Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

299results about How to "Improve reverse breakdown voltage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

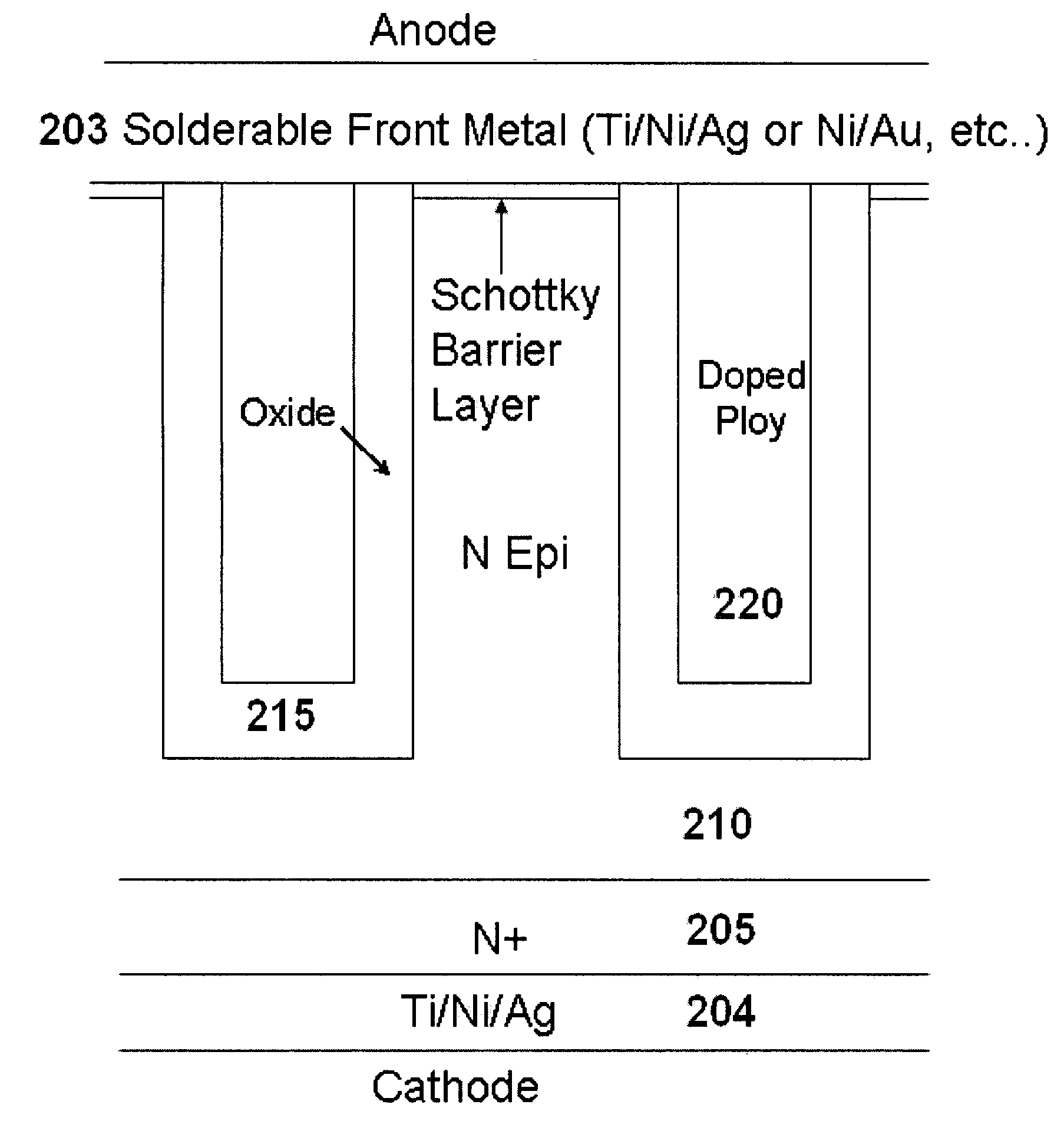

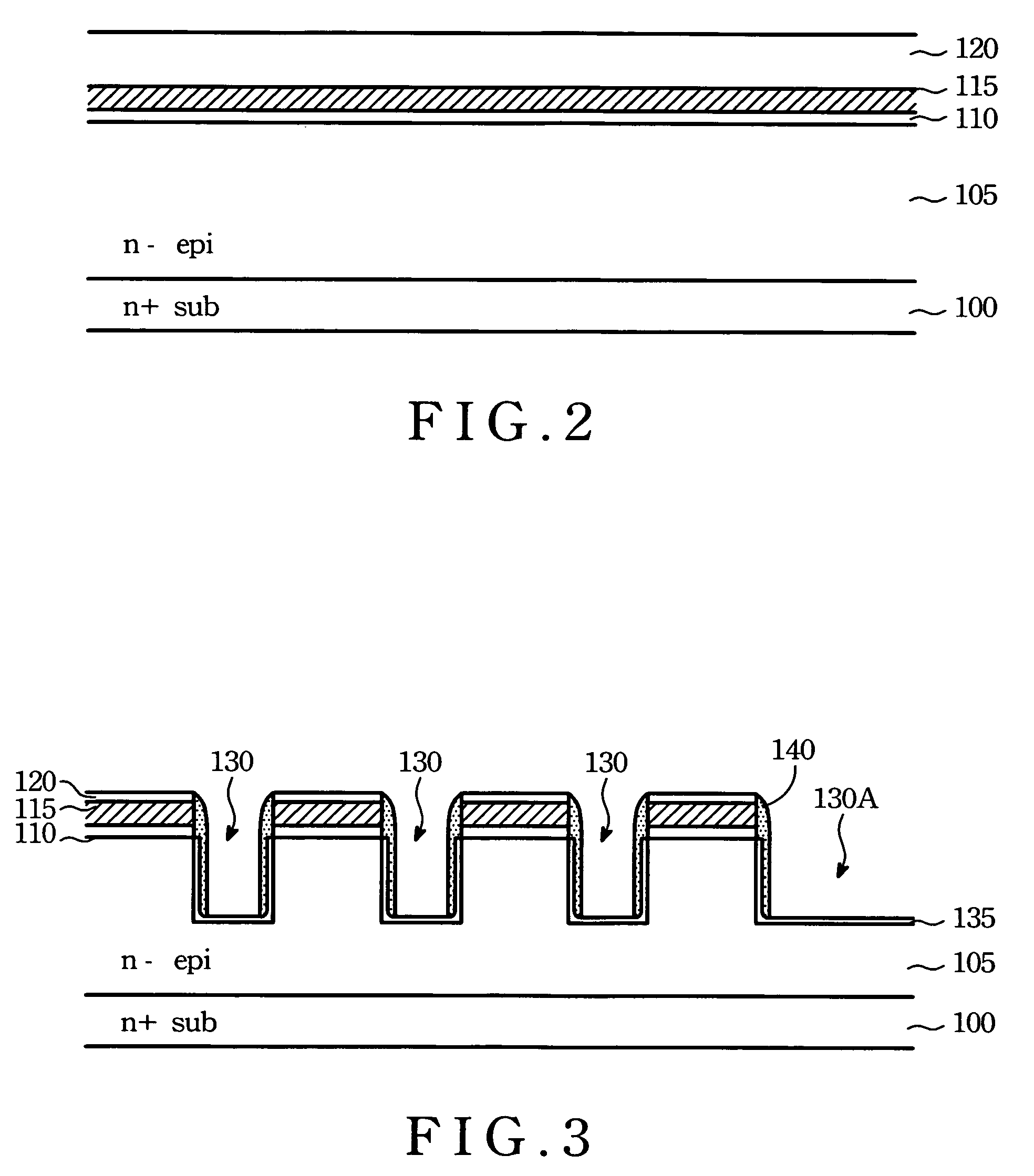

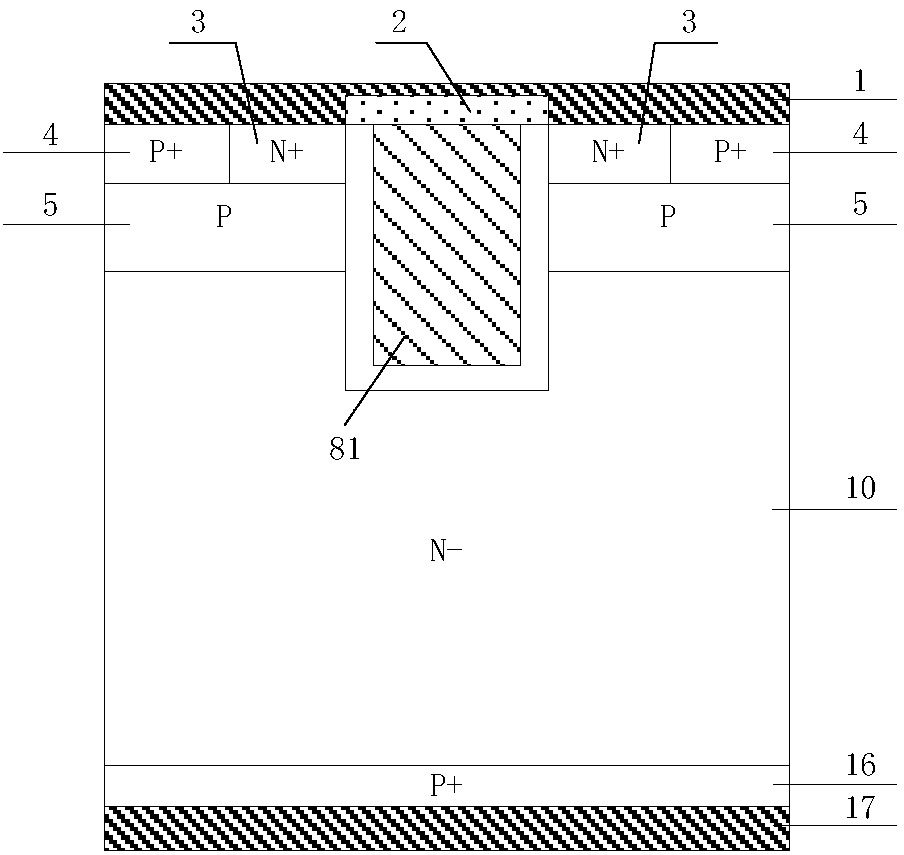

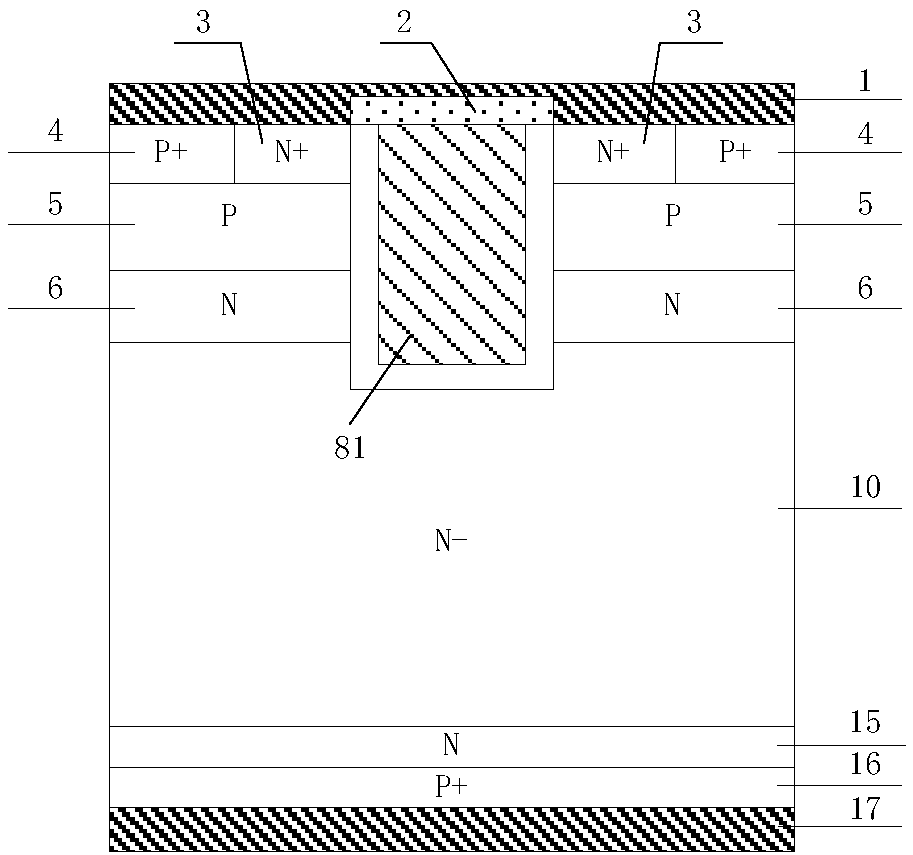

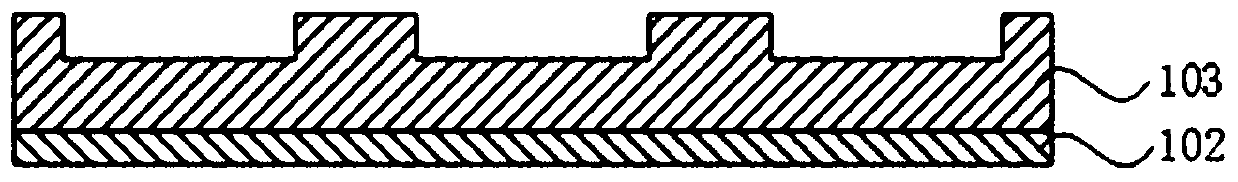

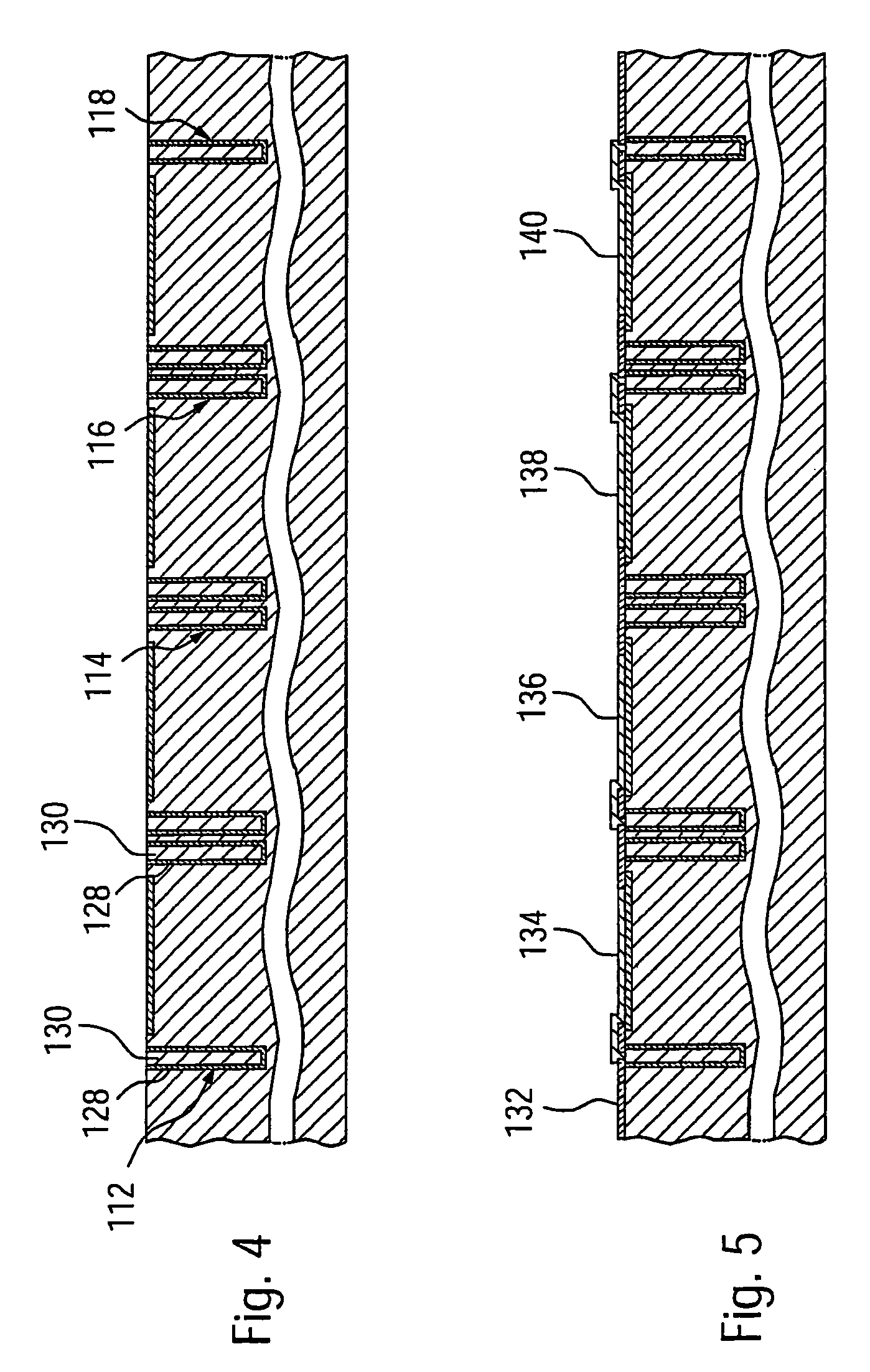

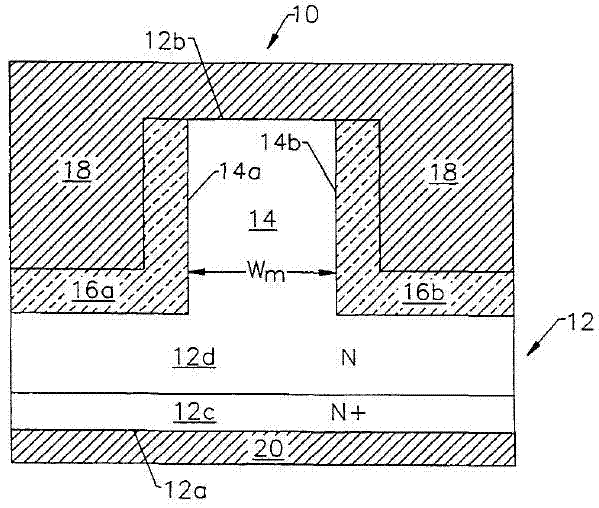

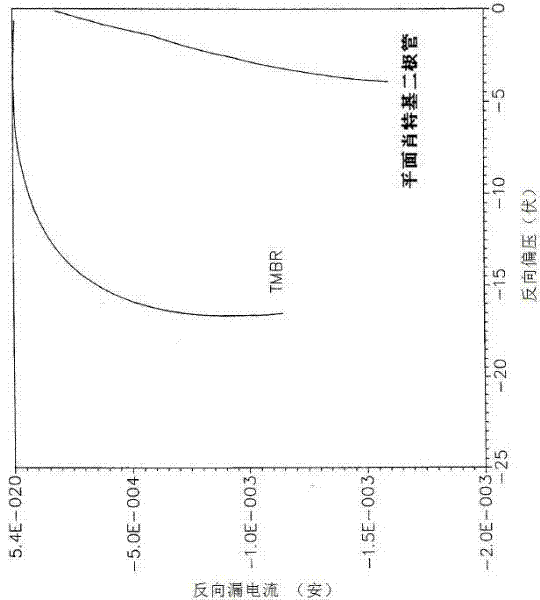

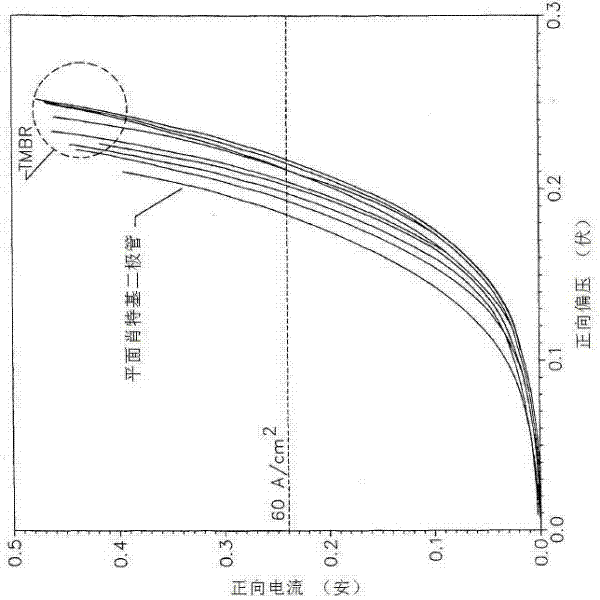

Trench schottky with multiple epi structure

InactiveUS20090309181A1Reduce doping concentrationIncrease the doping concentrationSemiconductor devicesDopantSchottky barrier

A trench Schottky barrier rectifier includes an cathode electrode at a face of a semiconductor substrate and an multiple epitaxial structure in drift region which in combination provide high blocking voltage capability with low reverse-biased leakage current and low forward voltage. The multiple structure of the drift region contains a concentration of first conductivity dopants therein which comprises two or three different uniform value from a Schottky rectifying junction formed between the anode electrode and the drift region. The thickness of the insulating region (e.g., SiO2) in the MOS-filled trenches is greater than 1000 Å to simultaneously inhibit field crowing and increase the breakdown voltage of the device. The multiple epi structure is preferably formed by epitaxial growth from the cathode region and doped in-situ.

