Additive manufacturing method of intermetallic compound part

A technology of intermetallic compounds and additive manufacturing, which is applied in the direction of manufacturing tools, metal processing equipment, plasma welding equipment, etc., can solve the problems of difficulty in preparing pure intermetallic compound parts, difficulty in manufacturing complex structural parts, long production cycle, etc., to achieve Strong production practicability, reduced processing difficulty, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

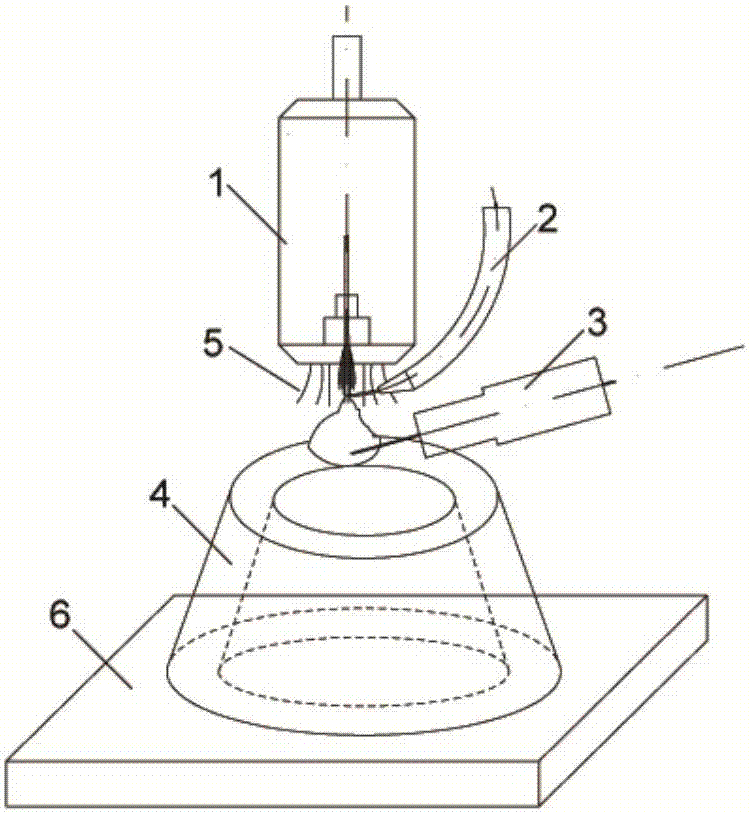

[0033] In this embodiment, to realize the arc additive manufacturing of Ni-Al intermetallic compound parts, two kinds of wires are used as filling materials, and the design dimensions of the parts are as follows: the inner diameter of the bottom is The inner diameter of the top is The wall thickness is 8mm, the height is 200mm, and the size of the substrate used is 400mm×400mm×20mm. The welding wire is Ni-1 pure nickel welding wire with a diameter of 1.2mm and 1070 pure aluminum alloy welding wire with a diameter of 1.0mm, and the substrate material is Q235 steel. The specific manufacturing steps are as follows:

[0034] (1) Fix the substrate on the experimental platform, determine the walking path of the welding torch according to the shape of the intermetallic compound part, and select the appropriate deposition starting point; in practice, each cross-section of the available part is a planar figure, the Plane graphics are composed of many lines, and each line is regarde...

Embodiment 2

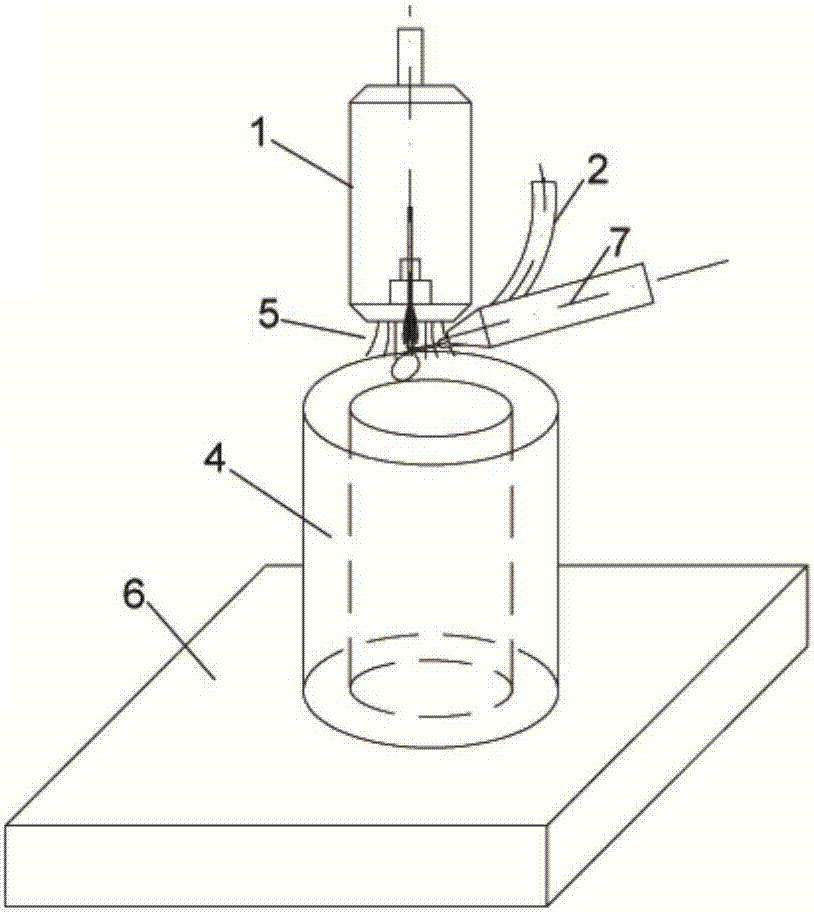

[0041] In this embodiment, to realize the arc additive manufacturing of Ni-Al intermetallic compound parts, one kind of wire material and one kind of powder material are used as filling materials, and the design dimensions of the parts are as follows: cylindrical inner diameter The wall thickness is 8mm, the height is 100mm, and the size of the substrate used is 300mm×300mm×10mm. The welding wire is Ni-1Z pure nickel welding wire with a diameter of 1.2mm and 150 mesh pure aluminum powder, and the substrate material is Q235 steel. The specific manufacturing steps are as follows:

[0042] (1) Fix the substrate on the experimental platform, determine the walking path of the welding torch according to the shape of the intermetallic compound part, and select the appropriate deposition starting point;

[0043] (2) Adjust the wire feeding speed of nickel wire to make it 3.48m / min, adjust the powder feeding rate of aluminum powder to make it 1.39g / min, and adjust the argon shielding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com