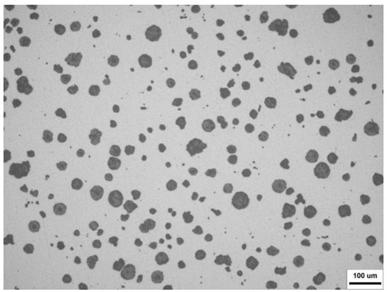

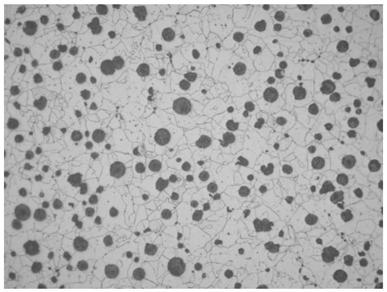

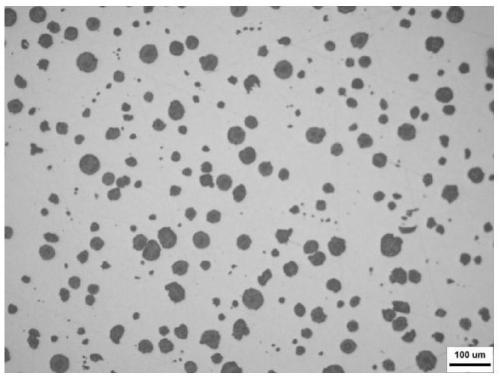

High strength and high extending nodular iron casting and preparation method thereof

The invention discloses a high strength and high extending nodular iron casting and a preparation method thereof. The high strength and high extending nodular iron casting comprises, by mass percentage, 3.1-3.3% of C, 4.1-4.3% of Si, 0<Mn<=0.2%, 0<P<=0.05%, 0<S<=0.02%, 0<Cu<=0.05%, 0<Sn<=0.01%, 0.03-0.045% of Mg, 0<Cr<=0.05%, 0<Ti<=0.05%, 0<Ni<=0.02%, 0<Al<=0.04%, 0<Mo<=0.03%, 0<Co<=0.01% and thebalance Fe and trace elements. The preparation method comprises burdening, fusing, detecting whether the content of components is qualified or not, nodulizing and inoculating, casting, cooling and heat treatment. The nodular iron casting can achieve both high strength and high extending performance.

Owner:SUZHOU TORIN MACHINERY CASTING

Manufacturing method for stator

InactiveCN104377902ARealize manufacturingIncrease slot fill rateManufacturing stator/rotor bodiesEngineeringConductor Coil

The invention belongs to the field of motors, and discloses a manufacturing method for a stator. The manufacturing method includes the following steps that according to the split manufacturing step of an iron core, at least three split bodies which can be axially stacked to form the stator iron core are manufactured; according to the winding step, stator windings are wound around the split bodies respectively, and branch winding coils are formed on the split bodies respectively; according to the assembling step, the split bodies where the branch winding coils are wound are axially stacked to form the stator. Large spaces can be provided for winding performed on the split bodies independently, in this way, the winding efficiency of the stator iron core is improved, the slot fullness rate of the stator is increased, and the material cost of the stator is lowered; openings of winding slots in the stator iron core can be designed to be small, and therefore the performance of a motor is improved. Meanwhile, because the split bodies are axially stacked and assembled, the roundness precision of the stator is guaranteed; the split bodies do not need to be welded, in this way, the assembling process is simplified, and then the production efficiency of the stator is easily improved.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

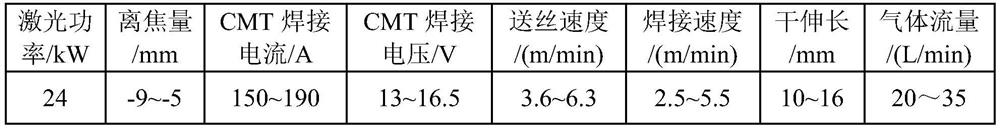

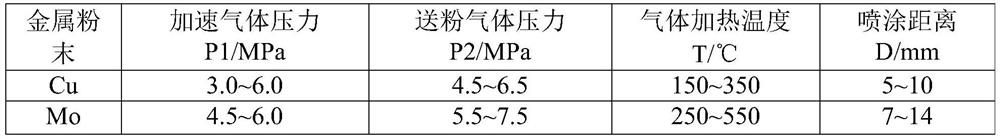

Compound pipe production method based on spraying technology

ActiveCN113458549AGood weld mechanical propertiesSimple designArc welding apparatusLaser beam welding apparatusHard metalTitanium