Owner:FORCE MOS TECH CO LTD

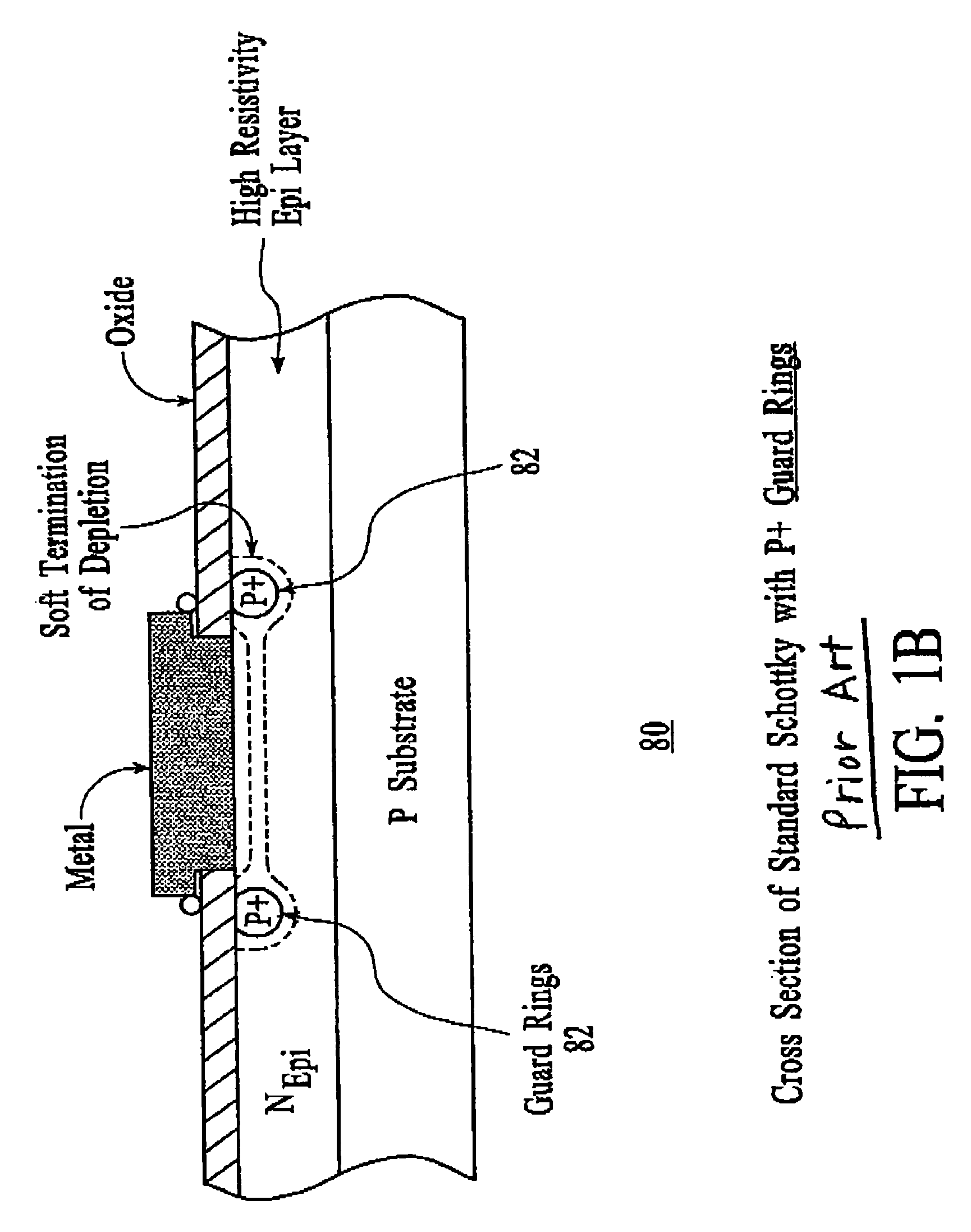

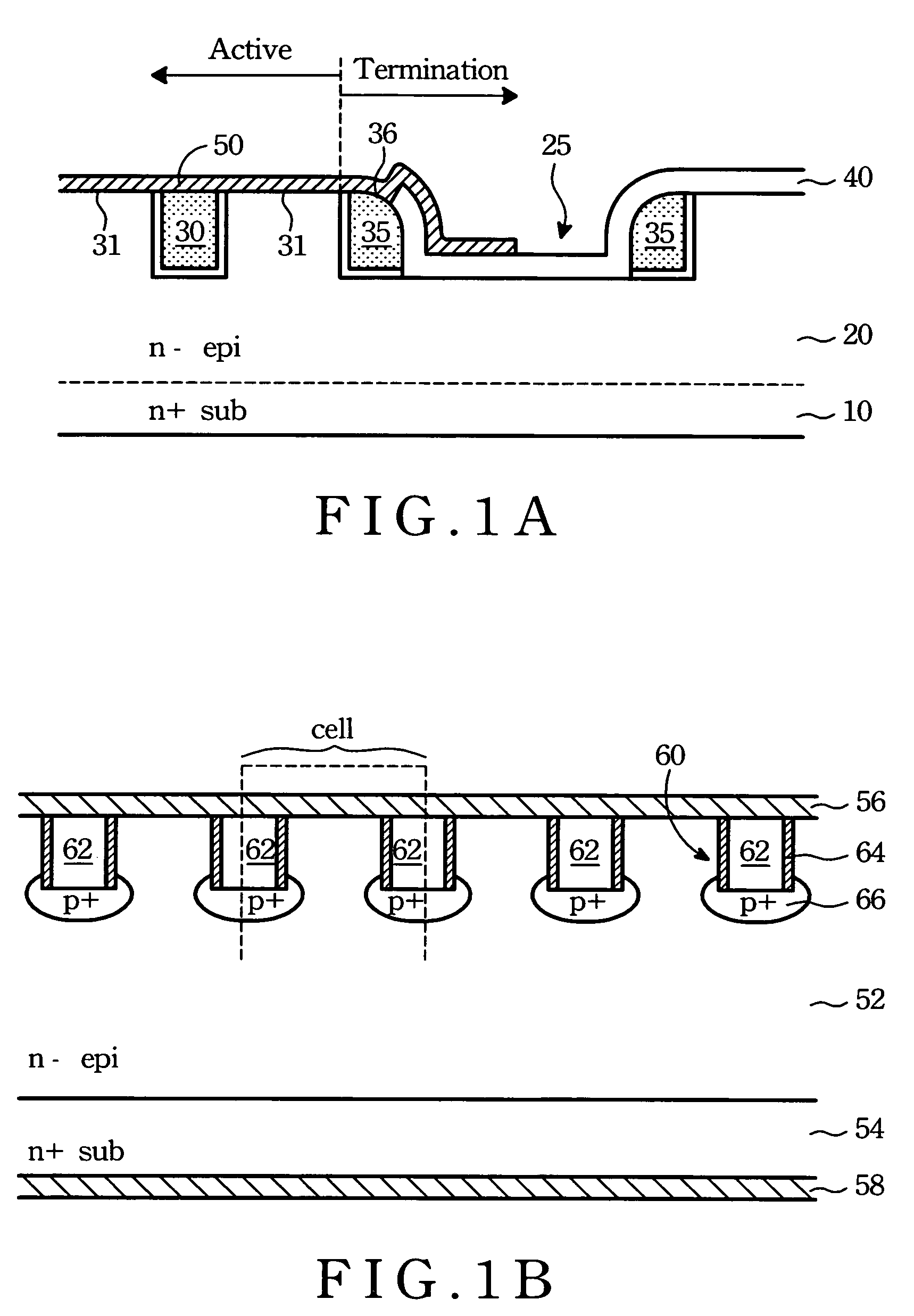

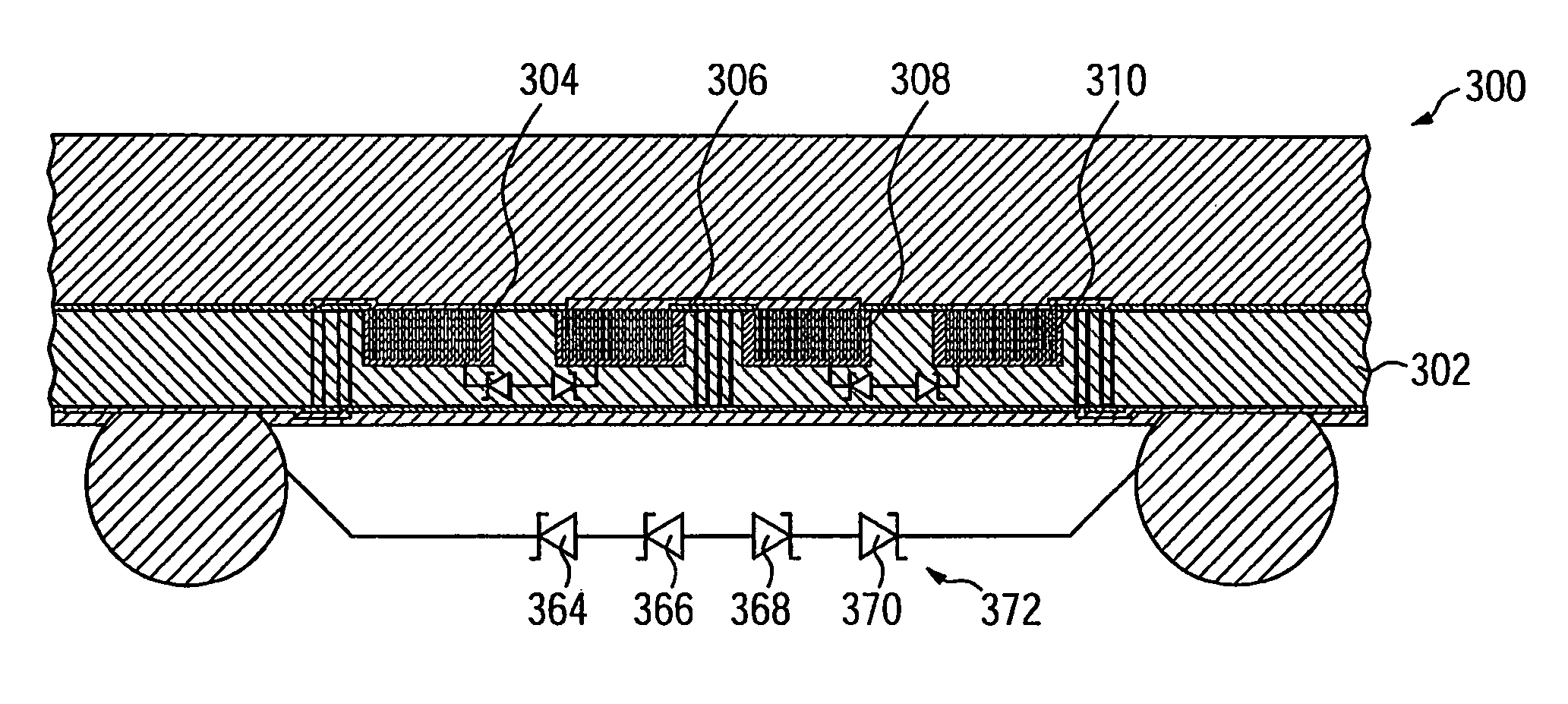

Integrated schottky diode using buried power buss structure and method for making same

InactiveUS7002187B1High resistivityLimit capacitanceThyristorSemiconductor/solid-state device manufacturingEngineeringLow leakage

An integrated Schottky diode and method of manufacture of such a diode is disclosed. In a first aspect, a Schottky diode comprises a semiconductor substrate. The semiconductor substrate includes an epitaxial layer (EPI) on the substrate region. The diode includes a plurality of guard rings in the EPI layer and a plurality of oxidized slots. Finally, the diode includes metal within the plurality of slots to form a Buried Power Buss. A portion of the metal is completely oxide isolated from the other elements of the diode. In a second aspect, a method for manufacturing a Schottky diode comprises providing a substrate region, A buried N+ region providing an epitaxial (EPI) layer. The method also includes providing a plurality of guard rings in the EPI layer and providing a plurality of slots in the semiconductor substrate that is in contact with the EPI layer and the substrate region. The method further includes a plurality of oxidizing the slots and providing metal within the plurality of slots to form a Buried Power Buss structure. A portion of the metal is completely oxide isolated from the other elements of the diode. Accordingly, the system and method in accordance with the present invention a Schottky diode is provided that has low forward drop, low leakage at low and high voltages, and has a high reverse breakdown voltage.

Owner:MICREL

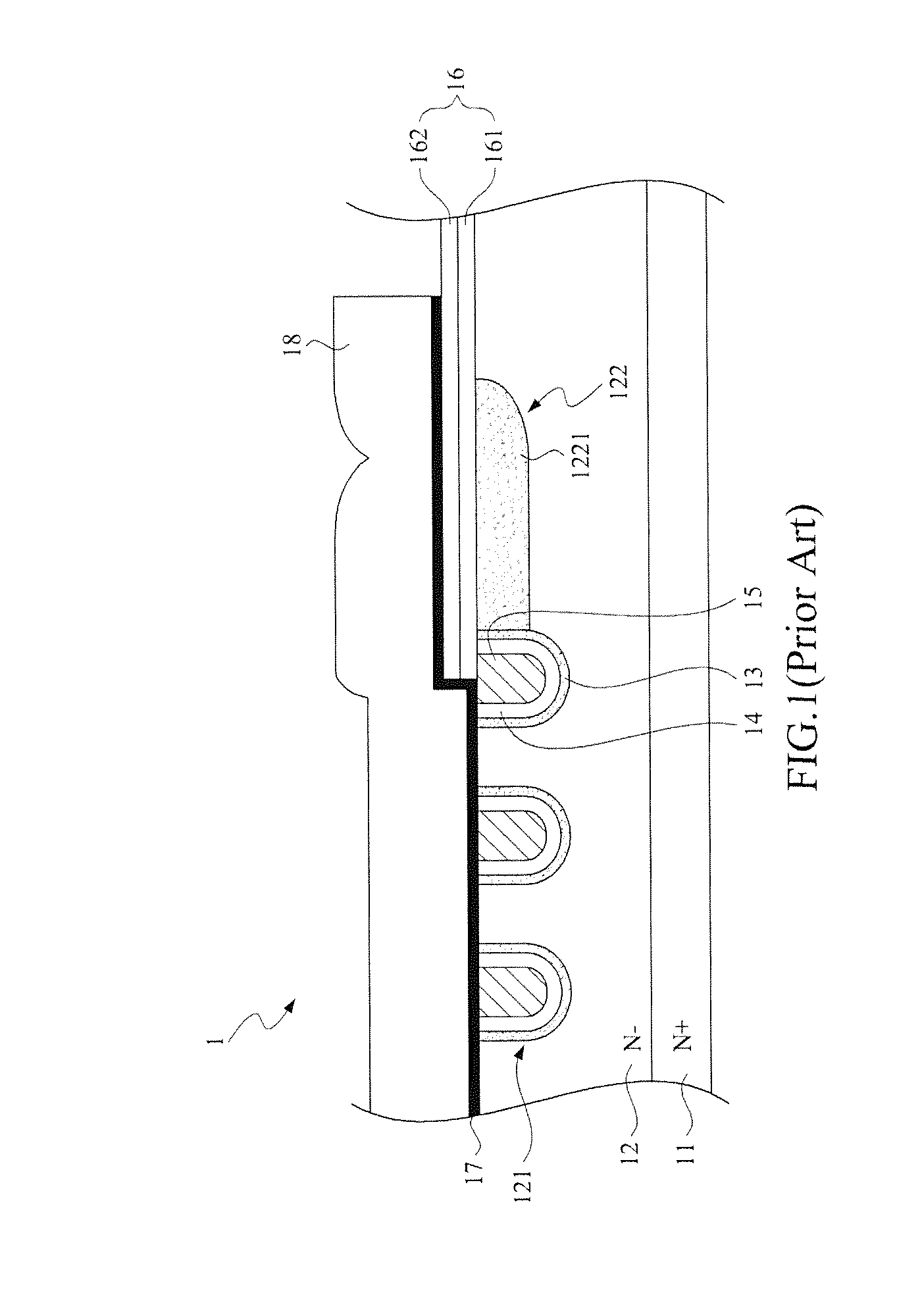

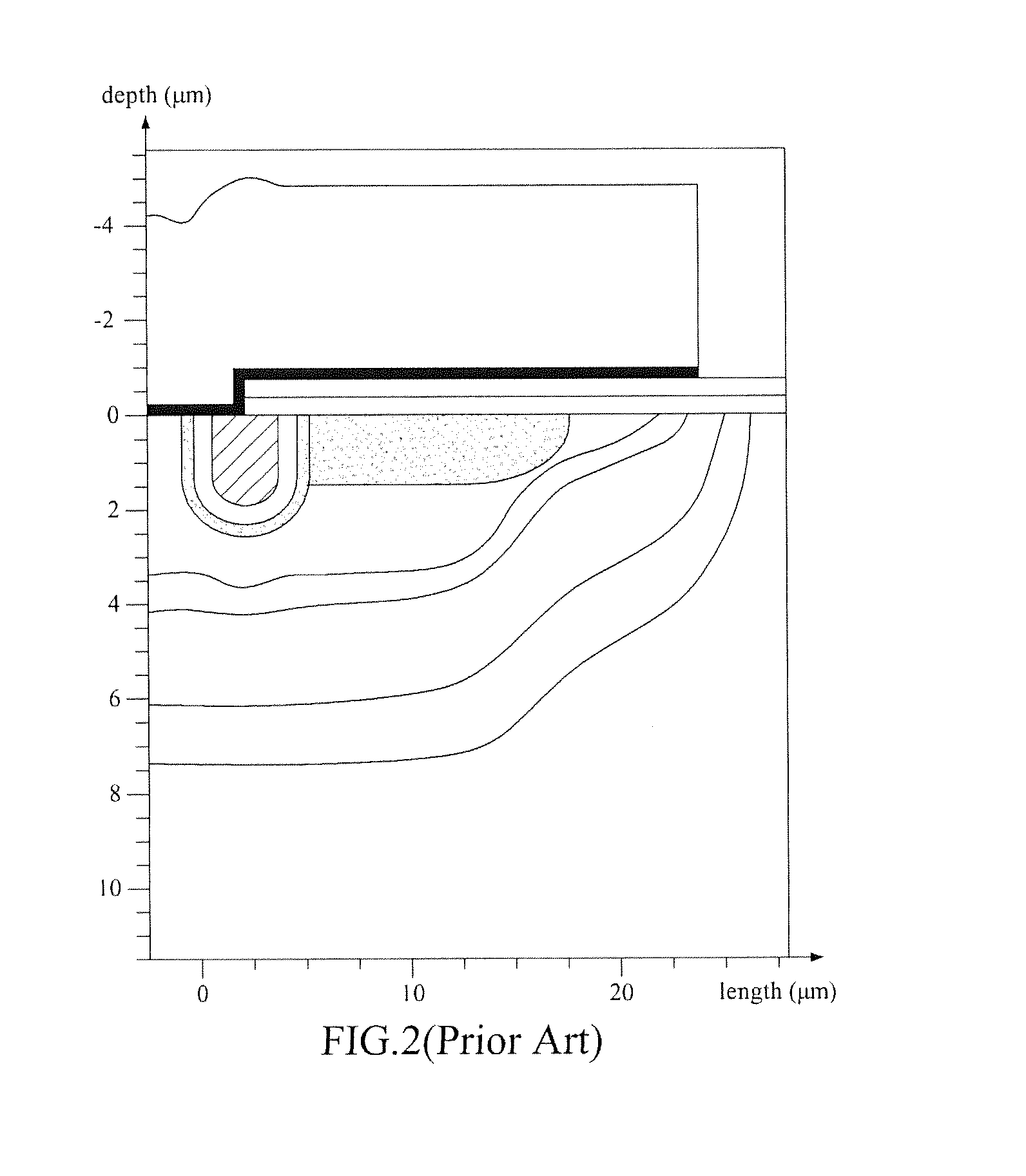

High switching speed two mask schottky diode with high field breakdown

InactiveUS7491633B2Minimise currentImprove reverse breakdown voltageSemiconductor/solid-state device manufacturingSemiconductor devicesSchottky barrierLOCOS

A power Schottky rectifier device and method of making the same are disclosed. The Schottky rectifier device includes a LOCOS structure grown on the bottom of the trenches by using nitride spacer on the sidewall of the trenches as a thermal oxidation mask. A polycrystalline silicon layer is then filled the first trenches. Under LOCOS structure, a p doped region is optionally formed to minimize the current leakage when the device undergoes a reverse biased. A Schottky barrier silicide layer formed by sputtering and annealing steps is formed on the upper surfaces of the epi-layer and the polycrystalline silicon layer. A top metal layer served as anode is then formed on the Schottky barrier silicide layer and extended to cover a portion of field oxide region of the termination trench. A metal layer served as a cathode electrode is then formed on the backside surface of the substrate opposite to the top metal layer.

Owner:CHIP INTEGRATION TECH +1

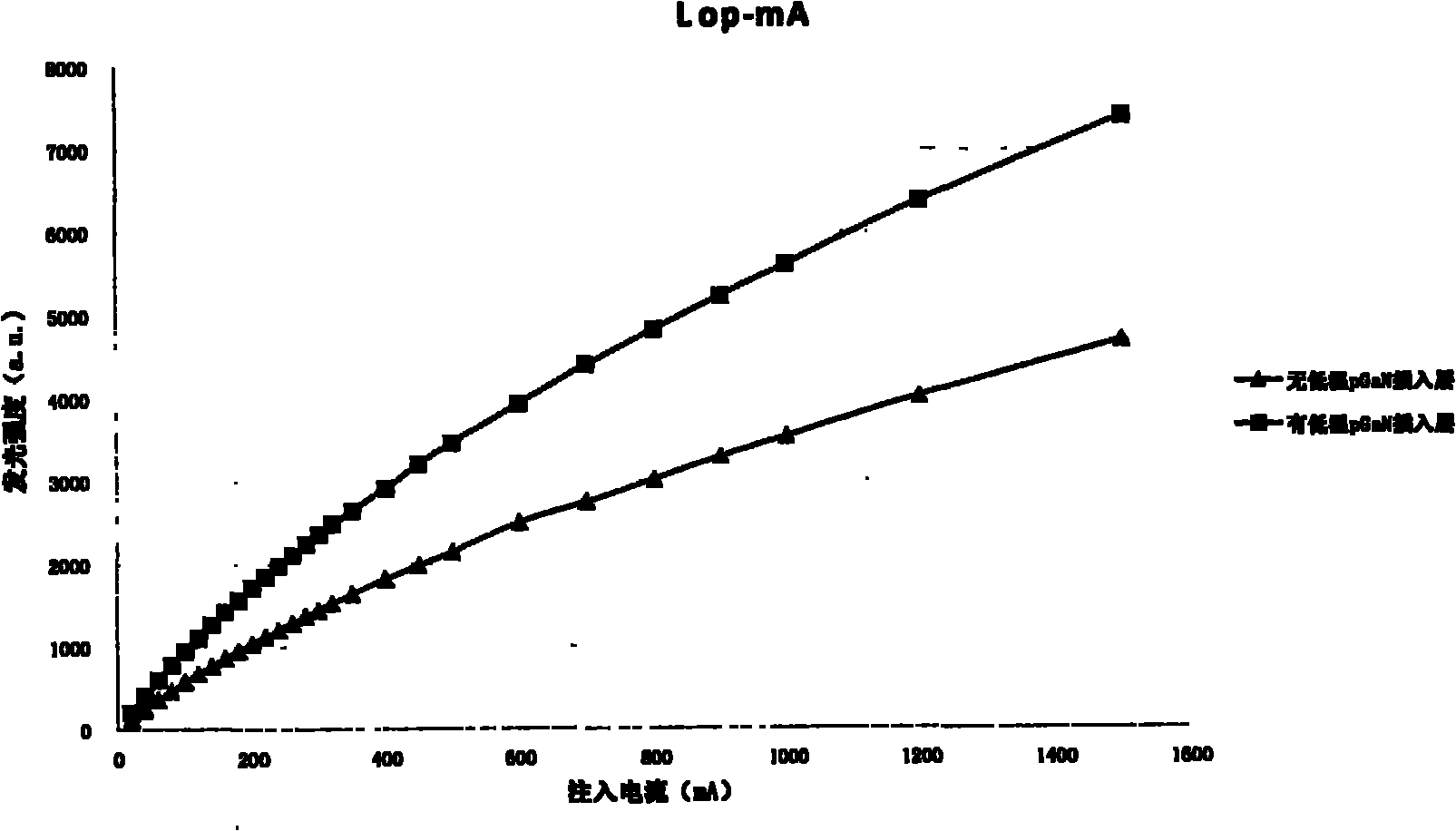

GaN light-emitting diodes with low-temperature p-type GaN layer

InactiveCN102005513AHigh luminous intensityImprove reverse breakdown voltageSemiconductor devicesLuminous intensityGallium nitride

The invention relates to GaN light-emitting diodes with a low-temperature p-type GaN layer. The main difference between the structure of the GaN light-emitting diodes of the invention and the structure of the existing GaN light-emitting diodes is that a low-temperature p-type GaN layer grows between an InGaN / GaN multiple-quantum well active light-emitting layer and a p-type AlGaN electron blocking layer, thereby physically separating the InGaN / GaN multiple-quantum well active light-emitting layer from the p-type AlGaN electron blocking layer on an interface. Results show that the luminous intensity and reverse breakdown voltage of the GaN light-emitting diodes are greatly improved.

Owner:上海蓝宝光电材料有限公司

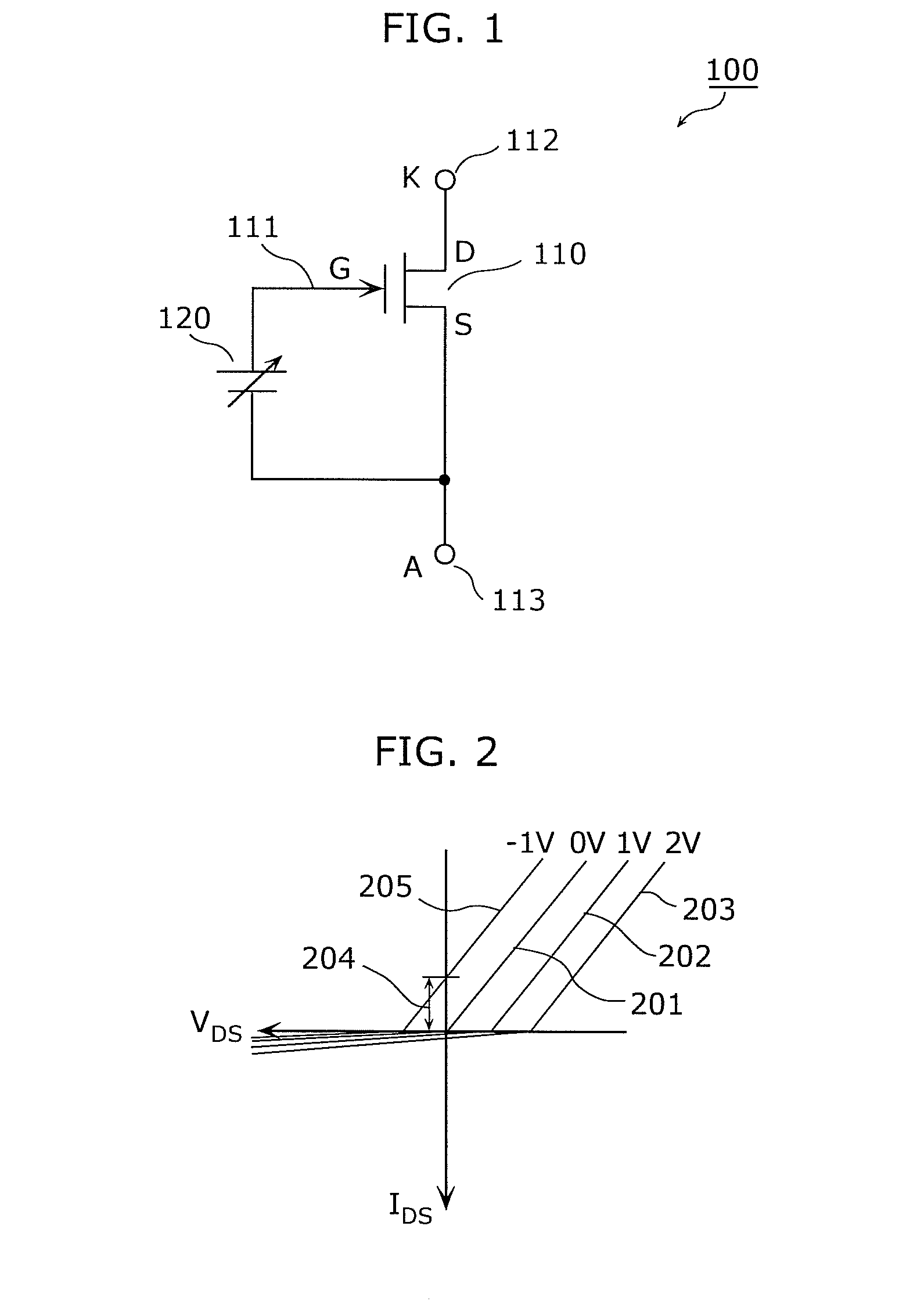

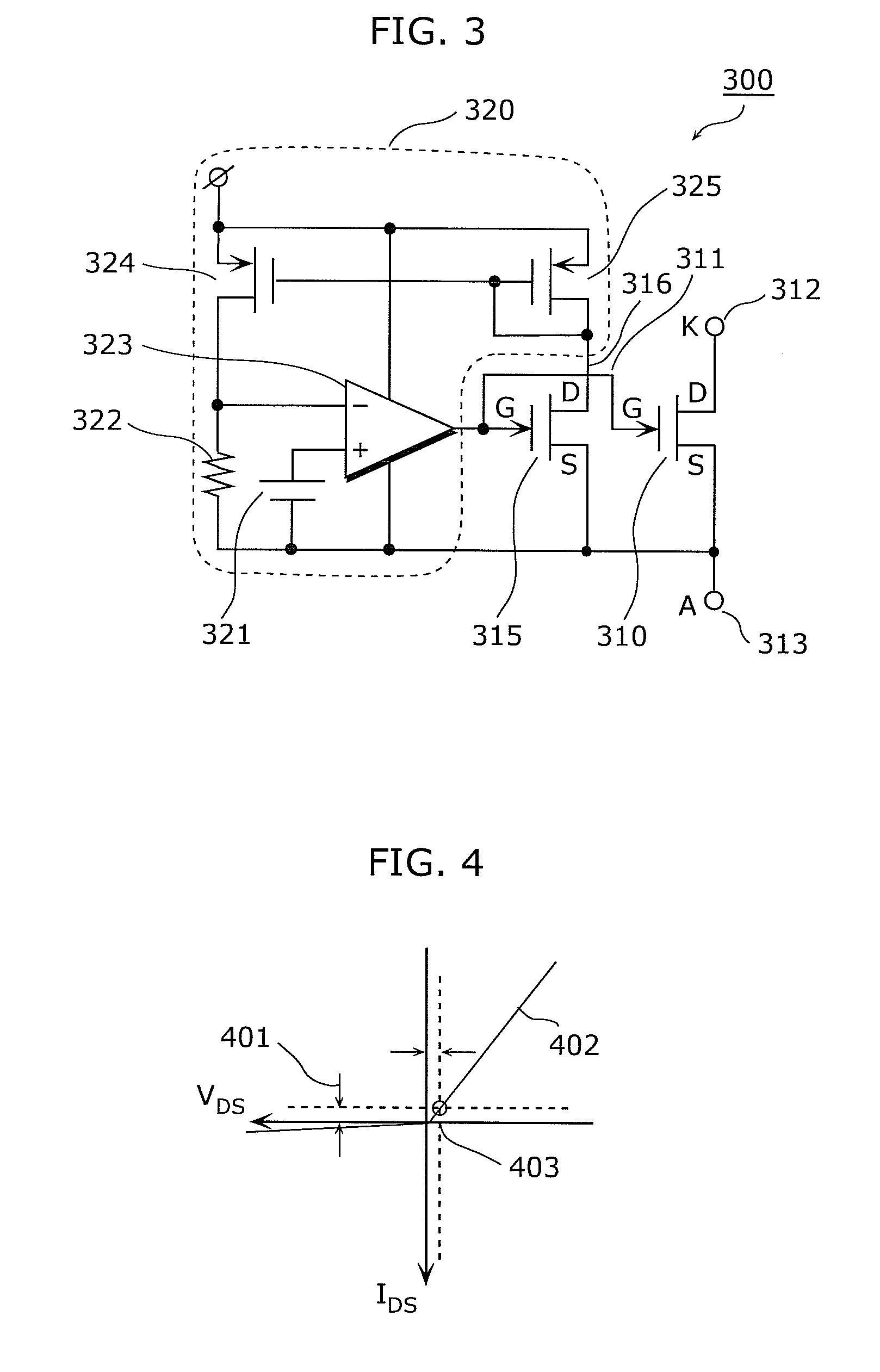

Diode circuit

InactiveUS20110304360A1Generate accuratelyImprove reverse breakdown voltageMeasurement using ac-dc conversionEfficient power electronics conversionGate voltageForward voltage

The present invention introduces a diode circuit which achieves ideal diode characteristics which observe an enough reverse breakdown voltage, and whose forward voltage is nearly 0 V. An active diode has an anode terminal and a cathode terminal. The active diode includes a transistor which has a gate terminal, a drain terminal connected to one of the anode terminal and the cathode terminal, and a source terminal connected to the other one of the anode terminal or the cathode terminal; and a gate voltage generating circuit which delivers a gate voltage to the gate terminal, the gate voltage being adjusted to be equal to a threshold voltage of the transistor.

