Refractory material for 3D printing and printing method thereof

A refractory material and 3D printing technology, applied in the field of refractory materials, can solve the problems of low degree of automated production, difficulty in mold manufacturing, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

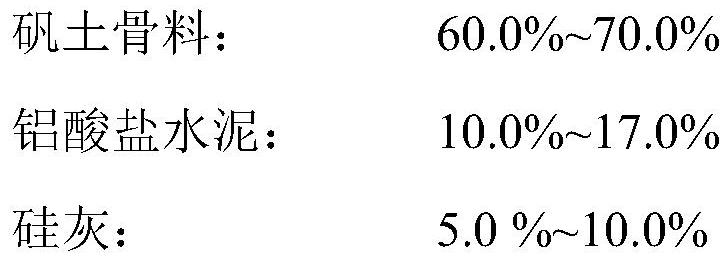

Embodiment 1

[0034] Select 31.5% by weight of 5-3mm bauxite aggregate, 28% of 3-1mm bauxite aggregate, 5.6% of 200-mesh bauxite aggregate, 4.9% of 325-mesh bauxite aggregate, and 10% alumina Put salt cement, 5% silica fume, 2.742% activated alumina micropowder, 0.05% starch ether, and 0.045% thixotropic lubricant into the mixer and stir for 3 to 5 minutes, then mix 0.344% sodium tripolyphosphate and 0.086% sodium hexametaphosphate, these two solid water reducers are added to 10% water and completely dissolved, then slowly poured into the mixer and stirred for 5-10 minutes, so that the solid raw material changes from a dispersed state to a viscoplastic slurry state, and then Add 1.733% polypropylene fiber into the blender, and stir thoroughly for 3-5 minutes to obtain a refractory material suitable for 3D printing. Open the printing control software of the 3D printer, set the printing speed of the printing head, material extrusion speed and other process parameters, and then import a 3D mod...

Embodiment 2

[0036] Select 24% by weight of 5-3mm bauxite aggregate, 21% of 3-1mm bauxite aggregate, 9% of 200-mesh bauxite aggregate, 6% of 325-mesh bauxite aggregate, and 17% of alumina Put salt cement, 10% silica fume, 4.32% activated alumina micropowder, 0.05% starch ether, and 0.18% thixotropic lubricant into the mixer and stir for 3 to 5 minutes, then mix 0.518% sodium tripolyphosphate and 0.172% sodium hexametaphosphate, these two solid water reducers are added to 7% water and completely dissolved, then slowly poured into the mixer and stirred for 5 to 10 minutes, so that the solid raw materials change from a dispersed state to a viscoplastic slurry state, and then Add 0.76% polypropylene anti-cracking fiber into the blender, and stir thoroughly for 3-5 minutes to obtain a refractory material suitable for 3D printing. Open the printing control software of the 3D printer, set the printing speed of the printing head, material extrusion speed and other process parameters, and then impo...

Embodiment 3

[0038] Select 29.25% by weight of 5-3mm bauxite aggregate, 24.7% of 3-1mm bauxite aggregate, 6.5% of 200-mesh bauxite aggregate, 4.55% of 325-mesh bauxite aggregate, and 14.49% of alumina Put salt cement, 7.5% silica fume, 4% activated alumina micropowder, 0.01% starch ether, and 0.12% thixotropic lubricant into the mixer and stir for 3 to 5 minutes, then mix 0.43% sodium tripolyphosphate and 0.129% sodium hexametaphosphate, these two solid water reducers are added to 8% water and completely dissolved, then slowly poured into the mixer and stirred for 5-10 minutes, so that the solid raw materials change from a dispersed state to a viscoplastic slurry state, and then Add 0.321% polypropylene anti-cracking fiber into the blender, stir well for 3-5 minutes to obtain a refractory material suitable for 3D printing. Open the printing control software of the 3D printer, set the printing speed of the printing head, material extrusion speed and other process parameters, and then import...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com