Ga2O3-material-based U-shaped grating type MOSFET and preparation method thereof

A -ga2o3, U-shaped technology, applied in the field of Ga2O3-based U-shaped gate MOSFET and its preparation, can solve the problems of large on-resistance, high cost, limitations, etc., achieve excellent material characteristics, improve withstand voltage and reverse Effects of breakdown voltage and on-resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

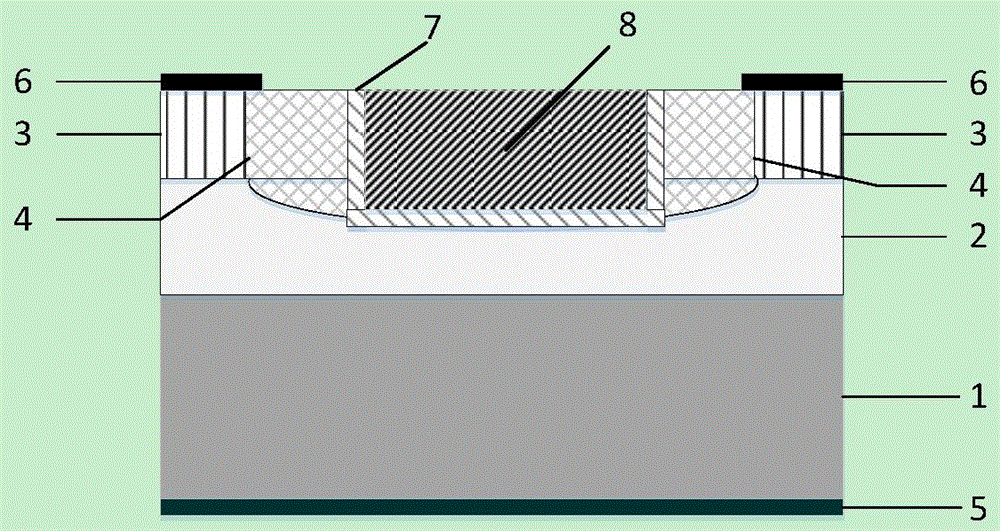

[0052] See figure 1 and figure 2 , figure 1 Provided for an embodiment of the present invention based on Ga 2 O 3 Cross-sectional schematic diagram of U-gate MOSFET of material, figure 2 Provided for an embodiment of the present invention based on Ga 2 O 3 A schematic top view of a U-gate MOSFET made of materials. The U-shaped gate MOSFET of the present invention includes: a substrate 1, a homoepitaxial layer 2, an N-type doped region 3, a P well region 4, a drain electrode 5, a source electrode 6, a gate oxide layer 7, and a gate electrode 8.

[0053] The substrate has a doping concentration of 10 18 -10 19 cm -3 , N-type β-Ga with doping elements such as Sn, Si, Al, etc. 2 O 3 (-201), N-type β-Ga 2 O 3 (010) or N type β-Ga 2 O 3 (001) Material; The homoepitaxial layer is β-Ga with the same doping element as the substrate material 2 O 3 , Doping concentration 10 15 cm -3 Magnitude; the doping element in the N-type doped region can be Sn, Si, Al and other elements, and the doping...

Embodiment 2

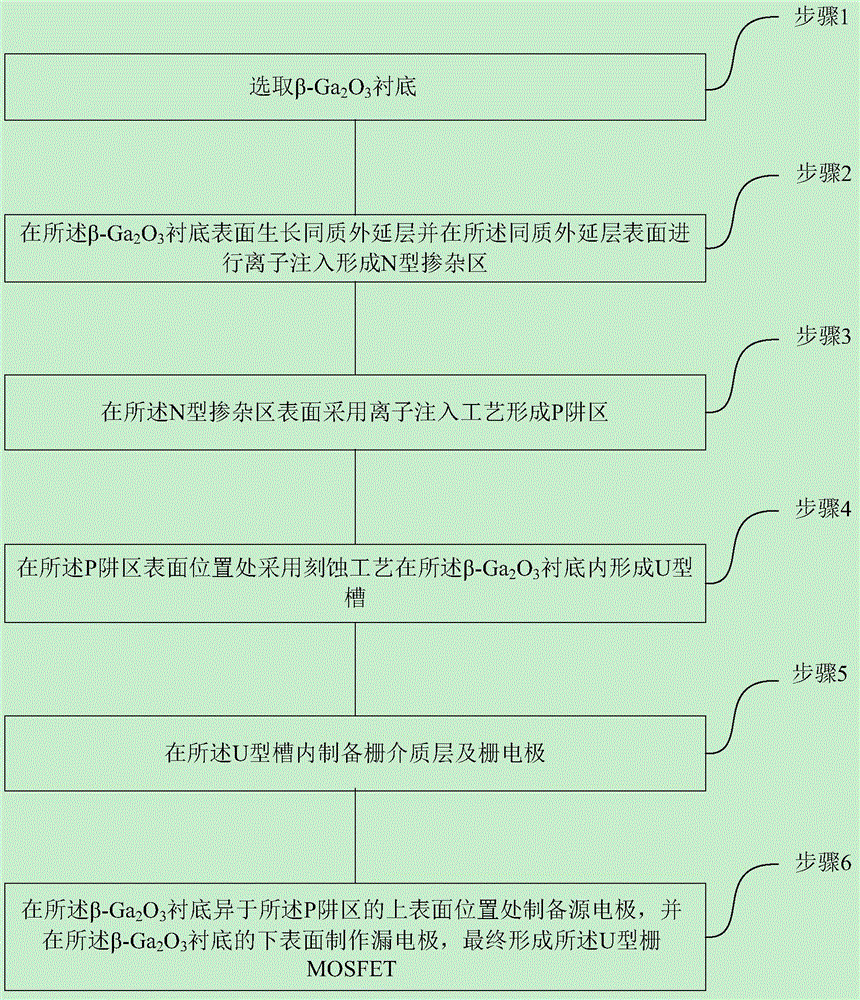

[0091] See also Figure 4a-Figure 4i and Figure 5 to Figure 8 , Figure 4a-Figure 4h Provides a Ga-based 2 O 3 Schematic diagram of the preparation method of U-gate MOSFET made of materials; Figure 5 Is a schematic structural diagram of a first mask provided by an embodiment of the present invention; Image 6 Is a schematic structural diagram of a second mask provided by an embodiment of the present invention; Figure 7 Is a schematic structural diagram of a third mask provided by an embodiment of the present invention; and Picture 8 This is a schematic structural diagram of a fourth mask provided by an embodiment of the present invention. In this embodiment, on the basis of the above embodiment, the method for preparing the U-gate MOSFET of the present invention is described in detail as follows:

[0092] Step 1: See Figure 4a , Prepare β-Ga 2 O 3 Substrate 1, the substrate doping concentration is 10 18 -10 19 cm -3 , The thickness is 200μm-600μm, and the substrate is pretreat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com