The invention discloses a compound pipe production method based on a spraying technology. The compound pipe production method based on the spraying technology comprises the following steps: firstly, producing a pure titanium or titanium alloy material and a carbon steel material into a bimetal layered structure compound plate with a required specification in a mode of assembling, explosive welding and continuous controlled rolling and controlled cooling; then designing and processing special grooves; and finally, conducting welding production of a bimetal compound pipe by adopting a laser and cold metal transition compound welding technology, the spraying technology and a pulse TIG welding method. According to the compound pipe production method based on the spraying technology, welding heat input is small, a transition layer can well prevent mutual dissolution of Ti and Fe and mutual dissolution of Ti and C, and generation of brittle hard intermetallic compounds is effectively avoided, so that the comprehensive mechanical performance of a pipe welding seam is guaranteed.

Owner:SHAANXI RAILWAY INST

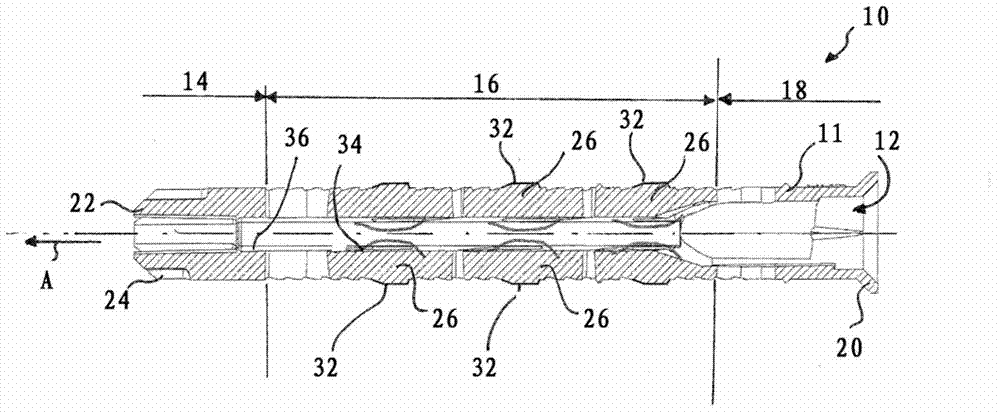

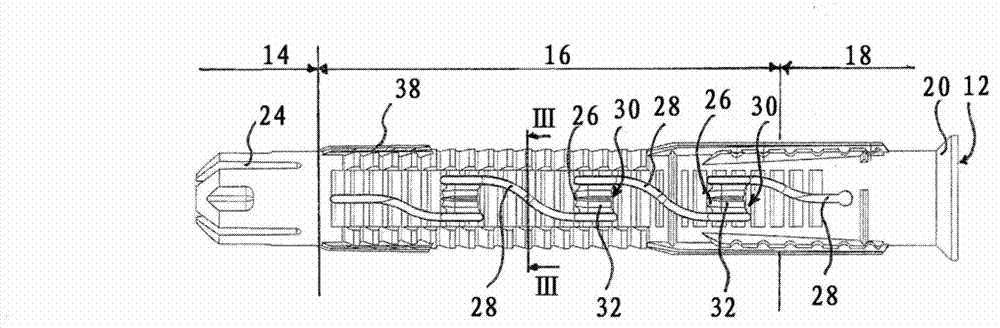

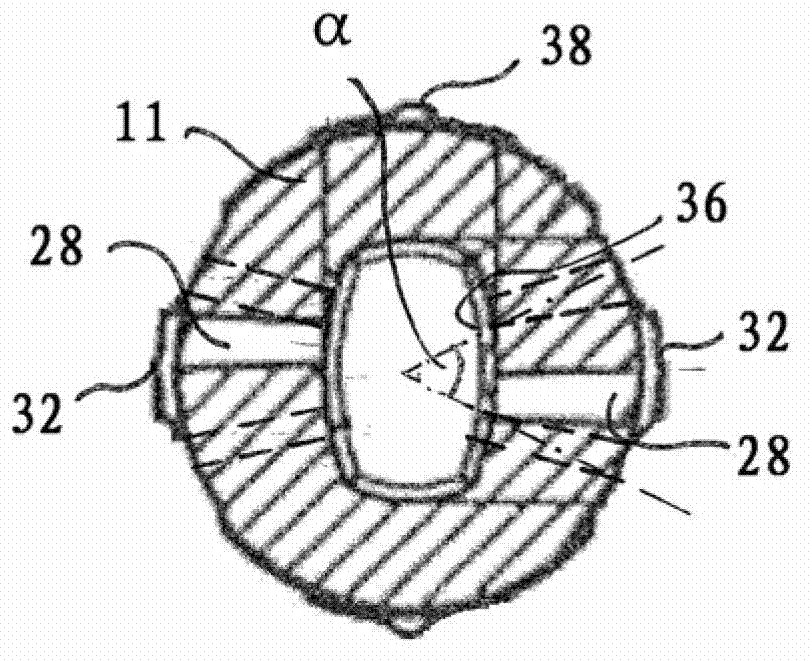

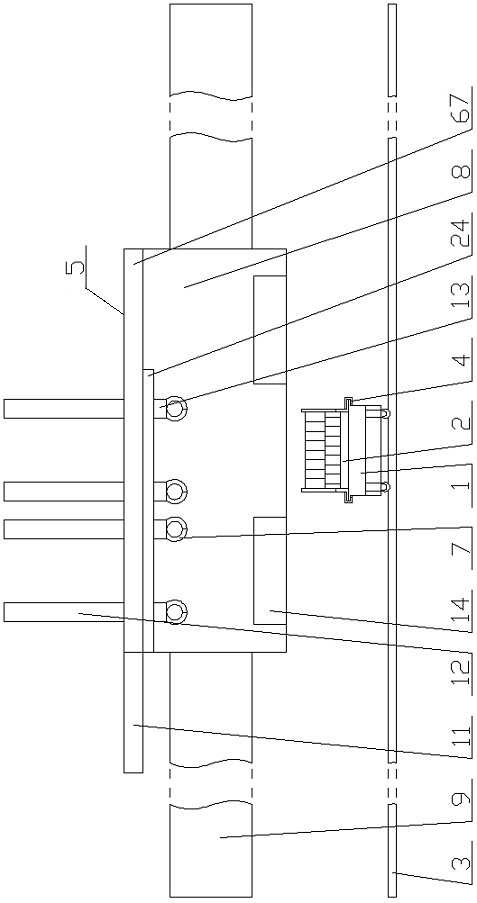

Expansion anchor

Owner:HILTI AG

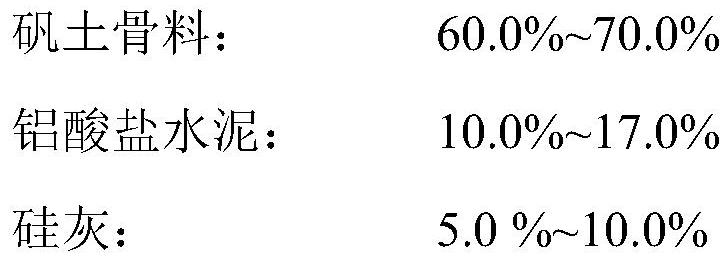

Refractory material for 3D printing and printing method thereof

InactiveCN112341217AImprove efficiencyQuality improvementAdditive manufacturing apparatusAluminateFiber

The invention discloses a refractory material for 3D printing and a printing method thereof. According to the material, the proportion of a traditional refractory casting part is improved, the material is composed of alumina aggregate, aluminate cement, silica fume, activated aluminum oxide micro-powder, additives, fibers and water in percentage by weight; and the additives comprise a solid waterreducing agent, a thickening agent and a thixotropic lubricant, and the additives improve the viscosity, fluidity and stackable property of the material and enhance the printability of the refractorymaterial. A 3D printing technology is used for producing a refractory component in the invention; convenience and rapidness are achieved, an automation degree is high, one-time integral forming of thecomponent is achieved, and large-scale continuous production is facilitated; the printed refractory component is good in compactness, the normal-temperature compression strength of the refractory component is remarkably improved, and production and manufacturing of refractory components which are complex and irregular in structure and difficult to manufacture through molds are achieved; and the whole production process is environmentally friendly, and sustainable development is facilitated.