Owner:PANASONIC CORP

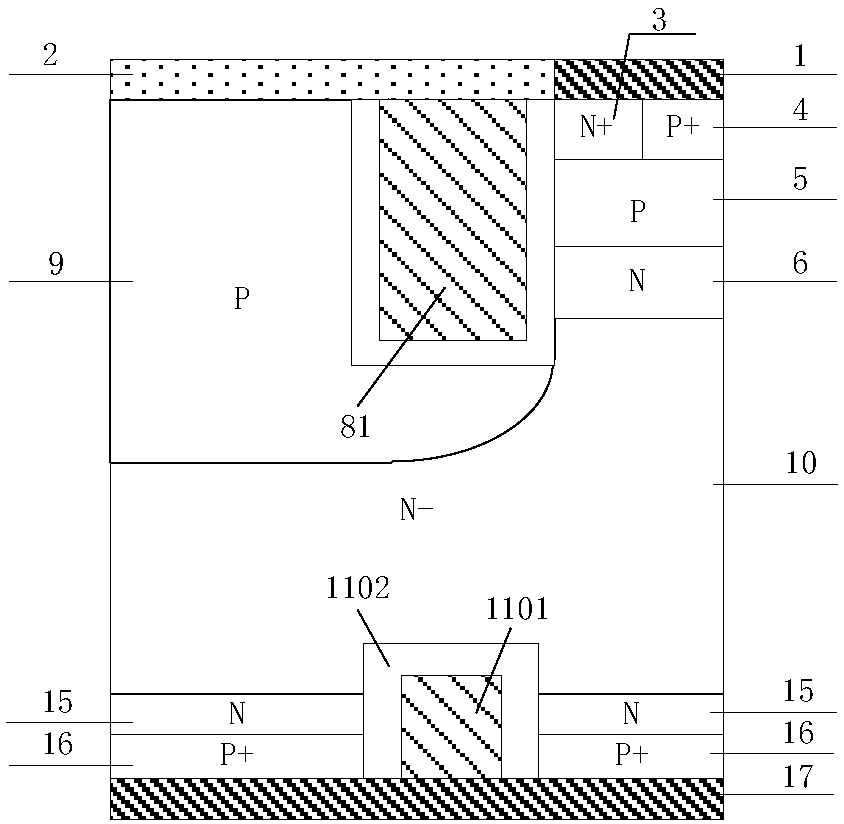

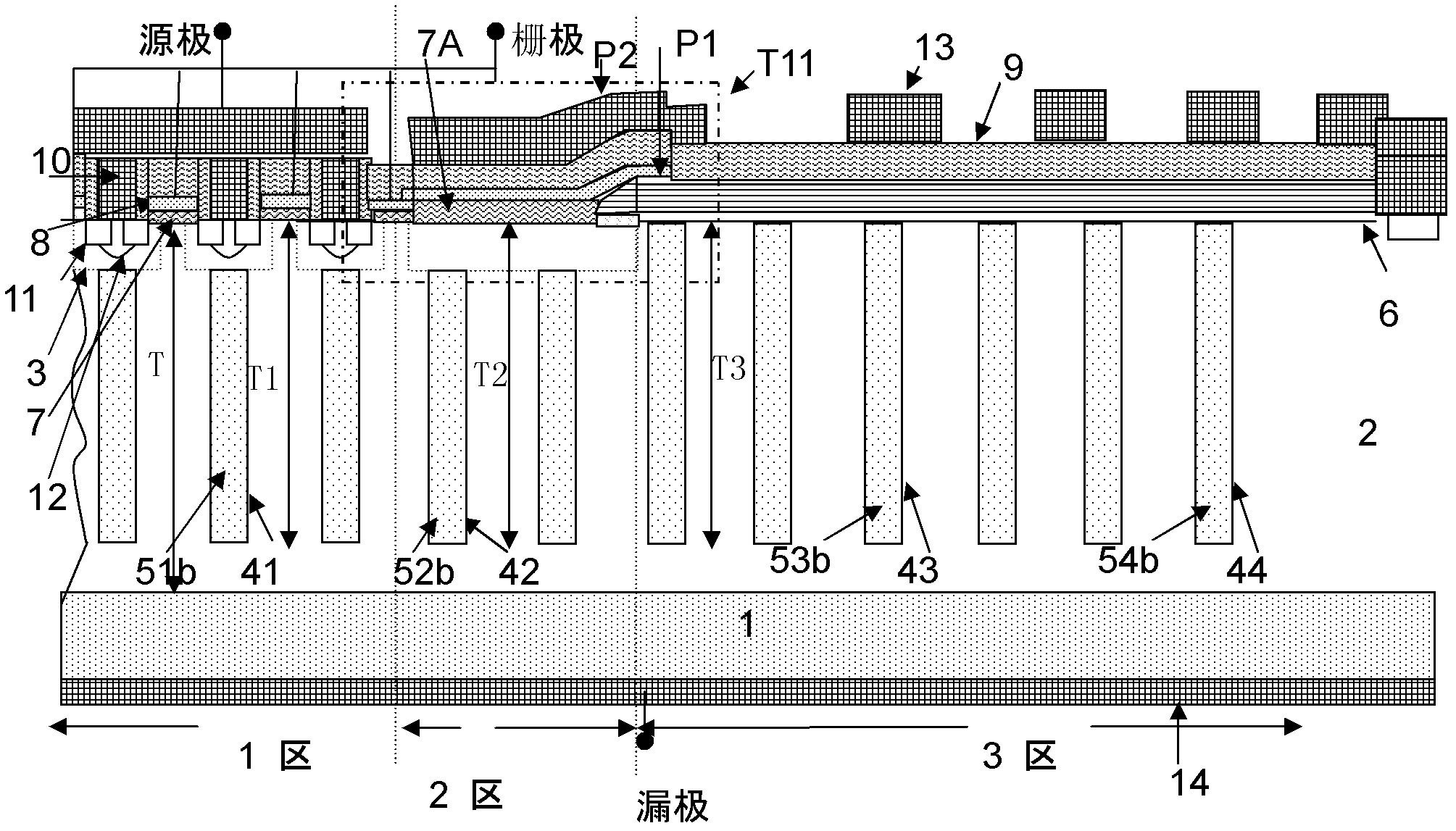

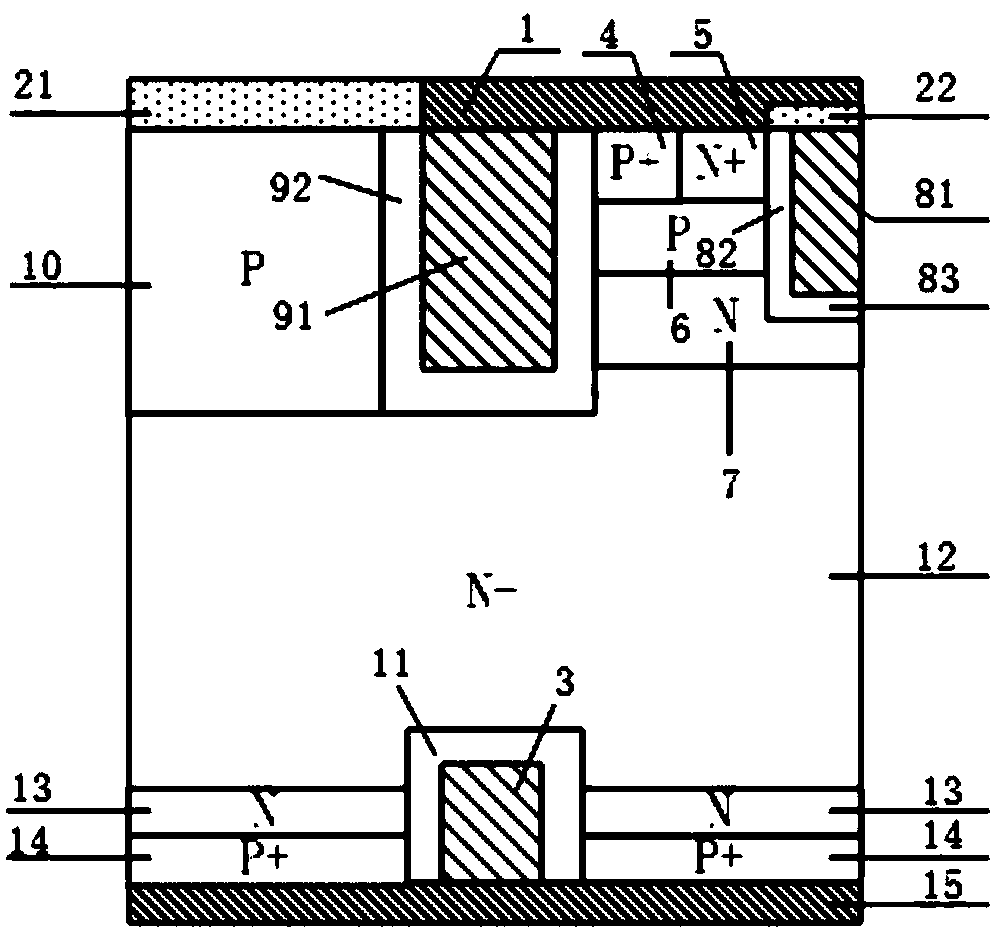

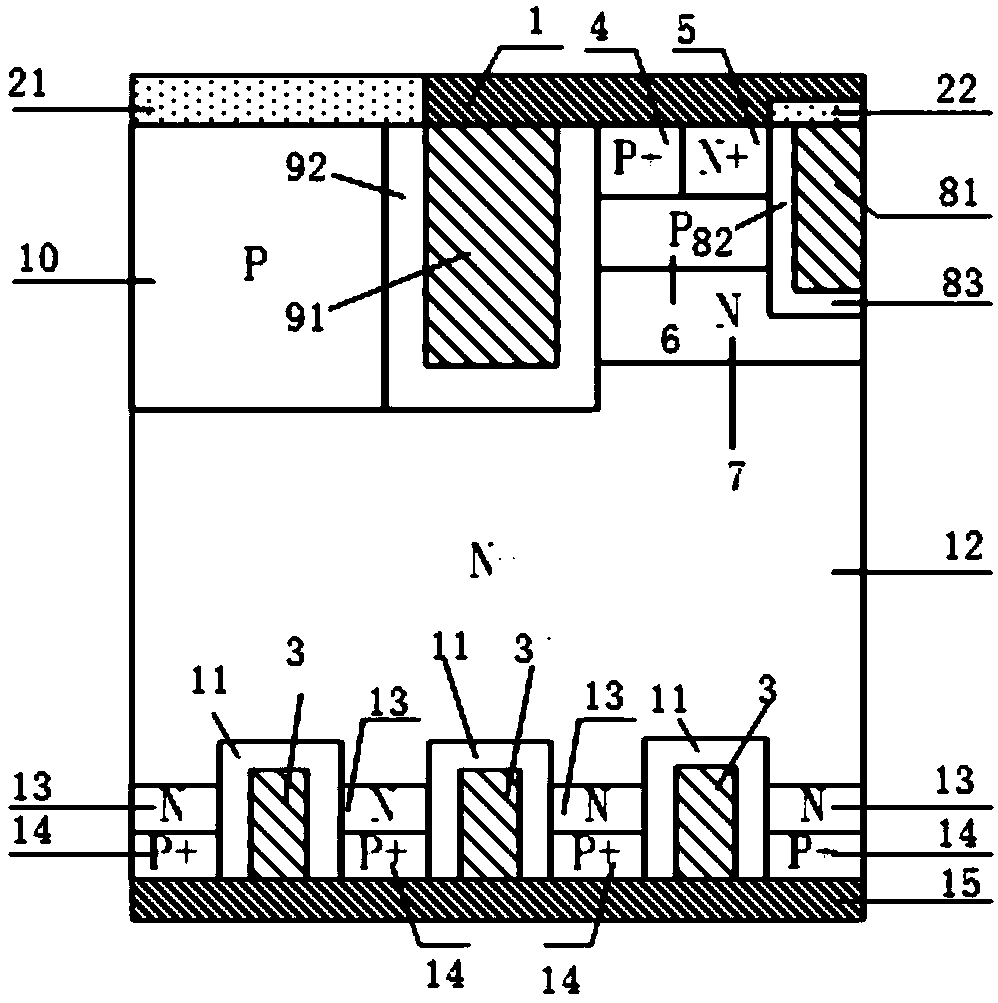

Reverse blocking type IGBT and manufacturing method therefor

ActiveCN107799587AImprove reverse breakdown voltageGood positive characteristicsSemiconductor/solid-state device manufacturingSemiconductor devicesCapacitancePower semiconductor device

The invention discloses a reverse blocking type IGBT and a manufacturing method therefor, and belongs to the technical field of a power semiconductor device. By introducing a floating P type body region on one side of a trench gate and introducing a trench collector structure in a collector region and a field stop layer, the positive breakdown voltage of a device is improved without influencing the threshold voltage and switch-on of an IGBT device; the gate-collector capacitance is lowered, and adverse influence caused by a Miller effect can be relieved; the overall gate capacitance is lowered, the switching speed of the device is improved, the switching loss of the device is lowered, and the compromising relation between forward switch-on voltage drop and switch-off loss of the conventional CSTBT device is improved; the problems of current, voltage oscillation and EMI in the device starting dynamic process can be avoided, and device reliability is improved; the current carrier enhancement effect at the emitter end of the device is improved, the current carrier concentration distribution in a drift region can be improved, and compromising between forward switch-on voltage drop andswitch-off loss can be further improved; and the reverse breakdown voltage of the device is improved, and high forward characteristic of the device is ensured while excellent reverse blocking performance is obtained.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

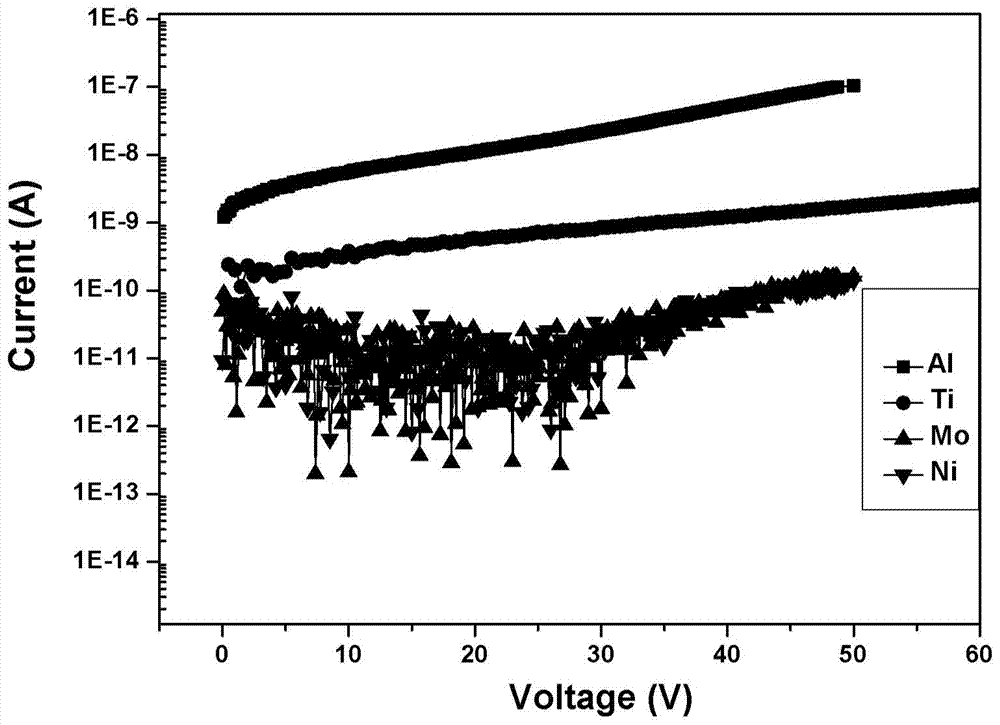

High-breakdown-voltage Schottky diode and making method

ActiveCN106876483AImprove reverse breakdown voltageReduce accumulationSemiconductor/solid-state device manufacturingSemiconductor devicesOptoelectronicsSchottky diode

The invention discloses a high-breakdown-voltage Schottky diode and a making method. The high-breakdown-voltage Schottky diode comprises a substrate (5), a Ga2O3 epitaxial layer (3), a low-doped n-type Ga2O3 film (4) and a passivation layer (8) from bottom to top. A ring metal cathode (1) and a circular metal anode (2) are arranged in the passivation layer (8). The ring center of the ring metal cathode and the circular center of the circular metal anode are at the same point. A silicon ion implanted region (7) is arranged under the ring metal cathode (1). Multiple H+ implanted regions (6) for adjusting the concentration of electrons are arranged between the Ga2O3 epitaxial layer (3) and the low-doped n-type Ga2O3 film (4), wherein the first H+ implanted region is close to the edge of a Schottky contact, and the distance of the last H+ implanted region from the edge of the inner ring of the metal cathode is greater than 1 micron. Through attraction of H+ to electrons, the concentration of electrons at the edge of the Schottky contact is reduced, and the reverse breakdown voltage of the Schottky diode is improved.

Owner:XIDIAN UNIV

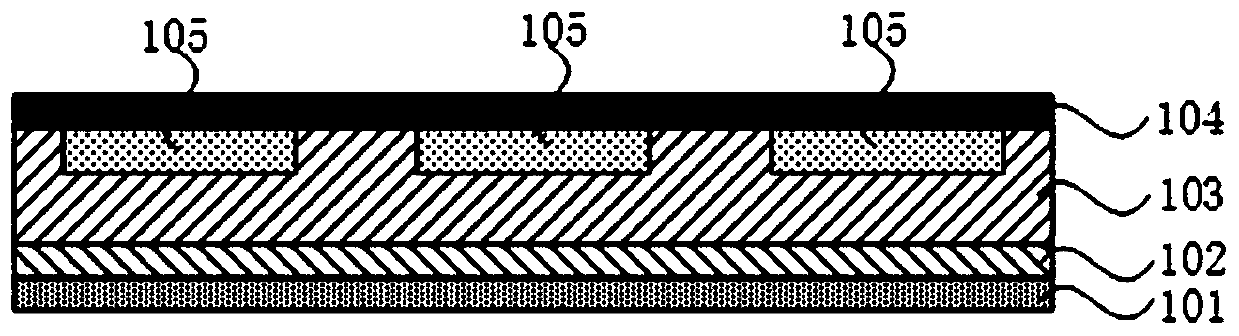

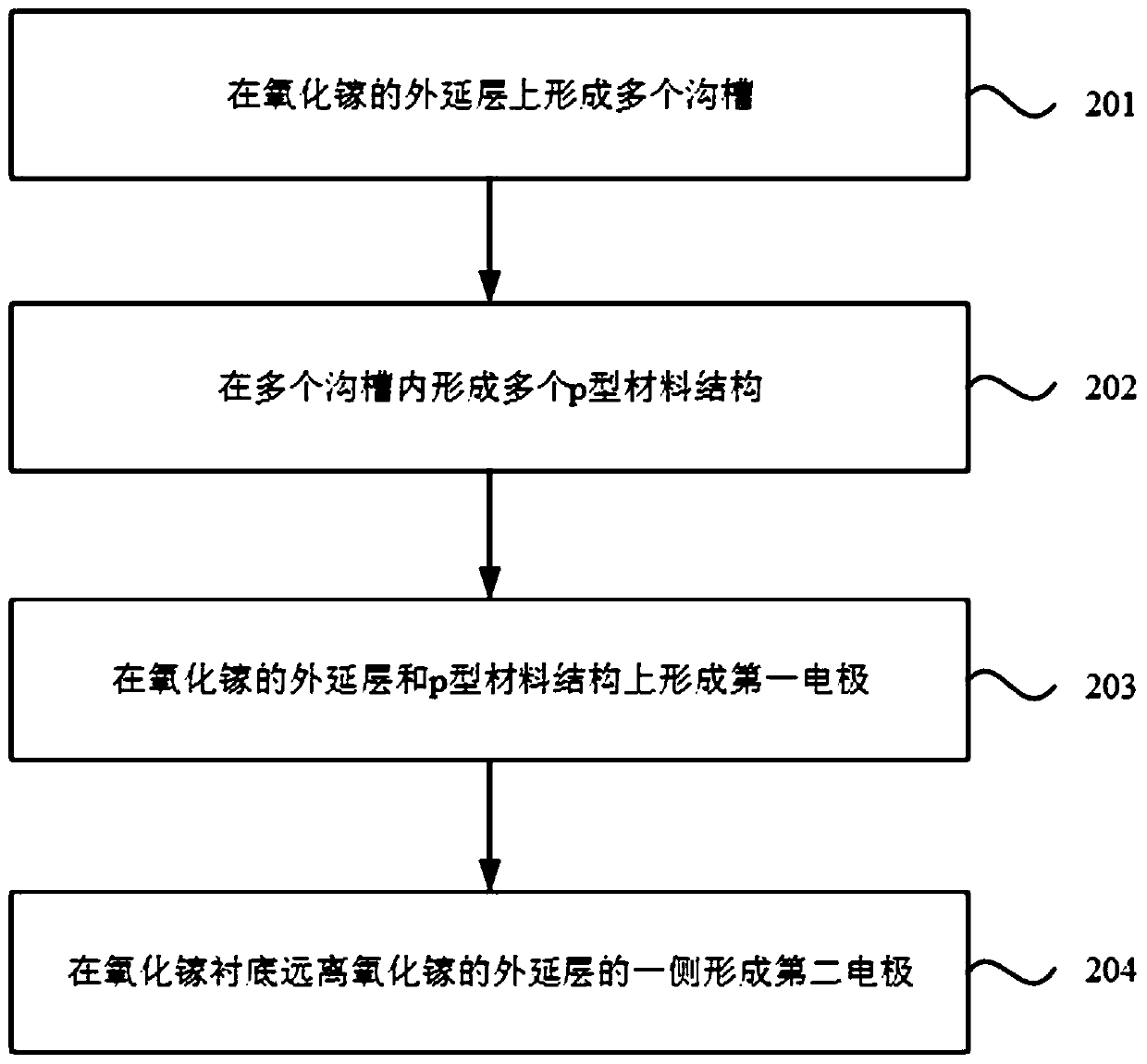

Schottky diode and preparation method thereof

ActiveCN109920857ALower turn-on voltageImprove reverse breakdown voltageSemiconductor/solid-state device manufacturingSemiconductor devicesSchottky diodeP type doping

The invention discloses a Schottky diode and a preparation method thereof. The Schottky diode comprises a gallium oxide substrate, a gallium oxide epitaxial layer on the gallium oxide substrate, a plurality of P-type material structures, a first electrode and a second electrode; a plurality of trenches are formed in the side, away from the gallium oxide substrate, of the gallium oxide epitaxial layer; the plurality of p-type material structures are located in the plurality of trenches; he first electrode covers the p-type material structures and the gallium oxide epitaxial layer; and the second electrode is located on the side, away from the gallium oxide epitaxial layer, of gallium oxide substrate. A heterogeneous PN junction structure is formed between the p-type material structures andthe gallium oxide epitaxial layer, thereby solving the problems of high technical difficulty and high cost accompanying with the manufacturing of high-performance Schottky diodes as the gallium oxidematerials are difficult to form p-type doping materials; and meanwhile, the manufactured Schotty diode has relatively low turn-on voltage at high voltage and high current, and has relatively high reverse breakdown voltage, thereby improving the working stability of the Schottky diode.

