Nanometer silicon carbide/crystal silicon carbide double graded junction fast recovery diode and preparation method thereof

A nano-silicon carbide, fast recovery technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of difficult adjustment of interface defects and difficult to accurately control reverse recovery performance indicators of reverse recovery current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

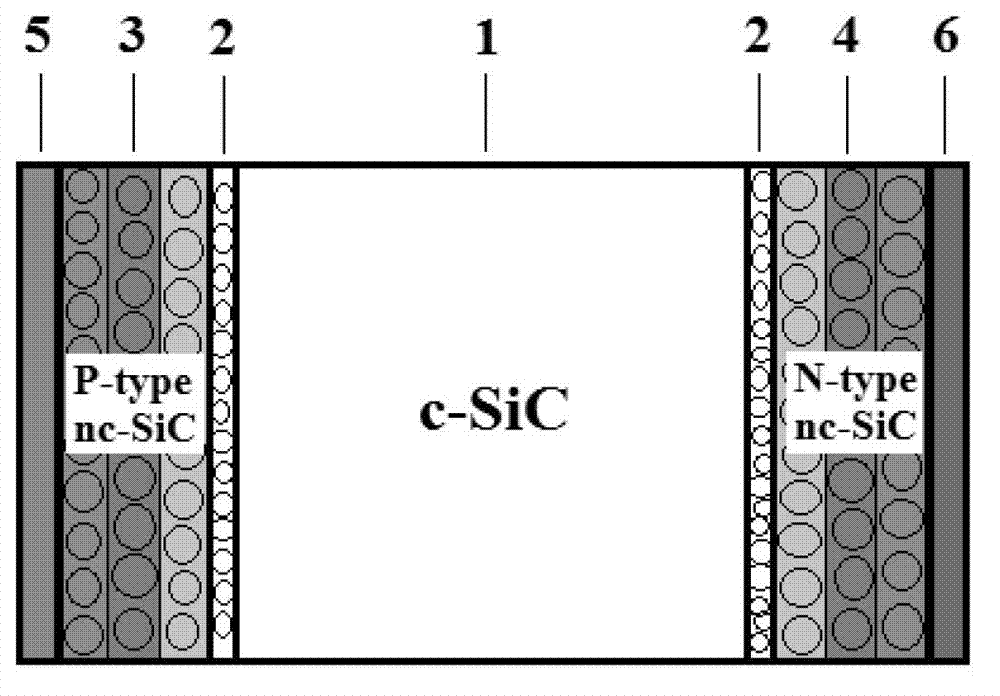

[0057] like figure 1 , the specific embodiment 1 of the product of the present invention, the thickness is about 50±2 μm, and the average carrier concentration range is 1.0×10 14 —9.0×10 14 cm -3 , double-sided polished N - The type 4H-SiC substrate is the substrate, the surface is the Si atomic plane, 8° away from the (0001) plane, and the surface micropipe density is lower than 30μP·cm -2 . Of course, the carrier concentration of the c-SiC substrate of the present invention can also be lower than 1.0×10 14 cm -3 , the thickness can be slightly thinner or thicker.

specific Embodiment approach 2

[0058] like figure 1 , the specific embodiment 2 of the product of the present invention is different from the embodiment 1 in the nc-Si thin film. On the left side of the 4H-SiC substrate, a layer of nc-Si thin film with a thickness of several nanometers is deposited. Smooth and tightly bonded.

specific Embodiment approach 3

[0059] like figure 1 , the specific embodiment 3 of the product of the present invention is different from the embodiment 1 and 2 in that the P-type nc-SiC multilayer film is described. 8-10 layers of P-type nc-SiC multi-layer films with a thickness of 0.05-0.08 μm and increasing boron doping deposited on the nc-Si ultra-thin film on the left side of the 4H-SiC substrate (note: the first layer may not Doping, that is, intrinsic), the nc-SiC grain is 4H-SiC type, and the carrier concentration of the multilayer film increases from 0 to 1.0×10 19 cm -3 . The nc-SiC film and 4H-SiC constitute P + P / N - Unilateral gradient heterogeneity structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com