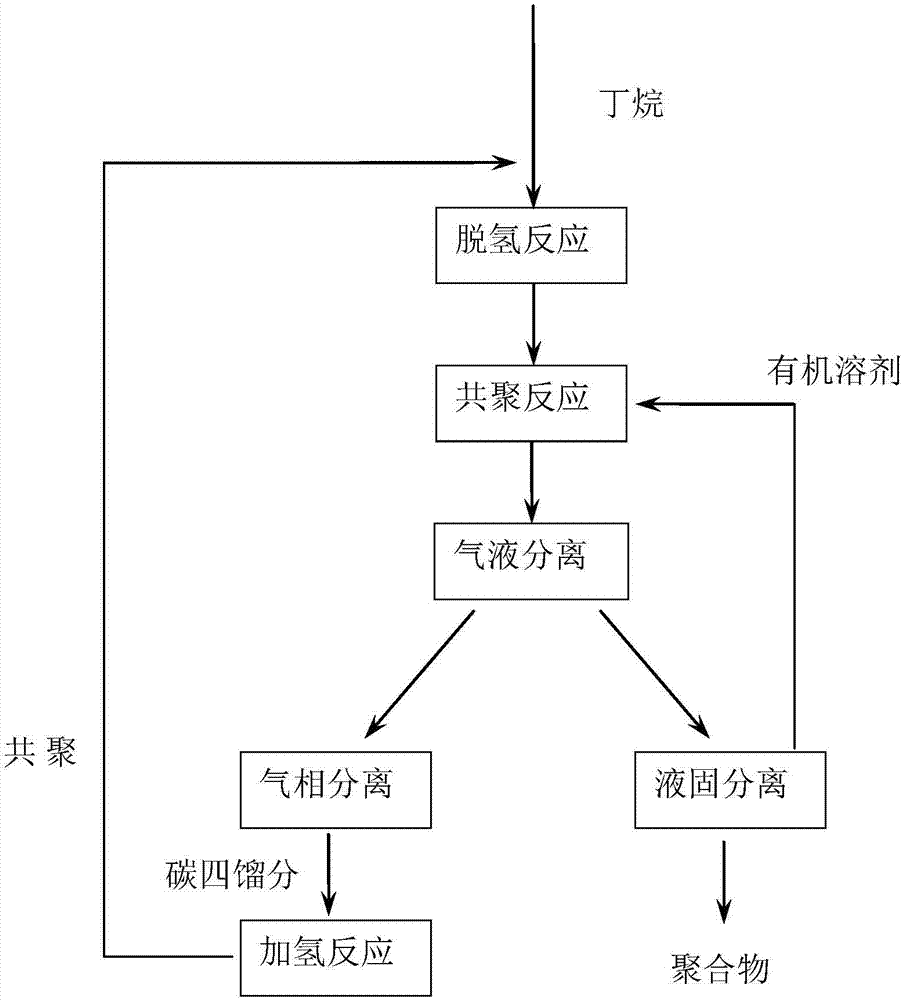

Device and method for processing butane

A butane and dehydrogenation technology, applied in the field of butane processing, can solve problems such as difficult distillation and separation of hydrocarbons, high operating costs, and difficulty in selecting selective solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In step (i) of the method for preparing a dehydrogenation catalyst in the present invention, the active component precursor is a compound that can form an active component in the final prepared dehydrogenation catalyst, for example, the active component precursor can preferably be At least one of ammonium hexachloroplatinate, ammonium tetrachloroplatinate and chloroplatinic acid. The precursor containing at least one of tin, bismuth and boron is a compound capable of forming at least one of tin, bismuth and boron in the final prepared dehydrogenation catalyst, for example, the precursor containing at least one of tin, bismuth and boron The precursor of at least one of can be nitrate, chlorite, nitrate, carbonate, chloride, phosphate, sulfate, acetate, fluoride, hydroxide of tin, bismuth or boron, Or an acid or base containing tin, bismuth or boron, preferably bismuth nitrate or stannous chloride. Further, the impregnation carried out in step (i) can be carried out step...

Embodiment 1

[0108] This example illustrates the butane processing method of the present invention.

[0109] (1) Immerse 60g of γ-alumina (Shandong Aluminum) in 0.03mol / L chloroplatinic acid (Sinopharm Chemical Reagent Co., Ltd.) and 0.1mol / L bismuth nitrate (Beijing Zhonglian Chemical Industry Co., Ltd.) at 75 °C (provided by the factory) for a total of 0.5 h, wherein the volume of the solution was measured according to the mass content of Pt and Bi; then the impregnated product was dried by rotary evaporation at 75 °C for 0.5 h, and then the dried product was placed in a muffle furnace , roasted in an air atmosphere at 450°C for 3h, and the roasted product was then immersed in a 0.25mol / L tin protochloride (Tianjin Guangfu Fine Chemical Research Institute) aqueous solution, wherein the volume of the solution was measured according to the Sn mass content; then in After drying by rotary evaporation at 75° C. for 0.5 h, it was further calcined in an air atmosphere at 450° C. for 3 h to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com