Owner:珠海镓未来科技有限公司

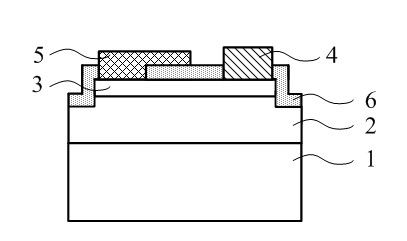

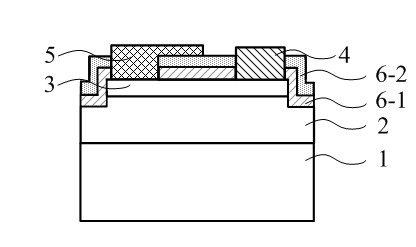

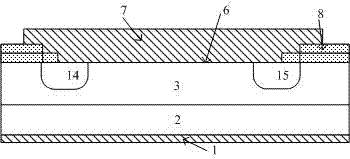

Hetetrostructure field effect diode and manufacturing method thereof

InactiveCN102097492AAchieving the shutdown characteristicLower on-resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesHigh resistanceMetal insulator

The invention discloses a hetetrostructure field effect diode and a manufacturing method thereof. The hetetrostructure field effect diode comprises a substrate as well as an insulation high-resistance semiconductor and a wide bandgap hetetrostructure barrier layer which are sequentially arranged on the substrate, wherein the insulation high-resistance semiconductor and the wide bandgap hetetrostructure barrier layer form a two-dimensional electron gas hetetrostructure epitaxial layer, an isolated table board is formed at the top of the insulation high-resistance semiconductor and the wide bandgap hetetrostructure barrier layer, an insulating medium layer is formed on the isolated table board, a cathode electrode and an anode electrode which are contacted with the wide bandgap hetetrostructure barrier layer are respectively formed on the insulating medium layer, wherein one part of the anode electrode is arranged on the wide bandgap hetetrostructure barrier layer, the other part of the anode electrode is arranged on the insulating medium layer to form a diode anode provided with a Schottky-MIS (metal-insulator-semiconductor) dual-structure electrode, and the anode electrode is made from a low-work function metal. According to the invention, the characteristics of low forward on voltage, low reverse leakage current and high reverse blocking voltage can be realized, thus, the method in the invention is applicable to manufacturing of a power type GaN-base hetetrostructure field effect diode.

Owner:SUN YAT SEN UNIV

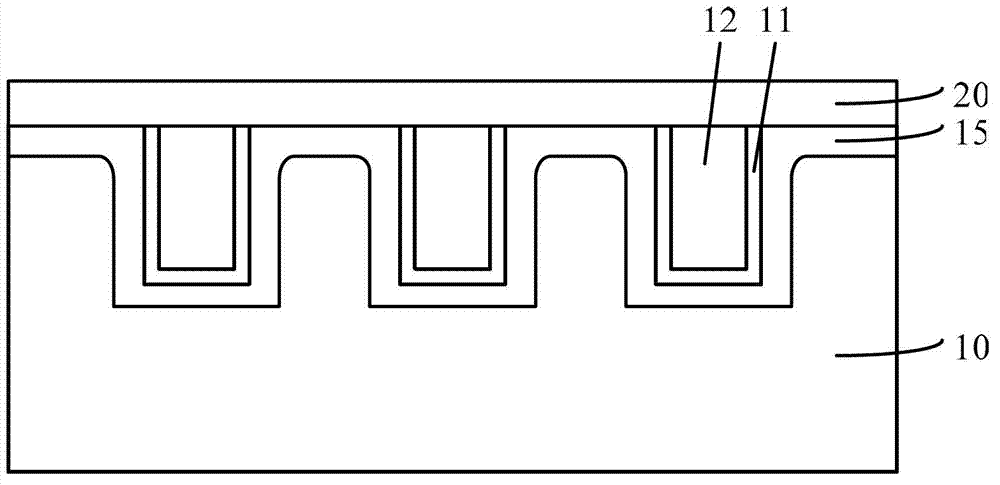

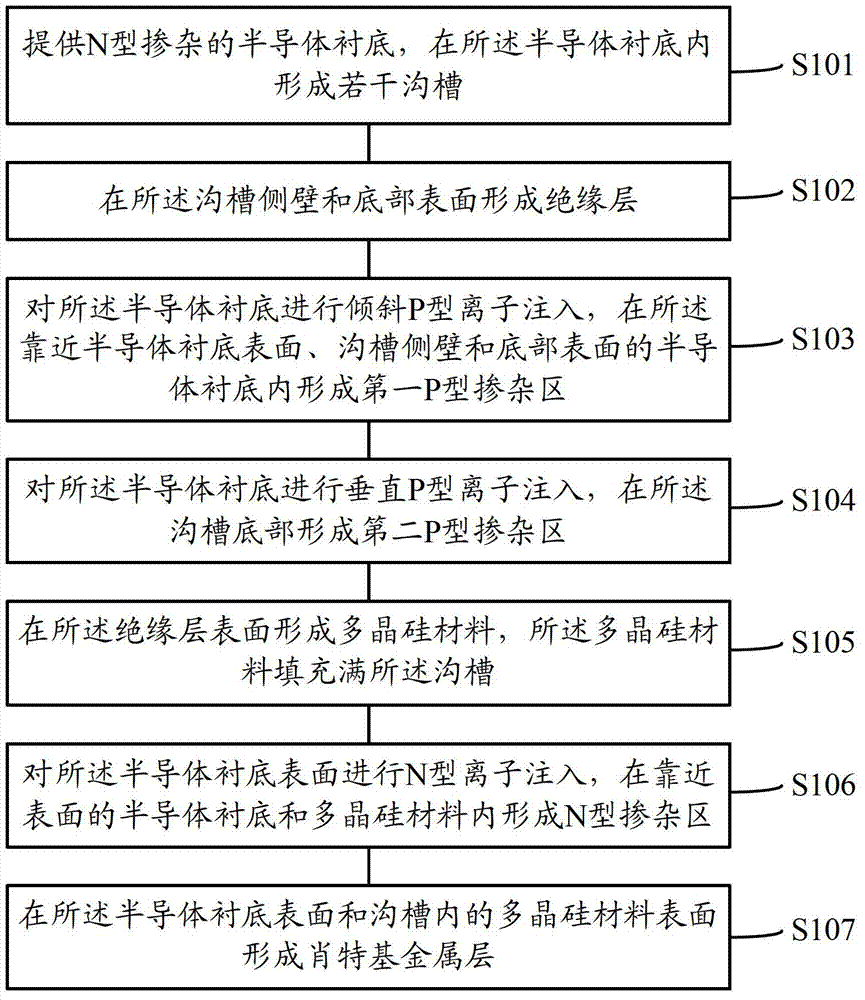

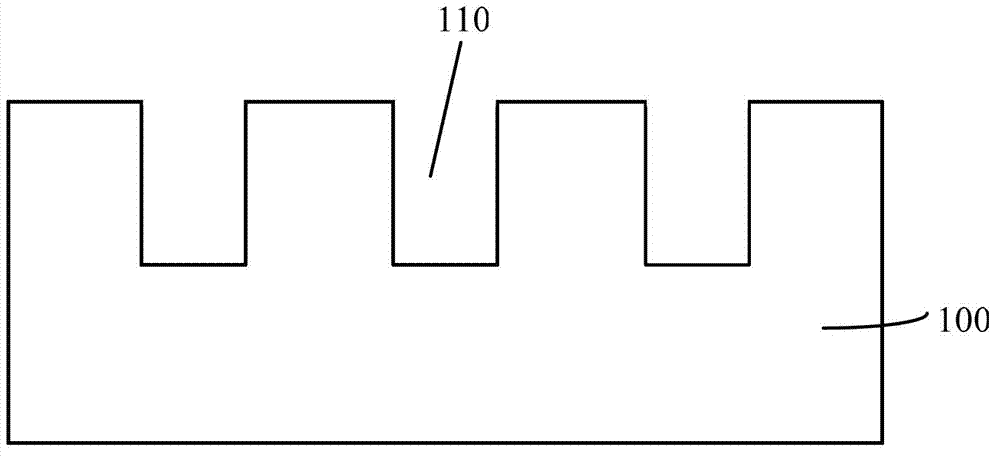

Schottky diode and method of formation of Schottky diode

ActiveCN102789979ANot easy to penetrateIncreasing the thicknessSemiconductor/solid-state device manufacturingSemiconductor devicesSchottky diodeP type doping

The invention discloses a Schottky diode and a method of formation of the Schottky diode. The method of formation of the Schottky diode comprises the following steps: providing a semiconductor substrate and forming a plurality of grooves inside the semiconductor substrate; obliquely injecting P type ions into the semiconductor substrate, and forming first P type doped regions inside the semiconductor substrate close to a surface of the semiconductor substrate, sidewalls of the grooves and a bottom surface; fully filling the grooves with polycrystalline silicon material; inversely forming N type doped regions inside the semiconductor substrate close to the surface and the polycrystalline silicon material; and forming Schottky metal layers on the surface of the semiconductor substrate and the surface of the polycrystalline silicon material. For the spacing between two first P type doped regions of adjacent grooves is less than the spacing between the adjacent grooves, the semiconductor substrate between the two first P type doped regions of the adjacent grooves in the Schottky diode can be cut off by a depletion region more easily when an inverse voltage is applied to two ends of the Schottky diode, so that the inverse breakdown voltage of the Schottky diode can be increased.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

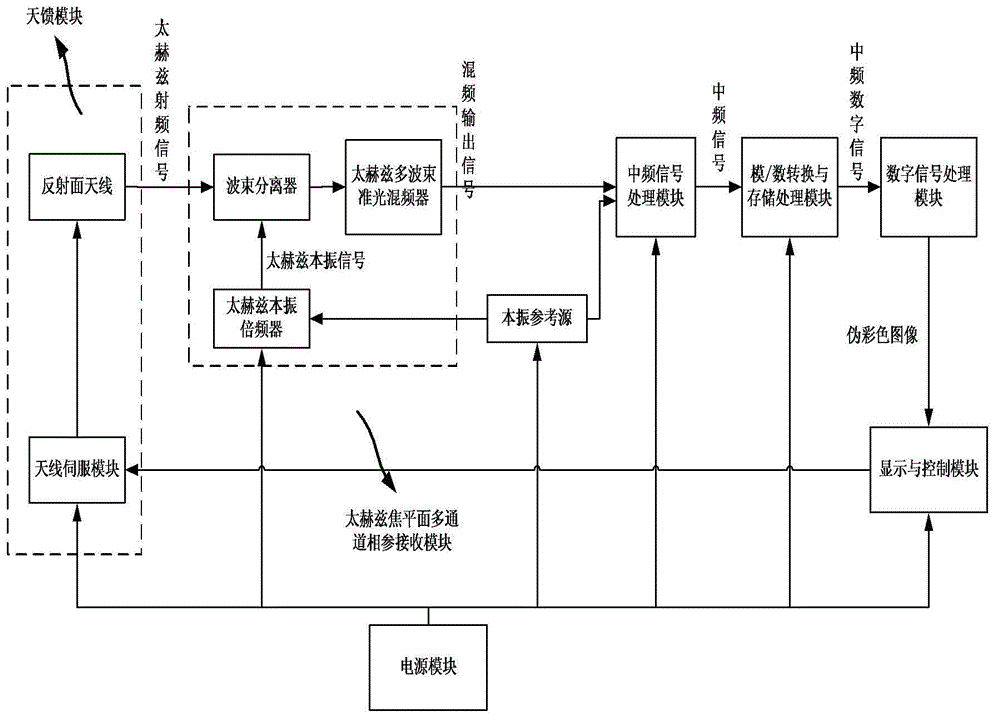

Portable terahertz passive type color camera

InactiveCN104038707AHighly integratedImprove machining accuracyTelevision system detailsAntenna arraysFrequency conversionImage resolution

Provided in the invention is a portable terahertz passive type color camera comprising a terahertz type multi-beam quasi-optical mixer having N1*N2 pixels. The terahertz type multi-beam quasi-optical mixer carries out frequency mixing on a received terahertz radio frequency signal and a terahertz type oscillator signal to generate N1*N2-path mixing output signals, wherein the N1 and N2 are natural numbers larger than or equal to 1; and each path of mixing output signal corresponds to one pixel. According to the invention, the terahertz type multi-beam quasi-optical mixer is used as the main receiving and frequency conversion element and the integration level is high; and the two-dimensional large-scale array can be realized well. The size of the whole receiving machine is small and the weight is light. The target identification capability can be improved in a complex background environment; and real-time imaging can be realized. The good resolution ratio and the high sensitivity are realized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