Owner:NANJING UNIV OF SCI & TECH

Stainless steel enamel glaze and stainless steel matte enamel manufacturing method

The invention relates to a stainless steel enamel glaze material and a stainless steel matte enamel manufacturing method. The stainless steel enamel glaze material comprises the following components in percentage by weight: 30-60% of a bright glaze material; 10%-30% of matte glaze; 3%-10% of clay; 0.1%-0.5% of sodium nitrite; 0.1%-0.5% of borax; 5%-20% of quartz; 1%-4% of aluminum oxide; and 1%-4%cobalt oxide. By improving the glaze components, the matt enamel glaze can be well matched with the expansion coefficient of a stainless steel base material, so that the problem of cracking and porcelain falling caused by mismatching of the expansion coefficient of the existing matt enamel glaze and the expansion coefficient of stainless steel are eliminated. Practical application shows that thestainless steel matte enamel pan bracket produced by adopting the enamel glaze is good in temperature resistance, not easy to explode porcelain and to discolor after being burnt for a long time, and excellent in corrosion resistance and easy to clean and maintain.

Owner:浙江睿达电器有限公司

Grating device capable of realizing 2d/3d conversion and display comprising the same

ActiveCN103345067BRealize manufacturingWith the function of three-dimensional stereoscopic displayDiffraction gratingsIdentification meansLED displayGrating

The invention relates to a grating device capable of achieving 2D / 3D conversion. The grating device comprises a frame-shaped machine frame, two grating recycling guide rails, a flexible slit grating, an upper locator, a lower locator, a grating tensioning and weighing unit and a plurality of grating recycling units. The grating device enables an LED display screen to directly have the three-dimensional display function, can achieve switch display between a 2D display mode and a 3D display mode according display contents, is simple in manufacturing process and can easily achieve production and manufacturing of large LED three-dimensional displayers.

Owner:FUZHOU UNIV

Glass fiber tape feeding system facilitating replacement of glass fiber tape roll

ActiveCN113752415AQuick changeIncrease productivityCoatingsTubular articlesGlass fiberStructural engineering

The invention discloses a glass fiber tape feeding system facilitating replacement of a glass fiber tape roll. An unwinding and feeding frame is detachably and fixedly connected to a notch of an epoxy dipping tank, an unwinding and feeding frame replacement device comprises a base frame arranged horizontally, a movable groove slidably connected with a track beam is fixedly connected to the bottom of one side of the base frame, and a transverse moving frame is arranged in the base frame. The transverse moving frame reciprocates in the base frame through a driving device C in the direction parallel to the track beam, two lifting frames are further arranged at the bottom of the transverse moving frame in the extending direction of the track beam, and the lifting frames move up and down through driving devices D correspondingly. The two sides of the bottoms of the lifting frames are further provided with grabbing clamps which are driven by a driving device E and used for clamping the unwinding and feeding frame. According to the structure, the glass fiber tape feeding system facilitating replacement of the glass fiber tape roll achieves rapid replacement of the unwinding and feeding frame for the glass fiber tape, the replaced glass fiber tape can also be directly used for production, and the production efficiency is improved.

Owner:盐城品冠高压电气有限公司

A trench Schottky semiconductor device with multiple insulating layer isolation and its preparation method

ActiveCN103137710BImprove concentrationImprove forward conduction characteristicsSemiconductor/solid-state device manufacturingSemiconductor devicesPower semiconductor deviceManufactured apparatus

The invention discloses a trench Schottky semiconductor device with various insulating layer isolation. Through various insulating layer structures, the electric field intensity distribution of drift regions is changed, and inverse voltage blocking properties of apparatuses are improved. The invention further provides a preparation method capable of achieving two-time photolithography processes to manufacture apparatuses.

Owner:SEMICON MFG ELECTRONICS (SHAOXING) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com