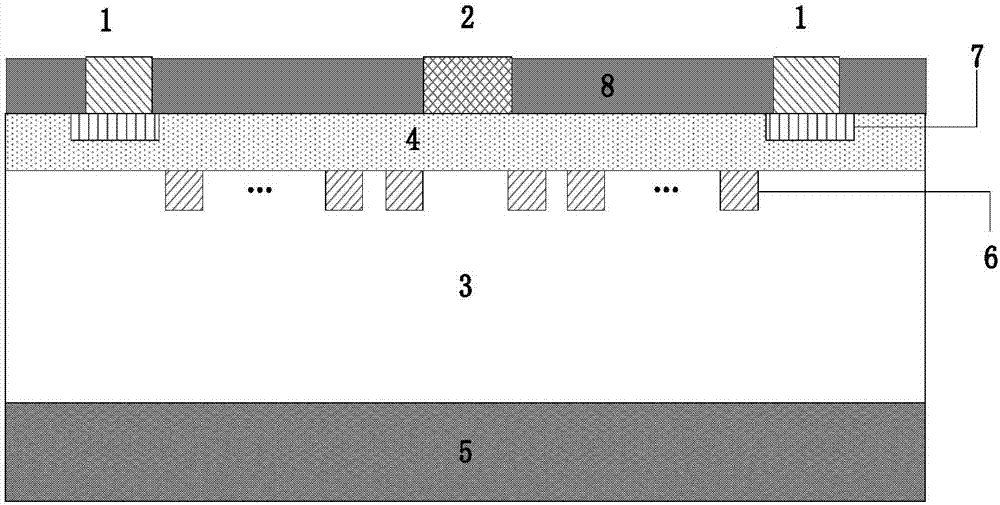

High-breakdown-voltage Schottky diode and making method

A Schottky diode, high breakdown voltage technology, applied in the field of microelectronics, can solve problems such as increased parasitic capacitance and enhanced parasitic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1, the substrate is sapphire, 12 H with a width of 2 μm and a depth of 20 μm + Injection area, H + The spacing between implanted regions is sequentially increased to 0.5 μm for Schottky diodes.

[0036] Step 1, wash the sample.

[0037] 1a) For Ga that has been grown epitaxially on the substrate 2 o 3 The sample of the layer was organically cleaned, ultrasonicated with acetone for 5 minutes, ethanol for 5 minutes, and then washed with flowing deionized water, in which the epitaxially grown Ga 2 o 3 The layer consists of two layers, the first layer has a carrier concentration of 10 14 cm -3 , Ga with a thickness of 1.5 μm 2 o 3 epitaxial layer, the second layer has a carrier concentration of 10 17 cm -3 , low-doped n-type Ga with a thickness of 130nm 2 o 3 film;

[0038] 1b) Chemical cleaning

[0039] Place the organically cleaned samples in HF:H 2 Corrode in O=1:1 solution for 30s, then wash with flowing deionized water and blow dry with high-puri...

Embodiment 2

[0070] Embodiment 2, making substrate is Ga 2 o 3 , 10 H with a width of 2.5 μm and a depth of 35 μm + Injection area, H + The spacing between the implanted regions was sequentially increased to 0.7 μm for Schottky diodes.

[0071] Step one, wash the sample.

[0072] 1.1) For Ga that has been epitaxially grown on the substrate 2 o 3 Layer samples were sonicated with acetone for 5 minutes, ethanol for 5 minutes, and then washed with flowing deionized water, in which the epitaxially grown Ga 2 o 3 The layer consists of two layers, the first layer has a carrier concentration of 10 15 cm -3 , Ga with a thickness of 1.3 μm 2 o 3 epitaxial layer, the second layer has a carrier concentration of 5×10 17 cm -3 , low-doped n-type Ga with a thickness of 110nm 2 o 3 film;

[0073] 1.2) Chemical cleaning

[0074] Step 1b) in Example 1 of this step is the same.

[0075] Step 2, depositing SiO with a thickness of 50nm 2 mask.

[0076] Put the dried sample into PECVD equipm...

Embodiment 3

[0103] Embodiment 3, making substrate is MgAl 2 o 4 , eight H with a width of 3 μm and a depth of 50 μm + Injection area, H + The spacing between the implanted regions was sequentially increased to 1.0 μm for Schottky diodes.

[0104] Step A, wash the sample.

[0105] A1) For Ga that has been epitaxially grown on the substrate 2 o 3 Layer samples were sonicated with acetone for 5 minutes, ethanol for 5 minutes, and then washed with flowing deionized water, in which the epitaxially grown Ga 2 o 3 The layer consists of two layers, the first layer has a carrier concentration of 10 16 cm -3 , Ga with a thickness of 1 μm 2 o 3 epitaxial layer, the second layer has a carrier concentration of 10 18 cm -3 , low-doped n-type Ga with a thickness of 100nm 2 o 3 film;

[0106] A2) Chemical cleaning

[0107] This step is the same as step 1b) in Example 1.

[0108] Step B, depositing SiO with a thickness of 50nm 2 mask.

[0109] Put the dried sample into PECVD equipment t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com