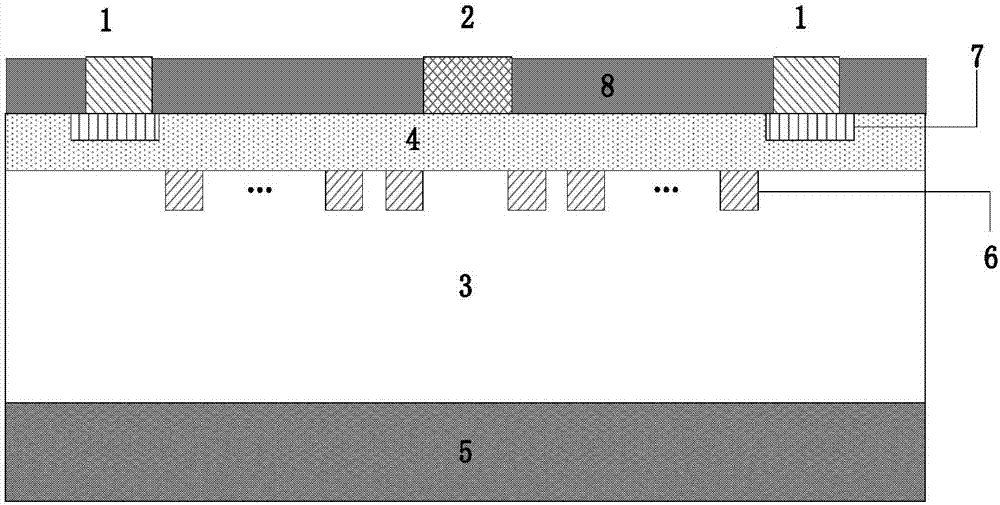

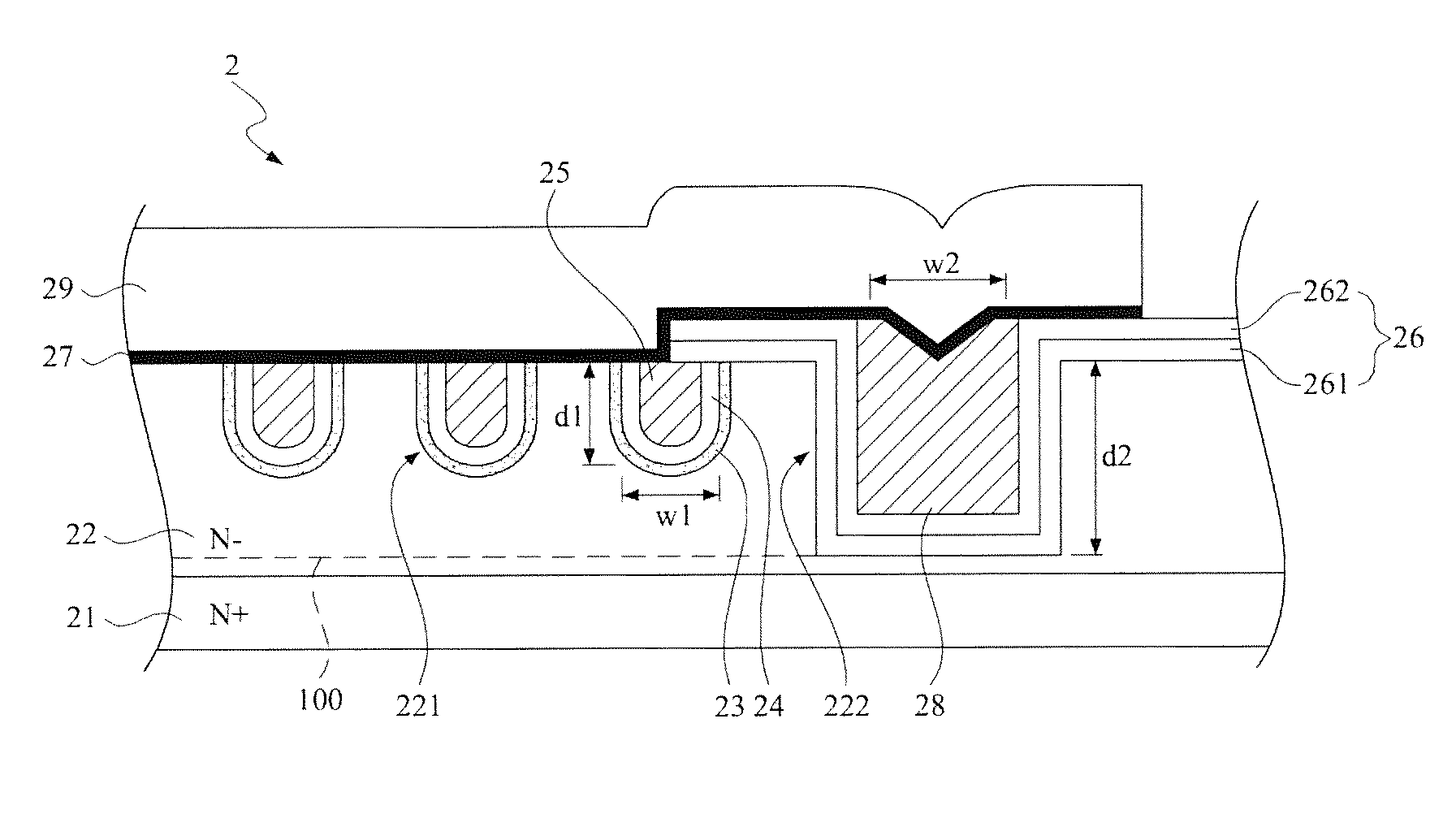

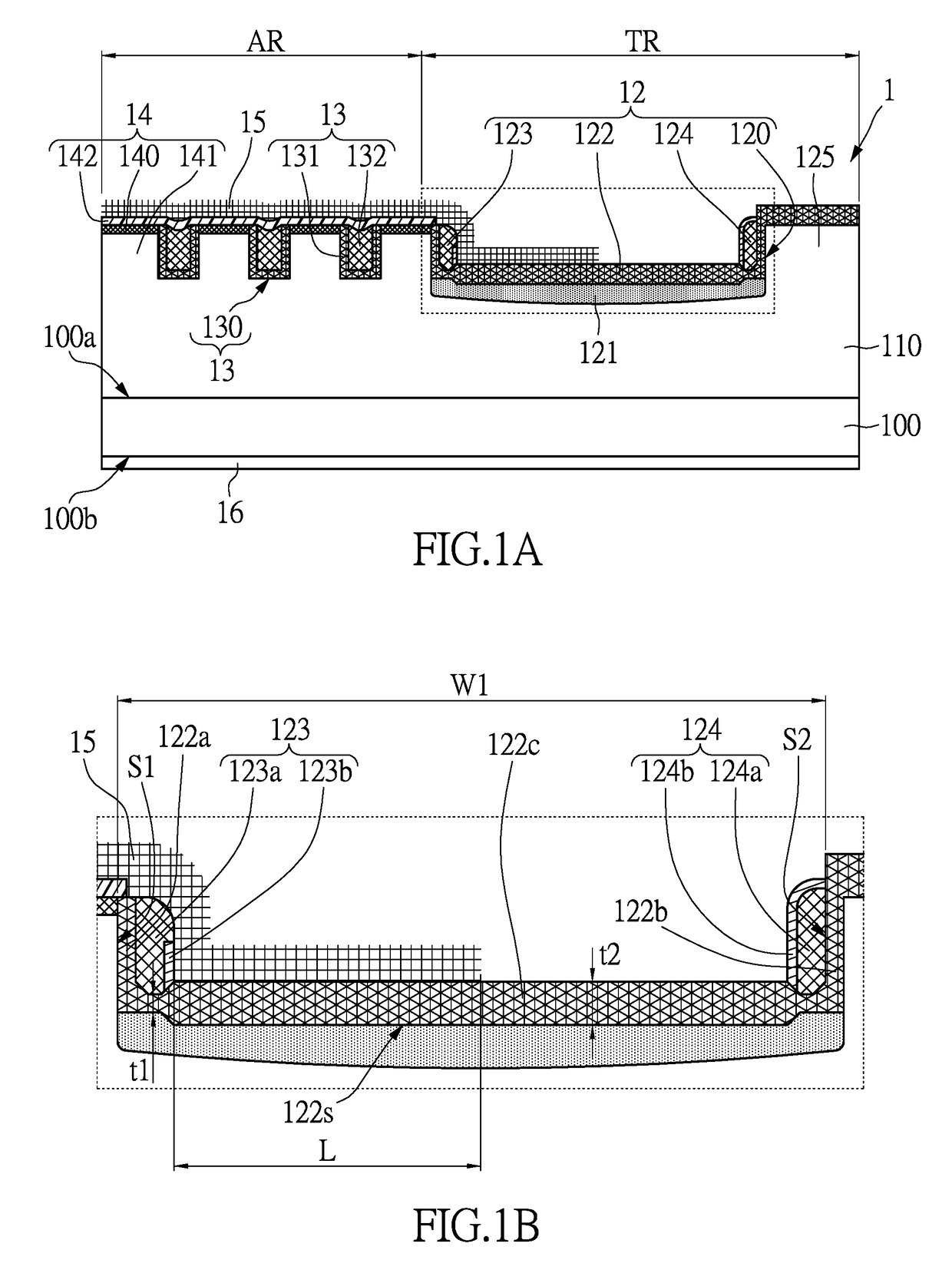

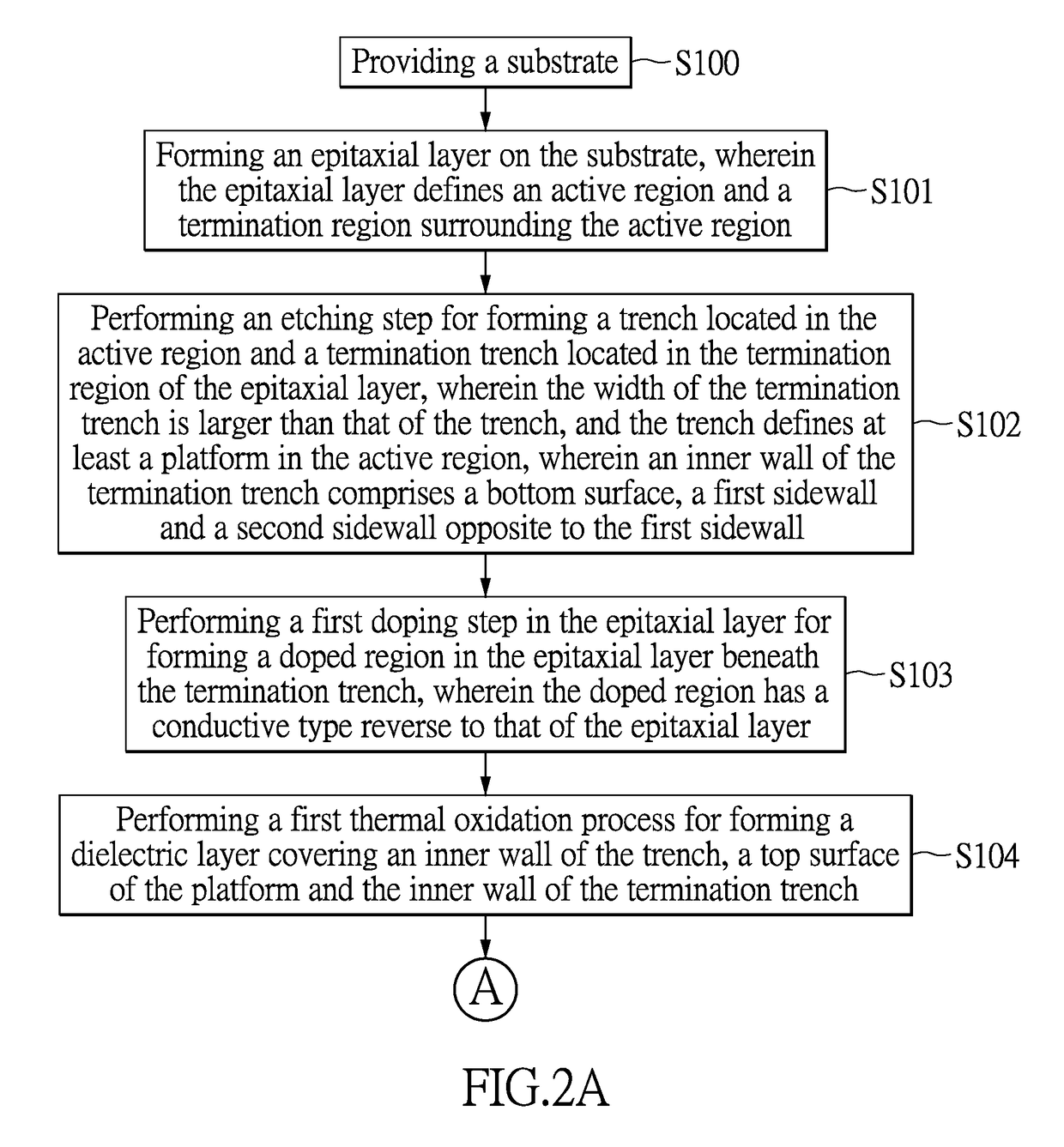

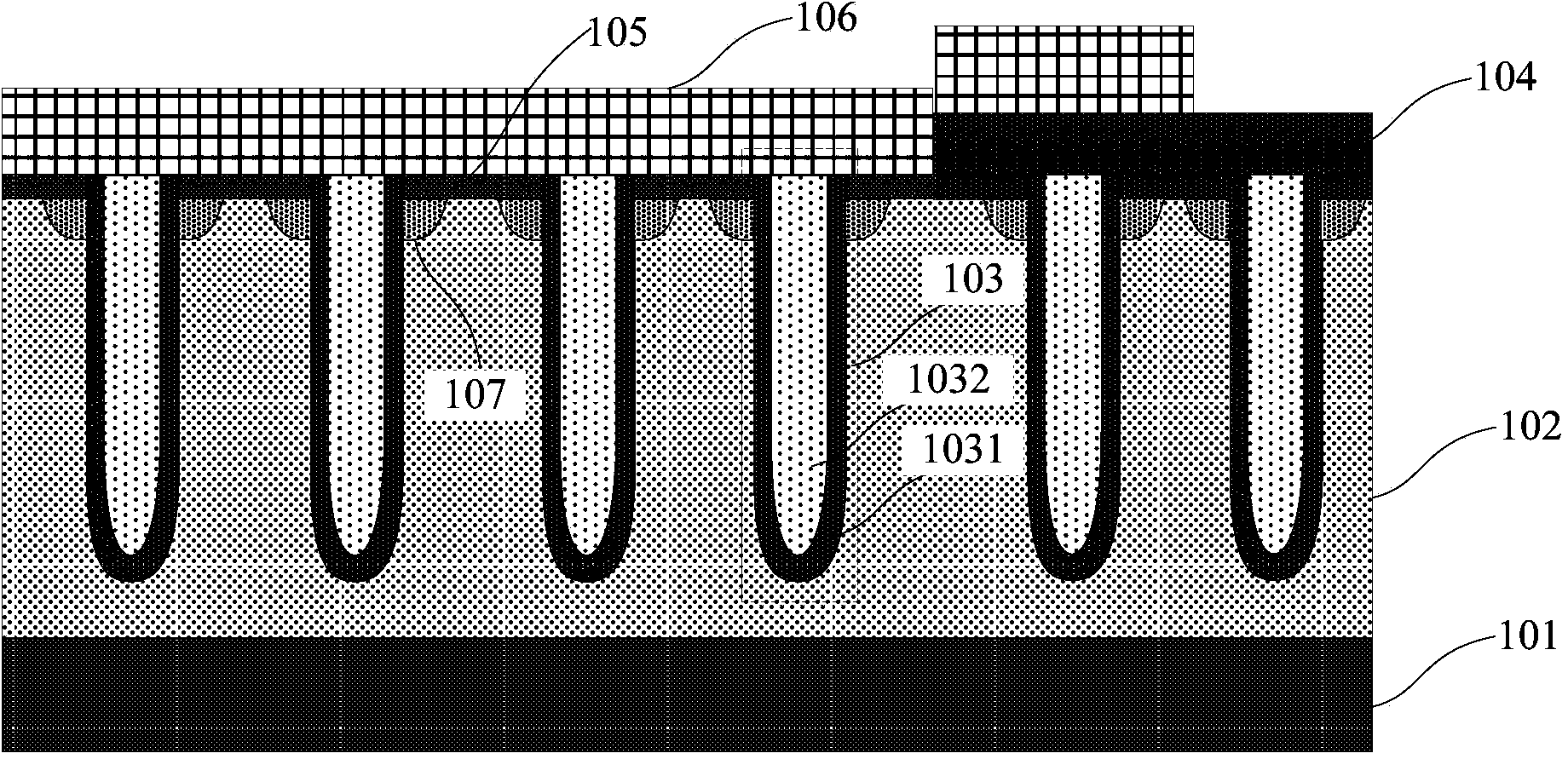

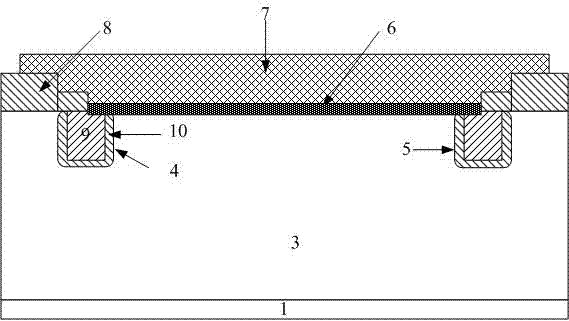

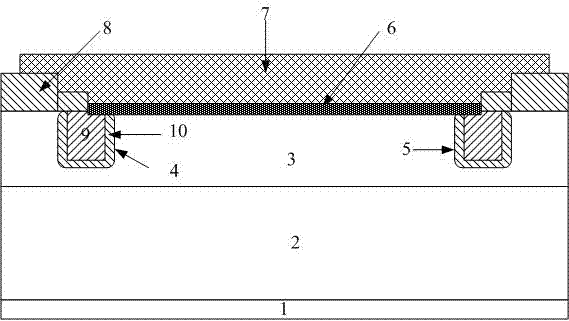

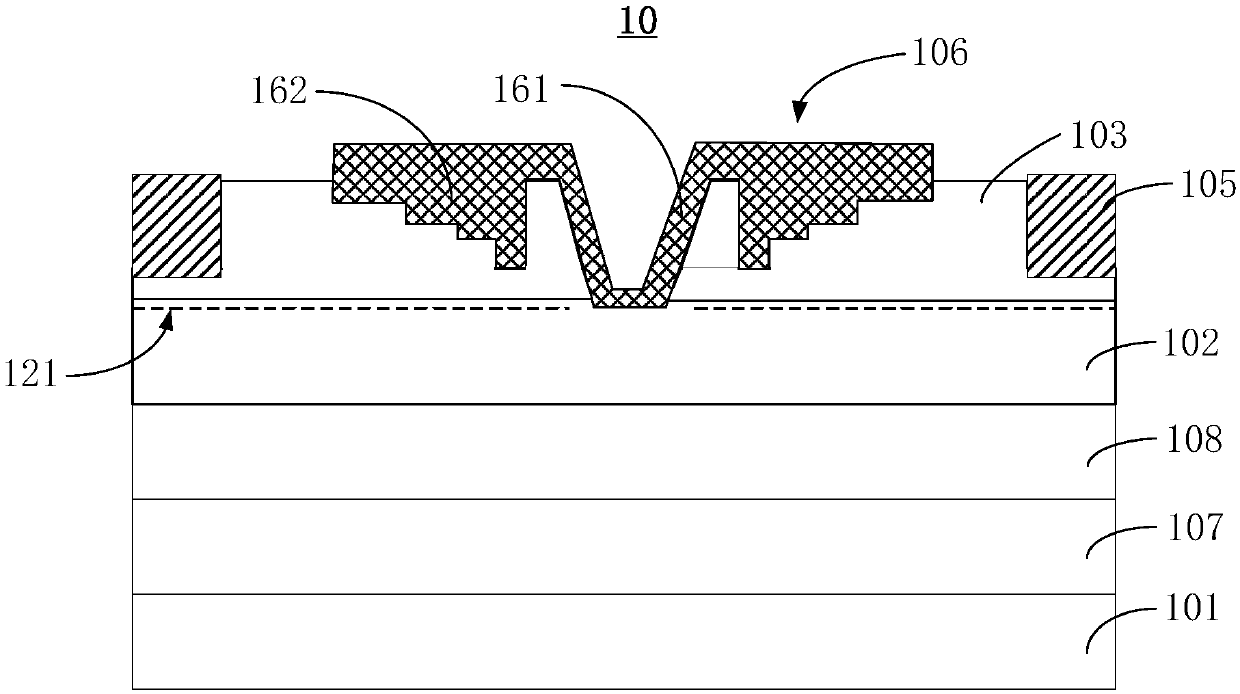

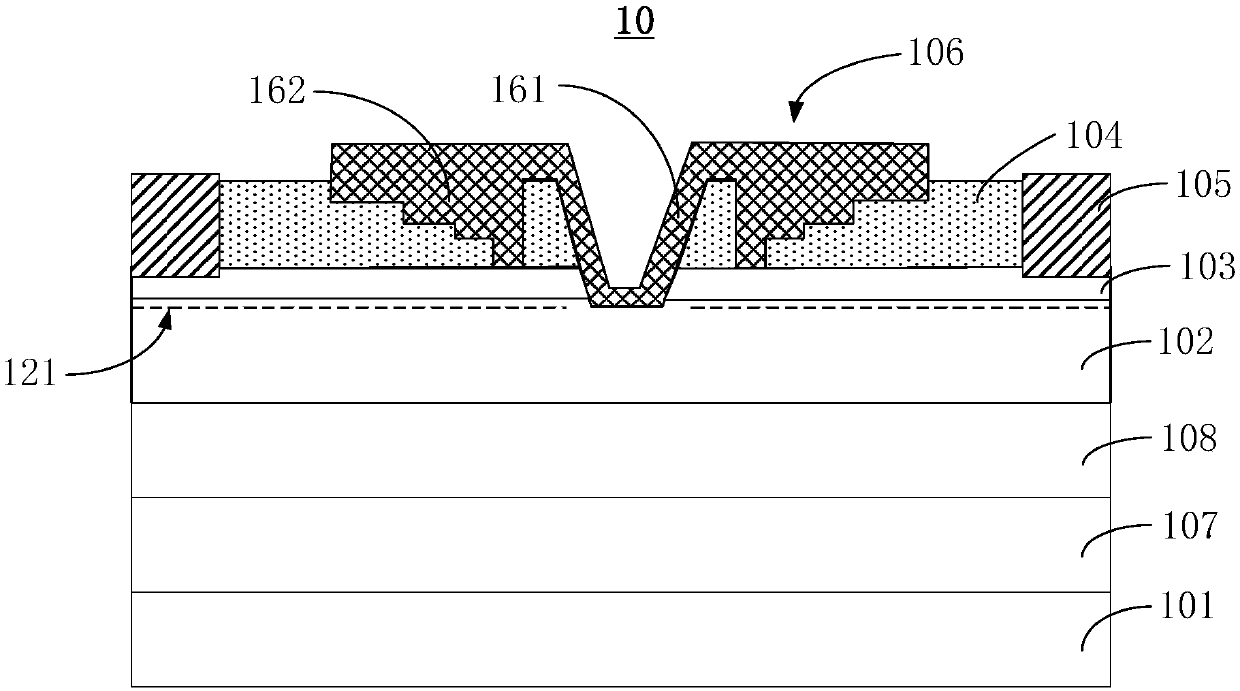

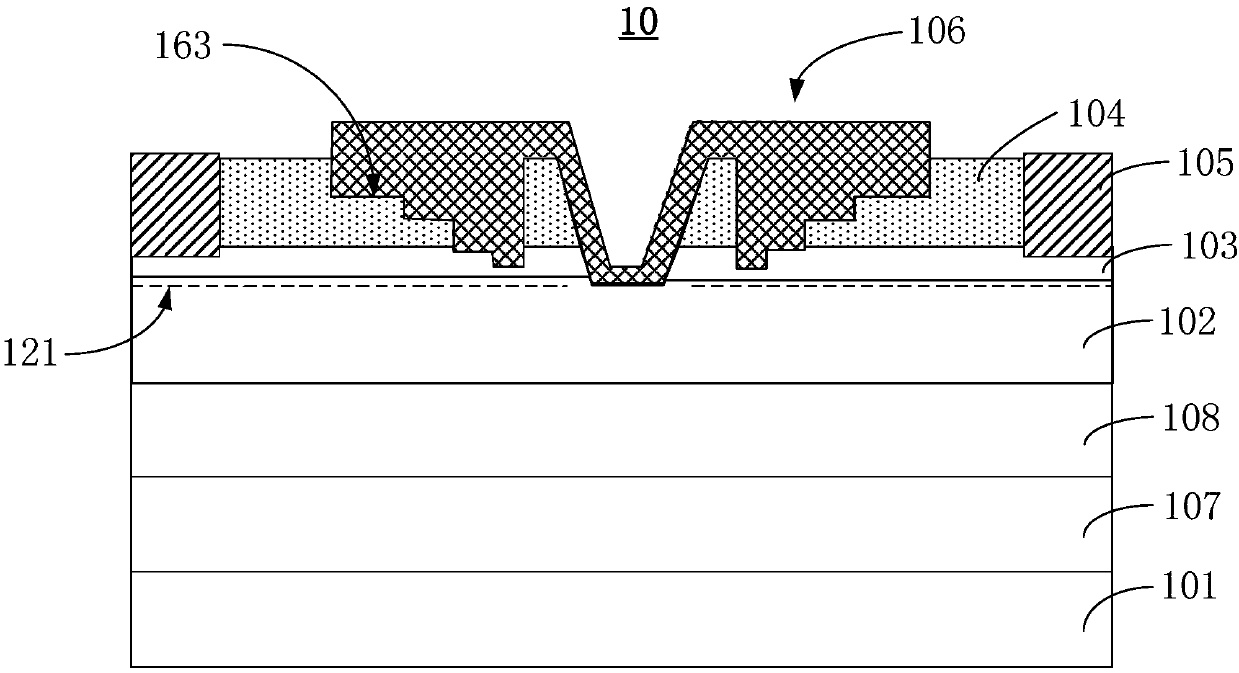

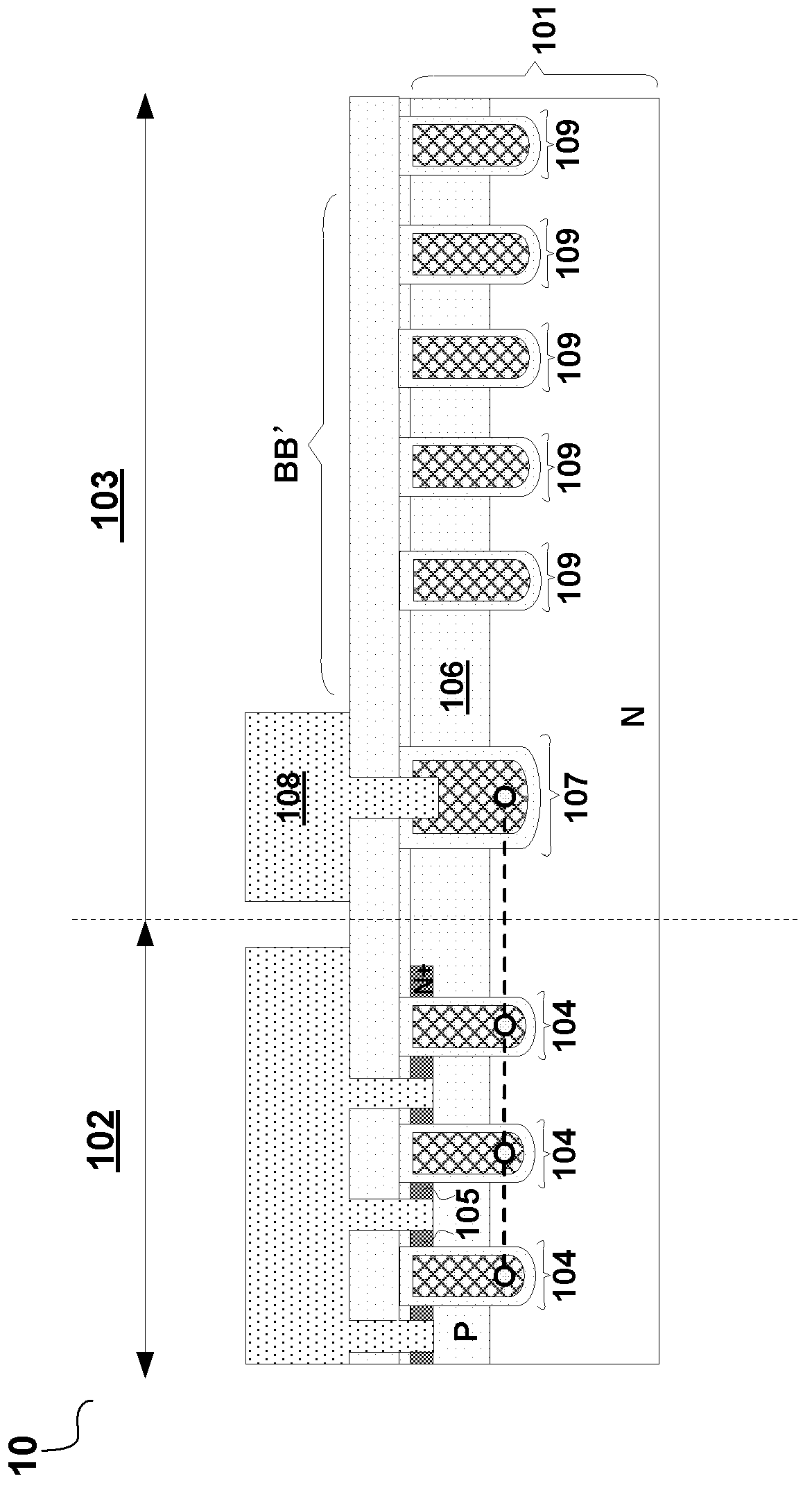

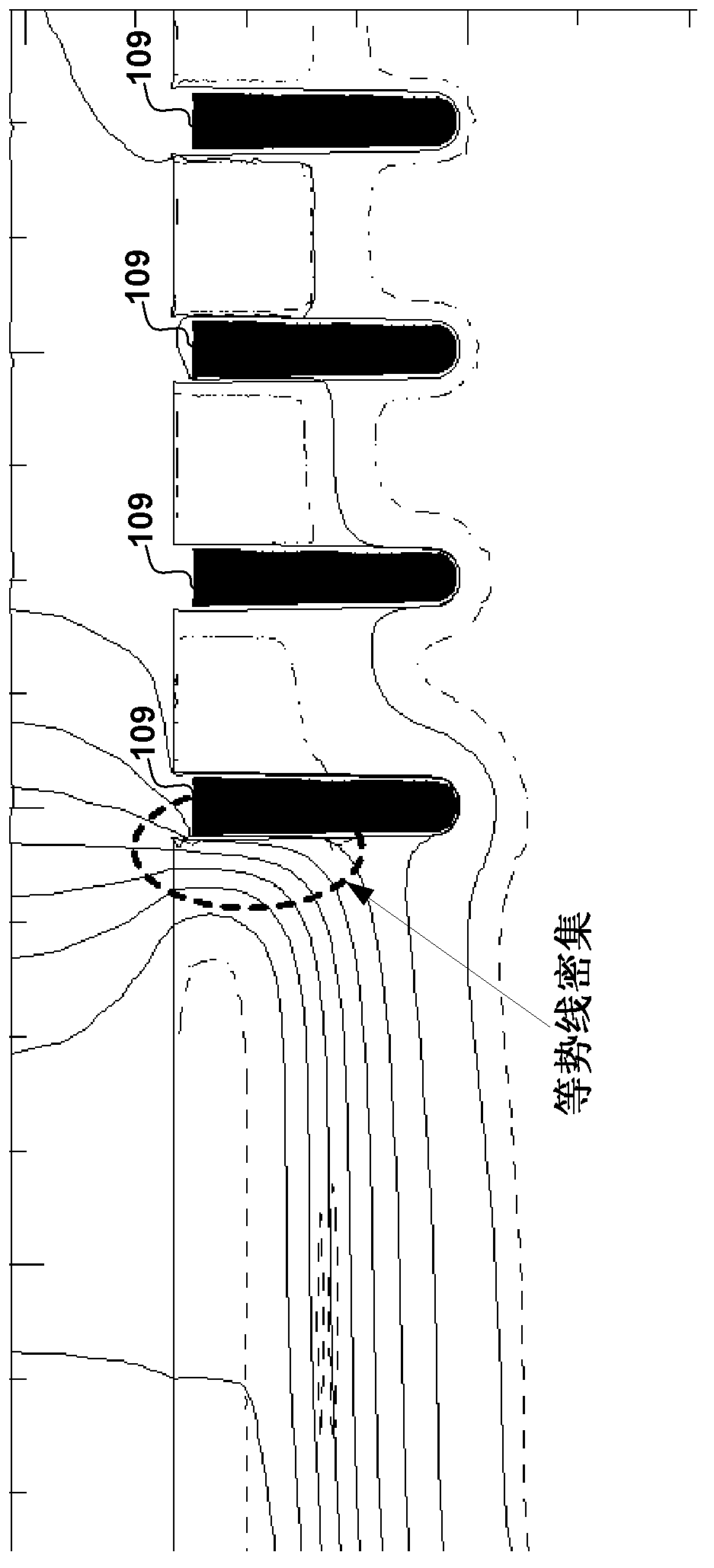

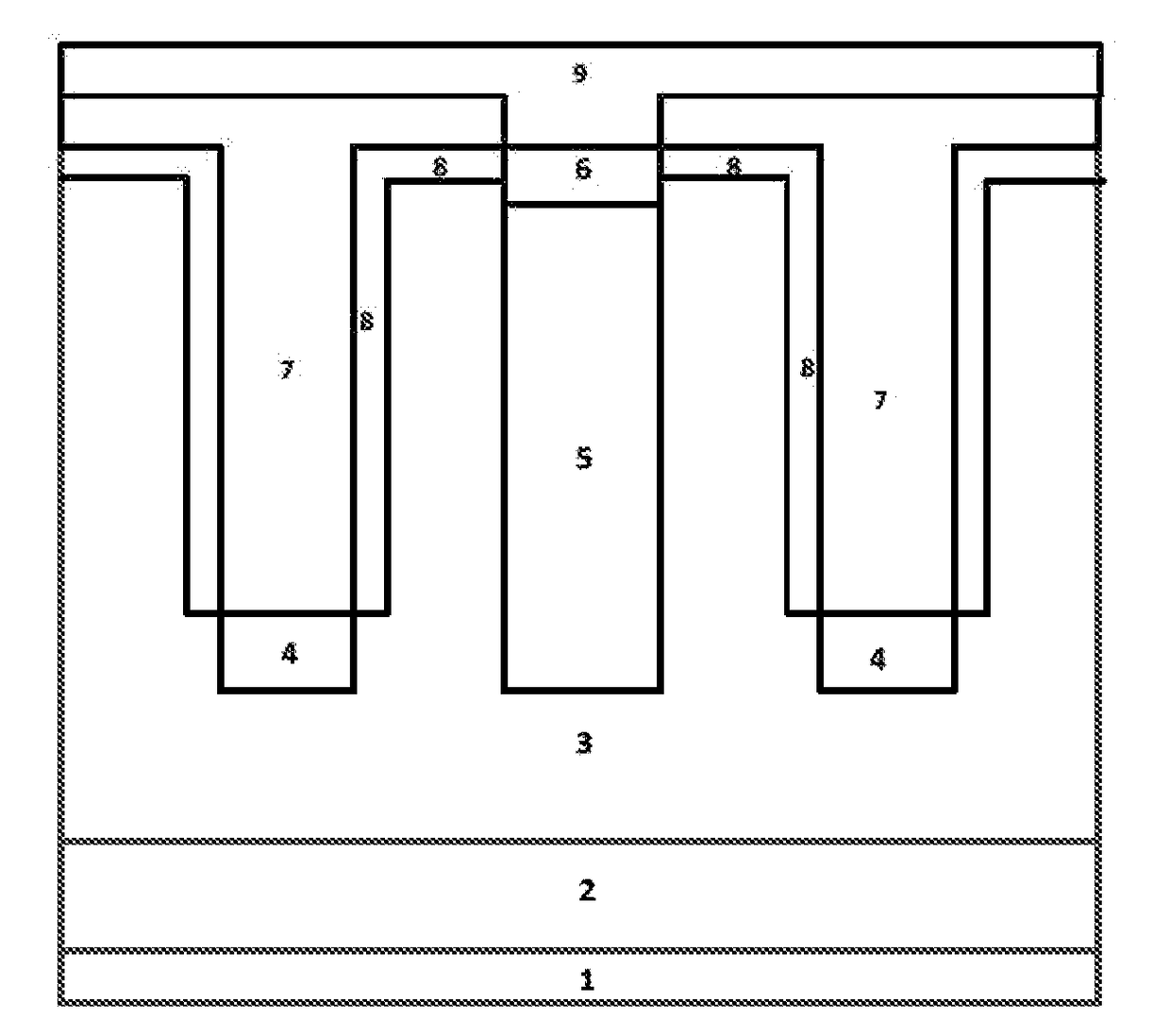

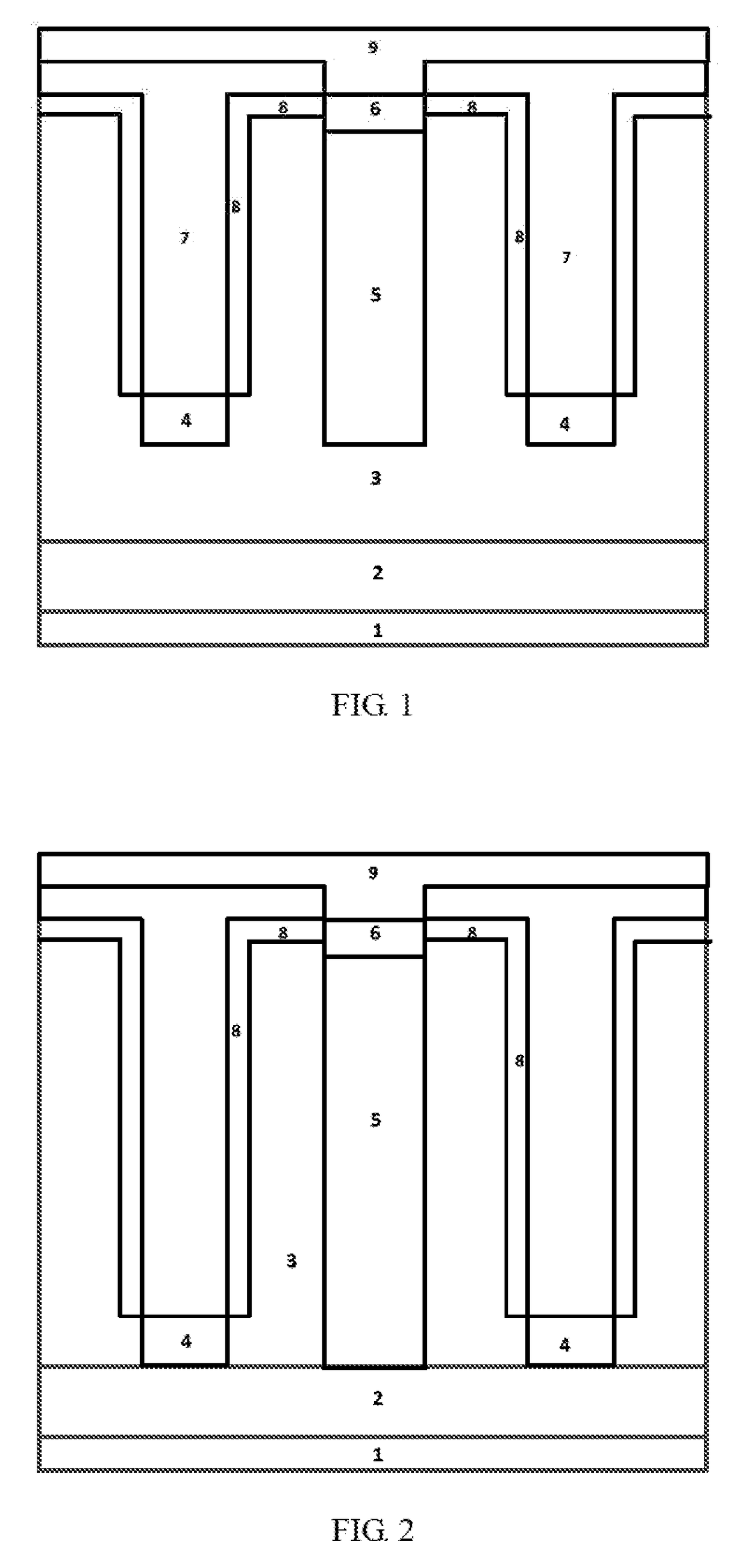

Trenched semiconductor structure

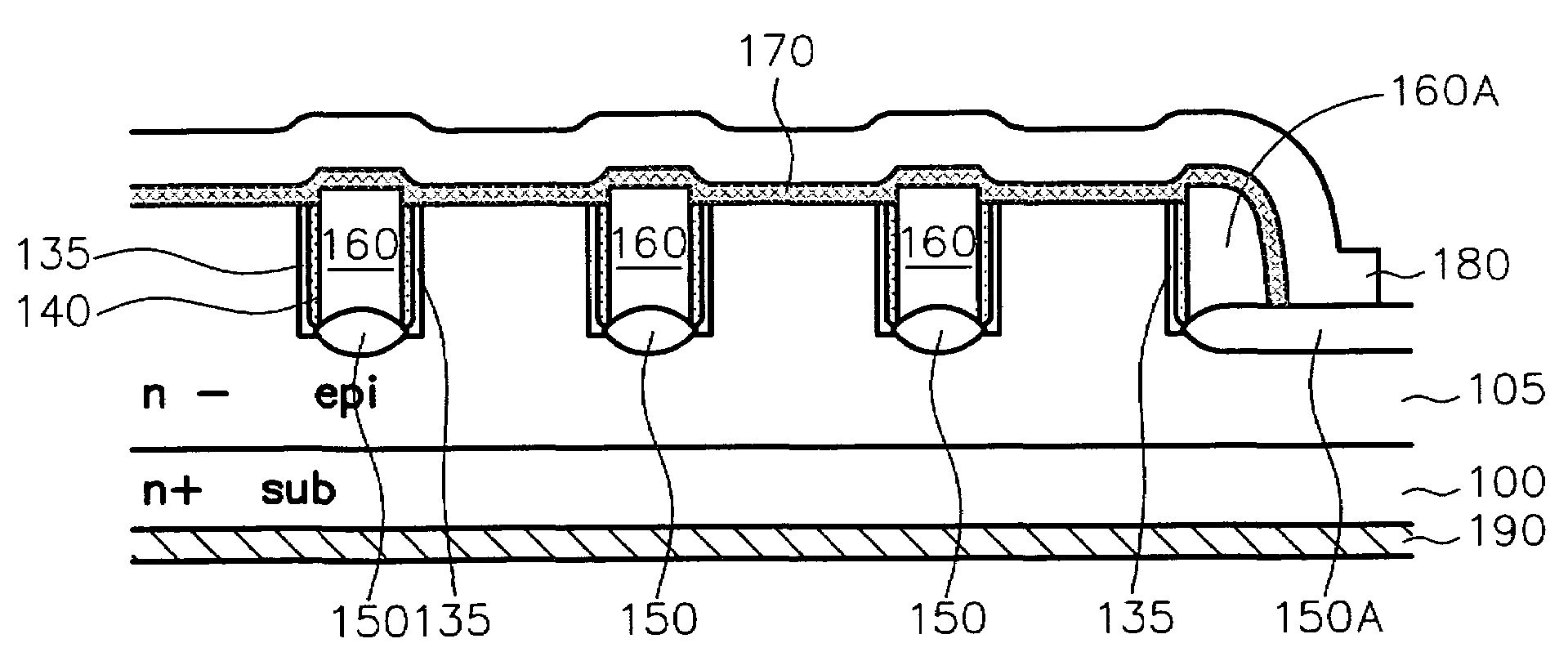

ActiveUS20130270668A1Reduce leakage currentImprove reverse breakdown voltageSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureDielectric layer

A trenched semiconductor structure comprises a semiconductor substrate, an epitaxial layer, an ion implantation layer, a termination region dielectric layer, an active region dielectric layer, and a first polysilicon layer. The epitaxial layer doped with impurities of a first conductive type is formed on the semiconductor substrate. A plurality of active region trenches and a termination region trench are formed in the epitaxial layer. The ion implantation layer is formed in the active region trenches by doping impurities of a second conductive type. The termination region dielectric layer covers the termination region trench. The active region dielectric layer covers the ion implantation region. The first polysilicon layer covers the active region dielectric layer and fills the active region trenches. The depth of the termination region trench is greater than that of the active region trenches and close to that of the depletion region under reverse breakdown.

Owner:TAIWAN SEMICONDUCTOR COMPANY LIMITED

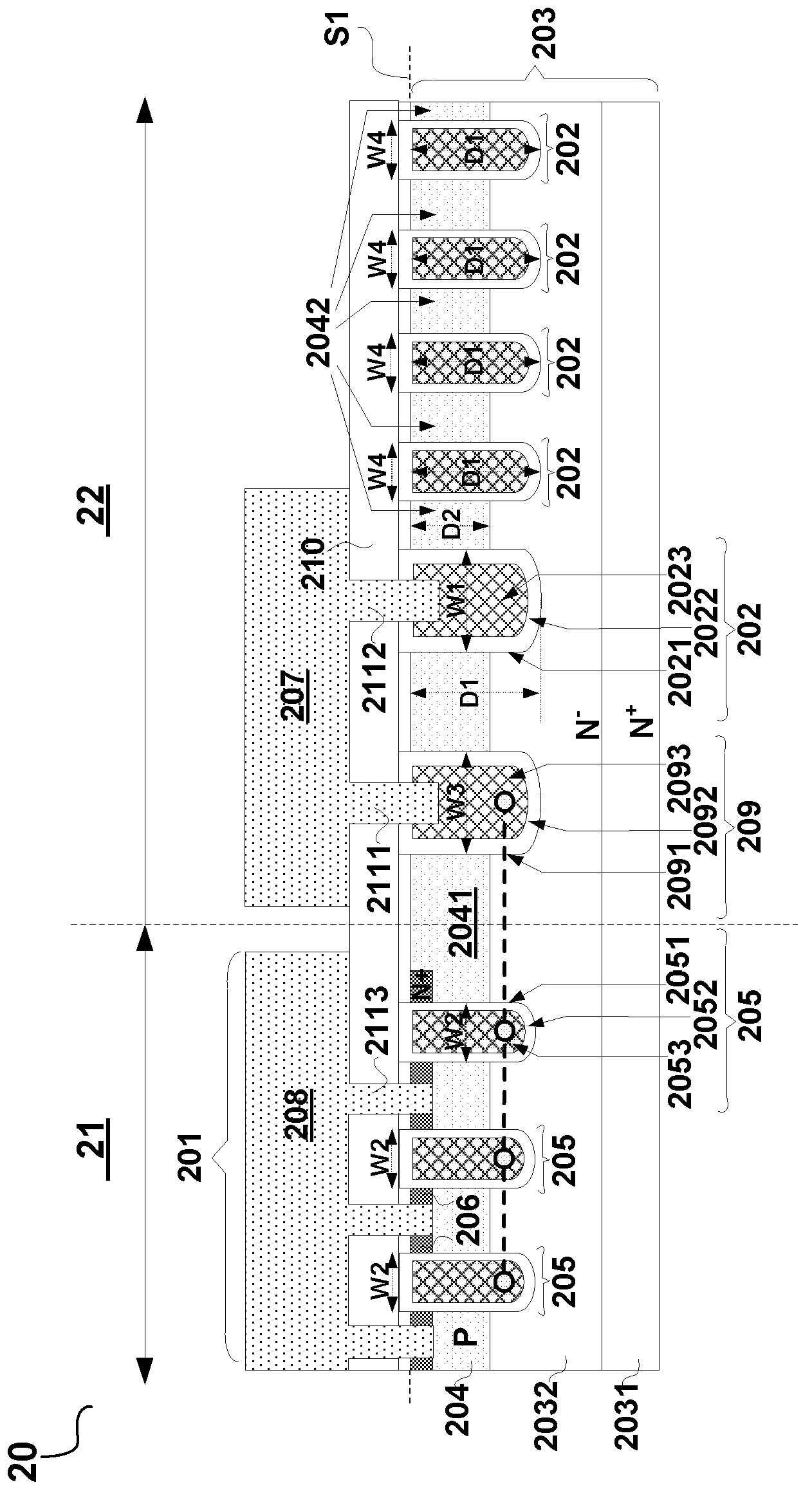

Diode device and manufacturing method thereof

ActiveUS20170148927A1Improve reverse breakdown voltageReducing reverse current leakageSemiconductor/solid-state device manufacturingSemiconductor devicesSchottky diodeTrench gate

A diode device and manufacturing method thereof are provided. The diode device includes a substrate, an epitaxial layer, a trench gate structure, a Schottky diode structure and a termination structure. An active region and a termination region are defined in the epitaxial layer. The Schottky diode structure and the trench gate structure are located in the active region and the termination structure is located in the termination region. The termination structure includes a termination trench formed in the epitaxial layer, a termination insulating layer, a first spacer, a second spacer and a first doped region. The termination insulating layer is conformingly formed on inner walls of the termination trench. The first and second spacers are disposed on two sidewalls of the termination trench. The first doped region formed beneath the termination trench has a conductive type reverse to that of the epitaxial layer.

Owner:DIODES TAIWAN S A R L

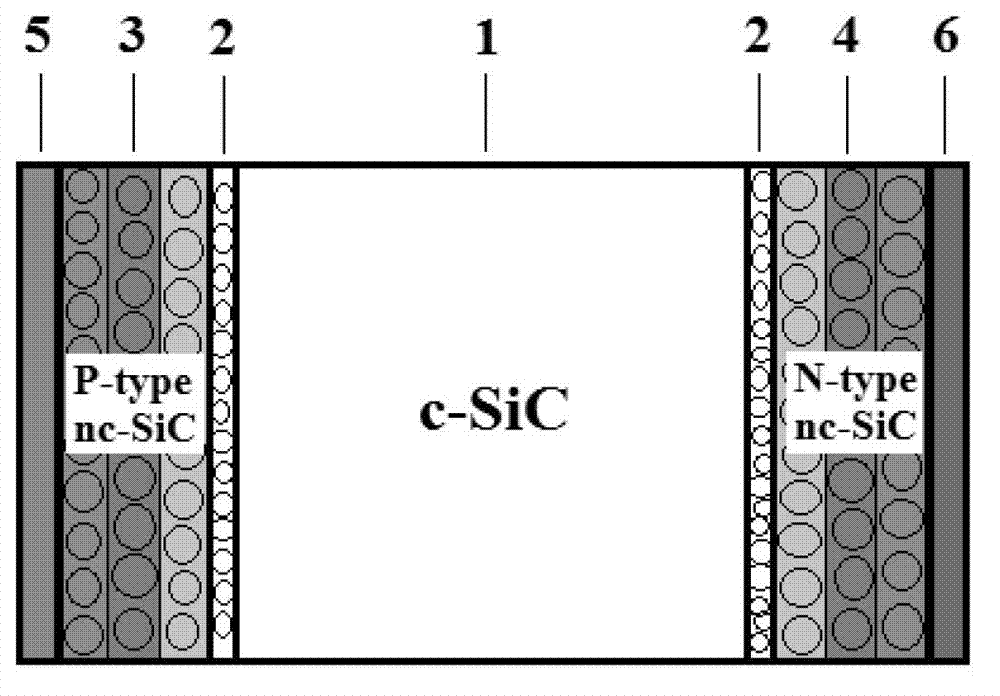

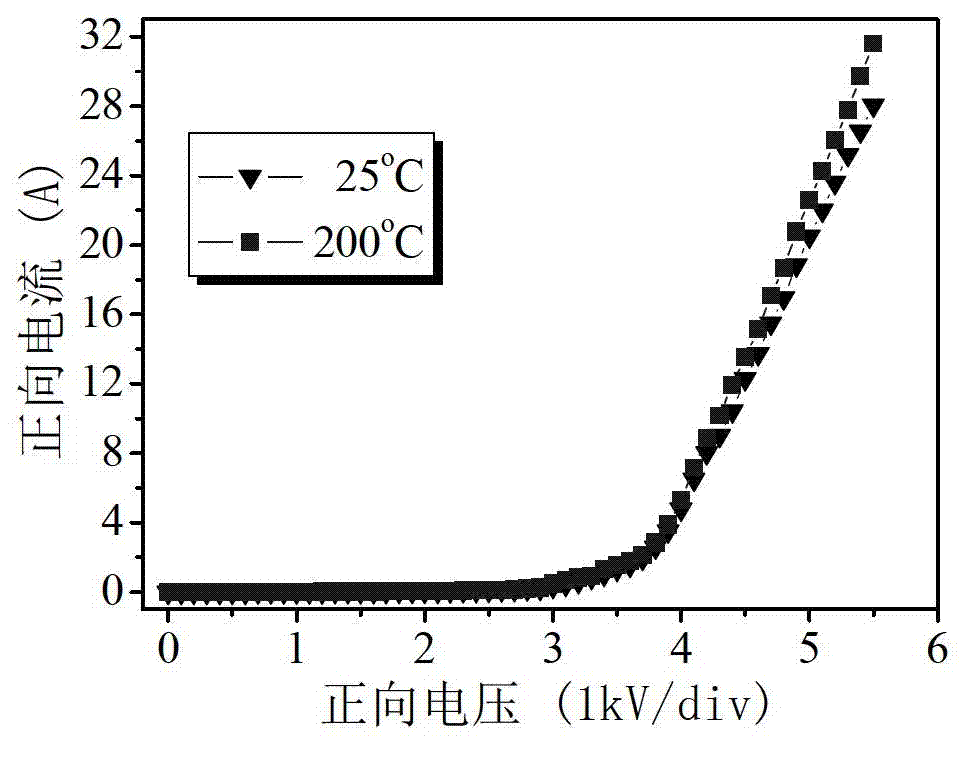

