Fully automatic dried beancurd stick and skin machine

An oil peeling machine, fully automatic technology, used in cheese substitutes, dairy products, applications, etc., can solve the problems of secondary pollution, need more manpower, and waste steam, and achieve the effect of ensuring hygienic requirements and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

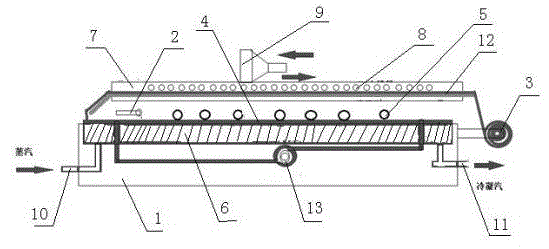

[0017] Accompanying drawing is the specific embodiment of the present invention.

[0018] Such as figure 1 The shown full-automatic bean curd stick and oil skin machine of the present invention includes a body 1, which is provided with a new slurry filling port 2, and the body includes a heating and cooling device and a transport transmission device, and the upper end of the heating and cooling device is provided with a drying device One side of the drying device is connected to the collection device 3, and the heating and cooling device includes a pulp tray 4, a cold air pipe 5 and a steam boiler 6, the pulp tray 4 and the cold air pipe 5 are arranged inside the new pulp filling port 2, and the steam boiler 6 is installed on the slurry The lower end of the tray 4, the drying device includes a drying chamber 7, a drying exhaust pipe 8 and a heat exchange dehumidification device 9, the heat exchange dehumidification device 9 is located at the upper end of the drying exhaust pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com