Nanometer silicon carbide/crystal silicon carbide double graded junction fast recovery diode and preparation method thereof

ActiveCN102820323AImprove reverse breakdown voltageImprove pressure resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesPower flowReverse recovery

The invention discloses a nanometer silicon carbide / crystal silicon carbide double graded junction fast recovery diode and a preparation method thereof. The nanometer silicon carbide / crystal silicon carbide double graded junction fast recovery diode comprises a monocrystal silicon carbide (4H-SiC) substrate, number nanometer nc-Si ultra thin layers respectively arranged on two sides of the 4H-SiC substrate, P and N type gradient doping multilayer nc-SiC thin films (4H-SiC type) and an alloy ohmic electrode deposited on an outer layer nc-SiC thin film, and a gradient doping multilayer nc-SiC multilayer film, the 4H-SiC substrate and the alloy ohmic electrode form an electrode / nc-SiC / 4H-SiC / nc-SiC / electrode double graded junction structure. The nanometer silicon carbide / crystal silicon carbide double graded junction fast recovery diode has the advantages that, compared with fast recovery diodes (FRD) prepared by other methods, reverse breakdown voltage improves by about 500V, withstand voltage capacity is strengthened, reverse recovery time is shortened to 100nS, high-speed switch is easy to achieve, surge current during reverse recovery is small, and loss and electromagnetic interference are reduced.

Owner:WEEN SEMICON TECH CO LTD

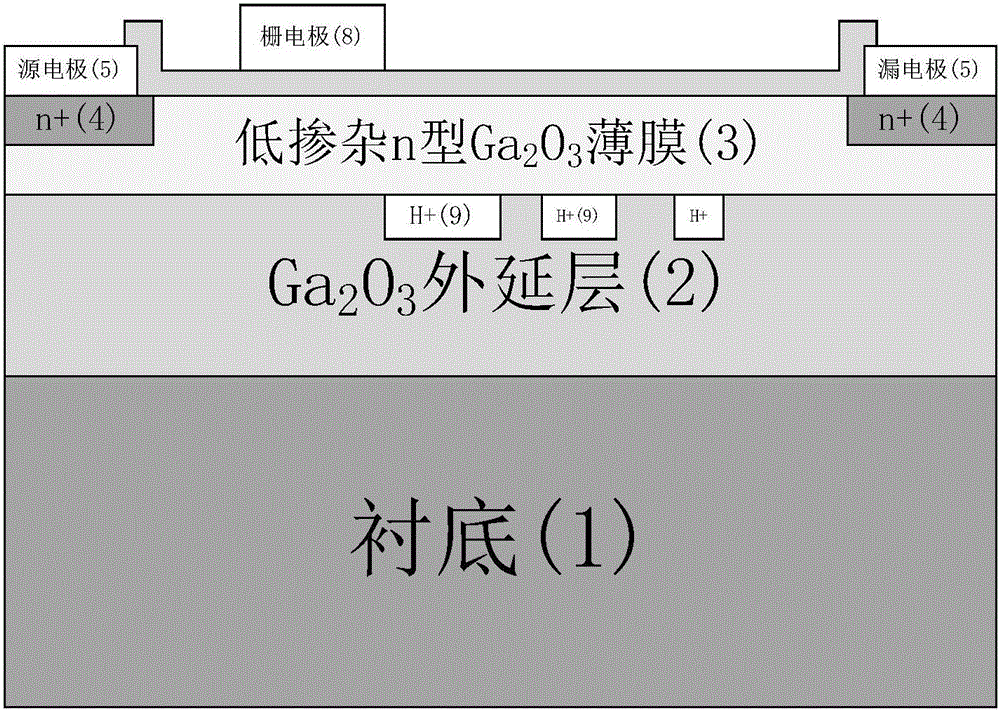

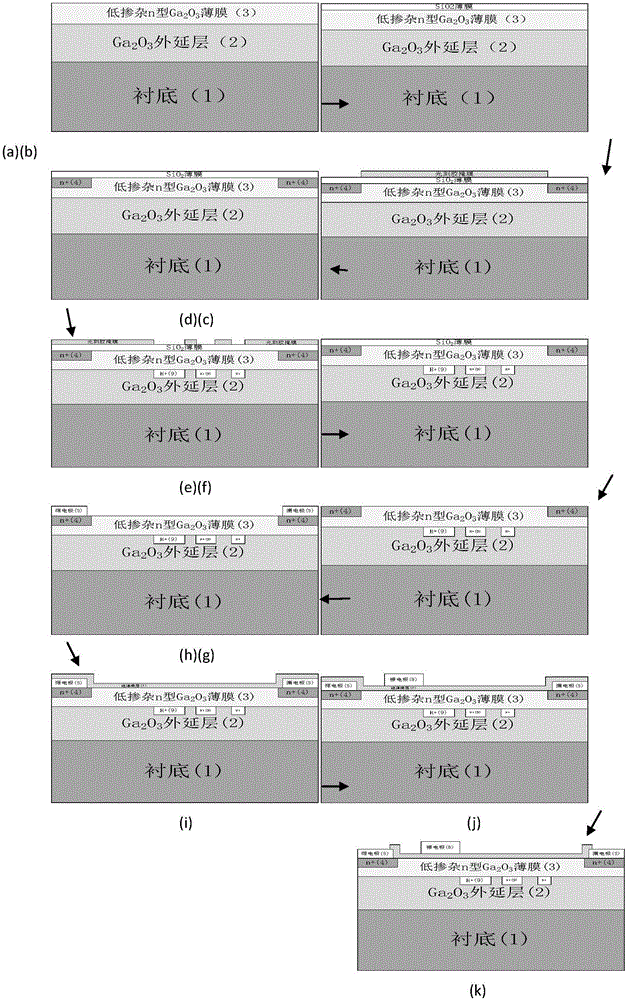

Metallic oxide semiconductor field effect transistor and manufacturing method thereof

ActiveCN106847881AWeaken agglomerationImprove reverse breakdown voltageSemiconductor/solid-state device manufacturingSemiconductor devicesPhysicsOxide semiconductor

The invention discloses a device structure of a metallic oxide field effect transistor and a manufacturing method thereof. The device structure comprises a substrate (1), a Ga2O3 epitaxial layer (2) and low-doped n-type Ga2O3 thin film (3) from bottom to top, the thin film is provided with a high-doped n-type ion-implanted region (4) and an insulated gate medium (7), the ion-implanted region is provided with a source electrode (5) and a drain electrode (6), the insulated gate medium is provided with a gate electrode (8), the Ga2O3 epitaxial layer is provided with multiple hydrogen-ion-implanted regions (9), the hydrogen-ion-implanted regions are located in the epitaxial layer between the gate electrode and the drain electrode, and meanwhile with the distance increase of the hydrogen-ion-implanted regions and the gate electrode, the widths of the hydrogen-ion-implanted regions are reduced, and intervals among the hydrogen-ion-implanted regions are increased. According to the device structure of the metallic oxide field effect transistor and the manufacturing method thereof, an electric field is adjusted through attraction of hydrogen ions to electrons, a breakdown voltage of a device is improved, and the device structure can be used as a power device and a high voltage switch device.

Owner:XIDIAN UNIV

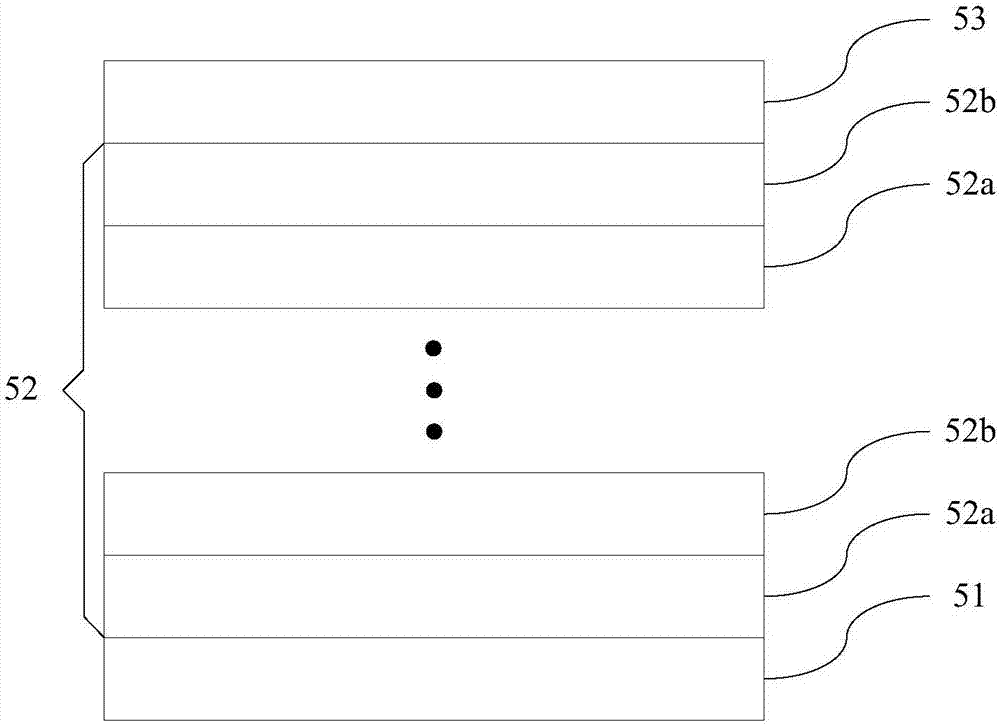

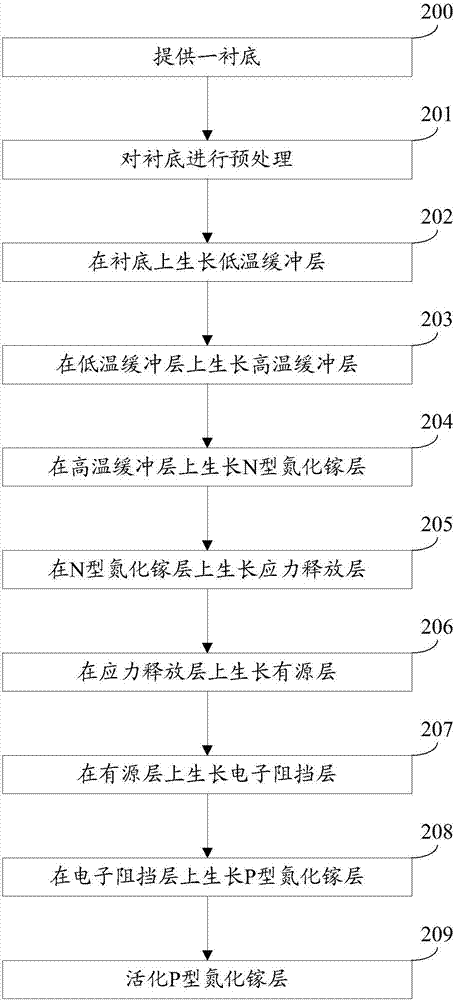

Epitaxial wafer of light emitting diode and manufacturing method thereof

ActiveCN106887494AReduce adverse effectsQuality improvementSemiconductor devicesIndiumGallium nitride

The invention discloses an epitaxial wafer of a light emitting diode and a manufacturing method thereof, and belongs to the semiconductor technology field. The epitaxial wafer comprises a substrate, a low-temperature gallium nitride layer, a high-temperature gallium nitride layer, an N-type gallium nitride layer, a stress releasing layer, an active layer, an electronic blocking layer and a P-type gallium nitride layer. The stress releasing layer comprises a first sublayer, a second sublayer and a third sublayer. The first sublayer is a gallium nitride layer doped with silicon. The second sublayer comprises multiple undoped indium gallium nitride layers and multiple undoped gallium nitride layers. The multiple undoped indium gallium nitride layers and the multiple undoped gallium nitride layers are alternatively stacked and arranged. The active layer comprises multiple indium gallium nitride layers and multiple gallium nitride layers. The multiple indium gallium nitride layers and the multiple gallium nitride layers are alternatively stacked and arranged. The third sublayer is the gallium nitride layer doped with indium and silicon. A doped concentration of the indium in the third sublayer is gradually increased or gradually reduced along a laminating direction of the epitaxial wafer. In the invention, LED brightness and a reverse breakdown voltage are finally increased.

Owner:HC SEMITEK ZHEJIANG CO LTD

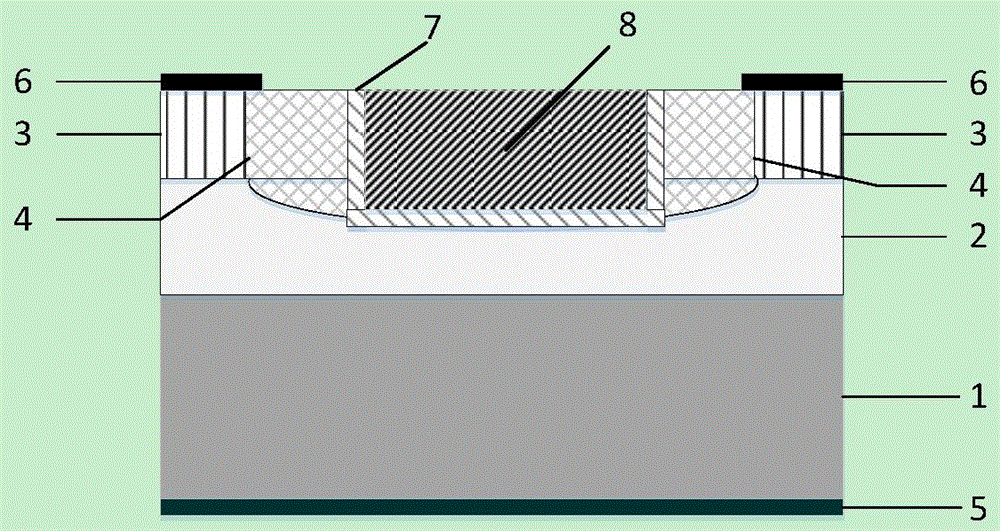

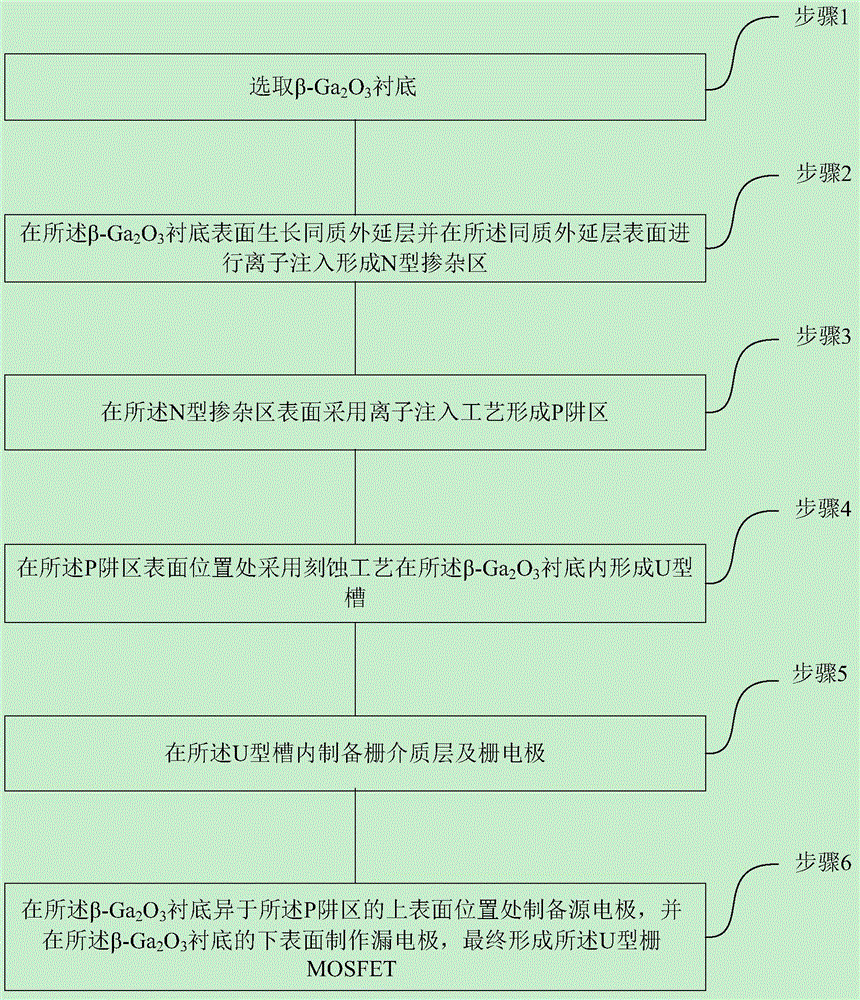

Ga2O3-material-based U-shaped grating type MOSFET and preparation method thereof

InactiveCN106449419AOvercome the disadvantage of high on-resistanceLower on-resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesMOSFETGrating

The invention relates to a Ga2O3-material-based U-shaped grating type MOSFET and a preparation method thereof. The method comprises steps: selecting a beta-Ga2O3 substrate; growing a homogeneous epitaxial layer on the surface of the beta-Ga2O3 substrate and carrying out ion implantation on the surface of the homogeneous epitaxial layer to form an N type doped region; carrying out treatment on the surface of the N type doped region by using an ion implantation process to form a P type well region; carrying out treatment on the surface of the P type well region by using an etching process to form a U-shaped groove in the beta-Ga2O3 substrate; preparing a gate dielectric layer and a gate electrode in the U-shaped groove; and preparing a source electrode on the upper surface, different from the P type well region, of the beta-Ga2O3 substrate and manufacturing a drain electrode on the lower surface of the beta-Ga2O3 substrate, thereby forming a U-shaped grating type MOSFET. According to the Ga2O3-material-based U-shaped grating type MOSFET provided by the invention, with the U-shaped grate electrode structure, a high on-resistance defect of the MOSFET power device is overcome; and the Ga2O3 material is applied to the substrate and the homogeneous epitaxial layer of the U-shaped grating structure, so that the voltage-withstanding capability and the reverse breakdown voltage of the MOSFET power device are improved; and the on resistance is reduced and the performance and device reliability of the power device are improved substantially.

Owner:XIDIAN UNIV

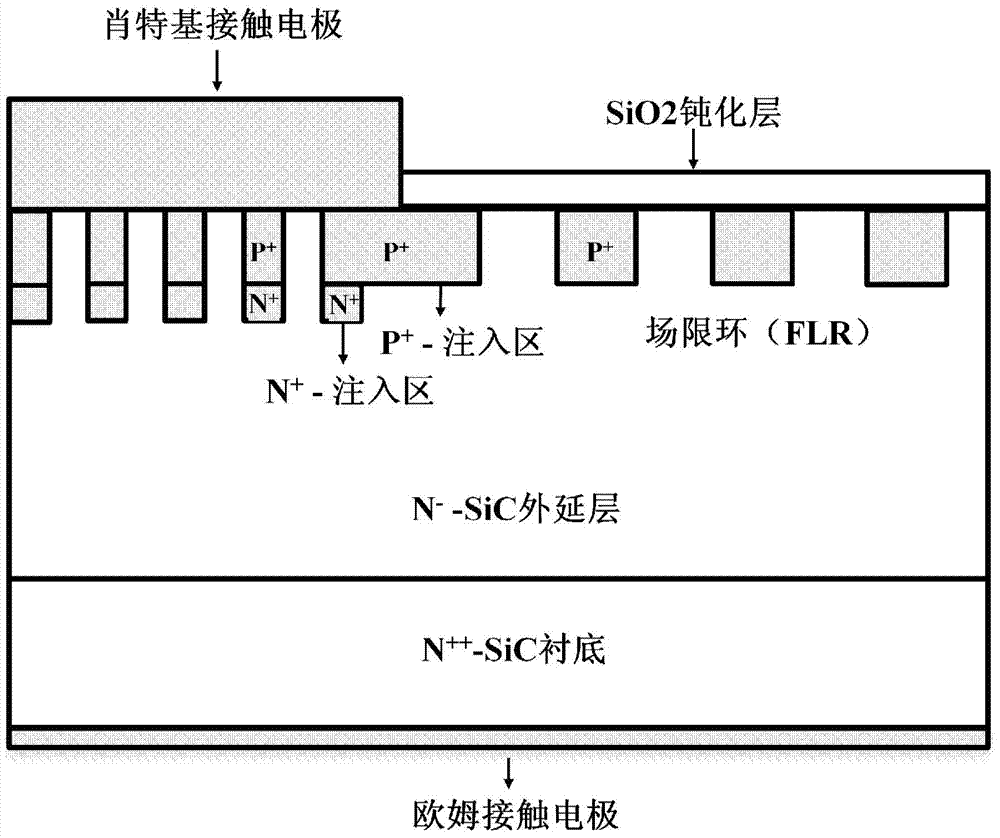

SiC Schottky diode and manufacturing method thereof

ActiveCN103579375ASimple preparation processLower on-resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesOhmic contactHigh pressure

The invention discloses a SiC Schottky diode and a manufacturing method of the SiC Schottky diode. The SiC Schottky diode comprises an N++-SiC substrate and an N--SiC epitaxial layer, wherein the N--SiC epitaxial layer is formed on the N++-SiC substrate, an N-type ohmic contact electrode is arranged on the reverse side of the N++-SiC substrate, a Schottky contact electrode is arranged on the surface of the N--SiC epitaxial layer, a selective P+-SiC area ring is arranged at the bottom of the Schottky contact electrode, an N+-SiC area ring which corresponds to the P+-SiC area ring is arranged at the bottom of the P+-SiC area ring, and serves as a protective ring when avalanche breakdown is carried out, a plurality of P+-SiC protective rings are arranged at the periphery of the Schottky contact electrode, and serve as a terminal protective structure of a diode device, a SiO2 passivation layer is arranged on the edge of the Schottky contact electrode, and a field plate is arranged on the top of the SiO2 passivation layer. According to the SiC Schottky diode and the manufacturing method of the SiC Schottky diode, the break-over voltage of the SiC Schottky diode can be close to the break-over voltage of a Si Schottky diode, and the SiC Schottky diode is in good cooperation with an existing system with a Si device, and can be applied to a switching power source with the high voltage ranging from 600V to 1200V and a power factor correction circuit, wherein the high voltage cannot be achieved when the Si Schottky device is used.

Owner:江苏中科汉韵半导体有限公司

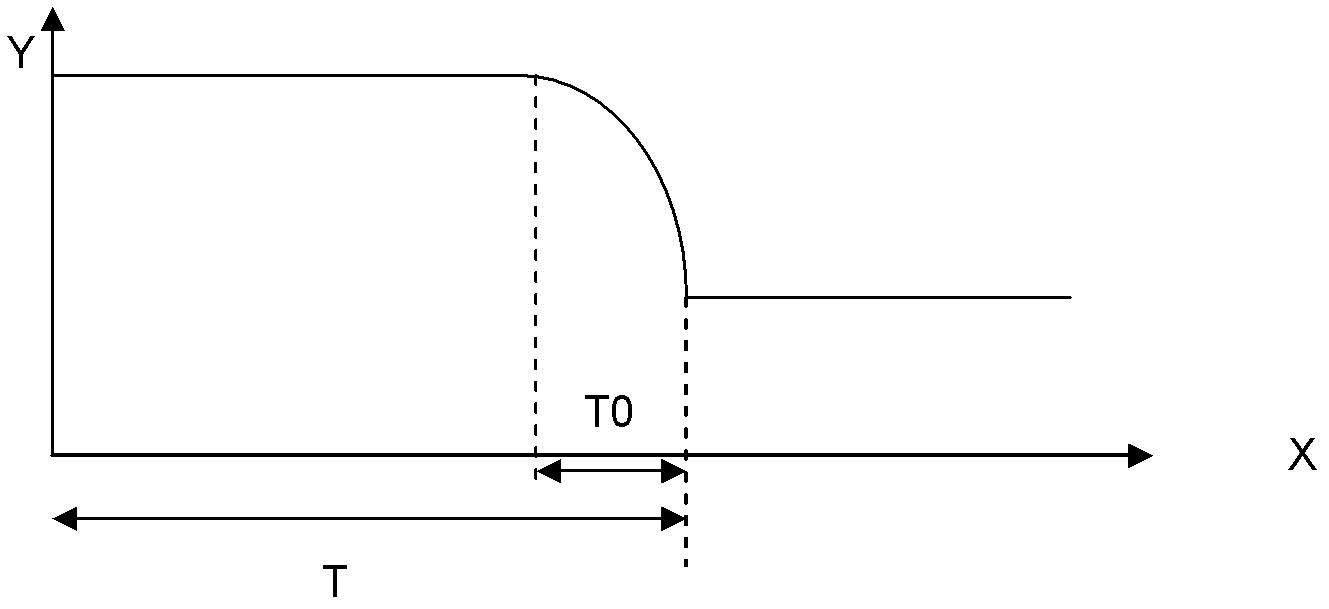

Super-junction device and manufacturing method thereof

ActiveCN103000665AImprove reverse breakdown voltageSemiconductor/solid-state device manufacturingSemiconductor devicesThin layerN type silicon

The invention discloses a super-junction device. All P-type thin layers in a current flow region do not contact with an N+ silicon substrate. The distances from the bottoms of all the P-type thin layers in the current flow region to the surface of the N+ silicon substrate are larger than the thickness of a transition region between an N-type silicon epitaxial layer and the N+ silicon substrate. The invention further discloses a manufacturing method of the super-junction device. Consistence between reverse breakdown voltage and overshoot current resistance of the super-junction device can be improved, and accordingly the reverse breakdown voltage and overshoot current resistance of the super-junction device can be improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Schottky barrier diode device structure and manufacturing method thereof

ActiveCN103943688AImprove reverse breakdown voltageReduce electric fieldSemiconductor/solid-state device manufacturingSemiconductor devicesConductive materialsDielectric layer

The invention provides a Schottky barrier diode device structure and a manufacturing method of the structure. The device structure comprises a first conductive type substrate, first conductive type epitaxial layers which are combined on the surface of the first conductive type substrate, a plurality of groove structures, second conductive type doping areas, a Schottky metal layer and an upper electrode. The groove structures comprise grooves formed in the first conductive type epitaxial layers, dielectric layers combined on the surfaces of the grooves, and conductive materials, the grooves are filled with the conductive materials, the second conductive type doping areas are formed at the positions, arranged on two sides of the groove structures, of the surfaces of the first conductive type epitaxial layers, and the Schottky metal layer is formed on the surfaces of the first conductive type epitaxial layers. The doping areas are added on two sides of the groove structures, the P / N knot is introduced, electric fields of the areas are reduced, and therefore reverse leakage currents are reduced. Meanwhile, JFET structures are introduced between the doping areas, reverse breakdown voltages of the Schottky barrier diode device structure are improved, and the reverse leakage currents are reduced.

Owner:CHINA RESOURCES MICROELECTRONICS (CHONGQING) CO LTD

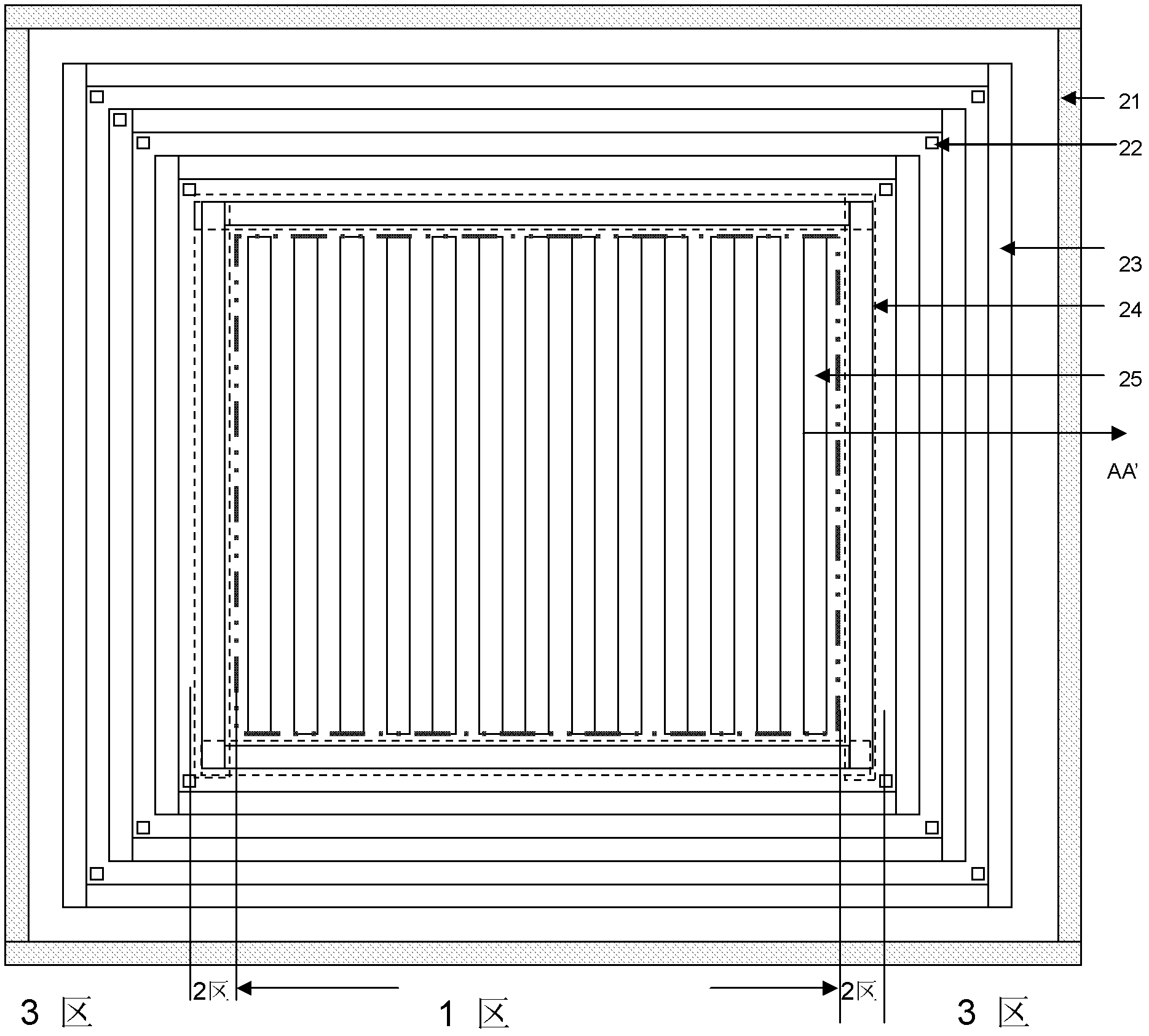

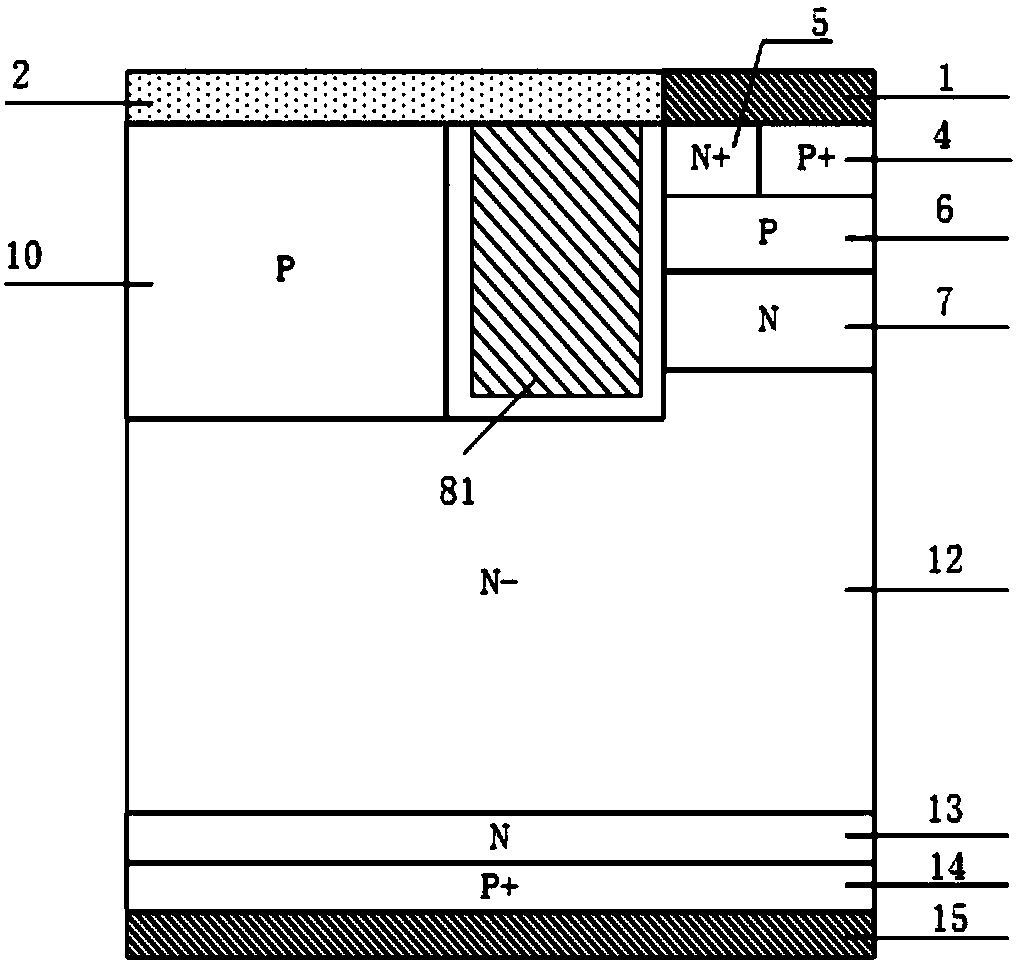

Reverse blocking type IGBT and manufacturing method therefor

InactiveCN107799588AImprove reverse breakdown voltageFast switching speedSemiconductor/solid-state device manufacturingSemiconductor devicesCapacitanceEngineering

The invention discloses a reverse blocking type IGBT and a manufacturing method therefor, and belongs to the technical field of a semiconductor power device. By introducing trench emitter and trench collector structures, the reverse breakdown voltage of a device is improved without influencing the threshold voltage and switch-on of an IGBT device; the overall gate capacitance is lowered, the switching speed of the device is improved, the switching loss and driving power consumption of the device are lowered, and the compromising relation between forward switch-on voltage drop and switch-off loss of the conventional CSTBT structure is improved; the problems of current, voltage oscillation and EMI in the device starting dynamic process can be avoided, and device reliability is improved; theelectric field concentration effect at the bottom of the trench is improved, the forward breakdown voltage of the device is improved, and reliability of the device is further improved; and the currentcarrier enhancement effect at the emitter end of the device is further improved, the current carrier concentration distribution in a drift region can be improved, and compromising between forward switch-on voltage drop and switch-off loss can be further improved. The manufacturing method disclosed in the invention is compatible with the existing manufacturing process of a CSTBT device.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Semiconductor device with improved ESD protection

ActiveUS8541865B2Quick switchImprove reverse breakdown voltageSemiconductor/solid-state device detailsSolid-state devicesElectricityPower semiconductor device

Owner:NXP BV

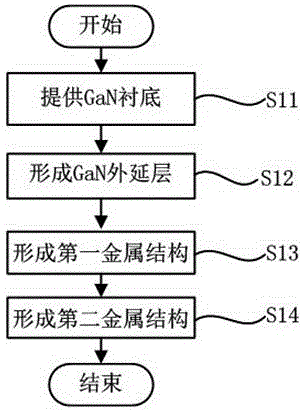

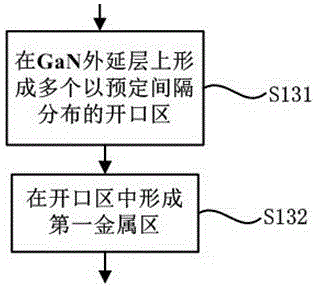

GaN-based power diode and preparation method thereof

InactiveCN105895708APrevent degradationExempt from P-type dopingSemiconductor/solid-state device manufacturingSemiconductor devicesPower diodeP type doping

The invention belongs to the technical field of semiconductor power electronic devices, and particularly discloses a GaN-based power diode and a preparation method thereof. The GaN-based power diode comprises a GaN substrate, a GaN epitaxial layer, first metal structures and a second metal structure, wherein the GaN substrate has first doping concentration; the GaN epitaxial layer is located on the GaN substrate and has second doping concentration; the second doping concentration is smaller than the first doping concentration; the first metal structures are distributed on the GaN epitaxial layer or in the GaN epitaxial layer at predetermined intervals; the second metal structure is formed on the first metal structures and the GaN epitaxial layer; the first metal structures and the GaN epitaxial layer form high barrier schottky contact; and the second metal structure and the GaN epitaxial layer form low barrier schottky contact. The GaN-based power diode has good reliability and relatively high reverse breakdown voltage when P-type doping on a GaN material is omitted.

Owner:FUDAN UNIV

Schottky diode and manufacturing method thereof

InactiveCN103094358AImprove reverse breakdown voltageImprove high frequency characteristicsSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorIsolation layer

The invention relates to a semi-conductor device, in particular to a novel channel schottky rectifier tube. The rectifier tube comprises a first semi-conductor layer, a first metal electrode arranged below the first semi-conductor layer, a first channel, a second channel, isolation layers, a barrier metal layer, an oxide layer, and a second metal electrode, wherein the first channel and the second channel are arranged in the first semi-conductor layer and are mutually separated, the isolation layers are located in the channels, the barrier metal layer is arranged above the first semi-conductor layer and between the first channel and the second channel, the oxide layer is arranged above the first semi-conductor layer outside the barrier metal layer, and the second metal electrode is arranged above the first semi-conductor layer. The depths of the channels are 2um-7um. By means of arrangement of the channels, reverse breakdown voltage of a schottky diode is improved.

Owner:BYD CO LTD

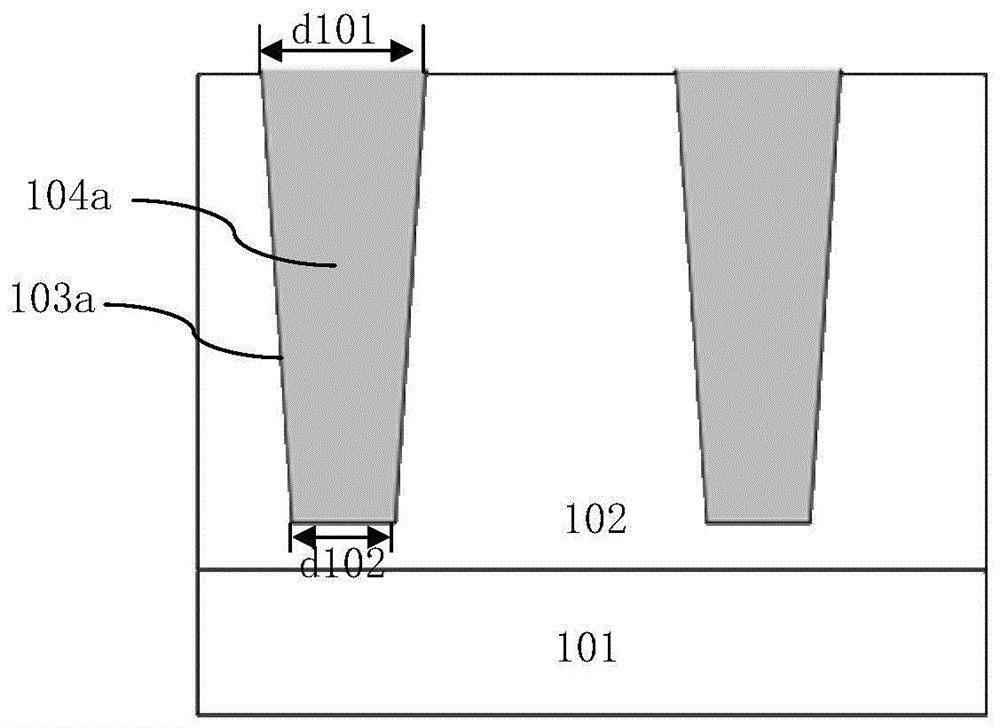

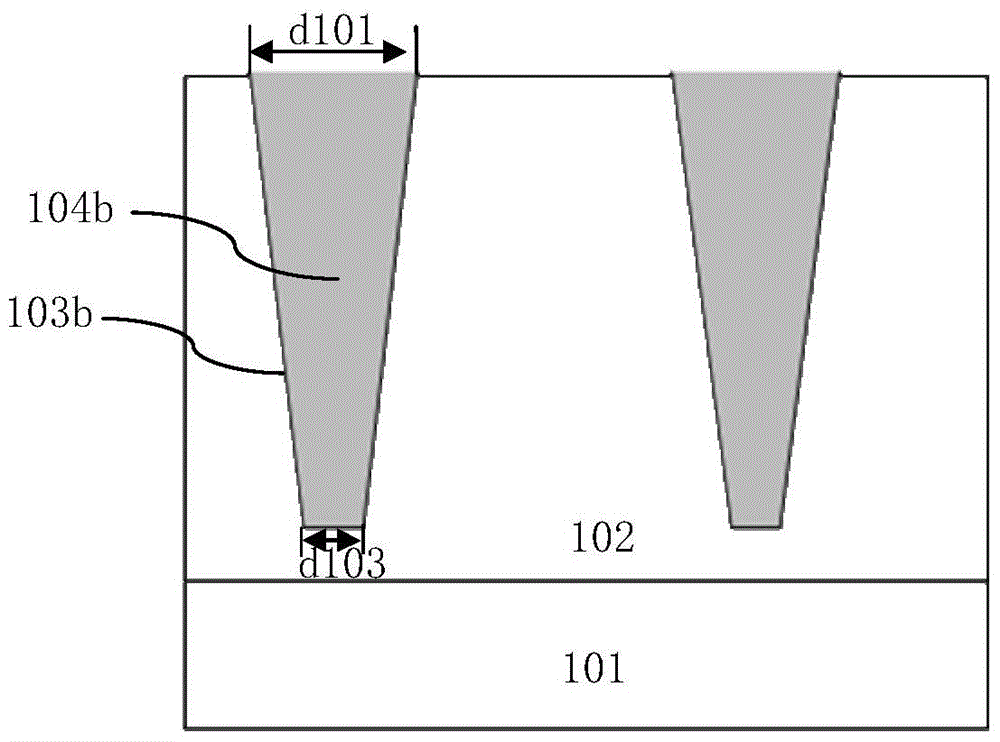

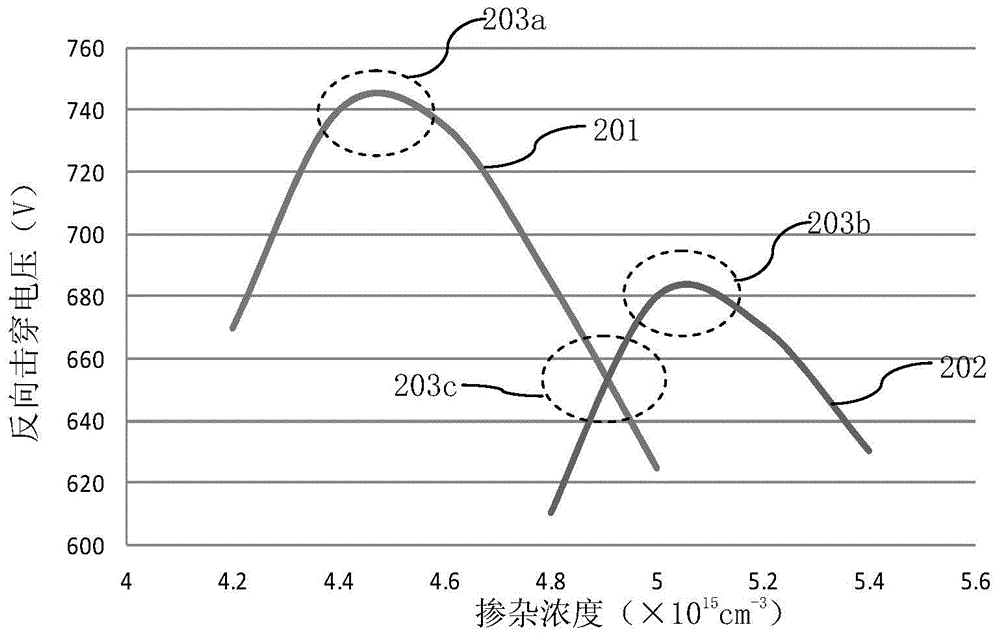

A manufacturing method for a groove type super junction

ActiveCN105702709AImprove in-plane uniformityImprove reverse breakdown voltageSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringBreakdown voltage

The invention discloses a manufacturing method for a groove type super junction. The method comprise the following steps: 1, a wafer, on which a first conductive type epitaxial layer forms, is provided; 2, a groove formation area is defined through adoption of a photoetching process, and the top width of the groove positioned at the middle area of the wafer is made to be larger than the top width of each groove at the edge area; 3, etching is carried out on the first conductive type epitaxial layer to form the grooves; and 4, second conductive type epitaxial layers formed through a same doped technology condition are filled in the grooves in epitaxial growth. According to the invention, the uniformity of a reverse breakdown voltage inside the surface of the super junction device of the same wafer can be raised; under a condition that the relatively high uniformity of a reverse breakdown voltage inside the surface of the super junction device of the same wafer is ensured, the reverse breakdown voltage of the super junction device is raised.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Schottky diode

InactiveCN102244106AAvoid electric field concentration effectImprove reverse breakdown voltageSemiconductor devicesReverse currentLow leakage

The invention belongs to the technical field of rectifying devices, in particular to a Schottky diode. According to the invention, an arc-shaped groove is used for increasing the revere performance of the device. Compared with the traditional product, the Schottky diode has the advantages of being capable of tolerating higher reverse voltage, having lower leakage currents before puncturing and a high forward and reverse current ratio; meanwhile, the driving capability of forward currents is hardly lost.

Owner:FUDAN UNIV

Semiconductor device and production method thereof

ActiveCN109786453ALow turn-on voltageSmall leakageSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor packageEngineering

The invention provides a semiconductor device and a production method thereof and relates to the field of semiconductor technology. The semiconductor device comprises a substrate, a first semiconductor layer, a second semiconductor layer, an ohmic electrode and a metal electrode. The metal electrode comprises an electrode channel and electrode side wings, wherein through the specific design of theelectrode side wing structure, two-dimensional electronic body width is further expanded, and field distribution is modulated. Through the semiconductor device, the problem that a semiconductor device structure has large electric leakage under reversed bias voltage can be solved, and the reverse breakdown voltage of the semiconductor device is further increased.

Owner:GPOWER SEMICON

Field effect transistor, marginal structure and relative manufacture method

ActiveCN103268887AImprove reverse breakdown voltageImprove job stabilitySemiconductor/solid-state device manufacturingSemiconductor devicesElectricityEngineering

The invention provides a field effect transistor, a marginal structure used for the field effect transistor and manufacture methods of the field effect transistor and the marginal structure. The field effect transistor comprises a transistor unit formed in an effective unit region and the marginal structure formed in a marginal region. The marginal structure comprises a plurality of groove-type isolation units which are sequentially distributed from inner side to outer side of the marginal region, wherein the starting groove-type isolation unit nearest to the inner side of the marginal region divides a body region of the field effect transistor into an effective body region and a suspension body region in electricity suspension, the starting groove-type isolation unit is connected with a grid region of the transistor unit in an electric coupling mode, and other groove-type isolation units are in electric suspension. The marginal region can not only well isolate the marginal region from the effective unit region so as to protect the transistor unit in the effective unit region against being influenced by carriers of the marginal region, but also solve the problem that the starting groove-type isolation unit is prone to breakdown, and has relatively high reverse breakdown voltage and good operation stability.

Owner:CHENGDU MONOLITHIC POWER SYST

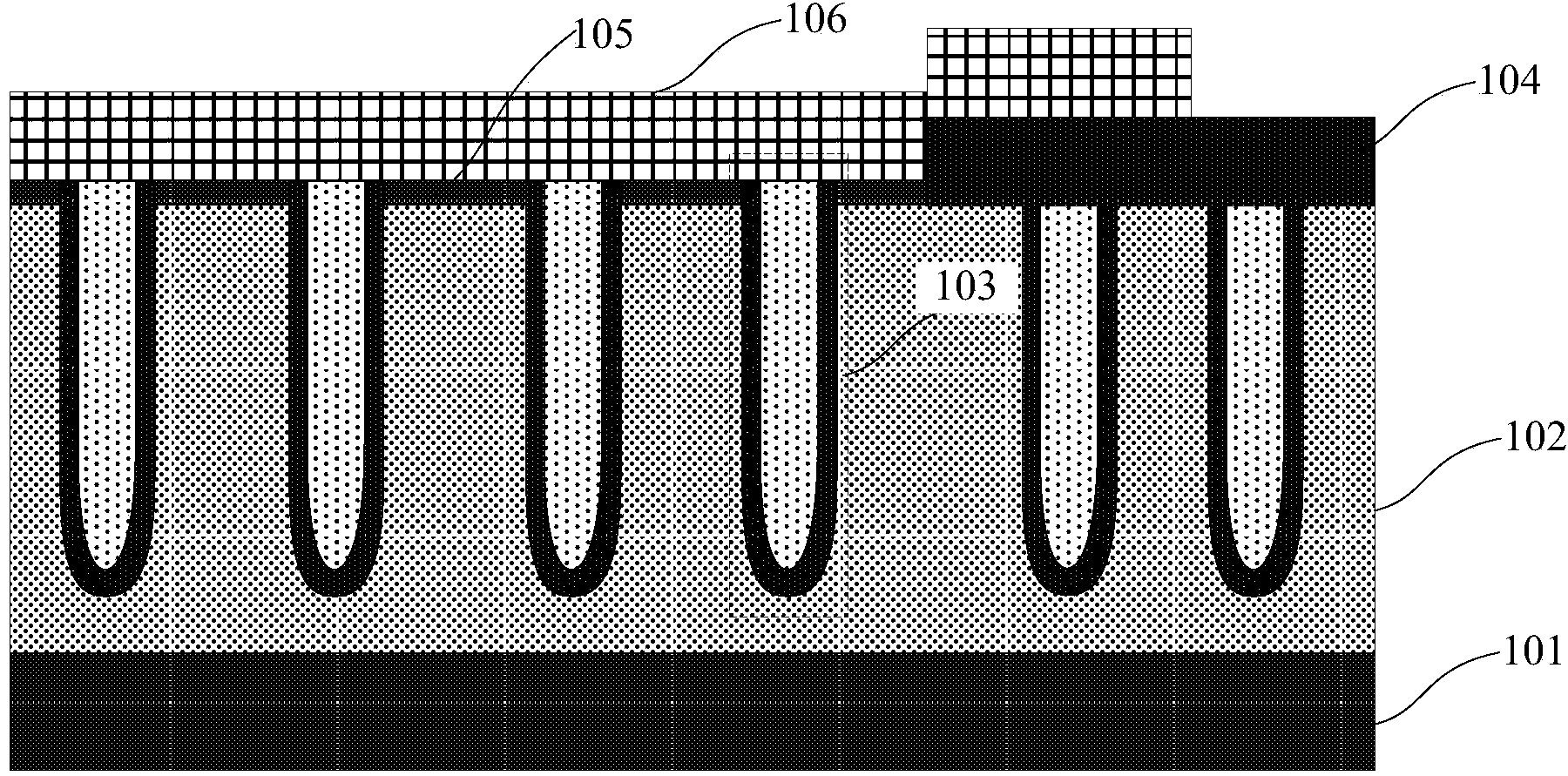

Super-junction schottky diode

InactiveUS20180026143A1Large forward currentSmall forward voltageSemiconductor/solid-state device manufacturingSemiconductor devicesPower flowEngineering

The present invention relates to the field of semiconductor technology, particularly to a super-junction schottky diode. According to the present invention, the effective area of schottky junction is increased by forming the schottky junction in the trench located in the body of the device. Therefore, the current capacity of this novel schottky diode can be greatly improved. In addition, a super-junction structure is used to improve the device's reverse breakdown voltage and reduce the reverse leakage current. The super-junction schottky diode provided in the present invention can achieve a larger forward current, a lower on-resistance and a better reverse breakdown characteristic.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

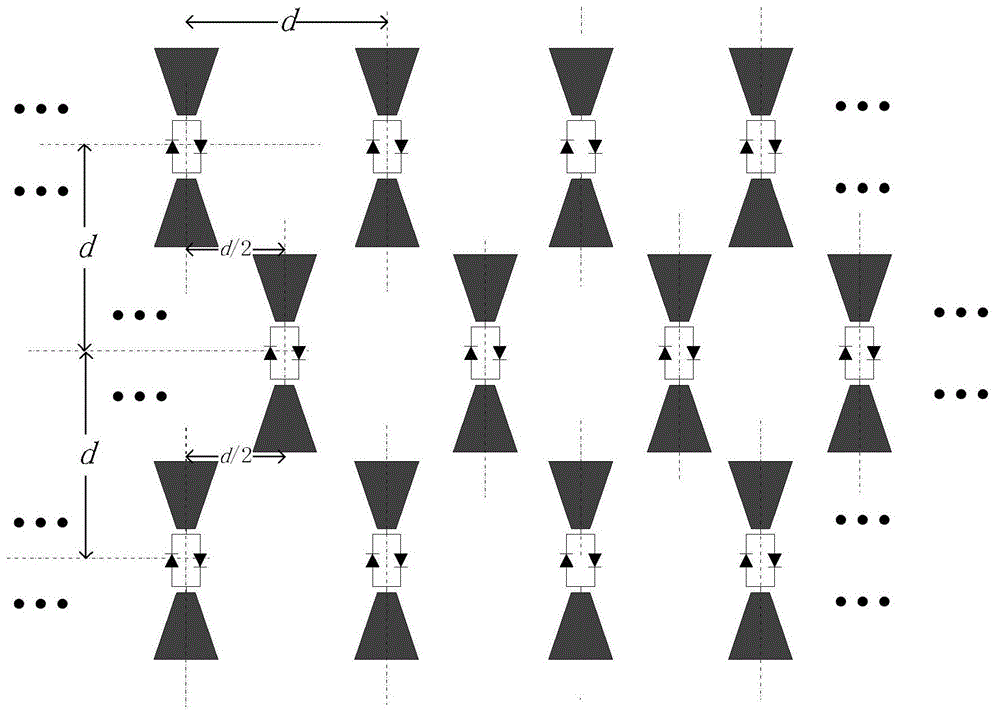

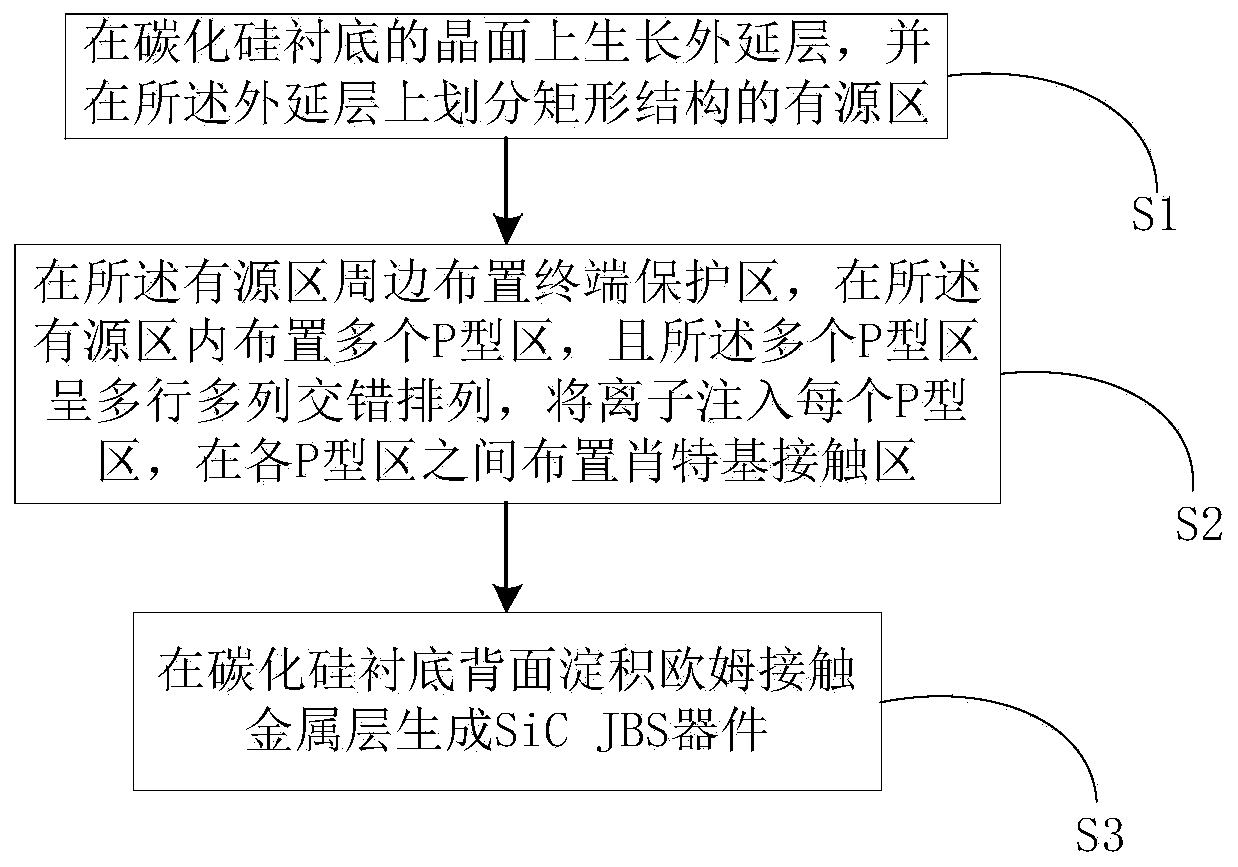

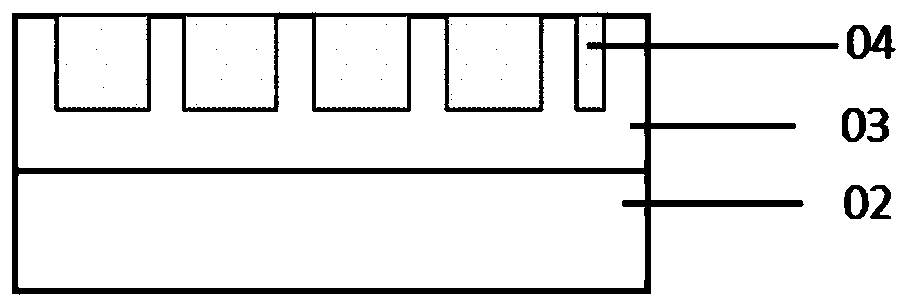

Layout method of SiC JBS device

PendingCN111261724AIncrease the area of the barrier regionGuaranteed reverse breakdown characteristicsSolid-state devicesSemiconductor/solid-state device manufacturingCarbide siliconSchottky barrier

The invention provides a layout method of a SiC JBS device, which comprises the following steps of: growing an epitaxial layer on the crystal surface of a silicon carbide substrate, and dividing an active region with a rectangular structure on the epitaxial layer, arranging a terminal protection region at the periphery of the active region, arranging a plurality of P-type regions in the active region, arranging the plurality of P-type regions in a multi-row and multi-column staggered manner, implanting ions into each P-type region, and arranging Schottky contact regions between the P-type regions, and depositing an ohmic contact metal layer on the back surface of the silicon carbide substrate to generate the SiC JBS device. The plurality of P-type regions are arranged in the SiC JBS devicein a multi-row and multi-column staggered manner, so that the reverse breakdown characteristic of the SiC JBS device is ensured, the Schottky barrier region area is increased, and the conduction capability is improved.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com